“Reliable and Cost-Effective CNC Milling Solutions: Unveiling SourcifyChina’s Competitive Factory Prices”

Discover the unmatched reliability and affordability of SourcifyChina’s CNC milling services. Get access to top-tier manufacturing solutions at competitive factory prices. Secure your production needs with trusted, efficient, and high-quality CNC milling from SourcifyChina.

SourcifyChina stands out for its commitment to quality and precision, providing buyers with reliable CNC mills at competitive prices. Their streamlined sourcing process ensures prompt delivery and customer satisfaction.

The company’s extensive network with top-rated factories means buyers receive products that meet stringent international standards. This guarantees a balance of performance and cost-efficiency.

With SourcifyChina, buyers benefit from transparent pricing, eliminating hidden costs. Their robust quality control procedures further ensure each machine undergoes rigorous testing before dispatch.

SourcifyChina offers excellent customer support, assisting throughout the purchasing process. Their multilingual team bridges communication gaps, making transactions smooth for international buyers.

Choosing SourcifyChina ensures access to cutting-edge technology. They keep up with industry advancements, ensuring that buyers get the latest, most efficient CNC machines available on the market.

In summary, SourcifyChina’s dedication to quality, extensive network, transparent processes, exceptional customer support, and access to advanced technology makes it the ideal choice for buyers seeking CNC mill prices from China.

CNC mill pricing varies widely, depending on factors like machine type, size, features, and brand reputation. Entry-level models start around $2,000, while advanced industrial machines can exceed $100,000.

– Entry-Level CNC Mills: Starting at $2,000 to $5,000 for hobbyists and small shops. Basic features and lower accuracy.

– Mid-Range CNC Mills: Ranging from $10,000 to $50,000. Suitable for small to medium enterprises, offering better precision and more advanced features.

– High-End CNC Mills: Priced between $50,000 to $100,000 and above. Used in large manufacturing units, featuring high precision, automation, and robust capabilities.

– Vertical vs. Horizontal Mills: Vertical mills are generally cheaper than horizontal ones, greatly influencing overall cost.

– Additional Features: Multi-axis capabilities, tool changers, and advanced software can significantly impact the price.

– Brand Reputation: Well-known brands tend to be more expensive due to reliability and better after-sales support.

– Used vs. New: Used CNC mills offer substantial cost savings but might lack warranty and latest features.

– Custom-Built Options: Custom-built machines tailored to specific needs can raise costs but maximize efficiency and capability.

Understanding these factors can help buyers make informed decisions, balancing cost with the required features and quality.

Determining the price of a CNC mill is essential for budgeting in manufacturing, prototyping, and engineering sectors. This process helps businesses plan their investments and optimize production costs.

– Budget Planning: Helps companies allocate funds accurately.

– Cost Analysis: Allows for comparison between different types of CNC mills.

– Return on Investment (ROI) Calculation: Assists in determining profitability.

– Customization Options: Evaluates the cost of additional features or capabilities.

– Maintenance Cost Estimation: Estimates long-term operational expenses.

– Supplier Negotiation: Aids in achieving the best possible deal.

– Production Capacity Planning: Ensures the price aligns with production needs.

– Market Analysis: Helps in understanding industry pricing trends.

– Quality Assessment: Balances price with machine quality and brand reputation.

– Financing Decisions: Supports loan and leasing choices.

– Tax Planning: Determines the benefits related to tax deductions.

– Lifecycle Cost Analysis: Estimates the total cost of ownership.

– Scalability Planning: Evaluates the cost implications of scaling up production.

– Feature Comparison: Helps in choosing between essential and non-essential features.

– Risk Management: Assesses financial risk associated with the investment.

– Forecasting: Aids in predicting future costs for similar equipment.

– Operational Efficiency: Determines how the price correlates with machine efficiency.

– Integration Costs: Considers additional expenses for integrating the CNC mill into existing systems.

– Training Expenses: Accounts for the cost of training staff to use the new equipment.

– Global Sourcing: Compares prices from international suppliers for cost-effectiveness.

Understanding the price dynamics of a CNC mill can significantly impact business decisions, improving both operational efficiency and financial outcomes.

SourcifyChina offers competitive CNC mill prices, ensuring affordability without compromising on quality. The company sources materials directly from trusted manufacturers, providing cost-effective solutions for various industrial needs.

Their CNC mills are crafted from high-grade metals such as aluminum, stainless steel, and titanium, each chosen for its durability and precision. This ensures consistent performance, essential for high-precision machining tasks.

The cutting-edge technology used by SourcifyChina minimizes material wastage, enhancing efficiency. High-strength metals are employed to withstand the rigors of continuous operation, reflecting the company’s commitment to sustainability and longevity.

By leveraging bulk purchasing power and streamlined logistics, SourcifyChina can further reduce CNC mill prices. This strategic approach provides enhanced value to customers, positioning SourcifyChina as a leader in cost-efficient manufacturing solutions.

SourcifyChina’s focus on quality materials and advanced technologies ensures that their CNC mills meet international standards. Customers can trust in the reliability and performance of these machines, ideal for both small batch processing and large-scale production.

In conclusion, SourcifyChina’s CNC mills stand out for their competitive pricing, exceptional quality, and efficient manufacturing processes. The strategic use of high-grade materials and state-of-the-art technology makes them a trusted partner in the global machining industry.

SourcifyChina’s CNC milling services prioritize affordability without compromising quality. They ensure competitive pricing through effective supply chain management and bulk material procurement. This allows them to offer cost-effective solutions to customers seeking precision machined components.

Quality control at SourcifyChina encompasses stringent measures from start to finish. They deploy state-of-the-art inspection equipment, such as coordinate measuring machines (CMM), to ensure dimensional accuracy of the CNC milled parts. This step guarantees that every product meets the specified tolerances and requirements.

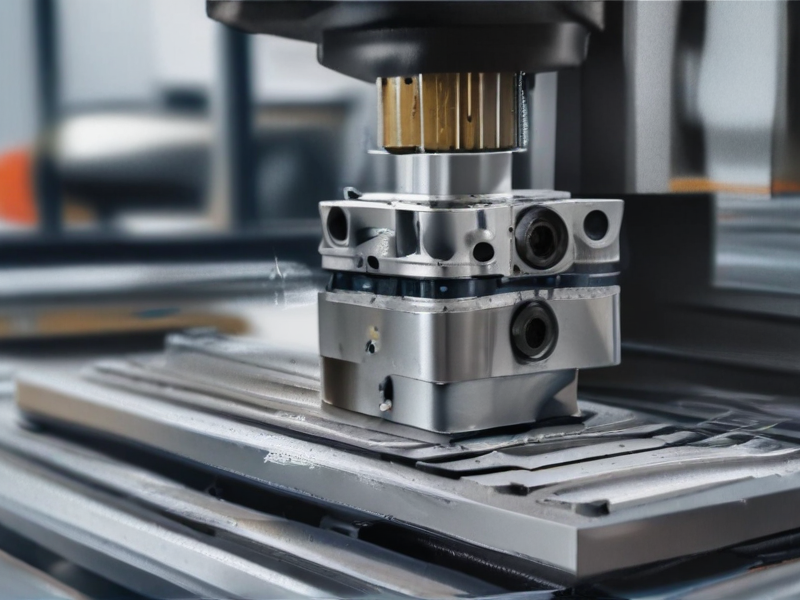

The manufacturing process at SourcifyChina involves meticulous planning and execution. Skilled engineers utilize advanced CNC machines programmed with CAD/CAM software for precise and repeatable operations. This ensures efficient material utilization and minimal waste, leading to consistent product quality.

To maintain high standards, SourcifyChina employs a multi-tiered quality assurance system. This includes in-process inspections, first article inspections (FAI), and final product evaluations. These checks identify any deviations and allow for immediate corrective actions, ensuring the end product’s reliability.

In summary, SourcifyChina offers competitive CNC milling prices by optimizing their manufacturing process and supply chain. Their rigorous quality control measures guarantee that each component meets high standards. These comprehensive approaches ensure that clients receive cost-effective yet high-quality CNC milled parts for their projects.

Sourcify is paving the way for businesses seeking cost-effective yet high-quality CNC milling services in China. Their transparent pricing model is tailored to accommodate varied project sizes and complexities.

China’s CNC milling services are known for their competitive pricing without compromising quality. Opting for these services can lead to significant cost savings due to lower labor costs and efficient production methods.

Sourcify ensures top-notch precision in every CNC milled component. The fusion of advanced technology with skilled craftsmanship leads to high-quality parts that meet global standards, ideal for industries ranging from aerospace to electronics.

The competitive edge lies in the combination of affordability and quality. Sourcify connects you directly with the best CNC milling manufacturers in China, ensuring that your operations are both cost-efficient and high-caliber.

Transparency in pricing is crucial. Sourcify’s robust network of vetted suppliers in China allows buyers to understand the cost breakdowns clearly, eliminating hidden fees and fostering a trust-rich transactional environment.

China’s CNC mill price advantage stems from bulk material sourcing and streamlined logistics. This economic efficiency translates to reduced prices for customers, while maintaining the integrity and accuracy essential for precision manufacturing.

By leveraging Sourcify’s expertise, clients gain access to a vast pool of CNC milling talent and technological innovations. This synergy ensures consistent delivery of precise parts and components tailored to specific requirements.

Lastly, Sourcify’s commitment to aiding your production processes extends beyond just providing cost advantages. Their comprehensive service package includes quality control, communication facilitation, and logistical support, ensuring a seamless manufacturing experience in China.

In conclusion, SourcifyChina offers an unbeatable combination of competitive CNC mill pricing and top-notch quality. Their extensive network and transparent business practices empower businesses to achieve excellence in manufacturing while optimizing costs and maintaining rigorous standards.

Investing in a CNC mill can offer immense benefits, making the purchase cost-effective in the long run. Below are some key advantages:

– Enhanced Precision and Accuracy: CNC mills provide highly accurate cuts, minimizing errors and reducing material waste.

– Increased Productivity: Automation speeds up manufacturing processes, enabling higher output rates and better resource utilization.

– Cost Efficiency: Lower labor costs and reduced waste lead to significant savings over time.

– Versatility: CNC mills can perform various functions, from cutting to drilling, on different materials, providing a wide range of applications.

– Consistency and Repeatability: Once programmed, CNC mills can produce identical products repeatedly, ensuring consistent quality.

– Reduced Downtime: Advanced diagnostics and maintenance features minimize machine downtime, improving overall efficiency.

– Scalability: Ideal for both small shops and large-scale manufacturing, allowing for easy scalability as production demands grow.

– Enhanced Safety: Automated processes reduce human interaction with dangerous machinery, enhancing workplace safety.

By understanding these benefits, it becomes evident that the initial investment in a CNC mill is outweighed by its long-term advantages, making it a valuable asset for any manufacturing operation.

When considering the price of a CNC mill, several features significantly influence the cost, such as material capabilities, size, precision, and software compatibility. Here’s a detailed breakdown:

– Material Capabilities: The types of materials the CNC mill can handle, such as metals, plastics, and composites, will impact the price. Mills that can process a wider range of materials are generally more expensive.

– Size and Weight: Larger mills with bigger work areas are typically pricier due to increased material and production costs.

– Precision and Tolerance: Higher precision and tighter tolerances usually result in a higher price due to the sophisticated components required.

– Spindle Speed and Power: Mills with higher spindle speeds and greater power can process materials faster and more efficiently, but they come at a premium.

– Axes Configuration: The number of axes (typically ranging from three to five) directly influences the price. More axes allow for complex shapes and operations, which increase the cost.

– Software and Controller: The type and quality of the software and the CNC controller (e.g., Fanuc, Siemens) are crucial factors. Advanced, user-friendly software with more features tends to be more expensive.

– Automation Features: Integrated features such as automatic tool changers, cooling systems, and robotic arms add convenience and efficiency but also increase the price.

– Brand and Warranty: Reputable brands with extended warranties often come at a higher cost due to their reliability and customer support.

Understanding these features will help you evaluate the true value of a CNC mill in relation to its price and make an informed purchasing decision.

SourcifyChina offers competitive prices for CNC milling services, catering to both custom products and specific project needs. Their advanced milling technology guarantees precision and high-quality finishes for various materials.

This reliability in quality and cost-efficiency makes SourcifyChina an attractive option for businesses looking to outsource their manufacturing processes. By addressing diverse requirements, they provide tailored solutions that meet industry standards.

SourcifyChina’s comprehensive suite of services includes design consultation, prototype development, and full-scale production. Ensuring customer satisfaction, they maintain transparent communication every step of the way.

Whether your project is large or small, SourcifyChina is committed to delivering superior products at affordable prices. Partnering with them ensures that you receive expert craftsmanship and valuable support in achieving your manufacturing goals. This blend of affordability and quality makes them a leader in the CNC milling industry.

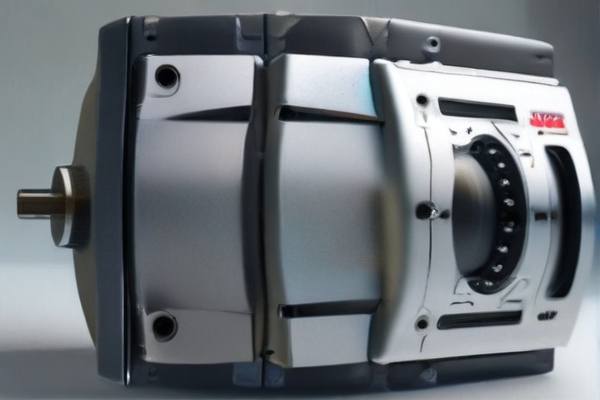

SourcifyChina is a prominent player in the realm of CNC milling, renowned for providing high-quality, competitively priced CNC mill machines tailored to meet a wide array of industrial needs. With a strong focus on innovation and efficiency, SourcifyChina ensures that each machine is crafted with precision, offering unparalleled performance and reliability. The company’s extensive product range caters to diverse sectors, from automotive to aerospace, ensuring that every client finds a solution that fits their specific requirements. Transparency and customer satisfaction form the cornerstone of SourcifyChina’s business ethos, reflected in their straightforward pricing models that provide exceptional value without hidden costs. By leveraging advanced technology and a dedicated team of experts, SourcifyChina not only meets but exceeds industry standards, establishing itself as a trusted partner for businesses looking to enhance their manufacturing capabilities. With an unwavering commitment to quality and affordability, SourcifyChina stands out as a go-to source for top-tier CNC milling solutions in the ever-competitive global market.

CNC (Computer Numerical Control) milling machines have become indispensable tools in the Aerospace, Defense, and Marine industries, where precision machining is critical. The price of CNC mills can vary widely, but investing in high-quality machines is often justified by the demanding requirements of these sectors. In aerospace, components such as turbine blades, structural airframe parts, and intricate engine elements must be manufactured to exacting standards to ensure safety and performance. This precision is achieved by CNC milling machines, which offer unparalleled accuracy and repeatability. In the defense sector, CNC mills are crucial for producing components like firearms, missile parts, and communication equipment. The integrity and reliability of these components directly impact national security, making the investment in high-end CNC milling machines essential.

Marine applications also benefit significantly from CNC milling technology, despite the initial price being a considerable investment. Shipbuilding involves the creation of complex components ranging from engine parts to intricate navigation systems and ergonomic controls for ship operations. CNC milling machines are capable of working with various materials like aluminum, steel, and composites—all essential in the marine industry for constructing corrosion-resistant and durable parts. The high precision offered by CNC mills ensures that every manufactured part fits perfectly within the larger assembly, reducing potential points of failure. These investments not only lead to higher quality and performance but also often result in long-term cost savings through reduced waste and fewer production errors. Thus, while the upfront cost of CNC mills may be high, their critical role in ensuring optimal performance and safety in Aerospace, Defense, and Marine applications makes them a justified and necessary expenditure.

Computer Numerical Control (CNC) milling machines have become indispensable in the automotive industry due to their unparalleled precision, efficiency, and versatility. From engine blocks to transmission components, CNC mills play a crucial role in fabricating intricate parts that demand high precision and durability. The cost of CNC mills can be substantial, but the investment is justified by the significant reduction in production time and waste. Automakers can streamline their manufacturing processes by utilizing CNC mills, ensuring consistency and repeatability across large-scale production runs. This consistency is vital for maintaining the high standards of quality and performance expected in modern vehicles. Furthermore, the adaptability of CNC mills allows automakers to quickly reconfigure their production lines for new models or components, enhancing their ability to respond to market demands swiftly.

In the electronics industry, CNC milling machines are equally critical, particularly in the realm of printed circuit board (PCB) fabrication and the production of intricate electronic housings. Precision is paramount in electronics manufacturing, as components must fit together seamlessly within tight tolerances. The initial expense of a CNC mill can be offset by the high-quality output it delivers, which minimizes the risk of costly errors and rework. In addition, advances in CNC technology have made it possible to work with a variety of materials, including high-performance plastics and specialized metals, essential for producing durable and reliable electronic devices. The ability to produce prototypes quickly and accurately also accelerates the development cycle, fostering innovation and reducing time-to-market for new electronic products. As a result, while the price of a CNC mill is a significant consideration, its benefits in enhancing production precision, efficiency, and flexibility make it a worthwhile investment for companies in the booming electronics sector.

In the construction industry, CNC mills are revolutionizing the way components are fabricated through precise and automated machining processes. The cost of acquiring a CNC mill can vary significantly based on its features, capabilities, and size, but this investment is often justified by the significant increase in productivity and accuracy. With prices starting from a few thousand dollars to hundreds of thousands for advanced models, construction firms can choose a machine that fits their specific project needs and budget. CNC mills enable the creation of complex shapes and customized parts with minimal human intervention, reducing both errors and labor costs. As a result, builders are able to achieve higher quality finishes and structural integrity in projects ranging from residential buildings to massive infrastructural developments.

In the realm of energy, particularly in renewable energy infrastructure like wind turbines and solar panel mounts, CNC mills play a crucial role in manufacturing components with high precision. The variability in CNC mill prices allows energy companies and suppliers to select machines that align with their production scales and financial plans. High-end CNC mills are capable of producing intricate parts necessary for optimized energy generation, such as turbine blades and intricate mounting systems, ensuring both efficiency and durability. Moreover, the automation offered by these machines can lead to a reduction in production errors and downtime, thus enhancing the overall operational efficiency and reliability of energy systems. As the demand for renewable energy sources increases, the investment in CNC mills aids in meeting industry standards and scalability, ultimately contributing to a more sustainable future.

The application of CNC (Computer Numerical Control) milling machines in the industrial equipment sector has revolutionized manufacturing processes by significantly enhancing precision, efficiency, and automation. A primary consideration for businesses investing in CNC mills is their price, which varies based on factors such as machine size, complexity, and functionality. High-end CNC mills, equipped with advanced features like multi-axis capabilities and high-speed spindles, typically command a premium price but offer substantial returns in terms of productivity and quality. Investments in such machines can be justified by their ability to produce complex parts with minimal human intervention, reduce material wastage, and ensure consistent output, ultimately driving down operational costs over time. Conversely, more affordable, entry-level CNC mills may appeal to small and medium-sized enterprises (SMEs) looking to upgrade from manual machining or seeking cost-effective solutions for lower volume production runs.

However, the initial CNC mill price is just one aspect of the overall cost-benefit analysis. Additional expenses such as maintenance, tooling, software, and training must also be considered. Industrial equipment companies must weigh these costs against the potential for increased production capacity, reduced lead times, and the ability to meet stringent quality standards. The scalability offered by CNC milling technology allows manufacturers to rapidly adapt to market demands and customize orders without extensive retooling, offering a competitive edge. Furthermore, as technology advances and economies of scale are achieved, the cost of CNC milling machines is expected to become more accessible, enabling a broader range of industries to adopt these tools. This ongoing evolution underscores the critical need for companies within the industrial equipment sector to stay informed about pricing trends and innovations in CNC technology to maintain operational efficiency and market competitiveness.

Computer Numerical Control (CNC) milling machines have revolutionized the medical devices industry, offering unparalleled precision and consistency in the manufacturing process. High-precision medical devices, such as surgical instruments, implants, and prosthetics, require exact dimensions and flawless finishes to ensure they function correctly and safely within the human body. CNC mills can achieve these stringent requirements by following computerized instructions that precisely control cutting tools, enabling the production of complex geometries and intricate features that are often challenging to achieve with conventional machining techniques. The cost of CNC milling machines, often referred to as the “CNC mill price,” ranges significantly based on the machine’s capabilities, precision, and features. Despite their varying prices, the investment in high-quality CNC mills can lead to significant long-term savings by reducing waste, minimizing errors, and improving the overall efficiency of the manufacturing process.

Moreover, the adaptability and versatility of CNC mills make them indispensable in the ever-evolving medical devices sector. As medical technologies advance, the demand for customized and patient-specific solutions is increasing. CNC milling allows manufacturers to rapidly prototype and produce small batches of highly specialized devices without the need for extensive retooling or setup changes, making it cost-effective and responsive to the fast-paced innovations in healthcare. The price of CNC mills often reflects the level of sophistication needed to meet these advanced requirements, but the potential return on investment is considerable when considering the improved capabilities and outcomes in patient care. The integration of CNC milling technology in the medical devices industry underscores its critical role in pushing the boundaries of what is possible, ensuring that patients receive the highest standard of care through precision-engineered medical solutions.

CNC milling, which stands for Computer Numerical Control milling, has revolutionized the machining and manufacturing industries by providing unparalleled precision, efficiency, and versatility. A CNC mill is a computer-controlled machine that employs a rotating, cylindrical cutting tool to remove material from a workpiece based on pre-programmed instructions. This advanced technology allows manufacturers to produce complex parts with tight tolerances in a fraction of the time it would take using traditional manual methods. The adoption of CNC mills has significantly enhanced productivity by reducing human error, lowering labor costs, and enabling mass production of consistent, high-quality components.

The price of CNC mills varies widely based on several factors such as size, power, axis configuration, and the level of automation. Entry-level CNC mills, suitable for small-scale operations or educational purposes, can start from a few thousand dollars, while high-end, industrial-grade machines with advanced features and larger capacities can exceed several hundred thousand dollars. The investment in a CNC mill can yield substantial returns by minimizing material wastage, shortening production cycles, and enabling rapid prototyping. Additionally, the precision and repeatability offered by CNC mills can open up new opportunities in industries such as aerospace, automotive, healthcare, and consumer electronics, where exacting standards are essential. As technology continues to evolve and become more accessible, the CNC mill price remains a critical consideration for manufacturers seeking to enhance their machining capabilities and maintain competitive advantage.

FAQs for Manufacturing CNC Mill Price Quality Work from SourcifyChina Factory

1. What factors influence the price of CNC mills from SourcifyChina?

The price of CNC mills from SourcifyChina is influenced by several factors, including machine specifications, materials used, precision level, production volume, and any additional features or custom requirements.

2. How does the quality of SourcifyChina’s CNC mills compare to other manufacturers?

SourcifyChina is renowned for its high-quality CNC mills due to stringent quality control processes, use of robust materials, and advanced manufacturing techniques. This ensures superior performance and longevity compared to many other manufacturers.

3. Can SourcifyChina customize CNC mills according to specific requirements?

Yes, SourcifyChina offers customization options to meet specific needs. Customers can specify dimensions, precision levels, and even request additional features to suit their unique manufacturing processes.

4. What types of materials can SourcifyChina’s CNC mills handle?

SourcifyChina’s CNC mills are capable of handling a wide range of materials including metals (aluminum, steel, titanium), plastics, and composites, providing flexibility for various industrial applications.

5. What is the lead time for manufacturing and delivering CNC mills from SourcifyChina?

The lead time for manufacturing and delivery varies based on the complexity and quantity of the order. Typically, it ranges from 4 to 12 weeks. Customers are advised to confirm with SourcifyChina for precise timelines.

6. Does SourcifyChina provide after-sales support and maintenance services?

Yes, SourcifyChina offers comprehensive after-sales support, including maintenance services, technical assistance, and spare parts supply to ensure optimal performance and longevity of their CNC mills.

7. How can I ensure the reliability of SourcifyChina as my CNC mill supplier?

SourcifyChina’s reliability can be confirmed through their extensive track record, positive customer testimonials, adherence to international standards, and regular quality checks throughout the manufacturing process.

8. Are there any warranties offered on CNC mills purchased from SourcifyChina?

Yes, SourcifyChina offers warranties on their CNC mills, covering manufacturing defects and providing repair services within the warranty period. Specific warranty details can be discussed at the time of purchase.

9. What payment terms and conditions does SourcifyChina offer?

SourcifyChina offers flexible payment terms, typically involving a deposit before production and the balance upon delivery. They accept various payment methods and are open to discussing terms to suit customer needs.

When considering CNC mill price manufacturing from SourcifyChina factory, keep the following tips in mind to ensure a smooth and cost-effective process:

1. Research Thoroughly: Start by understanding your specific requirements and researching the type of CNC mill machinery you need. SourcifyChina factory offers various options, so determine the specifications that best fit your production goals.

2. Quality Assessment: Ensure that the factory maintains high-quality standards. Check for certifications like ISO 9001, CE, and other relevant credentials. You can request samples or visit the factory if possible to review their quality control processes.

3. Detailed Quotations: Request detailed quotations that include itemized costs for machinery, customization, shipping, taxes, and any additional services. This will help you compare prices more transparently and avoid hidden fees.

4. Customization Options: Discuss customization needs upfront. SourcifyChina factory can offer tailored solutions based on your specific machining tasks, so clearly communicate your requirements to avoid costly modifications later.

5. Lead Times and Delivery: Confirm lead times and delivery schedules. Ensure that the factory can meet your production timelines effectively. Timely delivery can prevent production delays and additional costs.

6. Bulk Discounts: If you’re purchasing multiple units, negotiate bulk discounts. Factories like SourcifyChina are often willing to reduce prices for larger orders.

7. Warranty and Support: Ensure the CNC mills come with a warranty and reliable after-sales support. This can save costs on repairs and maintenance in the future.

8. Payment Terms: Clarify payment terms and consider options like staged payments linked to project milestones to manage cash flow efficiently.

9. Client References: Ask for references or testimonials from previous clients to gauge the factory’s credibility and reliability.

10. Souring Partner: Consider using a third-party sourcing partner if you’re unfamiliar with the local market. They can offer valuable insights, handle negotiations, and ensure quality standards are met.

By following these tips, you can navigate the complexities of CNC mill price manufacturing with SourcifyChina factory and secure a good deal that meets your production needs.

Q1: How can I get a quote for a CNC mill from SourcifyChina factory?

A1: To get a quote, you can visit the SourcifyChina website and fill out their contact form with details about your requirements. Alternatively, you can email their sales team directly with your specifications, and they will provide you with a detailed quotation.

Q2: What information do I need to provide to get an accurate CNC mill price?

A2: To receive an accurate price, you should provide information such as the type of CNC mill you need, its specifications (e.g., spindle speed, power, size), any additional features or accessories, and the quantity you plan to order.

Q3: Are there discounts available for bulk orders?

A3: Yes, SourcifyChina offers discounts for bulk orders. The discount rate can vary depending on the quantity and specific models you are purchasing. It’s best to discuss this directly with their sales team for detailed information.

Q4: What are the payment terms for purchasing a CNC mill from SourcifyChina?

A4: Payment terms may vary, but typically, SourcifyChina accepts payments through bank transfers, letters of credit, and sometimes, PayPal for smaller orders. A deposit is usually required to start the manufacturing process, with the balance due upon completion and prior to shipment.

Q5: How long does it take to manufacture and ship a CNC mill?

A5: Manufacturing time can vary depending on the complexity and quantity of your order. Standard models may take between 4-6 weeks to produce, while custom orders may take longer. Shipping time depends on your location and the shipping method chosen.

Q6: Do they offer warranties and after-sales support?

A6: Yes, SourcifyChina offers warranties on their CNC mills, typically ranging from 1 to 2 years. They also provide after-sales support, including technical assistance and spare parts supply. Specific terms will be detailed in the sales contract.

Q7: Can I visit the factory to see the CNC mills before purchasing?

A7: Yes, SourcifyChina welcomes factory visits. You can arrange an appointment through their sales team to tour the facility, see the manufacturing process, and inspect the CNC mills.

Q8: Are there any additional costs I should be aware of?

Sourcing CNC mill prices from SourcifyChina factory can be a streamlined process if approached methodically. Here are some tips to help you get accurate pricing and dependable service:

1. Clear Specifications: Define your CNC mill requirements precisely – size, axis, power, speed, and any special features. Detailed specifications help factories provide accurate quotes.

2. Request Quotations: Contact SourcifyChina directly via their website or email. Provide your specifications and request a detailed quotation. Ask for cost breakdowns, including unit price, shipping, taxes, and any additional fees.

3. Compare Prices: Get multiple quotations for comparison. Check for hidden costs and payment terms. Ensure you understand what is included in the price, like warranties and after-sales support.

4. Quality Assurance: Besides price, consider the quality. Check factory certifications like ISO, customer reviews, and past projects to ensure they meet your standards.

5. Sample Order: If possible, place a small order first. This helps to evaluate the machine’s performance, build quality, and factory reliability before committing to a larger purchase.

6. Factory Visit: If feasible, visit the factory to inspect the production facilities and meet the team. This builds trust and allows for negotiation on pricing and terms.

7. Negotiation: Discuss the price, especially if you plan a bulk purchase. Factories may offer discounts for larger orders or long-term partnerships.

8. Payment Terms: Clarify payment terms upfront. Common terms might include a down payment with the balance upon delivery or installment payments.

9. Logistics and Shipping: Confirm the logistics and shipping details. Ask about lead times, shipping methods, and insurance. SourcifyChina can help manage this process efficiently.

10. Legal & Contracts: Have clear contracts outlining terms, specifications, delivery timelines, and dispute resolution mechanisms. Legal agreements protect both parties.

By following these tips, you can effectively source CNC mills from SourcifyChina while ensuring you get the best value for your investment.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.