Choosing SourcifyChina for purchasing a CNC machine lathe from China offers unparalleled benefits. This reputable factory guarantees the highest quality standards, ensuring reliable and durable machines that meet stringent international benchmarks.

SourcifyChina is known for its competitive pricing. By eliminating middlemen, they provide cost-effective solutions without compromising on quality, making high-end CNC machine lathes accessible to businesses of all sizes.

Customer support is a cornerstone at SourcifyChina. Their dedicated, bilingual support team assists with everything from initial inquiries to post-purchase service, ensuring a seamless, stress-free experience.

Furthermore, SourcifyChina boasts quick delivery times thanks to streamlined logistics and strategic partnerships. Buyers can expect timely arrivals, reducing downtime and keeping business operations smooth.

They also offer customization options tailored to specific needs and applications. By understanding unique operational requirements, SourcifyChina provides bespoke CNC machine lathes that maximize productivity and efficiency.

In addition, SourcifyChina prioritizes transparency in every transaction. Detailed quotations and clear communication foster trust and minimize uncertainties, reassuring buyers they are making informed decisions.

Their robust quality control processes involve rigorous inspections and testing. This ensures that every machine leaving the factory adheres to the highest performance and safety standards.

For businesses concerned about environmental impact, SourcifyChina emphasizes sustainable practices. Their eco-friendly manufacturing processes help reduce the carbon footprint, aligning with global environmental goals.

Moreover, SourcifyChina maintains excellent relationships with global shipping carriers, ensuring reliable delivery schedules and reduced risk of delays, even amidst challenging global logistics scenarios.

Ultimately, choosing SourcifyChina means investing in a partner committed to excellence. Their comprehensive approach—from quality control and customization to exceptional customer support and sustainability—establishes SourcifyChina as the ideal choice for purchasing CNC machine lathes from China.

A CNC machine lathe is a precision tool for shaping materials such as metal or wood using computer numerical control. These machines vary in complexity, from simple two-axis setups to advanced multi-axis configurations.

– 2-Axis Lathes: Basic, suitable for straightforward turning operations.

– 3-Axis Lathes: Adds a Y-axis, allowing for more complex geometries.

– 4-Axis Lathes: Includes a B-axis for angular cutting, enhancing versatility.

– 5-Axis Lathes: Provides maximum flexibility and precision for intricate designs.

– Slant Bed Lathes: Offers rigidity and efficient chip removal, ideal for heavy-duty operations.

– Flat Bed Lathes: Less rigid but allows for larger workpieces.

– Vertical Turning Lathes (VTLs): Suited for large, heavy workpieces, with a vertically oriented spindle.

– Swiss-Type Lathes: Optimized for small, precise components, offering high accuracy and repeatability.

– Multi-Spindle Lathes: Increases production rates by allowing multiple operations simultaneously.

– Live Tooling Lathes: Equipped with rotating tools, enabling milling and drilling without removing the workpiece.

– CNC Mini Lathes: Compact and ideal for hobbyists or small-scale production.

These CNC lathes offer a range of capabilities suited to different manufacturing needs, enhancing efficiency and precision in modern machining.

CNC machine lathes are highly versatile tools used in manufacturing for precise, complex, and repetitive tasks. They enable the crafting of intricate parts with high accuracy.

– Automotive Industry: Producing engine components like shafts, gears, and cylinder heads.

– Aerospace: Manufacturing critical parts such as turbine blades and landing gear components.

– Medical Devices: Crafting surgical instruments and prosthetic devices with precision.

– Jewelry Making: Creating intricate designs and detailed engravings on various materials.

– Electronics: Fabricating housings, connectors, and other small, precise components.

– Woodworking: Shaping, drilling, and cutting wooden parts for furniture and decorative items.

– Oil and Gas: Producing parts for drilling rigs and refining equipment.

– Defense and Military: Manufacturing weapon components and other defense-related parts.

– Tool and Die Making: Producing dies, molds, and fixtures for various industries.

– Research and Development: Prototyping and testing new designs.

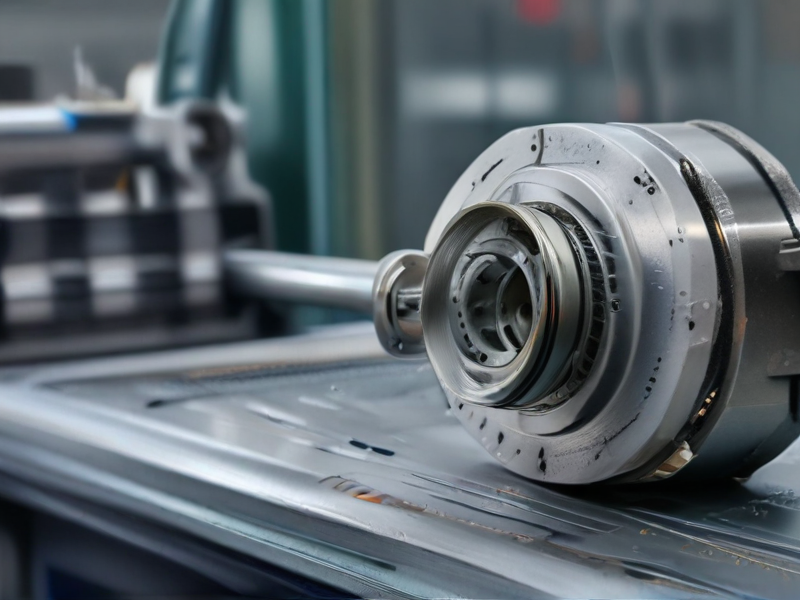

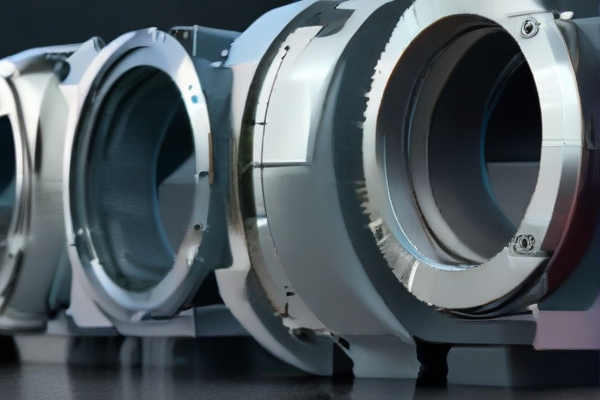

SourcifyChina CNC machine lathes are meticulously crafted from high-quality cast iron, which ensures stability and durability. Cast iron absorbs vibrations effectively, making it ideal for precision machining.

The guideways in these lathes are hardened and ground, often made from tool steel. This material resists wear and maintains accuracy over prolonged periods of use, crucial for precise operations.

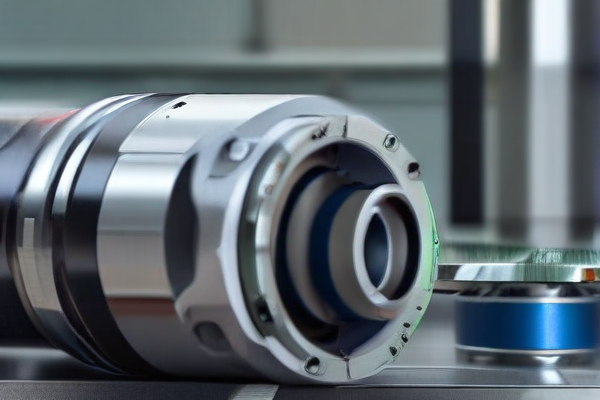

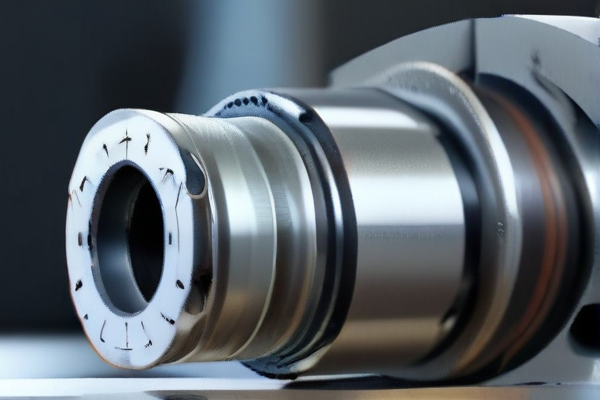

The spindle is usually made from alloy steel, offering excellent strength and heat resistance. It undergoes rigorous heat treatment and grinding processes to ensure it can withstand high-speed rotations and maintain concentricity.

The cutting tools used with these lathes are often composed of carbide or high-speed steel for extended lifespan and precise cutting capabilities. These materials are essential for achieving smooth finishes and detailed work.

SourcifyChina CNC machine lathes integrate advanced control units typically encased in high-quality aluminum or stainless steel. Such enclosures provide protection against environmental factors and enhance the machine’s overall lifespan.

In summary, the materials used in SourcifyChina CNC machine lathes—from the cast iron body to the high-speed steel cutting tools—ensure exceptional performance, accuracy, and durability. Each component is selected to meet the high standards demanded by precision machining applications.

SourcifyChina’s CNC machine lathe quality control process begins with stringent material selection. Only top-grade metals and alloys are chosen to ensure durability and performance. Each batch is tested to meet industry standards.

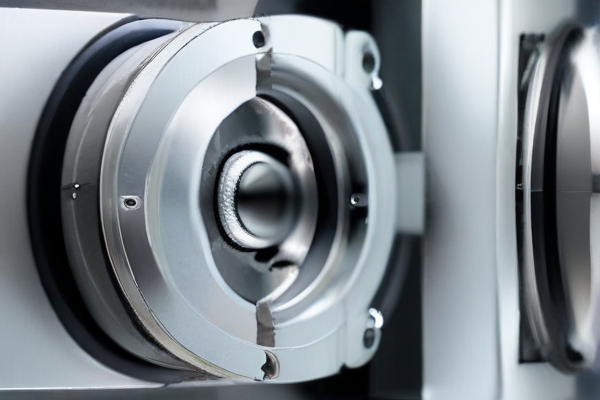

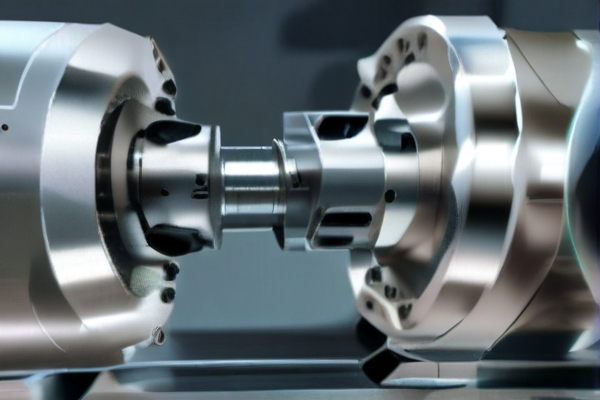

The next step involves precision machining, where advanced CNC technology ensures high accuracy and consistency. Each machine undergoes rigorous calibration checks, reducing the margin for error and ensuring each piece meets exact specifications.

A comprehensive inspection protocol is applied to each finished product. Dimensional accuracy, surface finish, and functional tests are conducted. Advanced metrology tools, including coordinate measuring machines, ensure that each component adheres to the highest standards.

Quality control extends to the assembly phase, where skilled technicians conduct detailed inspections. Each lathe is assembled with meticulous attention, and subassemblies undergo performance tests to confirm reliability and operational efficiency.

Before shipping, each machine is put through a final quality audit. This includes running the machine at full capacity to ensure optimal performance. Any deviations from set parameters are corrected immediately, guaranteeing that customers receive defect-free products.

The robust quality control process at SourcifyChina ensures each CNC machine lathe is built to last, performs efficiently, and meets all client expectations. Constant feedback is integrated into manufacturing, fostering continual improvement. This commitment to quality helps maintain the company’s reputation for excellence in the industry.

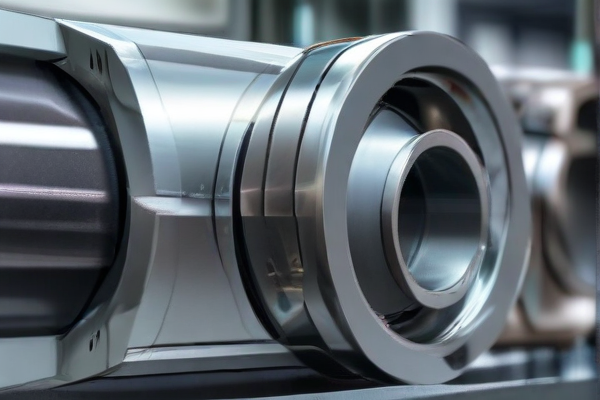

SourcifyChina specializes in providing high-precision CNC machine lathes that cater to diverse industrial requirements. These lathes excel in manufacturing intricate parts with unparalleled accuracy, enhancing production efficiency.

Their CNC machine lathes are renowned for their robust construction and advanced technological features. With computer numerical control, they achieve consistent and repeatable outcomes, crucial for maintaining quality in mass production.

The lathes are versatile, capable of handling a wide range of materials, including metals, plastics, and composites. This versatility makes them ideal for industries like automotive, aerospace, and electronics, where precision is paramount.

SourcifyChina’s CNC machine lathes are designed for user-friendly operation, reducing the learning curve and increasing productivity. Advanced software interfaces and customizable settings allow operators to achieve optimal results with minimal effort.

In addition to standard features, these lathes offer options for automation and integration with other machinery. This capability enables seamless workflow integration, aiding in the creation of smart manufacturing environments.

One of the standout attributes of SourcifyChina’s CNC lathes is their durability and low maintenance requirements. Built with high-quality components, they ensure long-term reliability, reducing downtime and operating costs.

SourcifyChina also provides excellent customer support, from initial consultation to post-installation services. Clients receive comprehensive training and troubleshooting assistance, ensuring they maximize the benefits of their CNC lathes.

Moreover, SourcifyChina emphasizes continuous innovation. By investing in research and development, they regularly update their CNC lathe offerings, incorporating the latest advancements in machine tool technology.

Overall, SourcifyChina’s CNC machine lathes are a valuable asset for any manufacturing enterprise. Their combination of precision, durability, versatility, and support helps businesses achieve production goals more efficiently and cost-effectively.

CNC machine lathes offer numerous advantages in modern manufacturing, combining precision, efficiency, and versatility to enhance production processes.

– High Precision: CNC lathes can produce highly accurate and consistent parts, reducing the likelihood of errors and ensuring uniformity across large production runs.

– Increased Efficiency: Automated operations minimize manual intervention, significantly speeding up production times.

– Versatility: These machines can create complex designs and handle a wide range of materials, from metals to plastics.

– Cost-Effective: Reduced labor costs and material waste contribute to lower overall production expenses.

– Safety: Automation reduces the risk of accidents and enhances workplace safety.

– Scalability: Easily scalable operations allow for quick adjustments to meet varying production demands.

– Complex Geometry: Capable of producing intricate shapes and patterns that would be difficult or impossible with manual lathes.

– Repeatability: Ensures that each component is identical to the last, which is crucial for parts that need to meet strict specifications.

– Reduced Human Error: The precision of computer control minimizes mistakes that can occur with manual operation.

– Easy to Program: User-friendly software allows for quick programming and adjustments, making it straightforward to transition between different jobs.

– Maintenance: CNC lathes require less frequent maintenance and downtime compared to traditional machines, enhancing productive hours.

– Resource Optimization: Efficient use of raw materials reduces waste, promoting sustainability.

– Data Integration: Integration with modern software systems allows for better tracking and optimization of production processes.

– Flexibility: Capable of simultaneous multi-tasking, allowing for more complex parts to be manufactured in a single setup.

Incorporating CNC machine lathes into a production line significantly benefits manufacturers by improving product quality and operational efficiency while reducing costs and enhancing safety.

CNC Machine Lathe Features

CNC machine lathes are precision tools that automate the process of cutting, sanding, knurling, drilling, and turning materials. They offer consistent, high-quality results through pre-programmed sequences.

– Precision and Accuracy: Provides exact and repeatable cuts with minimal human error.

– Automation: Programmed operations reduce the need for manual intervention.

– Complex Geometries: Handles intricate shapes that would be difficult manually.

– Material Versatility: Works with various materials like metals, plastics, and wood.

– High Efficiency: Accelerates production speed while maintaining quality.

– User-Friendly Interface: Easy programming via CAD/CAM software.

– Safety Features: Enclosures and automated shut-offs enhance operator safety.

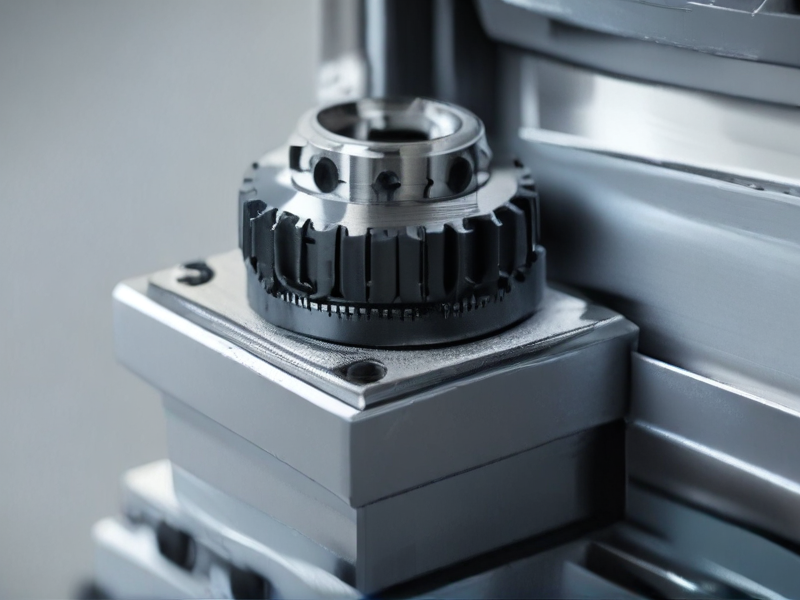

– Tool Turret: Multiple tools can be housed and changed automatically.

– Live Tooling: Supports milling, drilling, and tapping operations in addition to turning.

– Reduced Scrap: Greater efficiency and precision result in less material waste.

– Cost-Effective: Long-term savings due to reduced labor and material costs.

– Maintenance Alerts: Automatically scheduled maintenance to ensure consistent performance.

– Remote Monitoring: Some models offer the ability to monitor and control remotely.

These features collectively make CNC machine lathes indispensable in modern manufacturing, delivering high precision, efficiency, and versatility.

SourcifyChina offers high-quality CNC machine lathe services, providing customized products tailored to your specific requirements. Whether you need intricate parts or robust machinery, they ensure precision and reliability in every component.

Their advanced CNC lathes can handle a variety of materials, from metals to plastics, allowing for versatile production capabilities. This adaptability ensures that they can meet your project’s unique demands, no matter the complexity or scale.

With years of industry experience, SourcifyChina has built a reputation for delivering timely and accurate machining solutions. Their skilled workforce utilizes state-of-the-art technology to achieve superior results in every project they undertake.

Customer satisfaction is at the core of their business model. SourcifyChina prioritizes clear communication and a collaborative approach, ensuring that every custom product aligns with the client’s vision and specifications. Their commitment to quality is evident in the rigorous inspection processes they employ.

For businesses looking for dedicated machining services, SourcifyChina stands out as a reliable partner. They offer end-to-end solutions, from initial design consultation to final product delivery, ensuring a seamless experience.

Invest in your project’s success with SourcifyChina’s CNC machine lathe services. Their expertise and dedication to excellence make them an ideal choice for all your custom machining needs. Whether you are an industry veteran or new to CNC machining, they guide you through every step, guaranteeing exceptional outcomes.

SourcifyChina CNC Machine Lathe stands as a premier entity in the realm of precision engineering and manufacturing in China. Renowned for their commitment to quality and innovation, they specialize in the production and supply of advanced CNC lathe machines that cater to a diverse range of industrial needs. By leveraging cutting-edge technology and a skilled workforce, SourcifyChina ensures that each machine delivers superior performance, reliability, and precision. Their extensive product lineup includes a variety of CNC lathes designed to handle complex machining tasks with remarkable efficiency and accuracy. Furthermore, they pride themselves on exceptional customer service, providing tailored solutions and comprehensive support to meet the specific requirements of their global clientele. With a strong focus on continuous improvement and adherence to international standards, SourcifyChina CNC Machine Lathe remains a trusted partner for businesses seeking high-quality machining solutions in an increasingly competitive market.

CNC (Computer Numerical Control) lathe machines play an indispensable role in the aerospace, defense, and marine sectors due to their precision, efficiency, and versatility in fabricating complex components. In the aerospace industry, CNC lathe machines are instrumental in producing high-precision parts such as turbine blades, engine components, and structural elements. These components often require tight tolerances and superior quality, which CNC lathes deliver by automating and streamlining the manufacturing process. The ability to work with a wide range of materials, including high-strength metals and advanced composites, ensures that the parts can withstand extreme conditions and stresses encountered during flight. Consequently, CNC lathe applications contribute significantly to enhancing aircraft performance, safety, and reliability.

In the defense and marine sectors, CNC lathe machines are equally valuable for creating durable and precisely-machined components. For defense applications, this includes the production of weaponry, armored vehicles, and communication equipment, all of which demand exceptional accuracy and quality to ensure optimal functionality and safety. CNC lathes enable the efficient manufacturing of parts like barrels, missile components, and intricate electronic housings. In the marine industry, these machines are used to fabricate critical components for ships, submarines, and offshore platforms, such as propeller shafts, valve bodies, and structural supports. The robust construction and precision of CNC lathe-machined parts are crucial for withstanding the harsh marine environment, ensuring the longevity and performance of maritime vessels. Ultimately, CNC lathe technology is a cornerstone in advancing the aerospace, defense, and marine industries by providing high-quality, reliable, and efficient manufacturing solutions.

CNC (Computer Numerical Control) machine lathes play a transformative role in the automotive industry, offering unparalleled precision and efficiency in the manufacturing of various vehicle components. These advanced machines enable the production of intricate engine parts such as crankshafts, camshafts, and pistons with high accuracy. The lathe’s ability to execute complex cuts and shapes ensures that each component meets exact specifications, which is crucial for the high-performance demands of modern engines. Additionally, CNC machine lathes streamline the production process, reducing lead times and minimizing waste. This efficiency isn’t just beneficial for the bottom line; it also supports the automotive industry’s push towards more sustainable manufacturing practices by optimizing material usage and energy consumption.

In the field of electronics, CNC machine lathes are indispensable for manufacturing components that require precise dimensions and fine details. They are commonly used to create parts for consumer electronics, including connectors, enclosures, and intricate heat sinks. The precision offered by CNC lathes ensures that these components fit perfectly within the compact and tightly-regulated spaces of modern electronic devices. Furthermore, with the rise of miniaturization in electronics, CNC lathes are essential for producing small, complex parts that are both reliable and consistent. This high level of accuracy is vital for components to perform properly in applications such as smartphones, laptops, and medical devices, where even minor deviations can lead to significant performance issues. By leveraging CNC technology, electronics manufacturers can achieve robust, high-quality production while maintaining the exacting standards required in this fast-evolving industry.

Computer Numerical Control (CNC) machine lathes have revolutionized the construction industry by enhancing precision and efficiency. In the context of construction, CNC lathes are pivotal in fabricating critical components such as structural steel beams, custom metal fittings, and architectural fixtures. Controlled by precise programming, these machines ensure uniformity and high tolerance levels, essential for maintaining structural integrity and safety. The ability to machine complex shapes and details from a variety of materials allows construction projects to achieve bespoke designs and durability. Moreover, the automation capability of CNC lathes reduces manual labor, minimizes errors, and speeds up production timelines, thereby optimizing workflow and reducing overall project costs.

In the energy sector, CNC machine lathes play a crucial role in manufacturing parts for power generation equipment, including turbines, generators, and pumps. The precision machining enabled by CNC technology ensures that components fit perfectly and function efficiently, which is critical for performance and safety in energy systems. For renewable energy applications, CNC lathes contribute to the production of intricate parts for wind turbines, solar panel mounts, and hydroelectric components. The high precision and repeatability of CNC machining are also pivotal in the nuclear energy sector, where even the slightest deviation can have significant consequences. By facilitating the production of reliable and high-quality components, CNC machine lathes support the energy sector’s goals of efficiency, sustainability, and innovation.

The industrial equipment industry has undergone significant transformation with the advent of CNC (Computer Numerical Control) machine lathes, a game-changer in precision engineering and manufacturing. CNC machine lathes leverage advanced computer systems to control and automate the movement of machine tools, resulting in unparalleled accuracy and consistency in production. These machines are essential in creating intricate parts for a myriad of industries, including automotive, aerospace, and medical devices. By precisely controlling cutting tools, CNC lathes can produce complex geometries that would be difficult, if not impossible, to achieve using manual methods. Furthermore, the automation capabilities of CNC lathes notably reduce human error and labor costs, while simultaneously increasing production speed and efficiency.

Another significant advantage of CNC machine lathes in the industrial equipment sector is their versatility and adaptability. Modern CNC lathes can easily be reprogrammed to manufacture different components, making them highly flexible for small-batch and custom manufacturing. This adaptability meets the growing demand for tailored solutions and rapid prototyping, which are increasingly important in today’s competitive market. Additionally, the integration of CNC lathes with advanced software allows for real-time monitoring and adjustments, ensuring optimal performance and product quality. Moreover, continuous advancements in CNC technology, such as multi-axis machining and hybrid systems that combine additive and subtractive manufacturing, further expand the capabilities and applications of these machines, making them indispensable for the future of industrial manufacturing.

CNC (Computer Numerical Control) machine lathes have revolutionized the medical devices industry by providing precise and high-quality manufacturing solutions for components critical to patient care. These sophisticated machines enable the production of intricate parts such as surgical instruments, prosthetic joints, and dental implants with unparalleled accuracy. By utilizing advanced software to guide the lathing process, manufacturers can achieve complex geometries and tight tolerances required for medical devices. This precision is essential in an industry where even minor deviations can lead to significant consequences. For instance, CNC lathes can produce parts with micron-level accuracy, ensuring consistent and reliable performance of medical devices, thereby enhancing patient safety and treatment outcomes.

Moreover, the capability of CNC lathes to handle a variety of materials, including stainless steel, titanium, and biocompatible polymers, makes them indispensable in the medical devices sector. These materials often require meticulous machining to meet stringent biocompatibility and durability standards. CNC lathes excel in creating smooth surfaces and intricate details that reduce wear and improve the longevity of medical devices. The automation and repeatability of CNC machining also enable high-volume production while maintaining quality, thus meeting the increasing demand for medical devices. As a result, CNC machine lathes contribute significantly to the advancement of medical technology, enabling innovations that improve patient care and expand the possibilities for medical treatments.

A CNC (Computer Numerical Control) machine lathe is a powerful tool in the field of machining and manufacturing, revered for its precision, efficiency, and versatility. In machining applications, a CNC lathe automates the process of cutting, sanding, knurling, drilling, or deforming materials like metal, wood, or plastic to produce intricate parts with exacting tolerances. It operates by interpreting a sequence of numerical codes from a computer file to execute programmed commands. This automated control reduces human error, enhances consistency, and speeds up production, making CNC lathes indispensable in industries like aerospace, automotive, medical devices, and electronics where detailed and reliable machining is critical.

In manufacturing, the CNC lathe plays a crucial role in both prototyping and mass production. During prototyping, its capability to swiftly convert digital designs into physical components allows engineers to iterate and refine products rapidly. This accelerates the development cycle and brings innovations to market faster. For mass production, the CNC lathe excels in creating large volumes of complex parts with uniform quality and minimal manual intervention. Additionally, its capability to operate around the clock with minimal supervision increases productivity and reduces unit costs. Overall, the CNC machine lathe stands as a cornerstone in modern manufacturing, integrating advanced technology with precision engineering to meet the high demands of contemporary industries.

FAQ for CNC Machine Lathe Quality Work from SourcifyChina Factory

1. What are the capabilities of SourcifyChina’s CNC machine lathes?

SourcifyChina’s CNC machine lathes are equipped to handle high precision machining tasks, including turning, boring, drilling, threading, and grinding. They are suitable for both prototyping and large-scale production.

2. How does SourcifyChina ensure the quality of CNC lathe work?

Quality is ensured through rigorous inspections, state-of-the-art technology, and adherence to ISO 9001 standards. Each product undergoes thorough testing and quality checks at various production stages.

3. What materials can SourcifyChina’s CNC machine lathes process?

Our lathes can process a wide variety of materials including metals (such as aluminum, steel, and titanium), plastics, and composites, catering to diverse industry needs.

4. What are the lead times for CNC machined parts from SourcifyChina?

Lead times generally depend on the complexity and volume of the order but typically range from 2-6 weeks. We offer expedited services for urgent requirements.

5. Can SourcifyChina handle custom designs?

Yes, we specialize in custom CNC machining based on clients’ specific designs and requirements. Our team works closely with you from design to finished product to ensure all specifications are met.

6. What software does SourcifyChina use for designing and programming CNC machining tasks?

We use advanced CAD/CAM software such as SolidWorks, AutoCAD, and Mastercam to ensure precision and efficiency in the manufacturing process.

7. What industries does SourcifyChina cater to?

We serve a broad range of industries including aerospace, automotive, medical, electronics, and consumer goods. Our versatile capabilities make us a reliable partner across various sectors.

8. How can I get a quote for CNC machined parts from SourcifyChina?

To get a quote, you can send us your design files (preferably in CAD format) along with detailed specifications via our website or email. Our team will assess your requirements and provide a competitive quote.

9. What kind of post-processing services does SourcifyChina offer?

We offer a variety of post-processing services including anodizing, plating, powder coating, heat treatments, and assembly to meet your finishing requirements.

When considering CNC machine lathe manufacturing from SourcifyChina factory, keep the following tips in mind to ensure success and efficiency:

1. Research and Vet Suppliers: Begin by thoroughly researching potential suppliers. SourcifyChina can help connect you with reputable manufacturers, but it’s crucial to vet them independently through online reviews, recommendations, and possibly small sample orders.

2. Understand Your Needs: Clearly outline your manufacturing requirements including material specifications, tolerance levels, and production volumes. Precise communication of these needs to the factory can prevent costly errors and time delays.

3. Quality Assurance: Ensure the factory has robust quality control processes in place. Request details on their QC protocols and consider third-party inspections to verify product quality before large-scale production.

4. Technological Compatibility: Confirm that the factory’s CNC machines and technology match your manufacturing requirements. The latest CNC lathe technology can offer improved precision and efficiency, leading to a superior end product.

5. Prototype Production: Begin with a prototype to evaluate the factory’s capabilities. This step allows you to identify potential issues early and make necessary adjustments before committing to full-scale production.

6. Cost Transparency: Get a detailed breakdown of costs including material, labor, setup, and shipping. Transparent pricing helps in budgeting and avoiding unexpected expenses.

7. Communication Channels: Establish clear and consistent communication channels. Regular updates and open lines of communication help address any issues promptly and maintain production timelines.

8. Logistics and Delivery: Plan and confirm logistics in collaboration with the factory. This includes shipping methods, timelines, and customs requirements to ensure smooth delivery of your products.

9. After-Sales Support: Check if the factory provides after-sales support, such as maintenance services or parts replacement, which can be crucial for long-term manufacturing success.

By adhering to these tips, you can effectively leverage SourcifyChina’s resources and expertise to streamline your CNC machine lathe manufacturing process.

Sure, here are some frequently asked questions (FAQs) with answers for sourcing a CNC machine lathe from SourcifyChina factory:

Q: What types of CNC machine lathes does SourcifyChina factory offer?

A: SourcifyChina provides a wide range of CNC machine lathes, including vertical and horizontal lathes, multi-axis lathes, and specialty lathes customized for specific industrial applications.

Q: How can I request a quote for a CNC machine lathe?

A: You can request a quote by visiting the SourcifyChina official website and filling out the inquiry form, or by directly contacting their sales team via email or phone.

Q: What information do I need to provide for an accurate quote?

A: To get an accurate quote, you should provide detailed requirements such as the type of lathe, specifications (e.g., spindle speed, bed size), intended use, quantity, and any customization needs.

Q: Are there any minimum order quantity (MOQ) requirements?

A: The MOQ can vary depending on the model and customization requirements. It is best to discuss this directly with SourcifyChina’s sales team to get specific details.

Q: What is the lead time for CNC machine lathes?

A: Lead times can vary based on the complexity of the machine and current factory workload. Typically, lead times range from 4 to 12 weeks. Confirming the lead time during the quotation process is advisable.

Q: Does SourcifyChina provide any warranty or after-sales support?

A: Yes, SourcifyChina usually offers a standard warranty period and after-sales support. Details regarding the warranty period and support services can be discussed with their sales team.

Q: Can the CNC machine lathe be customized?

A: Yes, SourcifyChina offers customization options for CNC machine lathes to meet specific requirements. You can discuss your customization needs directly with their engineering team.

Q: How are the machines shipped and what are the shipping costs?

A: Machines are typically shipped via sea freight. Shipping costs depend on the destination, size, and weight of the machine. SourcifyChina can provide an estimated shipping cost during the quotation process.

Q: What payment methods are accepted?

A: SourcifyChina usually accepts various payment methods, including wire transfers (T/T), letters of credit (L/C), and other mutually agreed terms. Payment terms can be discussed with their sales team.

Sourcing a CNC machine lathe from SourcifyChina factory involves several key steps to ensure you get a quality product at a reasonable price. Here are some tips:

1. Company Background: Start with researching SourcifyChina’s reputation. Look for reviews, ratings, and client testimonials online.

2. Certifications and Compliance: Ensure the factory complies with international standards such as ISO certification.

1. Initial Inquiry: Send a detailed inquiry specifying the type of CNC lathe you need, including technical specifications, volume, and any customization requirements.

2. Response Evaluation: Assess the responsiveness and professionalism of their customer service team. Quick and clear responses often reflect better service quality.

1. Request Samples: Ask for product samples to evaluate their build quality and functionality.

2. Virtual or Physical Inspection: If possible, arrange for a tour of the factory either virtually or in-person to see their production processes.

1. Get Quotes: Obtain detailed quotations including unit price, shipping costs, and any other fees.

2. Negotiate: Don’t hesitate to negotiate terms such as price, lead time, and payment conditions.

1. Escrow Services: Consider using escrow services to protect your investment during the transaction.

2. Milestone Payments: Opt for payments in milestones—initial deposit, mid-production, and final before shipment.

1. Incoterms: Be clear on the Incoterms (e.g., FOB, CIF) to understand who bears the cost and risk during shipping.

2. Insurance: Ensure the shipment is insured to cover any potential damages during transit.

1. Warranty: Confirm warranty terms and after-sales service policies.

2. Technical Support: Check if they offer technical support and spare parts availability.

Following these steps will help you source a reliable CNC machine lathe from SourcifyChina factory effectively.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.