# Reliable Manufacturing: SourcifyChina CNC Router for Durable Aluminum Machining Solutions

SourcifyChina offers premium-quality CNC routers for aluminum, meeting international standards. Their advanced technology ensures precision and durability. Clients benefit from innovative machinery designed for optimal performance and longevity, advancing your production capabilities.

Cost-effectiveness is a key advantage. SourcifyChina provides competitive pricing without compromising quality. Buyers receive top-grade products at reasonable costs, enhancing their return on investment. This financial efficiency makes them a preferred choice.

Customer support at SourcifyChina is exceptional. From pre-purchase inquiries to after-sales service, their dedicated team assists clients at every step. This comprehensive support ensures a seamless purchasing experience, fostering buyer confidence and satisfaction.

Customized solutions are readily available. SourcifyChina can tailor CNC routers to meet specific client requirements. This flexibility allows businesses to procure machines that precisely fit their operational needs, supporting bespoke production processes and enhancing efficiency.

Stringent quality control measures are implemented. Each CNC router undergoes rigorous testing to ensure it meets the highest standards of performance and safety. This commitment to quality guarantees reliable and efficient machinery for buyers.

SourcifyChina boasts a robust supply chain network. This network facilitates prompt delivery and minimizes lead times, ensuring buyers receive their equipment swiftly. Timely procurement aids in maintaining operational continuity and meeting production deadlines.

Comprehensive training and technical support are integral to their service. SourcifyChina provides expert training on machine operation and maintenance, empowering clients to maximize their investment. Continuous technical support ensures smooth, uninterrupted production.

In conclusion, SourcifyChina stands out for its quality, affordability, customer service, customization, strict quality control, efficient delivery, and robust support. Choosing them for CNC routers for aluminum guarantees a superior procurement experience, optimizing your manufacturing processes and boosting production efficiency.

When choosing a CNC router for aluminum, it’s crucial to consider factors like machine power, spindle speed, and rigidity. Various types and options cater to both hobbyists and professionals, ensuring precision and efficiency in aluminum machining.

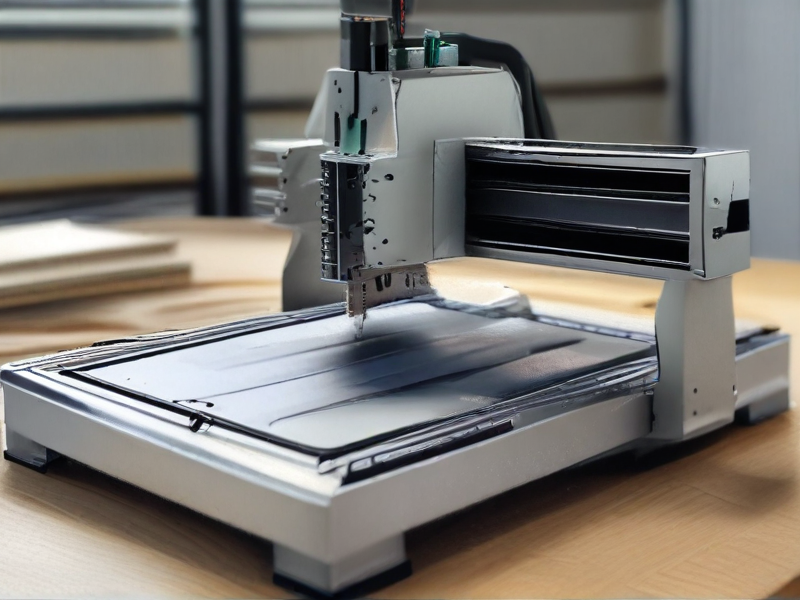

– Benchtop CNC Routers:

– Ideal for beginners and hobbyists.

– Compact and affordable, but limited in power and size.

– Popular models: Shapeoko, X-Carve.

– Mid-Range CNC Routers:

– Suitable for small businesses.

– Offer better power and accuracy.

– Brands to consider: CNC Shark, Avid CNC.

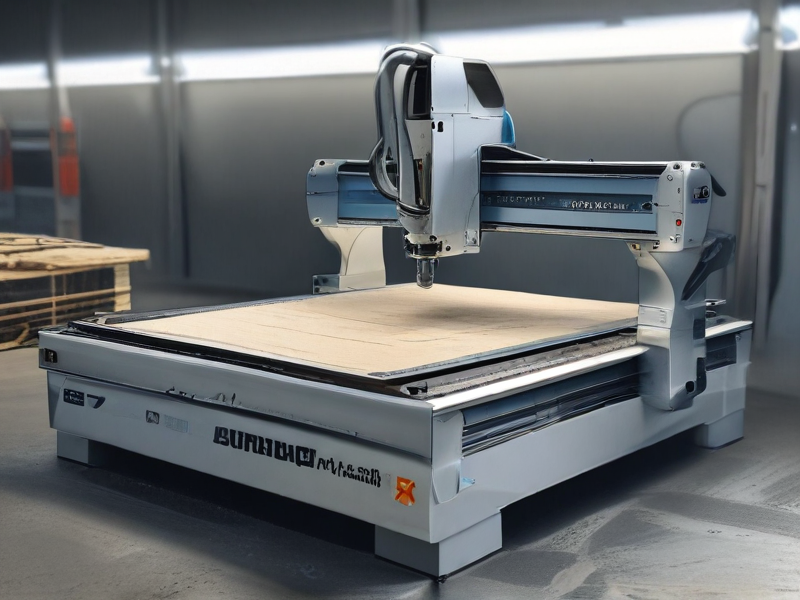

– Industrial CNC Routers:

– Designed for heavy-duty tasks and continuous operation.

– High power, large working areas, and exceptional precision.

– Examples: Haas Automation, Laguna Tools.

– Spindle Types:

– Air-Cooled Spindles:

– Easier maintenance.

– Suitable for light to moderate use.

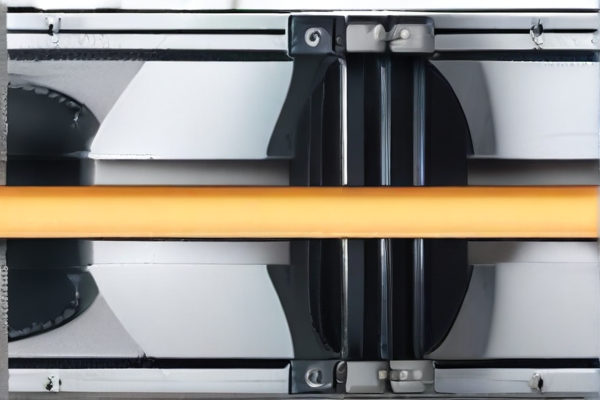

– Water-Cooled Spindles:

– Better for extended use.

– Offer lower noise and better cooling efficiency.

– Drive Systems:

– Lead Screw:

– More affordable, but slower speeds.

– Suitable for precision tasks.

– Ball Screw:

– More expensive, quicker, and precise.

– Ideal for professional and industrial use.

– Software Compatibility:

– Compatible with popular CAD/CAM software.

– Examples include Fusion 360, VCarve Pro, and Carbide Create.

– Additional Features:

– Vacuum Tables:

– Secure workpieces during machining.

– Automatic Tool Changers:

– Reduce manual intervention, increasing productivity.

– Dust Collection Systems:

– Maintain clean work environments and protect machine components.

Selecting the right CNC router for aluminum machining involves balancing budget, application requirements, and desired precision. From benchtop models for hobbyists to industrial machines for professionals, the market offers diverse options to meet varied needs.

A CNC router for aluminum is a powerful tool used in various industries for precise cutting, shaping, and engraving of aluminum materials. Its versatility makes it a staple in manufacturing, prototyping, and custom fabrication.

– Prototyping: Create detailed prototypes for products and components with high precision.

– Signage: Manufacture durable aluminum signs with intricate designs and lettering.

– Machinery Parts: Produce custom parts for machinery and equipment with exact specifications.

– Automotive: Fabricate components for automotive applications, including custom fittings and parts.

– Aerospace: Craft lightweight and strong aerospace components that meet stringent industry standards.

– Furniture Design: Design and create unique aluminum furniture pieces with complex detailing.

– Decorative Items: Produce decorative and artistic items, such as custom panels and architectural details.

– Electrical Enclosures: Manufacture custom aluminum enclosures for electrical and electronic devices.

– Marine Industry: Create corrosion-resistant parts and accessories for marine applications.

– Medical Devices: Fabricate precise components for medical equipment and devices.

– Robotics: Produce parts for robotics with high accuracy and repeatability.

– Custom Tooling: Develop specialized tools and dies for various manufacturing processes.

– Jewelry Making: Craft intricate aluminum jewelry with detailed engravings and shapes.

– RC Models and Drones: Manufacture lightweight and strong parts for RC models and drones.

– Musical Instruments: Build unique components for musical instruments, such as guitar bodies and drum hardware.

– Heat Sinks: Create custom heat sinks for electronic cooling solutions.

– Bicycle Parts: Fabricate lightweight yet durable bicycle components, such as frames and brackets.

– Home Improvement: Design and produce custom home improvement items like cabinet doors and trim.

– Education and Research: Utilize in educational settings and research labs for various projects and experiments.

Each of these applications showcases the versatility and precision of CNC routers in working with aluminum, making them invaluable assets across multiple sectors.

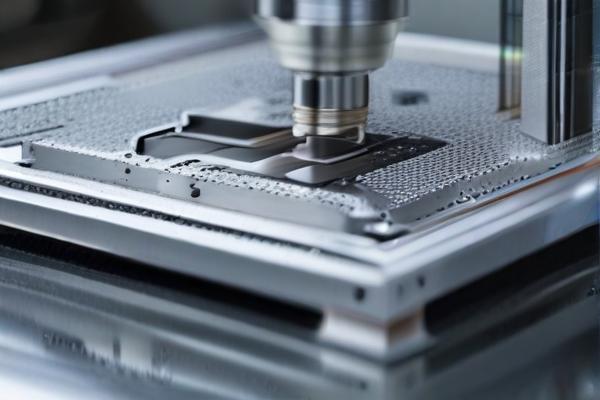

The SourcifyChina CNC router for aluminum is built with high-precision components designed specifically for cutting and milling aluminum. This machines offer robust performance and unmatched accuracy, making them ideal for both industrial and hobbyist applications.

The primary material used in the construction of these CNC routers is aircraft-grade aluminum, known for its strength-to-weight ratio. This material ensures the machine remains durable while maintaining a lightweight profile, which is crucial for high-speed operations and consistent performance.

To further enhance durability and stability, the SourcifyChina CNC router features linear guides and ball screws made from hardened steel. These components are precision-ground to reduce friction and provide smooth motion, which is essential for achieving fine, detailed cuts.

Additionally, the machine employs high-torque stepper motors to deliver precise control over the cutting head, enabling intricate designs to be executed with ease. The motors are encased in protective housings made from heat-resistant materials to ensure longevity and reliability under intensive use.

A key feature is its dust collection system, which helps keep the work area clean and reduces wear on internal components. The system is crafted from sturdy polycarbonate and industrial-grade plastics, offering a balance of durability and flexibility.

By integrating advanced software compatibility, the CNC router supports a variety of design formats. This flexibility allows for seamless transitions between different projects, providing an efficient workflow for users, regardless of complexity.

In conclusion, the SourcifyChina CNC router for aluminum embodies a commitment to quality through its meticulous choice of materials. With aircraft-grade aluminum, hardened steel, and advanced motor systems, the machine delivers reliability and precision. The inclusion of practical features like a dust collection system further solidifies its status as a comprehensive solution for aluminum milling needs, making it an excellent investment for anyone requiring high-performance machining.

The quality control manufacturing process for SourcifyChina CNC routers for aluminum starts with meticulous material selection. Only premium-grade aluminum alloys are chosen to ensure durability and precise machining, setting the foundation for high-quality output.

During production, advanced Computer Numerical Control (CNC) technology is employed to achieve precise dimensions and fine tolerances. This automation minimizes human error and ensures consistency across all units, enhancing the router’s performance and functionality.

Every CNC router undergoes rigorous testing phases, including vibration analysis and load testing, to verify structural integrity and operational efficiency. These assessments help identify any flaws early, ensuring only top-tier products reach the market.

The final step involves a comprehensive quality audit. Expert technicians scrutinize the CNC routers for finesse and compliance with industry standards, examining factors like surface finishing and component alignment. This exhaustive inspection ensures each unit excels in real-world applications.

Summarizing, SourcifyChina’s stringent quality control measures, from material selection to final audit, enable the production of high-performing CNC routers. These steps collectively ensure that every CNC router for aluminum meets the highest industry standards, promising end-users exceptional reliability and efficiency.

The SourcifyChina CNC router for aluminum is engineered to deliver precise and efficient cutting for industrial applications. It is equipped with advanced spindle technology, which ensures smooth operations and high cutting speeds.

The machine boasts an impressive build quality, featuring a robust frame designed to minimize vibrations. This enhances the precision and quality of the finished products, making it ideal for intricate designs.

Advanced software integration allows for seamless operation and compatibility with various design formats. This makes it user-friendly and adaptable, catering to both small-scale and large-scale production needs.

Additionally, the router offers a high degree of customization. Users can configure different tools and settings to suit specific project requirements. This versatility makes it a popular choice among professionals looking for both performance and flexibility.

Maintenance is straightforward, thanks to the design’s focus on ease of access and durability. With regular upkeep, the SourcifyChina CNC router can provide years of reliable service, ensuring a good return on investment for businesses.

In summary, the SourcifyChina CNC router for aluminum combines advanced technology, robust construction, and versatile functionality to meet diverse industrial needs. Its precision, ease of use, and low-maintenance design make it an excellent choice for both professionals and manufacturers looking to achieve high-quality results with aluminum materials.

CNC routers have revolutionized aluminum machining by offering precision, efficiency, and enhanced capabilities. These tools have made intricate designs and complex cuts far more achievable.

– Precision: CNC routers offer high-accuracy cuts, reducing the chance of errors and ensuring consistent results.

– Efficiency: The automated process increases production speed and reduces manual labor, which in turn minimizes operational costs.

– Consistency: Uniformity in production is guaranteed, making it ideal for large-scale manufacturing.

– Flexibility: Capable of executing a wide range of cuts and engravings, a CNC router adapts to varied design needs.

– Complex Designs: Easily handles intricate and detailed patterns that would be difficult with traditional methods.

– Reduced Waste: Optimizes material usage and minimizes scrap, contributing to cost savings.

– Safer Operations: Automation limits human involvement in potentially hazardous tasks, enhancing workplace safety.

– Versatility: Compatible with other materials, making it a valuable tool for diverse applications.

– Lower Maintenance: The durability and reliable components of CNC routers reduce downtime for maintenance.

A CNC router tailored for aluminum exhibits high precision, increased spindle power, and rigidity, ideal for demanding applications.

– High Precision: Ensures detailed and accurate machining of aluminum components with fine resolution.

– Increased Spindle Power: Handles the tough nature of aluminum, ensuring smooth and efficient cutting.

– Durability: Constructed with robust materials to withstand the stress of machining aluminum.

– Cooling System: Integrated coolant systems prevent overheating and maintain tool life.

– Advanced Software Compatibility: Works with sophisticated CAD/CAM software for seamless design translations and complex machining tasks.

– Tool Versatility: Supports a wide range of tool sizes and types for various applications.

– Automated Functions: Features such as auto tool changing and zero point clamping increase productivity and ease of operation.

– High-Speed Operation: Capable of high-speed cutting for efficient workflow.

– User-Friendly Interface: Intuitive controls and touchscreens simplify operation for users.

– Safety Features: Equipped with safety mechanisms such as emergency stop buttons and protective enclosures.

– Repeatability: Consistently produces identical parts over multiple runs, crucial for production efficiency.

– Cost-Efficiency: Optimizes material usage and reduces human error, resulting in lower operational costs.

– Flexibility: Adaptable to various aluminum grades and other non-ferrous metals.

These features make CNC routers indispensable tools in industries requiring precise and efficient aluminum machining.

SourcifyChina stands out in providing tailored CNC router solutions for aluminum, ensuring precision and durability. Their expertise in custom products and projects makes them a reliable partner for your industrial needs.

Utilizing advanced technologies, SourcifyChina’s CNC routers deliver exceptional accuracy. This precision allows for the creation of intricate aluminum designs, meeting the demands of various industries, from aerospace to automotive.

Beyond just routers, SourcifyChina offers a comprehensive suite of services, including design consultation and prototype development. Their team collaborates closely with clients to transform concepts into high-quality finished products efficiently.

SourcifyChina places a strong emphasis on durability and performance. Each CNC router is rigorously tested to ensure it can handle the rigors of aluminum machining, providing customers with long-lasting and reliable tools.

Customers appreciate SourcifyChina’s commitment to innovation. Incorporating the latest advancements in CNC technology, they continually enhance their machines’ capabilities, keeping them ahead in a competitive market.

Affordability is another key advantage of choosing SourcifyChina. They strive to offer cost-effective solutions without compromising quality, making high-performance CNC routers for aluminum accessible to a broad range of businesses.

In addition to manufacturing, SourcifyChina excels in after-sales support. Their dedicated service team ensures that any issues are promptly addressed, minimizing downtime and maintaining productivity.

Environmental responsibility is also a priority for SourcifyChina. They implement eco-friendly practices in their manufacturing processes, contributing to sustainable industry growth.

SourcifyChina’s customization options are extensive. From size and capabilities to specific component preferences, they work meticulously to meet each client’s unique requirements, delivering bespoke CNC routers that fit seamlessly into their operations.

Their reputation is built on trust and satisfaction. Many clients continue to partner with SourcifyChina for subsequent projects, citing their reliability and consistent delivery of high-quality custom CNC routers for aluminum.

SourcifyChina is your go-to source for cutting-edge CNC routers tailored to your aluminum machining needs. With a focus on precision, durability, and customer satisfaction, they turn your machining projects into successes.

SourcifyChina is a renowned company specializing in CNC routers for aluminum, epitomizing precision, innovation, and superior craftsmanship in the manufacturing sector. With a dedication to meeting the evolving needs of global industries, SourcifyChina delivers cutting-edge CNC technology designed to handle the intricacies and challenges of aluminum machining. Their products boast advanced features that ensure high accuracy, efficiency, and longevity, catering to diverse applications ranging from aerospace components to intricate architectural designs. The company prides itself on maintaining rigorous quality standards and providing exceptional customer support, ensuring that clients have access to the best solutions for their specific requirements. By focusing on continuous improvement and leveraging state-of-the-art manufacturing practices, SourcifyChina has established itself as a key player in the CNC router market for aluminum, transforming ideas into tangible products with unmatched precision.

CNC routers for aluminum hold a significant place in the aerospace, defense, and marine industries due to their unparalleled precision, efficiency, and versatility. In aerospace applications, the precise cutting abilities of CNC routers ensure that complex, lightweight aluminum components for aircraft and spacecraft can be fabricated with high accuracy and minimal material waste. This precision is crucial in aerospace engineering, where even the smallest discrepancy can lead to significant performance issues or safety risks. CNC routers enable the production of intricate parts, such as structural components, engine parts, and brackets, adhering to stringent specifications and tolerances. This precision not only enhances the performance and reliability of aerospace vehicles but also streamlines the manufacturing process, reducing lead times and costs.

In the defense and marine sectors, CNC routers for aluminum are indispensable for creating a wide range of critical components. For defense applications, the routers are employed to fabricate robust yet lightweight parts for military aircraft, vehicles, and weapons systems, ensuring that they can withstand harsh operational conditions while maintaining optimum performance. For the marine industry, CNC routers are used to manufacture components for boats, submarines, and offshore platforms, where corrosion resistance and durability are paramount. The ability to quickly and accurately produce custom parts on-demand enhances the versatility and responsiveness of these industries to emerging needs and challenges. Overall, the integration of CNC router technology in these sectors fosters innovation, boosts operational efficiency, and ensures the production of high-quality, reliable equipment.

In the automotive industry, CNC routers for aluminum have become indispensable tools due to their precision, efficiency, and adaptability. These high-speed machines facilitate the manufacturing of various automotive components such as engine blocks, transmission cases, and structural components. The high accuracy of CNC routers ensures that aluminum parts meet stringent tolerances, which is crucial for optimizing performance and safety. Additionally, CNC routers enable rapid prototyping, allowing automotive engineers to swiftly iterate and refine designs, thus shortening the development cycle. This is particularly advantageous for producing lightweight and durable parts that can help improve fuel efficiency and overall vehicle performance. Integration with computer-aided design (CAD) software further enhances these machines’ capability to deliver intricate and custom components, catering to the advanced requirements of modern automotive engineering.

In the electronics sector, CNC routers for aluminum play a vital role in the fabrication of enclosures, heat sinks, and circuitry boards. Aluminum’s excellent thermal conductivity and non-magnetic properties make it an ideal material for electronic applications. CNC routers can create intricate patterns and precise cuts required for high-performance heat sinks, ensuring optimal heat dissipation for sensitive electronic components. The precision offered by CNC routing machines is also crucial for fabricating custom aluminum enclosures that protect delicate electronics while providing a lightweight solution. These machines enable the mass production of complex products with consistent quality, ensuring reliability across large batches. Moreover, the CNC router’s automation capabilities enhance productivity and reduce manual labor, which is a considerable advantage when tackling large-scale electronic manufacturing requirements. The synergy of precision, speed, and adaptability in CNC routing continues to drive innovation and efficiency in the electronics industry.

A CNC router for aluminum has revolutionized the construction industry by significantly enhancing precision and efficiency in fabricating components and structures. Traditional methods of cutting and shaping aluminum are labor-intensive and prone to errors, leading to increased costs and extended project timelines. However, CNC routers leverage computer numerical control technology to achieve exact specifications consistently, allowing for the production of complex architectural elements, custom fixtures, and intricate facades. The ability to automate repetitive tasks not only boosts productivity but also ensures a higher degree of accuracy and quality control, which is crucial in construction where the margin for error is minimal. Moreover, these routers offer the flexibility to handle various aluminum grades, making them suitable for a broad spectrum of applications, from residential buildings to large-scale infrastructure projects.

In the energy sector, CNC routers for aluminum have found critical applications in the manufacturing of components for renewable energy systems, such as solar panels and wind turbines. Aluminum is favored for these applications due to its lightweight, durability, and excellent thermal conductivity. The precision of CNC routing ensures that each component is fabricated to exact tolerances, which is vital for the efficiency and longevity of energy systems. For instance, in the production of solar panel frames, CNC routers can precisely cut and shape aluminum to create robust and lightweight frames that can withstand environmental stresses while optimizing the panel’s exposure to sunlight. Similarly, in the wind energy sector, the routers are used to produce aerodynamic profiles for turbine blades, enhancing their efficiency in capturing wind energy. By streamlining the manufacturing process and ensuring high-quality outputs, CNC routers for aluminum play an integral role in advancing energy technologies towards a more sustainable future.

The industrial equipment industry has seen a transformative impact with the application of CNC routers for aluminum, bringing unprecedented precision, efficiency, and versatility to the manufacturing process. CNC (Computer Numerical Control) routers, controlled by pre-programmed software, allow for the automation of highly intricate cutting and shaping tasks on aluminum components, which are widely used in various sectors including automotive, aerospace, and consumer electronics. These routers facilitate the production of complex geometries and fine details that would be challenging and time-consuming to achieve with manual methods or conventional machining. By providing high-speed operations with consistent accuracy, CNC routers enhance both productivity and product quality, reducing the potential for human error and minimizing material waste. This level of precision and speed is particularly beneficial in industries requiring stringent dimensional tolerances and high-volume production runs.

Moreover, the adaptability of CNC routers for aluminum extends their utility across different scales of operation, from small-scale workshops to large industrial plants. They are capable of integrating seamlessly with other automated systems and advanced manufacturing technologies such as CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software, which streamlines the entire workflow from design to production. Businesses benefit from shorter lead times and the ability to quickly pivot to new design specifications or product iterations, which is crucial in today’s fast-paced market environments. Furthermore, the ability to produce custom, specialized parts on-demand helps companies meet specific client needs without the overhead associated with traditional tooling setups. Overall, the use of CNC routers for aluminum in the industrial equipment industry exemplifies the advancing synergy between cutting-edge technology and practical manufacturing solutions, fostering innovation, and maintaining competitive edges.

Computer Numerical Control (CNC) routers for aluminum have revolutionized the production of medical devices by enhancing precision, efficiency, and scalability. These advanced machines are capable of cutting, drilling, and shaping aluminum with remarkable accuracy, which is crucial in the manufacture of medical instruments and equipment. Aluminum is often chosen for medical applications due to its lightweight, non-toxic, and corrosion-resistant properties. The precision offered by CNC routers ensures that the intricate designs and tight tolerances required for medical devices such as surgical instruments, diagnostic equipment, and prosthetics are consistently met. This not only ensures the reliability and safety of the devices but also significantly reduces the time needed for production, enabling faster time-to-market for new innovations.

Moreover, CNC routers offer a high degree of repeatability, which is essential in the medical industry where standardization is critical. Each component fabricated using a CNC router adheres strictly to the required specifications, minimizing human error and ensuring uniformity across large production batches. This precision extends to custom medical solutions as well; for instance, CNC routers can quickly produce tailored prosthetic components to meet individual patient needs. Additionally, the versatility of CNC routers allows for quick adjustments in design and prototyping, facilitating rapid iterations and improvements. This adaptability is particularly beneficial in medical research and development settings, where new device prototypes need frequent alterations before final approval. In conclusion, CNC routers for aluminum are invaluable in manufacturing high-quality, reliable medical devices, combining precision engineering with the capability for mass production and customization.

CNC routers have revolutionized the machining and manufacturing of aluminum components, providing unmatched precision and efficiency. Unlike traditional manual routing, CNC (Computer Numerical Control) routers automate the cutting, shaping, and drilling processes, resulting in higher accuracy and reduced human error. This is particularly crucial when working with aluminum, a material known for its strength and low weight, which is extensively used in aerospace, automotive, and construction industries. By utilizing CAD (Computer-Aided Design) software, complex designs can be precisely replicated multiple times, ensuring consistency across production batches. Moreover, CNC routers can operate continuously, significantly increasing productivity and reducing lead times, making them indispensable in modern manufacturing environments.

In the realm of custom part production, CNC routers excel at producing intricate aluminum components that would be challenging or impossible to create with conventional methods. Their ability to execute detailed cuts and maintain tight tolerances allows for the production of high-performance parts required in sectors such as robotics, medical devices, and consumer electronics. Additionally, CNC routers support a variety of cutting tools and spindle speeds, enabling them to handle diverse aluminum alloys with ease. This versatility not only broadens the range of applications but also contributes to material conservation by optimizing cut paths and minimizing waste. Consequently, the use of CNC routers for aluminum machining not only enhances the quality and reliability of the final products but also promotes cost-effective and sustainable manufacturing practices.

Certainly! Here are some frequently asked questions (FAQs) with their answers regarding manufacturing CNC routers for aluminum quality work from SourcifyChina factory:

Q1: What materials are CNC routers from SourcifyChina designed to cut?

A1: SourcifyChina CNC routers are designed to cut a variety of materials, including aluminum, wood, plastics, and composites, with a specific focus on high-quality aluminum work.

Q2: How precise is the CNC router for aluminum work?

A2: Our CNC routers boast high precision with tolerance levels as tight as ±0.01 mm, ensuring excellent accuracy and high-quality finishes for aluminum projects.

Q3: What spindle power is best for cutting aluminum?

A3: For aluminum, we recommend a spindle power of at least 5.5 kW. Our CNC routers come equipped with high-power spindles to easily handle cutting aluminum.

Q4: How fast can the CNC router cut aluminum?

A4: The cutting speed can vary based on the specific router model and the complexity of the job, but generally, our CNC routers can cut aluminum at speeds up to 10,000 mm/min.

Q5: Do you offer customized CNC router solutions?

A5: Yes, SourcifyChina offers customized CNC router solutions tailored to your specific needs and applications, ensuring optimal performance for your unique aluminum cutting requirements.

Q6: What kind of technical support and training do you provide?

A6: We offer comprehensive technical support, including installation, maintenance, and troubleshooting. Additionally, we provide training sessions to ensure your team can operate the CNC router efficiently.

Q7: How durable are SourcifyChina CNC routers?

A7: Our CNC routers are built with high-quality components that ensure robustness and long-term durability, even under continuous use.

Q8: What safety features do your CNC routers include?

A8: Our CNC routers come with multiple safety features such as emergency stop buttons, protective enclosures, and automatic shutdown systems to ensure operator safety.

Q9: What is the delivery time for a CNC router from SourcifyChina?

A9: Delivery times vary based on the specific order and customization requirements, but typically, it takes about 6-8 weeks for production and delivery.

Q10: Can I visit the SourcifyChina factory to see the manufacturing process?

Choosing the right CNC router for aluminum manufacturing from SourcifyChina factory requires careful consideration of key factors to ensure optimal performance and quality. Here are some tips to help you make an informed decision:

1. Machine Rigidity: Aluminum machining demands robust machines. Ensure the CNC router has a strong, stable frame, preferably made of cast iron or steel, to minimize vibrations and maintain precision.

2. Spindle Power: Aluminum requires a powerful spindle to maintain cutting efficiency and surface finish. Look for a spindle with at least 3-5 kW power and high RPM capabilities for effective milling.

3. Cooling System: Aluminum machining generates considerable heat. A good CNC router should include a misting or flood coolant system to keep the cutting area cool, prevent tool wear, and ensure quality finishes.

4. Feed and Speeds: Verify that the router supports appropriate feed rates and can maintain stable speeds for aluminum cutting. Compatibility with high feed rates ensures faster and more efficient production.

5. Tooling Options: Choose a CNC router that accommodates a variety of cutting tools designed for aluminum, such as carbide end mills. Tool-changing capabilities can also enhance productivity.

6. Software Compatibility: Ensure the CNC router is compatible with advanced CAD/CAM software, which facilitates complex design and precise manufacturing processes.

7. Service and Support: SourcifyChina should offer robust after-sales service, including installation support, training, and maintenance. Verify their commitment to customer service before finalizing the purchase.

8. Customization: Factories like SourcifyChina often provide customization tailored to specific requirements. Discuss your production needs to see if custom builds or adjustments are necessary.

9. Reviews and References: Check reviews or ask for references from current users who have experience with SourcifyChina’s CNC routers. This feedback can provide insights into the machine’s long-term performance and reliability.

10. Cost and ROI: Evaluate the balance between cost and features to ensure a good return on investment (ROI). High-quality, durable machines might have higher upfront costs but offer better productivity and longer lifespan.

By focusing on these factors, you will find a CNC router from SourcifyChina that meets your aluminum manufacturing needs efficiently and effectively.

Sure! Here is a list of FAQs for sourcing a CNC router for aluminum from SourcifyChina factory:

Q1: How do I request a quote for a CNC router from SourcifyChina?

A1: To request a quote, visit the SourcifyChina website and fill out the inquiry form with your specific requirements. You can also contact their customer service directly via email or phone.

Q2: What is the lead time for production and delivery?

A2: The lead time can vary depending on the complexity and customization of the CNC router. Typically, it ranges from 4 to 8 weeks for production, plus additional shipping time depending on your location.

Q3: Are there customization options available for the CNC routers?

A3: Yes, SourcifyChina offers various customization options to meet your specific needs, including size, spindle power, and additional features. Be sure to mention your requirements when requesting a quote.

Q4: What kind of warranty do you provide on CNC routers?

A4: SourcifyChina provides a standard one-year warranty covering parts and labor. Extended warranties may be available upon request; make sure to inquire about this when discussing your purchase.

Q5: Do you offer technical support and training on how to use the CNC router?

A5: Yes, SourcifyChina offers comprehensive technical support and training either online or on-site (depending on location and availability), to help you set up and operate your CNC router efficiently.

Q6: Can I visit the factory for an inspection before placing an order?

A6: Absolutely. SourcifyChina encourages factory visits for inspections. You can schedule an appointment by contacting their customer service. Virtual tours may also be available.

Q7: What payment methods are accepted by SourcifyChina?

A7: They accept major payment methods such as bank transfer (T/T), Letter of Credit (L/C), and potentially other methods depending on your agreement.

Q8: Are spare parts readily available for maintenance?

A8: Yes, SourcifyChina maintains a stock of commonly used spare parts and can promptly supply them for maintenance and repairs.

Q9: Is there a minimum order quantity (MOQ) required for CNC routers?

A9: Generally, there is no strict MOQ for CNC routers, but it’s best to confirm your specific order requirements with the sales team.

Q10: How is the CNC router packaged for shipping?

Sourcing a CNC router for aluminum from a SourcifyChina factory involves several steps to ensure you get a high-quality product that meets your needs. Follow these tips to streamline the process:

1. Define Requirements: Determine the specifications you need—such as power, spindle speed, work area size, and software compatibility. Having clear requirements will help you communicate effectively with suppliers.

2. Use SourcifyChina’s Platform: Register on SourcifyChina’s website if you haven’t already. Utilize their search and filter functions to identify manufacturers that specialize in CNC routers for aluminum.

3. Verify Manufacturers: Check for certifications like ISO 9001 and reviews from other buyers. Reliable factories will often have these certifications and a track record of positive feedback.

4. Request Quotes: Contact multiple suppliers listed on SourcifyChina. Provide them with a detailed request for quote (RFQ) that includes your specifications and any additional requirements such as shipping terms and lead times.

5. Compare Offers: Evaluate quotes based on price, quality, and lead time. Don’t just go for the cheapest option; consider the value you are getting for the price.

6. Ask for Samples: Before placing a bulk order, request a sample to evaluate the machine’s build quality and performance. This step is crucial for verifying that the machine meets your standards for machining aluminum.

7. Conduct Due Diligence: Perform background checks on the factory. Verify their business license and check for any red flags in company reviews or business history.

8. Discuss Warranty and Support: Ensure you understand the warranty terms and what kind of after-sales support is available. Good customer support is invaluable for troubleshooting and maintenance.

9. Finalize Order: Once you’re satisfied with the factory’s credentials and the sample quality, proceed to finalize the order. Make sure all terms are clearly documented in the contract.

10. Monitor Production: Stay in touch with the supplier throughout the production process. Request progress updates and photos to ensure everything is on track.

By following these steps, you’ll be well-equipped to source a reliable CNC router for aluminum from a SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.