Choosing SourcifyChina Factory for purchasing CNC machining services from China ensures high-quality, precision-engineered parts at competitive prices. The factory boasts state-of-the-art machinery and skilled technicians who focus on delivering exceptional outputs tailored to your specifications. Additionally, they maintain strict quality control measures to guarantee that every product meets international standards.

Their commitment to customer service sets them apart, providing personalized consulting to understand your unique needs and requirements. They also offer swift and reliable delivery schedules, ensuring that your projects remain on track without unnecessary delays. By leveraging their extensive industry experience, SourcifyChina Factory is adept at handling both large-scale and small-scale orders efficiently.

Moreover, SourcifyChina Factory employs advanced technology, including CAD/CAM software, to streamline the production process. This allows for quick prototypes and seamless modifications, saving time and reducing costs. Their extensive supply chain network further enhances their capability to source high-quality materials cost-effectively.

Finally, their transparent pricing policy ensures that you receive a fair and accurate estimate for your projects, with no hidden fees. This financial transparency builds trust and long-term partnerships, making SourcifyChina Factory a top choice for those seeking reliable CNC machining services from China.

CNC Machining Prices: Types and Options

CNC machining prices vary based on factors such as material, complexity, quantity, and turnaround time. Understanding these factors helps in estimating costs more accurately.

– Material: Different materials like aluminum, steel, and plastics have varying costs.

– Complexity: Intricate designs and tight tolerances increase machining time.

– Quantity: Higher production volumes usually lower per-unit costs.

– Turnaround Time: Expedited services cost more.

– Machine Type: 3-axis, 4-axis, and 5-axis machines have different pricing structures.

– Labor: Skilled labor influences price, especially for custom designs.

– Post-Processing: Finishing options like polishing, anodizing, and painting add to costs.

– Geographical Location: Prices can vary significantly by region.

– Supplier: Different suppliers offer varying price points and service options.

– CAD/CAM Services: Design and programming services may be included in the cost.

Understanding these elements helps in managing CNC machining budgets effectively and helps in selecting the most cost-efficient options based on specific project requirements.

Understanding CNC machining prices can significantly aid various industries in budgeting and project planning. These costs can vary depending on material, complexity, and volume. Here are some critical applications for analyzing CNC machining prices:

– Product Development: Accurate pricing helps in forecasting expenses and ensuring the project remains within budget.

– Budget Planning: Businesses can plan their finances better by predicting machining costs in advance.

– Supplier Negotiations: Knowing the standard costs enables effective negotiation with suppliers for better rates.

– Cost Optimization: Identifying cost drivers helps companies optimize the design and manufacturing process to reduce expenses.

– Prototyping: Evaluating prices aids in deciding when prototyping is feasible without exceeding budget constraints.

– Inventory Management: Accurate pricing informs decisions about inventory levels, balancing cost with the need for readily available parts.

– Quality Control: Investing in high-quality CNC machining can reduce rework and associated costs, leading to overall savings.

– Production Scalability: Understanding price variations with scale helps businesses plan for increment in production efficiently.

– Competitive Analysis: Analyzing costs helps companies stay competitive by pricing their products appropriately in the market.

– Return on Investment: Companies can calculate the potential ROI of using CNC machining versus other methods.

– Custom Projects: Estimating costs for custom machining ensures that unique projects are financially viable.

– Lead Time Estimation: Knowing the costs helps in predicting lead times more accurately, critical for project timeline management.

– Material Selection: Pricing information assists in choosing materials that meet both budgetary constraints and project requirements.

– Technology Investment: Companies can make informed decisions about investing in in-house CNC capabilities versus outsourcing.

– Sustainable Practices: Evaluating machining prices can lead to more sustainable practices by reducing waste and energy consumption.

Understanding and managing CNC machining prices can lead to improved financial performance and project outcomes.

SourcifyChina offers competitive CNC machining prices, ensuring affordability without compromising on quality. Their pricing structures are designed to cater to both small-scale and large-scale production needs.

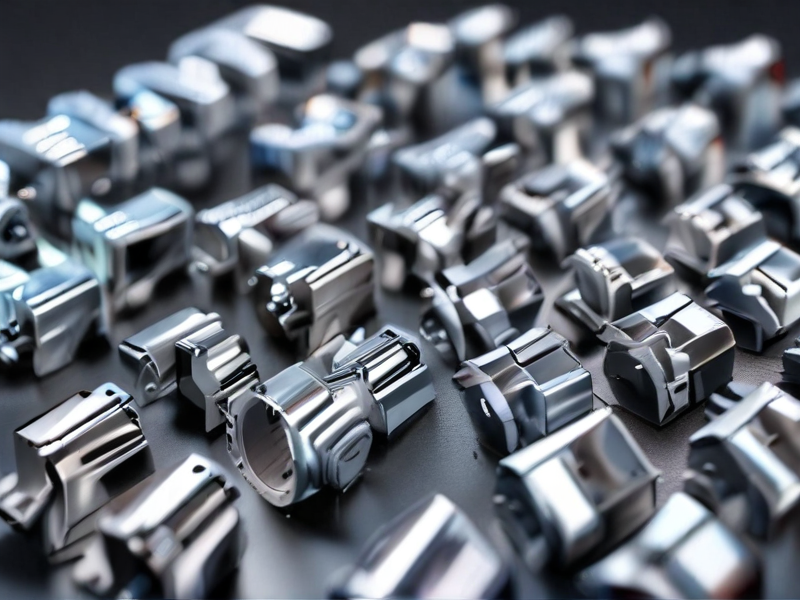

The material used significantly impacts the overall cost of CNC machining. SourcifyChina utilizes a variety of materials, including metals like aluminum, steel, brass, and titanium, as well as plastics like ABS and polycarbonate, ensuring versatility for different applications.

Precision and quality are paramount, with materials sourced from reliable suppliers to guarantee superior performance and durability. SourcifyChina’s advanced machinery and experienced technicians ensure that the final products meet exact specifications and standards.

Moreover, SourcifyChina emphasizes transparent pricing, helping clients understand the cost breakdown, including material expenses, labor, and overheads. This clarity is essential for budgeting and project planning.

In conclusion, SourcifyChina provides a balance of cost-efficiency and high-quality materials for CNC machining, making them a preferred choice for diverse manufacturing needs. Whether you’re in aerospace, automotive, or consumer electronics, they can meet your material and machining requirements effectively.

SourcifyChina’s CNC machining prices are competitive, reflecting their commitment to providing high-quality manufacturing services while maintaining cost-efficiency. Their transparent pricing structure ensures customers receive value without compromising on product standards.

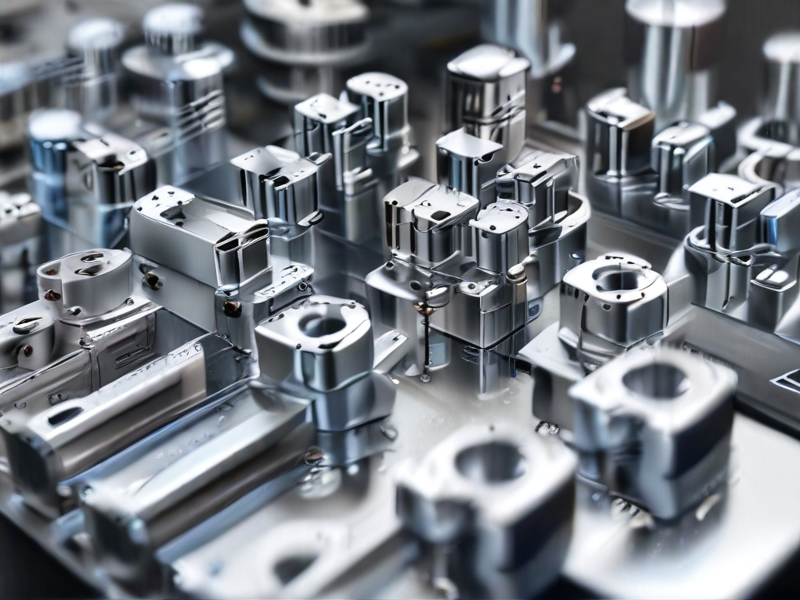

The quality control process at SourcifyChina begins with stringent raw material selection. Only materials that meet high-grade specifications are used, ensuring the foundation of quality is solid from the start. This careful selection is pivotal to the overall success of the manufacturing process.

During machining, advanced CNC machines are utilized to maintain precise tolerances. Continuous monitoring helps in identifying and rectifying deviations immediately. This real-time oversight minimizes errors, upholding the integrity of each piece.

Post-machining, thorough inspections are conducted using sophisticated measuring equipment. These inspections confirm that each part meets exact specifications. Parts are scrutinized for dimensional accuracy, surface finish, and overall integrity to ensure they align with client requirements.

The final stage involves a review by the quality assurance team. They cross-check orders against client specifications and ensure packaging is secure for safe transit. This meticulous approach reinforces client trust and ensures satisfaction with the end product.

SourcifyChina’s holistic quality control process, coupled with their competitive pricing, makes them a preferred choice for CNC machining needs. They consistently deliver precise, reliable components, fostering strong, long-term partnerships with their clients.

SourcifyChina offers cost-effective CNC machining services that prioritize both precision and speed. With advanced machinery and skilled technicians, they deliver high-quality components across various industries, all within budget-friendly parameters.

Their CNC machining prices are competitive, reflecting a balanced approach between affordability and quality. SourcifyChina ensures that customers receive excellent value for their investments, without compromising on the accuracy and durability of the machined parts.

Beyond just pricing, SourcifyChina’s capabilities include a wide range of materials such as metals, plastics, and composites. They utilize advanced technologies and methodologies to meet diverse manufacturing needs, ensuring adaptability and versatility in every project.

SourcifyChina also excels in producing complex geometries and fine details, thanks to their state-of-the-art CNC machines. This allows them to cater to highly specialized requirements, maintaining tight tolerances, and exceptional finish quality.

Their streamlined workflow, from initial design consultation to final product delivery, ensures efficient turnaround times. Clients benefit from prompt service and ongoing support, making it easier to meet tight production schedules and market demands.

Moreover, SourcifyChina maintains strict quality control measures throughout the machining process. Each component undergoes rigorous inspection to ensure it meets specified standards, providing clients with reliable and consistent quality.

In conclusion, SourcifyChina combines affordability, precision, and advanced capabilities to deliver outstanding CNC machining services. Whether for prototyping or large-scale production, they stand out as a reliable partner, capable of meeting the highest standards of quality and efficiency.

CNC (Computer Numerical Control) machining offers numerous advantages in terms of pricing, making it an attractive option for manufacturing industries. By utilizing automated precision and minimizing human error, CNC machining ensures cost-efficient production of high-quality parts.

– Highly Accurate and Consistent: CNC machines deliver precise and consistent results, reducing the need for costly revisions and wastage.

– Lower Labor Costs: Utilization of automated systems reduces the need for manual labor, leading to significant savings in labor costs.

– Efficient Production: Streamlined processes and faster production times lower overall manufacturing costs.

– Reduced Material Waste: Precision machining minimizes material waste, further reducing expenses.

– Scalability: CNC machining easily adapts to both small and large production runs, offering cost-effective solutions regardless of order size.

– Complex Designs Without Added Cost: CNC technology can handle complex and intricate designs without additional expenses, ensuring versatility.

– Lower Tooling Costs: CNC machines require fewer specialized tools, which can be expensive to produce and maintain in traditional manufacturing.

– Maintenance Savings: Automated systems generally require less maintenance and have longer lifespans compared to traditional machinery.

These benefits collectively contribute to the cost-effectiveness of CNC machining, making it a practical choice for various sectors seeking high-quality, affordable production solutions.

CNC machining prices depend on various factors that influence the final cost of production. Understanding these features can help in effectively budgeting and optimizing expenses.

– Material Costs: The type of material used, such as aluminum, steel, or plastic, can significantly impact the overall price.

– Complexity of Design: Intricate designs generally require more time and advanced machinery, leading to higher costs.

– Volume of Production: Higher volumes typically result in lower per-unit costs due to economies of scale.

– Machine Time: The amount of time the CNC machine is active directly correlates to cost; longer operations increase expenses.

– Labor Costs: Skilled labor required for programming, setup, and monitoring can affect the final pricing.

– Tooling Costs: Custom or specialized tools needed for specific jobs can add to the overall expenditure.

– Tolerances and Finishing: Higher precision and additional finishing processes, such as surface treatments or coatings, will increase the price.

– Maintenance and Downtime: Associated costs with machine maintenance and any downtime can indirectly influence pricing.

– Geographical Location: Local labor rates and material availability in different regions can cause price variations.

– Lead Time: Expedited orders or rush jobs usually come with higher costs compared to standard lead times.

Considering these factors can provide a clearer picture of CNC machining prices and help in making informed decisions for manufacturing projects.

SourcifyChina is a reputable provider of CNC machining services known for high-quality custom products and projects. With advanced technology and skilled engineers, they deliver precision and reliability, ensuring each project meets stringent specifications.

Their pricing structure is competitive, offering cost-effective solutions without compromising quality. Clients can expect transparent rates, which include material costs, machining, and finishing, making it easier to budget for comprehensive projects.

Custom products from SourcifyChina cater to various industries, including automotive, aerospace, and medical. By offering bespoke machining services, they help businesses achieve unique design goals and maintain production efficiency.

Customer satisfaction is paramount, and SourcifyChina excels in providing exceptional support and communication throughout the project lifecycle. From initial consultation to final delivery, their team ensures that client expectations are met or exceeded.

In conclusion, SourcifyChina’s CNC machining prices are both fair and transparent, making them a preferred choice for custom products and projects. Their commitment to quality, efficiency, and customer service makes them an industry leader.

SourcifyChina is a dynamic and innovative company specializing in CNC machining services, offering competitive pricing structures that appeal to both small businesses and large-scale industrial partners. The firm prides itself on a seamless blend of advanced technology and skilled craftsmanship, delivering precision components across various industries, including automotive, aerospace, and electronics. By leveraging state-of-the-art CNC machines and rigorous quality control processes, SourcifyChina ensures high-quality outputs with remarkable cost-efficiency. Their transparent pricing model, coupled with exceptional customer service, fosters long-term relationships and trust with clients globally. Beyond just machining, SourcifyChina provides comprehensive support through efficient supply chain management, helping clients streamline production and reduce overhead costs. This commitment to quality, affordability, and customer satisfaction positions SourcifyChina as a leading choice for CNC machining services.

CNC machining has become indispensable in the aerospace, defense, and marine industries, where precision and reliability are paramount. In aerospace, components such as turbine blades, engine parts, and intricate airframe structures demand exceptionally high tolerance levels that CNC machining can achieve. The ability to use a variety of materials such as titanium, aluminum, and high-temperature alloys further underscores its importance. However, the precision and quality assured by CNC machining come at a cost. Prices can vary based on material, complexity, and volume, with aerospace-grade components often warranting higher costs due to stringent certification and testing standards.

The defense sector similarly leverages CNC machining to produce critical components for weapons systems, vehicles, and communication devices. Given the harsh environments and critical functions these components must endure, achieving exact specifications is non-negotiable. The prices of CNC-machined parts in defense applications reflect the complexity and durability required. In the marine industry, CNC machining is employed for crafting parts like propellers, motor components, and hull fittings, which require resistance to corrosion and wear from saltwater environments. The cost factor here is influenced by the need for robust, long-lasting materials and the precision machining needed to ensure efficient, failure-free operation. Thus, while CNC machining is vital for these high-stakes industries, the associated costs are justified by the performance, safety, and longevity benefits it provides.

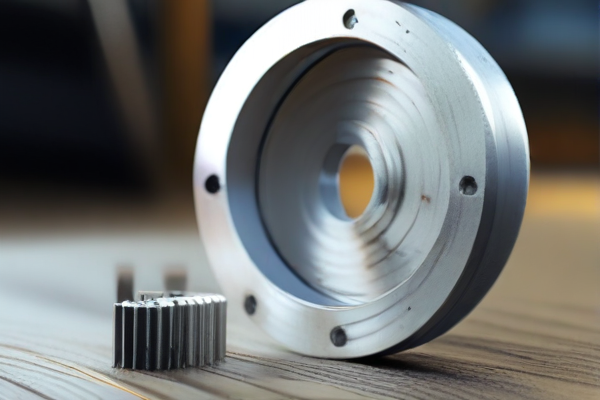

CNC machining has revolutionized the automotive industry by enabling the production of complex and precise components at competitive prices. The precision offered by CNC machining is crucial for the manufacturing of engine parts, transmission components, and custom fixtures used in vehicle assembly lines. For instance, engine blocks and cylinder heads, which require high levels of accuracy and consistency, are produced at a lower cost due to the efficiency of CNC machining processes. Additionally, the ability to produce prototypes and small batches without the need for specialized tooling further reduces production costs, making it viable for automotive companies to iterate designs quickly and innovate without incurring significant expenses. This cost-efficiency advantage has propelled CNC machining to be the backbone of high-precision automotive manufacturing tasks.

In the electronics industry, CNC machining plays a pivotal role in the production of intricate and minute components used in devices like smartphones, laptops, and circuit boards. The demand for high precision and miniaturization in this sector has driven CNC machining prices to be a critical factor in the overall production costs. With its ability to machine materials such as aluminum, plastic, and even copper with exceptional accuracy, CNC machining ensures that components like heat sinks, enclosures, and metal brackets are produced to exact specifications while maintaining cost-effectiveness. Furthermore, the rapid turn-around time offered by CNC machining allows electronics manufacturers to meet tight production schedules and swiftly respond to market demands. This efficiency in both production and price aligns with the perpetual advancements and swift product cycles characteristic of the electronics industry.

CNC (Computer Numerical Control) machining has revolutionized the construction industry by enabling precise and efficient fabrication of components. Complex structures, such as bespoke architectural elements and structural supports, can be manufactured to exact specifications using CNC processes. This precision reduces material wastage and cuts down the production time, allowing for quicker project turnarounds. However, the prices of CNC machining can vary greatly depending on the complexity, material, and quantity of the parts being produced. For instance, custom components made from high-strength materials such as titanium or advanced composites can be significantly more expensive compared to those made from standard metals like aluminum or steel. While the upfront costs for CNC machining might be higher than traditional methods, the long-term benefits in terms of durability and precision often justify the investment in high-end construction projects.

In the energy sector, CNC machining plays a critical role in the production of components for wind turbines, solar panels, and other renewable energy systems. The precision offered by CNC machining ensures that parts like turbine blades and mounting brackets have the optimal aerodynamic and structural properties necessary for efficient energy generation. The cost of CNC machining for energy applications is influenced by factors such as material choice, tolerance requirements, and production volume. For example, machining components for a large wind turbine might require expensive materials that can withstand harsh environmental conditions, thereby driving up costs. Nevertheless, the high initial expenditures can be offset by the improved performance and longevity of the machined parts. Effective utilization of CNC machining in the energy industry not only boosts the efficiency of renewable energy systems but also contributes to the overall reduction of operational and maintenance costs over the lifecycle of the equipment.

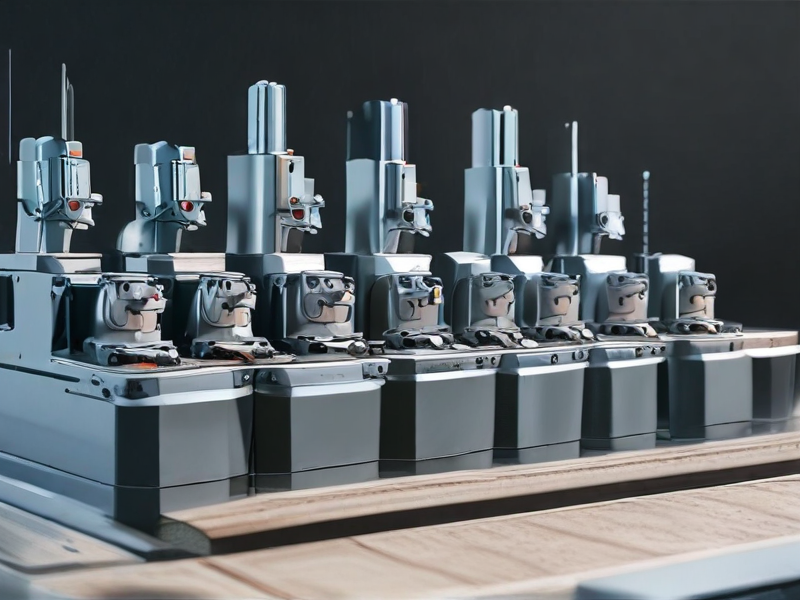

In the Industrial Equipment industry, CNC (Computer Numerical Control) machining plays a pivotal role due to its precision and cost-efficiency. CNC machining prices are a critical consideration for manufacturers seeking to optimize production costs without compromising on quality. This technology allows for the automated control of machining tools such as lathes, mills, routers, and grinders, which results in high-precision production of complex parts. The pricing for CNC machining is influenced by several factors including material selection, design complexity, tolerances, and production volume. Understanding and managing these costs can significantly influence the overall budget of industrial equipment manufacturing projects. By using CNC machining, manufacturers can reduce waste, increase production speed, and ensure consistent product quality, making it an invaluable resource in the Industrial Equipment sector.

Moreover, CNC machining prices also affect the scalability and flexibility of production lines in the Industrial Equipment industry. As demand for customized equipment grows—spanning sectors like aerospace, automotive, and heavy machinery—CNC machining’s ability to produce unique components efficiently becomes increasingly important. Cost-efficient machining enhances the ability to produce both small batches for prototyping and large batches for full-scale production runs without incurring prohibitive costs. The investment in CNC technology can therefore offer a competitive edge, enabling companies to respond swiftly to market demands and technological advancements. Consequently, a thorough understanding of CNC machining prices helps manufacturers make informed decisions about inventory, production scheduling, and resource allocation, ultimately driving profitability and innovation in the Industrial Equipment industry.

CNC (Computer Numerical Control) machining plays a crucial role in the manufacturing of medical devices, and its pricing significantly impacts the healthcare industry. Precision and accuracy are paramount in medical device production, where components often require intricate designs and high tolerances. CNC machining offers an unparalleled level of detail, producing parts that range from surgical instruments to intricate implantable devices such as heart valves or orthopedic screws. The pricing for CNC machining in this sector is influenced by factors including material choice, complexity of the part, and volume of production. High-precision materials like titanium or medical-grade stainless steel are commonly used, often driving up costs due to their challenging machining properties. Customization is also a significant factor; bespoke medical devices designed for individual patients can be more expensive due to the tailored nature of the work.

Another aspect affecting CNC machining prices in medical applications is the regulatory and certification requirements. Medical devices must comply with stringent regulatory standards such as FDA, CE marking, and ISO certifications, which necessitate meticulous record-keeping and quality assurance processes. These compliance measures add to the operational costs, ultimately influencing the final price of CNC machined parts. Additionally, investments in advanced CNC technologies, including multi-axis machining centers and high-precision finishing equipment, contribute to higher initial costs but are essential for ensuring the utmost reliability and performance of medical devices. Outsourcing to specialized CNC machine shops that cater to the medical industry can also affect pricing, balancing greater expertise and compliance with potentially higher service costs. In summary, CNC machining’s pricing for medical devices intertwines material and technical complexity, regulatory compliance, and the pursuit of unwavering precision, shaping both the costs and the opportunities for innovation in healthcare.

CNC (Computer Numerical Control) machining has revolutionized the landscape of manufacturing and machining by offering unparalleled precision, repeatability, and efficiency. In various industries ranging from aerospace to automotive, CNC machining is essential for creating intricate and complex parts with high levels of accuracy. The costs associated with CNC machining are influenced by several factors including material selection, machine setup time, labor cost, and the complexity of the design. For instance, while basic aluminum parts might be relatively cost-effective, machining more exotic materials like titanium or Inconel can be more expensive due to the additional wear and tear on tools and longer machining times. Further, the initial setup and programming of the CNC machine, especially for intricate designs, can add to the overall cost, making it crucial for companies to balance precision needs with budget constraints.

When evaluating CNC machining prices, it’s also important to consider secondary costs such as post-processing, quality control, and tooling. Advanced features like multi-axis machining can drive up costs but usually result in higher-quality outputs, reducing the need for further adjustments. Economies of scale also play a significant role in pricing; higher volumes often reduce the per-unit cost, making CNC machining an excellent choice for both prototyping and mass production. The transparency of CNC machining prices can be elusive due to the multitude of variables involved, but understanding these factors helps manufacturers optimize their designs and processes. One must always weigh the initial investment against the long-term benefits in terms of durability, performance, and scalability to make informed decisions in CNC machining applications.

Sure, here are some FAQs for CNC machining prices and quality work from SourcifyChina factory:

Q: What factors influence the pricing of CNC machining services?

A: CNC machining prices are affected by various factors including material cost, design complexity, tolerances, volume of production, machining time, and surface finishing requirements. At SourcifyChina, we strive to offer competitive pricing while maintaining high quality standards.

Q: How does SourcifyChina ensure the quality of CNC machined parts?

A: Quality is ensured through a rigorous quality control process which includes material verification, in-process inspections, and final inspections using precision measurement tools such as CMM (Coordinate Measuring Machines). We are ISO certified and adhere strictly to industry standards.

Q: What types of materials can SourcifyChina machine?

A: SourcifyChina offers CNC machining for a wide range of materials including aluminum, steel, stainless steel, brass, copper, plastics, and exotic materials like titanium and Inconel. We work with materials suited for diverse applications, ensuring suitability and durability.

Q: How can I get a quote for CNC machining services?

A: To receive a quote, simply provide us with your detailed design (CAD files), material specifications, quantity, and any other special requirements. You can send this information via our online form or email. We usually respond with a detailed quotation within 24-48 hours.

Q: What is the typical lead time for CNC machining orders?

A: The lead time varies depending on the complexity and volume of the order. Standard lead times range from 1 to 4 weeks. Rush services may be available upon request for urgent projects.

Q: Does SourcifyChina provide prototypes before full-scale production?

A: Yes, we offer prototyping services to help you validate your design before committing to full-scale production. This service ensures that any necessary adjustments can be made to achieve the desired quality and functionality.

Q: Can SourcifyChina handle high-mix, low-volume production runs?

A: Absolutely. We are equipped to handle both high-mix, low-volume production and high-volume production runs. Our flexible manufacturing setup allows us to cater to diverse manufacturing needs efficiently.

Q: How does SourcifyChina handle shipping and logistics?

A: We work with reliable shipping and logistics partners to ensure timely delivery of your parts. We offer various shipping options including air freight, sea freight, and express shipping depending on your urgency and budget.

When considering CNC machining prices from SourcifyChina factory, here are some key tips to get the best value:

1.

Material Selection:

– Cost of Materials: Different materials like aluminum, steel, and titanium vary significantly in price. Choose the appropriate material for your application to balance performance and cost.

– Availability: Common materials are cheaper and faster to source.

2.

Design Complexity:

– Simplicity: Complex designs increase machining time and cost. Optimize your design to reduce intricate features.

– Tolerance Levels: Tighter tolerances require more precise work, which can add to the cost. Specify appropriate tolerances for your project.

3.

Volume:

– Batch Production: Higher quantities often lower the price per unit due to economies of scale.

– Prototype Costs: Initial prototypes can be more expensive on a per-unit basis. Use prototypes to refine your design before large-scale production.

4.

Finishing Processes:

– Surface Finishing: Additional treatments like anodizing, powder coating, and painting add to the cost.

– Post-Machining: Secondary operations like threading, tapping, and deburring can increase costs.

5.

Lead Time:

– Urgency: Expedited services are more costly. Plan ahead to avoid rush fees.

– Production Schedule: Align your order with SourcifyChina’s production schedule for possible cost benefits.

6.

Manufacturing Location:

– SourcifyChina operates factories with cost-efficient labor, but shipping and import taxes should be considered.

7.

Supplier Communication:

– Clear Specifications: Provide detailed drawings and material specifications to avoid misunderstandings.

– Regular Updates: Maintain open communication for timeline updates and any potential adjustments.

8.

RFQ (Request for Quote):

– Request detailed quotes from SourcifyChina and compare with other suppliers to ensure competitive pricing.

Conclusion:

Efficient design, clear communication, and understanding of the cost factors can help control CNC machining prices from SourcifyChina. Always balance quality and cost to ensure a successful manufacturing outcome.

Sure! Here’s a concise FAQ for sourcing CNC machining prices from SourcifyChina factory:

Q1: What factors influence the CNC machining prices at SourcifyChina?

A1: The primary factors include material type, part complexity, quantity, machining time, and additional services like surface finishing or post-processing. Providing detailed drawings and specifications will yield the most accurate quotes.

Q2: How can I get a quote for CNC machining from SourcifyChina?

A2: You can submit your design files (e.g., CAD, STEP) and specifications directly through SourcifyChina’s online form or email. Ensure all relevant details like tolerances and surface finishes are included for an accurate quote.

Q3: What is the typical turnaround time for quotes?

A3: SourcifyChina usually provides quotes within 24-48 hours after receiving detailed project information.

Q4: Are there minimum order quantities (MOQ) for CNC machining services?

A4: SourcifyChina has flexibility with MOQs, accommodating both small prototype orders and large production runs. Specific MOQs depend on the project complexity and total cost.

Q5: How are the prices structured at SourcifyChina?

A5: Prices are calculated based on material costs, labor, machine time, and any additional processing required. Volume discounts may apply for larger orders.

Q6: What types of materials and finishes are available?

A6: SourcifyChina offers a wide range of materials including various metals (aluminum, steel, titanium) and plastics (ABS, nylon). Finishing options range from anodizing and powder coating to polishing and bead blasting.

Q7: Are there any hidden costs I should be aware of?

A7: SourcifyChina strives for transparency. However, additional costs might arise from shipping, custom tooling, or expedited services. Always clarify these aspects during the quoting process.

Q8: Can SourcifyChina handle complex and custom CNC parts?

A8: Yes, SourcifyChina is equipped to handle complex geometries and custom requirements, supported by experienced engineers and advanced machinery.

Q9: What quality control measures does SourcifyChina employ?

A9: SourcifyChina implements stringent quality control through in-house inspections, adhering to international standards. They can also provide inspection reports and certifications upon request.

Q10: How can I track my order’s progress?

Sourcing CNC machining prices from a factory like SourcifyChina effectively involves a few strategic steps:

1. Define Your Requirements: Clearly document the specifications of your machining project, including materials, tolerance, quantity, finish, and any other details.

2. Initial Research: Visit SourcifyChina’s official website and familiarize yourself with their services and product portfolio. Identify their contact details and any online RFQ (Request for Quote) forms.

3. Prepare Your RFQ: Craft a detailed RFQ. Include the following:

– Technical drawings or CAD files.

– Material specifications.

– Surface finish and treatment.

– Quantity and potential order frequency.

– Desired delivery timeline.

4. Contact SourcifyChina: Submit your RFQ through their website or via email. If they have a specific RFQ form, use it to ensure you provide the necessary details.

5. Follow Up: If you don’t receive a response within a week, follow up to confirm they received your request and to inquire about the status of your quote.

6. Evaluate the Quote: Once you receive the quote, evaluate it based on price, lead time, and any included services such as quality control, shipping, and customer support.

7. Negotiate if Necessary: If the initial quote isn’t quite aligned with your budget, don’t hesitate to negotiate. Discuss possible cost reductions such as bulk order discounts or different material options.

8. Request Samples: Before placing a significant order, request samples to assess the quality of the machining and ensure it meets your standards.

9. Consider Total Cost: Account for additional factors like shipping costs, import duties, and any other fees when comparing prices.

10. Establish a Relationship: If satisfied with the initial order, build a long-term relationship with the supplier for better terms and smoother transactions in the future.

By following these steps, you’ll effectively source competitive CNC machining prices from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.