Choosing SourcifyChina Factory ensures precision and quality in CNC machining plastics due to their advanced technology. Their state-of-the-art equipment guarantees high accuracy and consistent output, meeting international standards.

SourcifyChina offers competitive pricing without compromising quality. Their cost-efficient processes and lean manufacturing techniques ensure you get the best value for your investment, making them budget-friendly.

Customer service at SourcifyChina is top-notch. They provide timely updates, quick responses, and personalized support through every stage of the production process, ensuring a smooth experience and peace of mind for buyers.

The factory has robust quality control measures to ensure each product meets stringent standards. This commitment to excellence results in reliable, durable plastic parts that perform well in various applications.

Additionally, SourcifyChina has extensive experience and expertise in CNC plastic machining. Their skilled workforce and innovative methods enable them to handle complex designs and specifications with ease, ensuring flawless execution.

In summary, SourcifyChina Factory stands out for its cutting-edge technology, cost efficiency, exceptional customer service, stringent quality control, and expert craftsmanship. Partnering with them ensures superior CNC machined plastic parts tailored to your precise needs.

CNC machining of plastics involves using computer-controlled machines to precisely cut, shape, and form plastic components. Various types of plastics, such as thermoplastics and thermosets, are used in different applications for their unique properties.

– ABS (Acrylonitrile Butadiene Styrene):

– Good mechanical properties

– Easy to machine

– Common in automotive and consumer electronics

– Acrylic (PMMA):

– Transparent and lightweight

– Excellent optical clarity

– Used in displays and signs

– Nylon (Polyamide):

– High strength and toughness

– Good wear resistance

– Common in mechanical components

– POM (Polyoxymethylene):

– High rigidity and dimensional stability

– Low friction and wear

– Ideal for precision gears and bearings

– PTFE (Polytetrafluoroethylene):

– High chemical resistance

– Low friction

– Used in seals, bushings, and gaskets

– Polycarbonate:

– High impact resistance

– Good temperature tolerance

– Used in safety equipment and optical lenses

– PEEK (Polyether Ether Ketone):

– High mechanical strength

– Excellent chemical resistance

– Suitable for aerospace and medical applications

– UHMWPE (Ultra-High-Molecular-Weight Polyethylene):

– Extremely high abrasion resistance

– Low coefficient of friction

– Used in lining, wear strips, and guide rails

CNC machining offers high precision and repeatability, making it ideal for prototyping and mass production of plastic components. Various plastics offer unique advantages depending on the specific requirements of the project, ensuring a wide range of industrial applications.

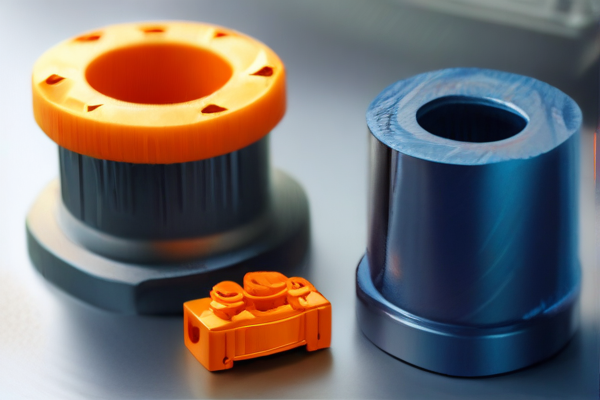

CNC machining plastics is a versatile process utilized for creating precision components in various industries due to its accuracy and efficiency.

– Medical Devices: Custom components like surgical instruments and prostheses.

– Aerospace: Lightweight, durable parts for aircraft interiors.

– Automotive: Prototype parts and functional testing components.

– Consumer Electronics: Housings and structural parts for gadgets.

– Industrial Equipment: Custom gears, spacers, and covers.

– Prototyping: Rapid development of prototypes for design validation.

– Robotics: Manufacturing of precise, durable robot components.

– Signage and Displays: Specialized parts for retail and promotional displays.

– Packaging: Production of precision molds for packaging solutions.

– Sports Equipment: Custom high-performance components.

– Renewable Energy: Components for wind turbines and solar panels.

– Home Appliances: Custom parts for kitchen and home devices.

– Marine Industry: Lightweight and resistant parts for boating equipment.

– Optical Industry: Precision parts for instruments and lenses.

– Education and Research: Custom components for experimental setups and research projects.

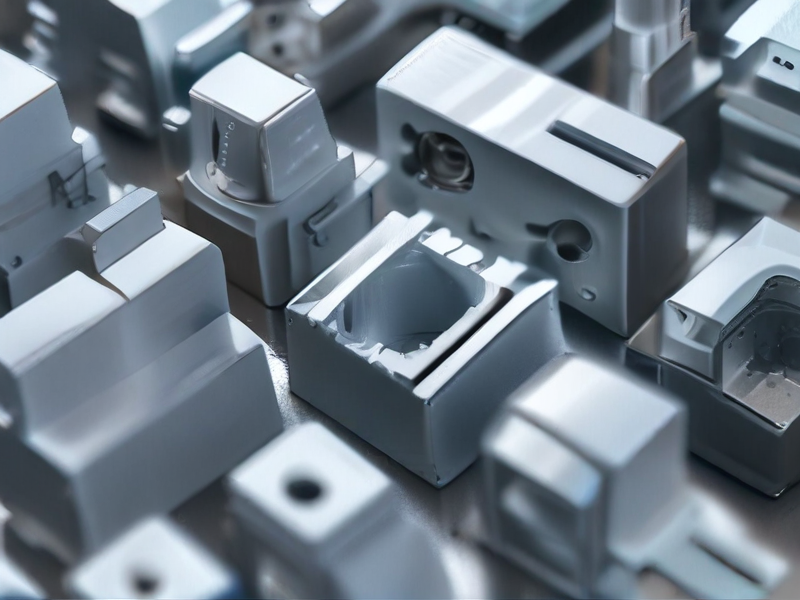

SourcifyChina specializes in CNC machining of various plastics, offering precision and quality in each product. Their capabilities include working with a wide range of plastics like ABS, polycarbonate, acrylic, and nylon, which are known for their durability and versatility.

ABS plastic is valued for its toughness and impact resistance, making it suitable for automotive parts and consumer electronics. Polycarbonate is another popular choice due to its high transparency and excellent dimensional stability, ideal for lenses and electronic components.

Acrylic, also known as PMMA, offers superior optical clarity and weather resistance, perfect for display cases and signage. Nylon’s high strength and wear resistance make it suitable for gears and bearings in mechanical applications.

SourcifyChina’s expertise ensures that each plastic part meets stringent quality standards, providing reliable performance across various industries. With advanced CNC machining techniques, they deliver precise and consistent results for complex geometries and tight tolerances.

Their commitment to quality and customer satisfaction is evident in their meticulous attention to detail and use of state-of-the-art machinery. This dedication makes SourcifyChina a trusted partner for businesses needing high-quality CNC machined plastic parts.

By leveraging their extensive experience and technological capabilities, SourcifyChina continues to innovate and expand their material offerings, ensuring they meet the evolving needs of their clients in a competitive market.

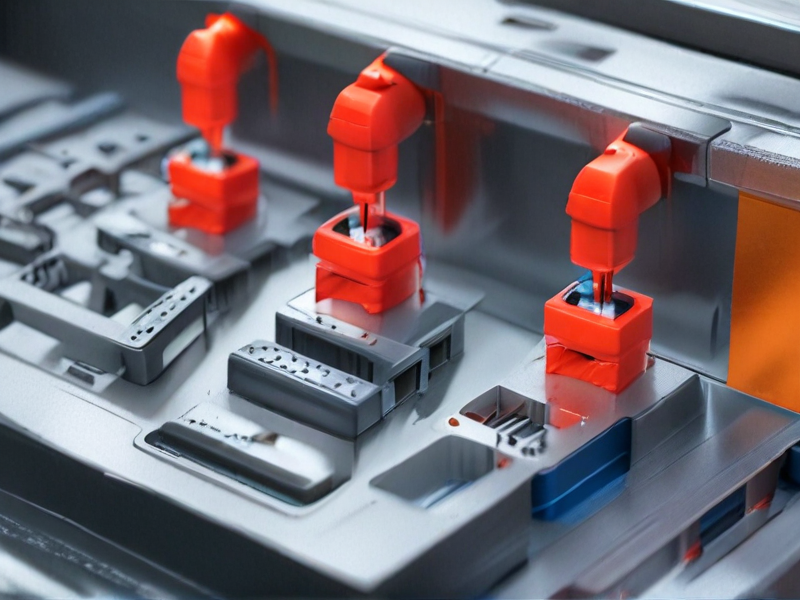

SourcifyChina employs stringent quality control measures in their CNC machining plastics manufacturing process. Each stage of production, from material selection to final inspection, is meticulously monitored to ensure the highest standards.

Material selection is crucial, with SourcifyChina sourcing only premium-grade plastics. Rigorous testing is performed to verify the material’s properties, ensuring durability and performance meet industry specifications.

Precision in CNC machining is maintained through advanced equipment and skilled technicians. Each component undergoes detailed inspections using cutting-edge measurement tools to guarantee dimensional accuracy and consistency.

The final inspection phase includes comprehensive quality checks, ensuring each product meets the required specifications before dispatch. This thorough quality control process ensures customer satisfaction and product reliability.

In summary, SourcifyChina’s CNC machining plastics manufacturing process emphasizes quality control at every step. From material selection to final inspection, their commitment to precision and excellence ensures superior products.

SourcifyChina demonstrates advanced CNC machining capabilities for plastics, integrating precision technology and expertise to meet various industrial needs. With state-of-the-art equipment, they produce complex and detailed plastic components tailored to specific requirements.

Their skilled team ensures quality and consistency in every project, handling diverse plastics such as ABS, PEEK, and acrylics. SourcifyChina excels in tight tolerances, providing reliable and high-performance parts that fulfill stringent client specifications.

The company’s comprehensive services include prototyping, mass production, and custom manufacturing. Their innovative approach encompasses design assistance that optimizes material selection and production techniques, enhancing the end product’s function and durability.

SourcifyChina also focuses on cost efficiency without compromising quality, offering competitive pricing and timely delivery. Their streamlined processes reduce lead times while maintaining rigorous quality control standards, ensuring each component meets or exceeds industry benchmarks.

In addition, they emphasize sustainability by utilizing eco-friendly materials and implementing waste reduction practices. This commitment to environmental responsibility underscores their dedication to not only meeting client needs but also promoting sustainable manufacturing practices.

The customer-centric approach of SourcifyChina ensures each client receives personalized attention and tailored solutions. Their proactive communication and transparent workflows foster strong partnerships, driving mutual success and ongoing innovation in CNC machining for plastics.

SourcifyChina’s dedication to excellence positions them as a preferred provider for plastic machining solutions, catering to a wide array of industries from aerospace to consumer goods. They continuously invest in technology and skilled personnel, ensuring they stay at the forefront of the CNC machining sector.

Overall, SourcifyChina’s capabilities in CNC machining plastics are comprehensive and robust, providing high-quality, cost-effective, and eco-friendly solutions. Their commitment to precision, innovation, and customer satisfaction makes them a reliable partner in the manufacturing industry.

CNC machining plastics offer numerous advantages, enhancing precision, efficiency, and material utilization in various industrial applications.

– Precision and Accuracy: CNC machines operate with high levels of precision, ensuring consistent and accurate production of plastic parts.

– Complex Geometries: The technology can handle intricate designs, enabling the production of complex plastic components.

– Material Versatility: CNC machining is compatible with a wide range of plastics, including ABS, polycarbonate, and acetal, among others.

– Speed and Efficiency: Automated processes minimize production times and labor costs, enhancing overall efficiency.

– Prototyping and Production: Ideal for both rapid prototyping and large-scale production, catering to diverse manufacturing needs.

– Reduced Waste: CNC machining maximizes material utilization, reducing waste and contributing to cost savings.

– Consistency: Repeatedly produces parts with uniform quality and specifications, essential for high-volume manufacturing.

– Surface Finish: Achieves excellent surface finishes, reducing the need for additional post-processing.

– Minimal Tool Wear: Durable tools reduce wear and tear, lowering maintenance costs.

– Customizability: Easily adaptable for custom and complex project requirements, offering design flexibility.

– Reduced Human Error: Automation reduces the likelihood of human errors, ensuring superior product quality.

– Time-Saving: Rapid setup and turnaround times accelerate production processes.

– Scalability: Easily scalable to meet varying production demands, from prototypes to mass production.

– Environmental Benefits: Enhanced material efficiency contributes to environmentally friendly manufacturing practices.

In summary, CNC machining plastics provide efficient, precise, and versatile solutions across various industries, from automotive to consumer electronics.

CNC machining plastics offers precision and versatility, making it ideal for producing complex parts with tight tolerances.

– Accuracy and Precision: CNC machines provide high accuracy and repeatability, essential for intricate designs and detailed components.

– Material Versatility: A wide range of plastics, including ABS, polycarbonate, and nylon, can be machined, each with unique properties suitable for different applications.

– Cost-Effective Prototyping: CNC machining allows for rapid prototyping, enabling quick adjustments and testing of plastic parts without the need for expensive molds.

– Surface Finish: CNC machining can achieve smooth surface finishes, reducing the need for additional post-processing.

– Durability and Strength: Machined plastic parts can offer significant strength and durability, suitable for functional and load-bearing applications.

– Scalability: CNC machining is suitable for both low and high-volume production, offering flexibility in manufacturing.

– Complex Geometries: Capable of producing complex shapes and intricate geometries that might be challenging with other manufacturing methods.

– Consistency: Ensures consistent quality across multiple parts, reducing variability and ensuring reliable performance.

– Efficiency: Automated processes increase production speed and reduce manual labor, improving overall efficiency.

– Environmental Impact: Machining plastics can generate less waste compared to traditional methods, as it removes material only where needed.

These features make CNC machining plastics a valuable method for creating high-quality, precise plastic components for various industries.

SourcifyChina offers high-quality CNC machining for plastic custom products, catering to diverse industries. Their advanced machinery ensures precision and consistency in every project.

With expertise in various plastic materials, SourcifyChina delivers tailored solutions to meet specific requirements. They handle everything from design to production with meticulous attention to detail.

The company’s services extend to prototyping, small-batch production, and large-scale manufacturing. This flexibility makes them a reliable partner for any size project.

Committed to innovation and efficiency, SourcifyChina employs the latest CNC technologies. This guarantees superior products that meet stringent industry standards.

Customer satisfaction is paramount at SourcifyChina. They work closely with clients to understand their needs, ensuring each project’s success. With a focus on quality and reliability, SourcifyChina is your go-to for custom CNC machined plastic products.

SourcifyChina, a leading player in the realm of CNC machining plastics, is renowned for its precision manufacturing and innovative solutions tailored to diverse industrial needs. Specializing in the high-precision CNC machining of plastic components, the company leverages cutting-edge technology and state-of-the-art equipment to deliver superior products to a global clientele. SourcifyChina’s commitment to quality and customer satisfaction is reflected in its rigorous quality control processes and adherence to international standards. The company offers a comprehensive range of services, including prototyping, low-volume production, and mass production, ensuring flexibility and scalability for projects of all sizes. By maintaining a robust supply chain and fostering strong partnerships with material suppliers, SourcifyChina ensures the timely delivery of high-quality, cost-effective solutions. Their team of skilled engineers and technicians work closely with clients to understand their unique requirements, providing customized solutions that enhance performance and efficiency. SourcifyChina’s dedication to continuous improvement and innovation makes it a trusted partner for businesses seeking reliable and efficient CNC machining plastic services.

CNC machining plastics have become increasingly vital in the aerospace, defense, and marine industries, thanks to their unique properties such as lightweight, corrosion resistance, and high tensile strength. In aerospace applications, components like brackets, housings, and air ducts are often crafted from engineering plastics to reduce weight and enhance fuel efficiency. Precise CNC machining ensures these parts meet the demanding tolerances and performance standards required for safe and efficient aircraft operation. Additionally, the ability to machine complex geometries allows for the creation of custom parts that can withstand the high-pressure and high-temperature environments typical of aerospace applications.

In the defense sector, CNC-machined plastic components play crucial roles in the development of lightweight and durable equipment. Parts such as connectors, insulators, and enclosures benefit from plastics that offer resistance to harsh environmental conditions, including extreme temperatures and chemical exposure. Marine applications similarly leverage CNC machining plastics to produce parts that endure prolonged exposure to seawater without corroding or degrading. Plastic components like impellers, valves, and covers are beneficial in marine environments due to their buoyancy and reduced maintenance needs. Overall, the precision and versatility of CNC machining allow these industries to produce highly specialized, reliable components that meet stringent safety and performance criteria.

CNC machining plastics in the automotive industry offers precise, efficient, and cost-effective solutions for producing complex components. The ability to create intricate shapes and detailed features makes CNC machining ideal for crafting high-performance parts such as dashboards, door panels, and under-the-hood components from engineering plastics like ABS, polycarbonate, and nylon. These materials are chosen for their durability, lightweight properties, and resistance to chemicals and heat. CNC machining ensures consistent quality and tight tolerances, which are critical for automotive applications where reliability and safety are paramount. Additionally, the rapid prototyping capabilities of CNC machining facilitate the quick iteration of designs, enabling faster development cycles and innovation in automotive technology.

In the electronics industry, CNC machining plastics plays a crucial role in the fabrication of enclosures, connectors, and other precision components. Engineering plastics like polycarbonate, PEEK, and acrylic are commonly used due to their excellent electrical insulation properties, mechanical strength, and thermal stability. CNC machining allows for the production of custom housings and parts with intricate geometries required for modern electronic devices, from smartphones to medical equipment. This precision ensures that components fit together seamlessly, enhancing the overall performance and durability of the devices. Furthermore, CNC machining supports the miniaturization trend in electronics by enabling the creation of small, detailed parts with high accuracy, which is essential for compact and efficient electronic designs.

In the construction industry, CNC (Computer Numerical Control) machining of plastics is revolutionizing the way complex architectural components are created. High-precision CNC machines can fabricate intricate plastic elements, such as window frames, wall panels, and decorative fixtures, with unparalleled accuracy and consistency. This technology allows for the production of custom parts that are not only lightweight but also resistant to weathering and corrosion, making them ideal for both interior and exterior applications. Additionally, the use of plastics in construction reduces material waste, as CNC machining processes can be optimized to utilize every inch of raw material effectively. This efficiency not only lowers costs but also supports sustainable building practices by minimizing the environmental impact associated with construction waste.

In the energy sector, CNC machining of plastics plays a crucial role in the production of components for renewable energy systems, such as wind turbines and solar panels. Plastics are favored for their lightweight and durable properties, which are essential for the efficient operation and longevity of these systems. For instance, precision-machined plastic parts are used in the housings and insulators of electrical components, enhancing the overall performance and reliability of energy generation equipment. Moreover, CNC machining enables the creation of complex geometries that are necessary for advanced designs in energy technology, including the intricate blades of wind turbines and the specialized connectors in solar arrays. By ensuring high precision and consistency, CNC machining helps in optimizing the efficiency of renewable energy systems, contributing to the broader goal of sustainable energy production.

CNC machining plastics have revolutionized the industrial equipment industry, offering unparalleled precision and efficiency for creating intricate components and prototypes. Computer Numerical Control (CNC) machines utilize pre-programmed software to dictate the movement of tools and machinery, allowing for the automated and highly accurate production of parts. This technology is particularly beneficial when working with plastics, as it ensures consistent quality and precise tolerances. Industries such as automotive, aerospace, and medical equipment rely on CNC machining to produce custom plastic components with complex geometries that traditional manufacturing methods struggle to achieve. The ability to quickly prototype and iterate designs using CNC machining reduces lead times and accelerates the development process, driving innovation and competitiveness.

Furthermore, CNC machining of plastics enables cost-effective production runs, whether for single units or mass production. Plastics offer advantages such as lightweight properties, chemical resistance, and flexibility, making them ideal for various industrial applications. For example, in the automotive industry, CNC-machined plastic components are used in dashboard assemblies, under-the-hood parts, and fluid handling systems. In medical equipment, CNC precision enables the manufacture of critical components, such as housings for diagnostic devices and custom prosthetic parts. The adaptability of CNC machining allows for seamless adjustments and refinements, ultimately reducing material waste and enhancing overall production efficiency. By leveraging CNC machining for plastics, the industrial equipment industry can achieve higher accuracy, superior quality, and faster turnaround times, ensuring that they meet the stringent demands of modern manufacturing.

CNC machining of plastics has revolutionized the medical device industry by offering precision, consistency, and rapid prototyping advantages that are critical for developing life-saving equipment. Medical devices demand the highest levels of accuracy and hygienic standards, and CNC machining can meet these requirements efficiently. Plastics such as polycarbonate, PEEK, and medical-grade silicone are frequently used due to their biocompatibility, strength, and durability. With CNC machining, these materials can be shaped into intricate components with tolerances as tight as a few micrometers. This precision ensures that parts fit perfectly, which is crucial for devices like ventilators, diagnostic equipment, and surgical instruments where even the slightest error could lead to failure.

Moreover, CNC machining facilitates rapid prototyping, allowing medical device manufacturers to quickly transition from concept to testing phases. This is a critical advantage in a field where time-to-market can significantly impact patient outcomes. For instance, during public health crises, the ability to swiftly produce reliable medical devices can save countless lives. Additionally, CNC machining supports small to medium-scale production runs, making it ideal for custom medical devices tailored to specific patient needs, such as custom prosthetics and implants. The flexibility in design and adaptability in production make CNC machining of plastics an invaluable asset in advancing medical technology, ensuring devices are robust, safe, and tailored to the stringent demands of the healthcare sector.

CNC (Computer Numerical Control) machining of plastics is a crucial process in the manufacturing industry, allowing for the precise and efficient production of plastic components. This technology employs computer-controlled machines to remove material from a plastic workpiece, shaping it into the desired form with high accuracy and repeatability. CNC machining is compatible with a wide range of plastics, including ABS, polycarbonate, and nylon, each offering distinct properties suitable for different applications. The process is particularly advantageous for creating complex geometries and fine details that would be difficult or impossible to achieve through traditional machining methods. Additionally, CNC machining minimizes material waste and enhances production speed, making it an economical choice for both prototyping and high-volume production.

In the realm of manufacturing, CNC machining of plastics is widely used across various industries, including automotive, aerospace, medical, and consumer electronics. In the automotive sector, for instance, plastic components such as dashboards, instrument panels, and under-the-hood parts benefit from the precision and durability provided by CNC machining. The medical industry relies on CNC-machined plastics for devices and components that require strict adherence to safety and hygiene standards, such as surgical instruments and diagnostic equipment. Furthermore, the electronics industry uses CNC machining to produce housings, connectors, and other critical parts that demand tight tolerances and high-quality finishes. Overall, the ability to rapidly produce high-quality plastic parts with intricate designs makes CNC machining an indispensable tool in modern manufacturing.

Sure! Here are some FAQs with answers regarding CNC machining plastics quality work from SourcifyChina factory:

Q: What types of plastics can SourcifyChina factory machine?

A: SourcifyChina factory can machine a wide range of plastics including ABS, PVC, Nylon, Polycarbonate, PEEK, Acrylic, Delrin, and PTFE among others.

Q: What is the typical turnaround time for CNC machined plastic parts?

A: The typical turnaround time varies based on the complexity and volume of the order, but generally, it ranges from 1 to 3 weeks.

Q: How does SourcifyChina ensure the quality of CNC machined plastic parts?

A: SourcifyChina uses state-of-the-art CNC machines, rigorous quality control processes, and experienced technicians to ensure high-quality parts. They also perform regular inspections and tests to meet customer specifications.

Q: Can SourcifyChina handle both small and large volume orders?

A: Yes, SourcifyChina is equipped to handle both small prototype runs and large production orders, providing flexibility based on customer needs.

Q: What tolerances can be achieved with CNC machining at SourcifyChina?

A: SourcifyChina can achieve tight tolerances up to ±0.005 inches, depending on the material and part complexity.

Q: Are there any additional services offered alongside CNC machining?

A: Yes, SourcifyChina offers additional services such as finishing, assembly, and packaging to provide a complete manufacturing solution.

Q: How can I request a quote for CNC machining services?

A: You can request a quote by providing your design files and specifications through SourcifyChina’s website or by contacting their customer service team directly.

Q: What file formats are accepted for CNC machining projects?

A: SourcifyChina accepts various file formats including STEP, IGES, STL, and DXF for CNC machining projects.

Q: Does SourcifyChina provide design assistance or consulting services?

A: Yes, SourcifyChina offers design assistance and consulting services to help optimize your design for manufacturability and cost-effectiveness.

Q: Is SourcifyChina ISO certified?

A: Yes, SourcifyChina holds ISO certification, ensuring adherence to international quality management standards.

When considering CNC machining for plastics manufacturing, particularly from a proficient provider like SourcifyChina factory, there are several important tips to keep in mind to ensure high-quality results:

1. Material Selection: Choose the right type of plastic for your application. Common options include ABS, Polycarbonate, Nylon, PEEK, and Acrylic. Each material has unique properties, so selecting the correct one ensures durability and performance.

2. Precision and Tolerances: CNC machining provides high precision, but tight tolerances can be more challenging with plastics due to their flexibility and thermal expansion. Work closely with SourcifyChina factory to define realistic tolerances for your parts.

3. Tooling and Speeds: Use the proper tools and machining speeds to avoid melting or warping the plastic. Carbide tools are often recommended, and the right feed rates and spindle speeds will prevent overheating.

4. Part Design: Simplify your design to minimize potential machining issues. Avoid very thin walls, sharp internal corners, and deep cavities because these can be difficult to machine and may compromise the part’s integrity.

5. Cooling and Lubrication: Proper cooling and lubrication are essential to avoid heat buildup, which can lead to part deformation. Discuss with your CNC service provider the best cooling techniques for the plastic material being used.

6. Surface Finish: Different plastics can achieve different surface finishes. Determine whether your application requires a specific finish, such as a smooth surface or a textured one, and communicate this to SourcifyChina factory.

7. Quality Control: Ensure that the factory offers robust quality control measures. This might include CMM (Coordinate Measuring Machine) inspections and other verification methods to ensure that parts meet specifications.

8. Prototyping and Testing: Start with prototyping to validate your design and material choice. Prototyping helps identify any potential issues before full-scale production, saving time and costs.

Collaborating with an experienced provider like SourcifyChina factory and following these tips can result in high-quality, precise plastic components suitable for various applications.

What types of plastics can SourcifyChina factory machine?

SourcifyChina can machine a wide range of plastics including ABS, polycarbonate, nylon, PEEK, PTFE, Delrin (acetal), and acrylic, among others.

What CNC machining services does SourcifyChina offer?

SourcifyChina provides precision CNC milling, turning, drilling, and cutting services tailored to various plastic materials.

How can I get a quote for CNC machining services?

To get a quote, you can submit your design files (e.g., CAD files) and specific requirements through SourcifyChina’s website or contact their sales team directly via email.

What is the typical lead time for CNC machining projects?

Lead times vary based on project complexity and volume, but standard projects typically take 1-2 weeks from order confirmation to shipment.

Can SourcifyChina handle both small and large volume orders?

Yes, SourcifyChina is equipped to handle orders ranging from small prototypes to large production runs.

What quality control measures are in place at SourcifyChina?

SourcifyChina implements rigorous quality control procedures, including in-process inspections, final product testing, and adherence to international quality standards like ISO 9001.

Are there any limitations on part size for CNC machining?

While there are some size limitations, SourcifyChina can machine parts up to 1 meter in length. Specific size capabilities depend on the material and design complexity.

How does SourcifyChina ensure material authenticity and quality?

SourcifyChina sources materials from reputable suppliers and provides material certificates upon request to verify authenticity and quality.

Can SourcifyChina provide design assistance?

Yes, their engineering team can offer design assistance to optimize your parts for manufacturability and cost-efficiency.

What are the payment terms for orders?

Payment terms typically include a deposit upon order confirmation and the balance before shipment. Specific terms can be discussed with the sales team.

Sourcing CNC machined plastics from a factory like SourcifyChina involves strategic planning and clear communication. Here are some tips to ensure a smooth process:

1. Define Requirements Clearly: Precisely outline the specifications, tolerances, and types of plastics needed. Providing detailed technical drawings can help avoid misunderstandings.

2. Research the Factory: Verify SourcifyChina’s credibility through reviews, testimonials, and any available case studies. Check their certifications and quality management systems.

3. Request Samples: Before placing a large order, ask for samples. This allows you to evaluate the quality of their work and ensure it meets your standards.

4. Communicate Effectively: Establish a direct line of communication with a representative. Clear, concise communication helps in resolving issues quickly and ensures that your expectations are understood.

5. Negotiate Terms: Discuss pricing, payment terms, and delivery schedules. Ensure all costs are transparent, including shipping, duties, and other potential fees.

6. Quality Control: Implement quality control measures. This could involve third-party inspections or agreeing on an in-house quality assurance process with the factory.

7. Evaluate Equipment and Capabilities: Make sure SourcifyChina has the appropriate CNC machinery and expertise in machining the type of plastic you require.

8. Set Up a Contract: Draft a comprehensive contract detailing all terms, conditions, and expectations to protect both parties legally.

9. Monitor Production: Regularly monitor the production process. Regular updates and possibly visiting the factory can help ensure timelines and quality standards are adhered to.

10. Plan for Logistics: Ensure that shipping and logistics are well-organized to avoid delays and extra costs. Collaborate with SourcifyChina to arrange efficient transportation.

By focusing on these key areas, you can effectively manage the sourcing process and achieve a successful partnership with SourcifyChina for CNC machining plastics.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.