Quality Assurance

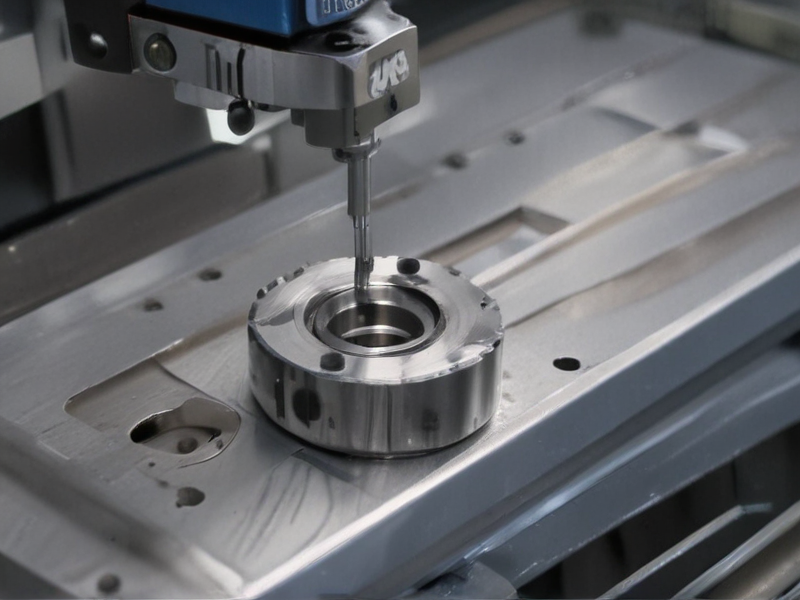

SourcifyChina Factory ensures stringent quality control to meet international standards. Their advanced CNC machining technology and skilled workforce guarantee precision and durability in every product, which minimizes defects and enhances overall customer satisfaction.

Cost-Effective Solutions

By optimizing their production processes, SourcifyChina Factory provides highly competitive pricing without compromising on quality. This cost-effectiveness makes it an attractive option for buyers looking to maximize their return on investment while maintaining high standards.

Timely Delivery

Understanding the importance of deadlines, SourcifyChina Factory is committed to timely delivery. Their efficient supply chain management and reliable logistics partners ensure that orders arrive on schedule, helping buyers maintain operational continuity.

Customizable Services

SourcifyChina Factory offers customizable machining services tailored to specific buyer requirements. With their flexible production capabilities, they can handle small to large orders, catering to diverse industry needs with bespoke solutions.

Strong Customer Support

The factory prides itself on stellar customer support, providing buyers with continuous assistance from order placement to post-purchase services. Their responsive team addresses queries and resolves issues promptly, fostering long-term relationships.

Sustainability Commitment

SourcifyChina Factory is committed to sustainable manufacturing practices. By reducing waste and utilizing eco-friendly materials, they not only enhance their environmental credentials but also offer buyers a responsible and ethical sourcing option.

In conclusion, choosing SourcifyChina Factory for CNC machining needs combines quality, cost-efficiency, timely delivery, customization, excellent customer support, and sustainability. This holistic approach makes it a preferred partner for buyers seeking reliability and excellence in their manufacturing projects.

A CNC machinist operates computer numerical control (CNC) machines to create precision parts and components. They work in various industries, including automotive, aerospace, and manufacturing, using diverse equipment and techniques.

Types and options for CNC machinists:

– Lathe Machinist: Specializes in turning operations using CNC lathes.

– Milling Machinist: Operates CNC milling machines to create complex shapes.

– Grinder Machinist: Uses CNC grinders for high-precision finishing.

– Router Machinist: Works with CNC routers primarily for wood, plastic, and composites.

– Laser Machinist: Utilizes CNC laser cutting and engraving machines.

– Waterjet Machinist: Operates CNC waterjet cutters for various materials.

Career paths and certifications:

– Certification Programs: Offered by organizations like NIMS (National Institute for Metalworking Skills).

– Apprenticeships: Hands-on training combined with academic coursework.

– Advanced Training: Specialized courses for multi-axis machining, CAD/CAM software.

– Quality Control: Focuses on inspection and quality assurance techniques.

– Supervisory Roles: Leadership positions such as shop supervisor or foreman.

Skills and competencies:

– Technical Knowledge: Proficiency in G-code programming and machine setup.

– Attention to Detail: Accuracy in measurements and machining processes.

– Problem-Solving: Identifying and resolving machining issues.

– Blueprint Reading: Understanding technical drawings and specifications.

– Mechanical Aptitude: General understanding of machinery and tools.

Tools and software:

– CAD/CAM Software: Examples include AutoCAD, SolidWorks, and Mastercam.

– Measuring Instruments: Calipers, micrometers, and coordinate measuring machines (CMMs).

– Cutting Tools: End mills, drills, taps, and tool holders.

– Maintenance Tools: For routine equipment upkeep and troubleshooting.

Career outlook and opportunities:

– Job Growth: Increased demand in manufacturing and high-precision industries.

– Specialization: Opportunities for specialization in specific types of CNC machining.

– Advancements: Potential for career advancement into engineering or managerial roles.

Overall, becoming a CNC machinist offers diverse career paths, requiring a blend of technical skills and practical experience.

A CNC Machinist is skilled in operating CNC (Computer Numerical Control) machines to produce precision parts and components from raw materials. Their expertise is essential in various industries that require high accuracy and efficiency in manufacturing processes.

– Aerospace Industry: Crafting precision components for aircraft and spacecraft.

– Automotive Sector: Manufacturing intricate parts for engines, transmissions, and body components.

– Medical Devices: Creating high-precision surgical instruments and prosthetics.

– Defense: Producing critical parts for military equipment and weaponry.

– Electronics: Fabricating components for computers, smartphones, and other electronic devices.

– Tool and Die Making: Designing and producing specialized tools and industrial molds.

– Custom Manufacturing: Creating bespoke parts for various custom projects.

– Oil and Gas: Machining parts for drilling equipment and refining processes.

– Renewable Energy: Producing components for wind turbines and solar panels.

– Consumer Goods: Making precise parts for household appliances and gadgets.

CNC Machinists ensure that products meet stringent quality standards and specifications, contributing significantly to the advancement and reliability in these diverse fields.

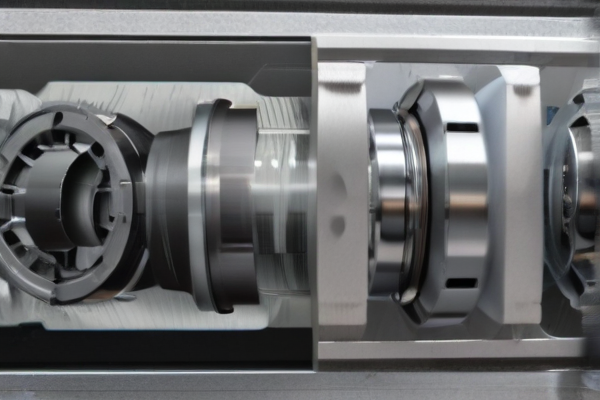

SourcifyChina CNC machinists are experts in utilizing cutting-edge machinery and high-quality materials to produce precise and durable components. They often work with metals such as aluminum, stainless steel, and titanium, which are known for their strength and resistance to corrosion. Each material is chosen based on the specific requirements of the project, ensuring optimal performance and longevity.

The machinists also employ a variety of advanced techniques, including laser cutting, milling, and turning, to achieve the desired specifications. Their proficiency with CAD (Computer-Aided Design) programs allows for intricate and complex designs to be realized with exceptional accuracy.

Additionally, SourcifyChina CNC machinists prioritize sustainability and efficiency in their manufacturing processes. They select materials that not only meet the technical needs of the project but also minimize environmental impact. Recycled metals and eco-friendly options are often considered to align with green manufacturing practices.

SourcifyChina places a strong emphasis on quality control to ensure each component meets stringent industry standards. This commitment to excellence is evident in the precision and reliability of the final products delivered to clients across various sectors. With a focus on innovation and meticulous craftsmanship, SourcifyChina CNC machinists continue to set high benchmarks in the industry.

SourcifyChina, a leader in CNC machining, emphasizes precision and efficiency in its quality control process. Each component undergoes rigorous inspections at every production stage to ensure adherence to exact specifications, minimizing errors and enhancing performance.

The company’s quality control begins with careful selection of raw materials. Only materials that meet strict quality standards are used, thus ensuring the durability and reliability of the final products. This initial step is crucial for achieving consistent manufacturing excellence.

Advanced testing and measurement tools are utilized throughout the machining process. SourcifyChina employs state-of-the-art technology, such as coordinate measuring machines and laser scanners, to verify dimensional accuracy and surface finish. This meticulous approach helps in maintaining the highest levels of precision.

In-process quality checks are performed by skilled machinists and quality control engineers. They continuously monitor the production, identifying and addressing any deviations immediately. This real-time feedback loop is vital for maintaining consistent output quality.

Final inspections involve exhaustive testing, including functional tests, stress tests, and visual inspections. Each part must pass these tests before it is approved for delivery. This thorough vetting process guarantees that customers receive only top-notch products.

Training and continuous improvement are integral parts of SourcifyChina’s quality control. Regular training sessions for machinists and engineers keep them updated on the latest methodologies and technologies. This commitment ensures that the team is always capable of meeting the continually evolving industry standards.

Customer feedback plays a crucial role in SourcifyChina’s quality control strategy. Post-delivery, the company gathers feedback to identify areas for improvement and adjustments in the process, ensuring future projects meet or exceed expectations.

SourcifyChina’s dedication to quality control in CNC machining results in products that are not only precise but also reliable, ensuring customer satisfaction and long-term success. This holistic approach integrates advanced technology, skilled personnel, and rigorous standards to build a robust manufacturing process that consistently delivers excellence.

SourcifyChina CNC machinists exemplify precision and expertise in the realm of manufacturing. Their hands-on experience and cutting-edge technology enable them to produce intricate components with unparalleled accuracy. Equipped with advanced CNC machines, SourcifyChina ensures high-quality output aligned with client specifications.

To meet diverse manufacturing demands, SourcifyChina’s CNC machinists specialize in working with various materials. From metals like aluminum and stainless steel to plastics and composites, their adeptness in machining different substances showcases their versatility. This material adaptability is crucial for industries that require custom-tailored solutions.

Innovation is at the core of SourcifyChina’s machining capabilities. Their CNC machinists are proficient in leveraging the latest software and techniques to optimize production processes. This results in reduced lead times and cost-efficient manufacturing, without compromising on quality. Continuous training ensures their team stays ahead of technological advancements.

Beyond just machining, SourcifyChina offers value-added services such as product design consultation and prototyping. Their CNC machinists collaborate closely with clients to transform ideas into tangible products. This holistic approach ensures that the final output aligns perfectly with the client’s vision, enhancing customer satisfaction.

Quality assurance is a cornerstone of SourcifyChina’s operations. Their CNC machinists adhere to stringent quality control measures throughout the production cycle. Utilizing tools such as coordinate measuring machines (CMM), they ensure that every component meets precise dimensional and tolerance criteria. This commitment to quality guarantees reliable performance in the field.

In conclusion, SourcifyChina’s CNC machinists embody a blend of technical skill, innovation, and commitment to quality. They have established themselves as reliable partners in high-precision manufacturing, capable of meeting diverse industry needs. By combining advanced technology with a customer-focused approach, SourcifyChina sets the standard for excellence in CNC machining.

The role of a CNC machinist offers numerous benefits, making it an attractive profession in the manufacturing industry. From precision to efficiency, CNC machinists contribute significantly to modern production processes.

Key

Benefits of Being a CNC Machinist:

– High Precision: CNC machinists can produce high-quality components with minute precision, reducing errors and waste.

– Job Security: With the demand for skilled machinists on the rise, job security in this field is robust.

– Versatile Skills: Machinists acquire skills that are applicable across various industries including automotive, aerospace, and medical devices.

– Good Compensation: Competitive salaries and potential for overtime make this profession financially rewarding.

– Automation Proficiency: Machinists become adept at operating and programming sophisticated machinery, which is valuable in tech-driven industries.

– Career Advancement: Opportunities for growth and specialization, such as in CNC programming or supervisory roles, are plentiful.

– Creative Problem-Solving: The job often involves solving unique machining challenges, which keeps the work engaging.

– Remote Monitoring: Advancements in technology allow machinists to monitor CNC machines remotely, offering flexibility.

– Work Environment: Many CNC machinists work in clean, well-lit environments that are ergonomically designed.

– Contributive Role: They play a critical part in product development and innovation, adding to a sense of professional fulfillment.

Overall, the numerous advantages of being a CNC machinist make it a promising career for those inclined towards machinery and precision work.

A CNC machinist utilizes computer-numeric-controlled machinery to create precision metal, plastic, or wooden parts, essential in various manufacturing sectors. Their expertise ensures high-quality production and efficiency.

– Programming Proficiency: Able to write and interpret CNC programs.

– Technical Skills: Knowledgeable in machine operation, setup, and maintenance.

– Blueprint Reading: Reads and understands complex technical drawings.

– Precision Measurement: Uses precise measuring tools like calipers and micrometers.

– Problem Solving: Diagnoses and fixes issues with machines or parts.

– Material Knowledge: Understands different materials’ properties and suitable machining techniques.

– Quality Control: Ensures products meet stringent quality standards.

– Safety Practices: Adheres to safety protocols to prevent accidents.

– Tool Selection: Chooses appropriate tools and settings for specific tasks.

– Adaptability: Quickly adapts to new technologies and methods.

These features highlight a CNC machinist’s essential role in manufacturing, where precision, efficiency, and safety are paramount.

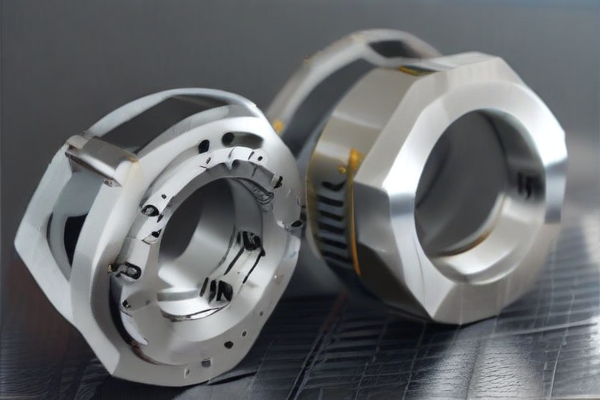

SourcifyChina CNC Machinist offers exceptional custom products and projects tailored to meet specific client needs. Utilizing advanced CNC machining technology, the company ensures precision and high-quality output on every piece.

Their extensive range of services includes milling, turning, and complex 5-axis machining. SourcifyChina caters to various industries, including automotive, aerospace, and medical, delivering parts that meet stringent quality standards.

Customization is at the heart of their operations. Clients can provide detailed specifications, and SourcifyChina’s skilled team will bring those visions to life with unparalleled accuracy.

Timely delivery and competitive pricing further set SourcifyChina apart in the CNC machining landscape. Their commitment to customer satisfaction drives continuous improvement and innovation.

In sum, SourcifyChina CNC Machinist combines technical expertise with customer-focused service, making them a go-to provider for customized CNC machined products and projects. Their dedication to excellence ensures clients receive products that exceed expectations.

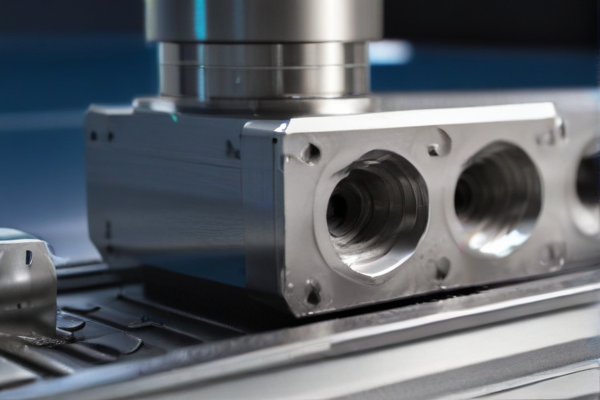

SourcifyChina CNC Machinist is a leading manufacturing company specializing in precision CNC (Computer Numerical Control) machining services that cater to a global clientele. Renowned for its state-of-the-art facilities and a team of highly skilled machinists, the company offers a wide range of services including milling, turning, drilling, and complex part fabrication. SourcifyChina employs the latest in CNC technology to ensure unparalleled accuracy and consistency in every project, making it the go-to choice for industries ranging from aerospace and automotive to medical devices and electronics. With a strong commitment to quality and customer satisfaction, the company adheres to stringent international standards and employs rigorous quality control measures throughout the production process. Whether it’s prototyping or large-scale production runs, SourcifyChina CNC Machinist delivers customized solutions that meet the specific needs and timelines of their clients, all while maintaining competitive pricing. Their exceptional reliability and innovative approach make them an integral partner for businesses seeking advanced machining solutions.

In the Aerospace, Defense, and Marine industries, CNC machinists play a pivotal role in manufacturing precision components critical to the performance and safety of advanced machinery and vehicles. These sectors demand parts that meet rigorous standards, often requiring complex geometries and tight tolerances only achievable through Computer Numerical Control (CNC) machining. For aerospace applications, this includes the production of jet engine components, airframe parts, and intricate chassis elements. CNC machinists ensure that each piece is manufactured to exact specifications, using advanced materials like titanium and high-strength alloys to provide durability and performance. In defense, CNC machinists craft specialized components for weapons systems, vehicles, and protective equipment. The precision and reliability of these parts are paramount, as they can be the difference between mission success and failure.

For marine applications, CNC machining is crucial in the production of high-performance and reliable components for ships, submarines, and offshore platforms. Marine environments present unique challenges like corrosion and high-pressure conditions, necessitating the use of robust, corrosion-resistant materials that CNC machinists shape with extreme accuracy. Propulsion systems, navigation instruments, and structural elements are some of the critical components produced via CNC machining. The versatility of CNC technology allows for the development of innovative marine solutions, such as custom propellers and advanced hull designs, enhancing the efficiency and longevity of marine vessels. Across all these sectors, the expertise of CNC machinists ensures the production of high-quality, reliable components that meet stringent industry standards and contribute to the advancement of technology and safety in challenging environments.

In the automotive industry, CNC machinists play a crucial role in the manufacturing process by producing high-precision components required for vehicle assembly. These professionals use Computer Numerical Control (CNC) machinery to create intricate parts such as engine blocks, transmission components, and brake rotors from various materials like aluminum, steel, and titanium. The precision and consistency offered by CNC machining ensure that every part meets strict tolerance and quality standards, which is essential for the safety and performance of the vehicles. Additionally, CNC machinists often work closely with design and engineering teams to prototype new components, allowing for rapid iterations and improvements in vehicle innovation and efficiency.

Similarly, in the electronics sector, CNC machinists are indispensable when it comes to fabricating the delicate and precise components needed for electronic devices. From the intricate housings for smartphones and tablets to the precision connectors and circuit boards, CNC machining allows for the production of components that meet the tiny tolerances required in modern electronics. CNC machinists use a variety of materials, including plastics, metals, and composites, to produce these components. Their skills ensure that the parts fit together perfectly in final assemblies and perform reliably under various conditions. By leveraging advanced CNC technology, the electronics industry can push the boundaries of miniaturization and functionality, paving the way for more sophisticated and versatile consumer and industrial electronics.

CNC machinists play a pivotal role in the construction industry by fabricating precise components essential for building robust infrastructure. Utilizing advanced Computer Numerical Control (CNC) machines, these skilled professionals create metal and composite parts with extreme accuracy. This precision is crucial for the structural integrity of buildings, bridges, and other civil engineering projects. For instance, CNC-machined components such as custom brackets, support beams, and intricate fittings ensure that construction assemblies align perfectly, thereby enhancing the durability and safety of structures. Additionally, the efficiency of CNC machining reduces material waste and accelerates project timelines, which is a significant advantage in large-scale construction endeavors.

In the realm of energy applications, CNC machinists contribute immensely to the development and maintenance of energy generation systems, including renewable energy technologies. Components for wind turbines, solar panels, and energy storage systems often require complex geometries and high tolerances that CNC machines can achieve with reliability and consistency. For wind energy, for example, CNC machinists manufacture parts like turbine blades and motor housings, which need to withstand extreme environmental conditions while maintaining performance. In the oil and gas sector, precision-machined parts such as valve components, pipelines, and drilling equipment are essential for safe and efficient operations. Hence, CNC machinists are critical in not only fostering innovative energy solutions but also ensuring the longevity and dependability of existing energy infrastructure.

The industrial equipment industry heavily relies on the expertise of CNC (Computer Numerical Control) machinists, who play a critical role in transforming raw materials into precision-engineered parts. CNC machinists operate sophisticated machinery such as lathes, mills, and grinders that are pre-programmed with computer software to execute complex and precise tasks. These machines are indispensable for producing components that demand high levels of accuracy and repeatability, which are commonly required in sectors like aerospace, automotive, and medical device manufacturing. By utilizing CNC technology, the industrial equipment industry can achieve tighter tolerances and superior finishes, enabling the production of high-quality, reliable machinery that meets stringent regulatory standards.

Furthermore, CNC machinists contribute significantly to increasing production efficiency and reducing lead times. With their in-depth understanding of materials, tooling, and programming, CNC machinists can optimize machining processes to minimize waste and maximize output. This proficiency in process optimization is crucial for the industrial equipment industry, as it allows companies to remain competitive in a global market characterized by rapid technological advancements and increasing customer demands. Additionally, CNC machinists are adept at troubleshooting and maintaining the machinery, ensuring that equipment operates smoothly and reducing downtime. Their expertise not only enhances the overall productivity of manufacturing operations but also ensures that the end products are of the highest possible quality.

CNC machinists play a pivotal role in the creation and refinement of medical devices, leveraging their technical expertise to produce precision components essential for patient care. Utilizing advanced Computer Numerical Control (CNC) machinery, these skilled technicians meticulously transform raw materials into highly accurate and reliable parts, such as orthopedic implants, surgical instruments, and diagnostic equipment. The stringent regulations and standards in the medical field necessitate unwavering attention to detail and adherence to strict tolerances. CNC machinists ensure each piece complies with rigorous quality control measures, thereby contributing to the flawless performance of these critical devices during surgical procedures and patient treatments.

Moreover, the complexity and diversity of medical device components demand a high level of customization and adaptability in CNC machining processes. CNC machinists must be adept at programming sophisticated machinery to produce parts with intricate geometries and fine surface finishes, often working with biocompatible materials like titanium, stainless steel, and medical-grade plastics. Their deep understanding of material properties and machining techniques enables them to optimize manufacturing processes, reduce production times, and minimize material waste. Through their expertise, CNC machinists not only enhance the efficiency and effectiveness of medical devices but also play an indispensable role in advancing medical technology and improving patient outcomes.

A CNC (Computer Numerical Control) machinist is a specialized professional in the machining and manufacturing industry who expertly operates CNC machines to produce precision parts and components. These machines, controlled by sophisticated software, are capable of executing complex, high-precision tasks that traditional manual machines cannot achieve. CNC machinists program and operate these computerized systems, ensuring that each piece adheres to exact specifications, often down to fractions of millimeters. Their expertise reduces the likelihood of errors, minimizes waste, and significantly enhances the efficiency and consistency of the manufacturing process. The demand for CNC machinists has surged due to the increasing reliance on automation and precise manufacturing in industries such as aerospace, automotive, and medical devices.

In the broader scope of manufacturing, CNC machinists play a crucial role in bridging the gap between design and production. They interpret technical drawings and CAD (Computer-Aided Design) models to create machine programs that guide tools in cutting, drilling, and shaping materials like metals, plastics, and composites. Their work involves meticulous planning, machine setup, monitoring of operations, and quality control to ensure that each product meets stringent industry standards. Manufacturing facilities rely on the skill and precision of CNC machinists to maintain production flow, improve product quality, and reduce production times. This integration of CNC machining in manufacturing not only enhances productivity but also allows for greater customization and rapid prototyping, making it fundamental to modern manufacturing processes.

Sure! Here are some frequently asked questions (FAQ) with answers about manufacturing CNC machinist quality work from SourcifyChina Factory:

Q1: What is CNC machining?

A1: CNC (Computer Numerical Control) machining is a manufacturing process where computers control machine tools. It allows for precision and repeatability in creating complex parts from various materials like metals, plastics, and composites.

Q2: What types of materials can be used in CNC machining at SourcifyChina Factory?

A2: SourcifyChina Factory can work with a wide range of materials including but not limited to aluminum, stainless steel, brass, copper, plastics, and composites to meet your precise specifications.

Q3: How does SourcifyChina ensure the quality of CNC machined parts?

A3: SourcifyChina employs rigorous quality control processes including first article inspection, in-process quality checks, and final inspections according to ISO 9001 standards. Advanced measuring instruments are utilized to ensure precision.

Q4: What CNC machining services does SourcifyChina offer?

A4: SourcifyChina offers numerous CNC machining services such as milling, turning, drilling, and tapping. They cater to various industries including automotive, aerospace, medical, and electronics, delivering custom and complex parts.

Q5: Can SourcifyChina handle large production runs?

A5: Yes, SourcifyChina is equipped to handle both small batch prototypes and large-volume production runs, ensuring scalability as per your project requirements.

Q6: What is the typical lead time for CNC machined parts from SourcifyChina?

A6: Lead times vary based on the complexity and quantity of the order, but SourcifyChina aims to deliver within 2-4 weeks. Expedited services are also available for urgent projects.

Q7: How can I get a quote for my CNC machining project at SourcifyChina?

A7: You can request a quote by submitting your design files (CAD/3D models) and project details through SourcifyChina’s online form or by contacting their customer service team directly.

Q8: Does SourcifyChina offer design assistance for CNC machined parts?

A8: Yes, SourcifyChina provides design for manufacturability (DFM) feedback to help optimize your part designs for better machinability and cost efficiency.

Q9: What tolerances can be achieved with CNC machining at SourcifyChina?

When working with a CNC machinist manufacturing partner such as SourcifyChina factory, there are key tips to ensure successful collaboration and optimal results:

1. Detailed Specifications: Begin by providing clear and detailed specifications, including CAD drawings, material preferences, tolerances, and finishing requirements. The more precise your inputs, the better the output.

2. Prototyping: Request prototypes before mass production. This allows you to verify the design and functionality, providing an opportunity for adjustments and preventing costly errors during large-scale production.

3. Communication: Maintain open and consistent communication. Use platforms like email, video calls, or project management tools to stay updated on progress and promptly address any issues or questions.

4. Quality Standards: Ensure the factory adheres to strict quality control processes. Request information about their quality assurance procedures, and ask for certifications and reports that verify their standards.

5. Sample Evaluation: Evaluate initial samples thoroughly. Check dimensions, material integrity, and finishing to ensure they meet your standards. Don’t hesitate to give feedback for necessary modifications.

6. Lead Times: Understand the lead times for production and shipping. Discuss and agree on realistic timelines to avoid any disruptions in your project schedule.

7. Cost Transparency: Get a detailed breakdown of costs, including machining, material, finishing, and shipping. Clarify any other potential additional charges to avoid surprise costs.

8. Factory Visits: If feasible, visit the factory to understand their capabilities and operations. This also builds stronger relationships and trust with your manufacturing partner.

9. Volume Discounts: Inquire about discounts for higher volume orders. Establishing a long-term relationship can often lead to better pricing and priority service.

10. Compliance: Verify that the factory complies with international manufacturing standards and environmental regulations to avoid future compliance issues.

By following these tips, you can ensure a productive and efficient partnership with SourcifyChina or any CNC manufacturing provider.

Q1: What is SourcifyChina and how can it help with sourcing CNC machinists?

A1: SourcifyChina is a platform that specializes in connecting businesses with qualified CNC machinists in China. They assist with finding skilled labor, ensuring quality control, and managing logistics for your manufacturing needs.

Q2: How experienced are the CNC machinists sourced from SourcifyChina?

A2: SourcifyChina collaborates with factories that employ highly skilled and experienced CNC machinists. Many of these professionals have years of expertise in precision machining across various industries including automotive, aerospace, and electronics.

Q3: What quality assurance measures are in place for CNC machining through SourcifyChina?

A3: SourcifyChina implements stringent quality control protocols, including regular inspections, performance evaluations, and adherence to international standards such as ISO 9001. This ensures that the output meets your specifications and quality requirements.

Q4: How does SourcifyChina handle communication with CNC machinists?

A4: SourcifyChina facilitates seamless communication by providing bilingual project managers who ensure that your specifications and requirements are clearly understood and executed by the CNC machinists.

Q5: Can I get prototypes made before mass production?

A5: Yes, SourcifyChina can arrange for prototype production. This allows you to review and approve the design and quality before commencing with large-scale manufacturing.

Q6: What is the lead time for sourcing CNC machinists from SourcifyChina?

A6: Lead times can vary based on the complexity and volume of your project. Typically, SourcifyChina provides detailed timelines during the initial consultation phase to set clear expectations.

Q7: How are costs determined for CNC machining services through SourcifyChina?

A7: Costs are calculated based on factors such as material type, project complexity, volume, and lead time. SourcifyChina offers competitive pricing and provides detailed quotations after assessing your specific needs.

Q8: Is it possible to visit the factory where my products will be machined?

A8: Yes, SourcifyChina can arrange factory visits. This transparency allows you to observe the production process and meet the CNC machinists handling your project.

Q9: How does SourcifyChina handle shipping and logistics?

A9: SourcifyChina manages the entire logistics chain, from factory to final destination, ensuring timely delivery. They handle documentation, customs clearance, and coordinate shipment logistics.

Sourcing a CNC machinist from a factory in China, like SourcifyChina, can be streamlined by following these tips:

1. Research Reputable Platforms: Begin with established platforms like Sourcify, Alibaba, or Global Sources to identify reliable factories.

2. Verify Credentials: Check for certifications such as ISO 9001, which indicate quality management standards. Also, look for customer reviews and feedback.

3. Detailed Inquiry: Specify your requirements in detail—materials, tolerances, finishes, and quantities. A clear RFQ (Request for Quotation) helps in getting accurate quotes.

4. Communication: Maintain clear and consistent communication. Utilize emails, video calls, and even WeChat for quick and efficient exchanges.

5. Samples and Prototypes: Request samples or prototypes to evaluate the machinist’s capabilities before committing to large orders.

6. Assess Capabilities: Ensure the factory has the necessary equipment and expertise. Modern CNC machinery and skilled operators are crucial for quality.

7. Quality Control: Establish robust quality control processes. Specify inspections at various production stages and set clear quality standards.

8. Visit the Factory: If possible, visit the factory to inspect the facilities and meet the team. This can provide valuable insights into their operation and reliability.

9. Cost and Lead Time: Negotiate not just on price but also on lead time and payment terms. Clear agreements help in avoiding misunderstandings later.

10. Logistics and Shipping: Consider logistics. Ensure the factory has experience with international shipping and can handle the documentation efficiently.

11. Local Insights: Partner with local consultants or agencies like Sourcify that have on-ground knowledge and can bridge language and cultural gaps.

By adhering to these steps, you can effectively source a skilled CNC machinist from SourcifyChina or similar factories, ensuring high-quality production and reliable supply chain management.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.