Technology and Applications of cnc router for woodworking

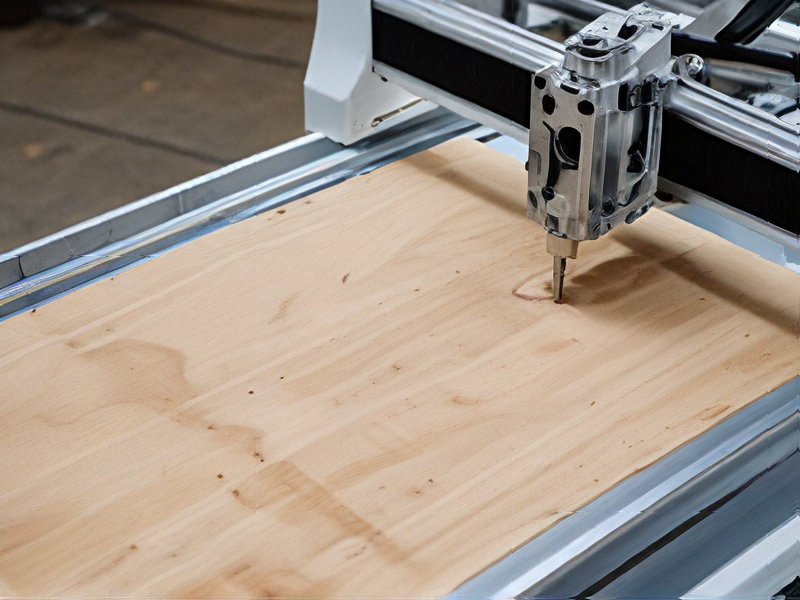

CNC routers have revolutionized woodworking, offering precision, efficiency, and versatility.

They utilize computer-aided design (CAD) files to automatically carve, shape, and route various materials like wood, MDF, acrylic, and composites.

Applications in Woodworking:

* Custom Furniture: Create intricate designs, personalized details, and complex shapes for unique furniture pieces.

* Cabinet Making: Produce precise, perfectly matched cabinetry with smooth edges and accurate joinery.

* Molding and Trim: Cut and shape moldings, door frames, and decorative trim with high accuracy and consistency.

* Sign Making: Engrave and cut lettering, logos, and designs on wood for signage and personalized gifts.

* Prototyping: Quickly and accurately produce wood prototypes for design testing and refinement.

CNC routers offer advantages like:

* Precision: Eliminate human error and achieve consistently accurate cuts.

* Efficiency: Automate repetitive tasks, saving time and labor costs.

* Versatility: Handle a wide range of materials and design complexities.

The ease of programming and the ability to produce intricate designs make CNC routers indispensable tools for modern woodworking.

Quality Testing Methods for cnc router for woodworking and how to control quality

Quality testing for CNC routers in woodworking involves verifying several key aspects:

Accuracy:

* Positioning: Use precision gauges to measure the router’s ability to consistently reach programmed coordinates.

* Cutting Depth: Verify the router cuts to the desired depth with minimal variance.

Repeatability:

* Cut Profile Consistency: Machine multiple identical parts to ensure consistent shape and dimensions.

Surface Finish:

* Roughness Measurement: Employ a surface roughness tester to evaluate the smoothness of machined surfaces.

* Visual Inspection: Examine finished parts for scratches, chipping, or other surface defects.

Control:

* Software Calibration: Regularly calibrate the CNC software to ensure accurate path generation and machine control.

* Tool Wear Monitoring: Track tool wear and replace worn tools promptly to maintain consistent cut quality.

Maintenance:

* Regular Inspections: Conduct routine inspections of mechanical components, bearings, and electrical systems to identify potential issues.

* Lubrication and Cleaning: Maintain proper lubrication and cleanliness to ensure smooth operation and prevent wear.

By implementing these testing methods and adherence to a strict maintenance schedule, woodworkers can ensure high-quality output from their CNC routers.

Tips for Procurement and Considerations when Purchasing from cnc router for woodworking

Purchasing a CNC router for woodworking requires careful consideration.

Here are some tips:

1. Define Your Needs:

Determine the types of projects you’ll undertake, the materials you’ll work with, and the required cutting area. This helps narrow down options.

2. CNC Type:

Choose between a desktop, stand-alone, or gantry-style router based on your workspace, budget, and project complexity.

3. Spindle Power:

Consider the material’s hardness and the type of cuts you’ll make. More powerful spindles handle denser woods and intricate designs better.

4. Cutting Area:

Ensure the cutting area is large enough to accommodate your typical projects.

5. Software Compatibility:

Check if the router works with design software you’re familiar with or plan to use.

6. Dust Collection:

Invest in a good dust collection system to maintain a clean workspace and protect your health.

7. Budget:

CNC routers range in price significantly. Set a realistic budget and prioritize features essential to your needs.

8. Reputation and Support:

Research reputable brands and consider their customer support, warranty, and availability of spare parts.

9. Training:

Seek training or resources to learn how to operate and maintain your CNC router effectively.

Remember, purchasing a CNC router is a substantial investment. Take your time, research thoroughly, and choose a machine that meets your specific woodworking requirements.

FAQs on Sourcing and Manufacturing from cnc router for woodworking in China

## FAQs on Sourcing and Manufacturing from CNC Router Woodworking Companies in China

1. What are my options for sourcing CNC router services in China?

You can choose from online platforms connecting you with manufacturers, industry directories, and attending trade shows focused on woodworking machinery and CNC technology.

2. What factors should I consider when selecting a manufacturer?

* Experience: Look for companies specializing in CNC woodworking and with a proven track record.

* Machine Capabilities: Ensure they have machines suitable for your projects’ size, materials, and complexity.

* Quality Control: Inquire about their quality assurance processes and certifications.

* Communication: Choose a manufacturer with effective English communication and responsiveness.

3. How can I ensure quality and accuracy in my CNC woodworking project?

* Detailed Drawings: Provide precise CAD files or detailed drawings with all specifications.

* Prototyping: Request prototypes or samples to verify quality and accuracy before bulk production.

* Quality Inspections: Conduct thorough inspections at different stages of production.

4. What are the typical lead times for CNC router woodworking projects?

Lead times vary depending on project complexity, order quantity, and manufacturer capacity. Typically, expect 2-6 weeks for production.

5. How do I handle shipping and logistics?

Most manufacturers offer shipping services, but you can also arrange your own. Consider factors like packaging, insurance, and import regulations.

Remember to establish clear communication, negotiate pricing, and secure contracts before commencing production.