Technology and Applications of cnc machine router

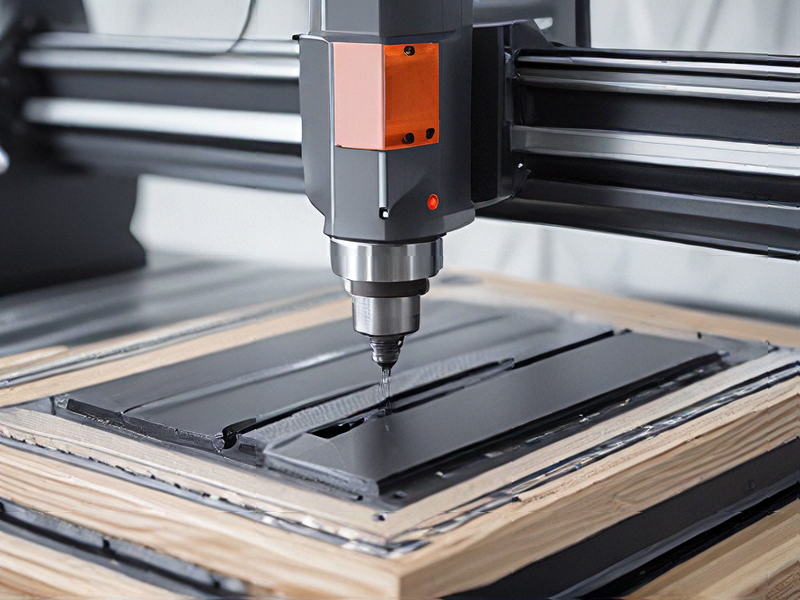

A CNC (Computer Numerical Control) machine router is a versatile tool that automates the process of cutting, carving, and engraving various materials, including wood, aluminum, plastics, and composites. Utilizing computer programming, CNC routers operate with high precision, allowing for complex shapes and designs to be executed with minimal manual intervention.

Technology: At its core, a CNC machine router consists of three main components: the computer system, the mechanical structure, and the spindle. The computer system uses CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to create and modify designs, translating them into a G-code language that the router understands. The mechanical structure includes rails, motors, and a moving bed, facilitating movement on multiple axes (commonly X, Y, and Z), and the spindle holds the cutting tool. Advanced models can also incorporate features like automatic tool changers, vacuum hold-down, and dust collection systems.

Applications: CNC routers find applications across various industries:

1. Furniture Manufacturing: Custom designs, intricate patterns, and joint fabrication.

2. Sign Making: Production of detailed signs, logos, and displays with clean cuts and finishes.

3. Prototyping: Rapid production of prototypes for industrial design, allowing for faster iterations.

4. Woodworking: Detailed carvings and 3D reliefs in artistic and functional woodworking projects.

5. Aerospace and Automotive: Machining lightweight components from composites and alloys.

The automation and precision offered by CNC routers significantly enhance productivity, reduce waste, and enable the creation of intricate designs that would be challenging to produce manually. This technology continues to evolve, incorporating advancements like AI and IoT for predictive maintenance and smart manufacturing processes.

Quality Testing Methods for cnc machine router and how to control quality

Quality testing for CNC machine routers is essential to ensure precision and reliability in machining processes. Here are several key methods for quality testing and control:

1. Visual Inspection: A thorough visual check of the finished workpieces helps identify surface defects, dimensional inaccuracies, and any obvious flaws. This initial examination can catch errors early.

2. Measurement Tools: Utilizing calipers, micrometers, and gauges allows for precise measurement of the dimensions of the machined parts. Regular calibration of these tools is crucial for maintaining accuracy.

3. CMM (Coordinate Measuring Machine): For highly intricate components, a CMM can be employed for comprehensive 3D measurements. This tool accurately assesses the geometry of parts against CAD specifications.

4. Cutting Tool Inspection: Regular inspection and maintenance of cutting tools ensure that they remain sharp and effective. Dull tools not only affect the quality of the work, but they can also lead to increased wear on the CNC machine.

5. Process Monitoring: Implementing real-time monitoring systems can track the CNC machining process for abnormalities, such as vibration or temperature changes, which can indicate potential issues.

6. Statistical Process Control (SPC): This involves using statistical methods to monitor and control the production process. By analyzing variations, adjustments can be made proactively to maintain quality.

7. Documentation and Records: Keeping comprehensive records of processes, measurements, and inspections helps in identifying trends and preventing issues in future runs.

By systematically applying these quality testing methods and ensuring continuous monitoring, CNC machine routers can achieve high levels of precision and reliability, ultimately leading to improved product quality and customer satisfaction.

Tips for Procurement and Considerations when Purchasing from cnc machine router

When procuring a CNC machine router, several key factors and considerations can ensure you make a well-informed purchase:

1. Define Your Needs: Assess the specific applications you intend to use the router for, including material types (wood, metal, plastic), dimensions, and precision requirements.

2. Budget: Establish a clear budget that includes not only the purchase price but also potential maintenance, software, tooling, and operational costs.

3. Machine Specifications: Look for specifications like spindle speed, cutting area, motor power, and axis capabilities. Ensure the machine’s capabilities align with your project’s demands.

4. Brand Reputation: Research manufacturers and suppliers. Look for established brands with positive customer reviews, reliable support, and warranty policies.

5. Software Compatibility: Confirm that the router is compatible with the CAD/CAM software you plan to use. Ease of integration can significantly affect productivity.

6. Training and Support: Inquire about training programs for operators and technical support availability post-purchase. A robust support system can minimize downtime.

7. Maintenance and Parts Availability: Investigate the ease of obtaining replacement parts and the recommended maintenance schedule. A machine with readily available parts minimizes long-term costs.

8. Future Scalability: Consider a router that allows for future upgrades or expansion. This can save costs in the long run as your capabilities grow.

9. Delivery and Installation: Ensure there are clear terms regarding delivery, installation, and setup. Some manufacturers offer additional services that can ease the transition.

10. Return Policy: Understand the manufacturer’s return policy in case the machine does not meet your expectations.

By carefully considering these aspects, you can make an informed decision that aligns with your operational goals and budget.

FAQs on Sourcing and Manufacturing from cnc machine router in China

FAQs on Sourcing and Manufacturing CNC Machine Routers in China

1. What are CNC machine routers?

CNC (Computer Numerical Control) machine routers are automated tools that cut and engrave materials like wood, metal, and plastic with high precision. They are widely used in manufacturing and woodworking industries.

2. Why source CNC machine routers from China?

China has a robust manufacturing infrastructure, competitive pricing, and a wide range of suppliers. Many Chinese manufacturers offer advanced technology and quality products that meet international standards.

3. How do I find a reliable supplier?

Research suppliers through platforms like Alibaba, Made-in-China, or Globalsources. Check reviews, request references, and verify their business licenses and certifications.

4. What are the key factors to consider?

Consider price, quality, after-sales service, lead times, and minimum order quantities. Ensure the supplier adheres to international standards and can provide necessary certifications.

5. How can I ensure product quality?

Request samples before placing a bulk order. Conduct third-party quality inspections during production and before shipment. Regular communication with the supplier can also help maintain quality.

6. What shipping options are available?

Shipping methods include air freight, sea freight, and express delivery. Choose based on your budget, timeline, and urgency of the order.

7. Are there any tariffs or customs duties?

Yes, importing goods may incur customs duties or tariffs depending on your country’s regulations. Research local laws and factor these costs into your budgeting.

8. Can I customize my CNC machine?

Most manufacturers offer customization options for machine specifications, sizes, and features to meet specific needs.

By addressing these FAQs, businesses can better navigate the sourcing and manufacturing process of CNC machine routers in China.