Reliable

SourcifyChina: Revolutionizing Factory CNC Technology for Precision and Efficiency

Discover how SourcifyChina leverages advanced CNC technology to enhance manufacturing precision and efficiency. This reliable source showcases innovations in factory automation and quality control, transforming industrial production standards.

SourcifyChina Factory stands out as a leading supplier for buyers seeking CNC technology from China. Renowned for their high-quality products, they continuously meet stringent global standards and ensure reliability in every purchase.

One of the distinct advantages is their experienced team, which offers expert guidance throughout the buying process. This ensures that buyers obtain the most suitable CNC technology tailored to their specific needs.

Additionally, SourcifyChina excels in providing competitive pricing without compromising on quality. Their strong network in the manufacturing industry allows them to negotiate the best deals, translating into substantial savings for buyers.

Their exceptional customer service is another critical reason to choose SourcifyChina. They offer responsive and personalized support, addressing inquiries and resolving issues promptly to ensure a smooth purchasing experience.

Moreover, efficient logistics and timely delivery are guaranteed. SourcifyChina has established robust partnerships with top-tier shipping companies, ensuring that orders arrive promptly and in perfect condition.

In summary, choosing SourcifyChina Factory for purchasing CNC technology from China means gaining access to top-notch products, expert guidance, competitive pricing, excellent customer service, and reliable logistics.

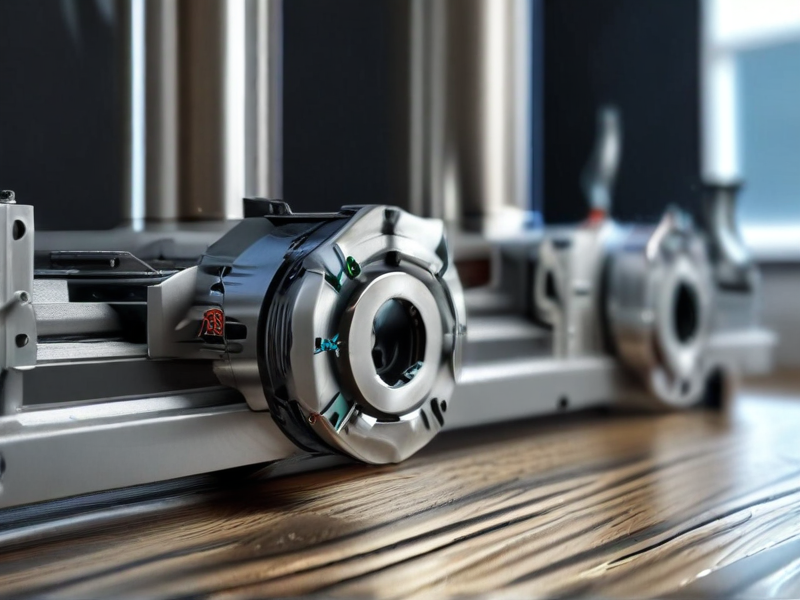

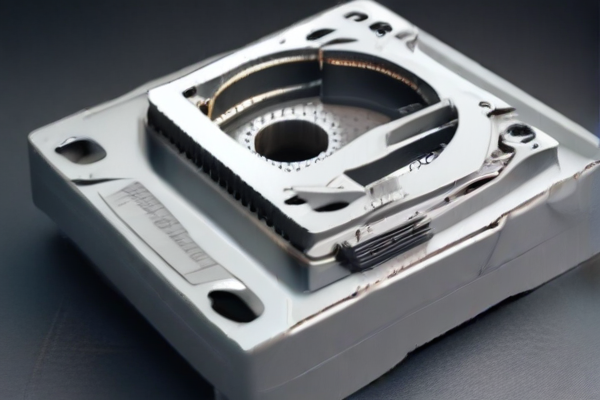

CNC (Computer Numerical Control) technology revolutionizes manufacturing with precision, automation, and versatility. Various CNC machines cater to different needs, enhancing productivity and accuracy in numerous industries.

– CNC Milling Machines: Used for cutting and drilling, providing high precision.

– CNC Lathes: Ideal for producing cylindrical parts, including screws and shafts.

– CNC Routers: Perfect for cutting soft materials like wood, plastic, and foam.

– CNC Plasma Cutters: Utilize a plasma torch to cut metals with high precision.

– CNC Laser Cutters: Offer high accuracy for cutting and engraving a variety of materials.

– CNC Grinders: Designed for precision grinding of metal components.

– CNC Electric Discharge Machines (EDM): Used for creating intricate shapes and fine details.

– CNC Drilling Machines: Specialized for precise and repetitive drilling operations.

– 5-Axis CNC Machines: Provide enhanced flexibility and capability to work on complex parts.

– CNC Water Jet Cutters: Utilize high-pressure water to cut a wide range of materials without heat damage.

CNC technology offers unparalleled precision, efficiency, and flexibility, making it indispensable in modern manufacturing. Each machine type addresses specific needs, allowing industries to achieve high-quality results and streamline production processes.

CNC technology, or Computer Numerical Control technology, is revolutionizing manufacturing by automating the control of machining tools through computers. This technology enables precise, consistent, and efficient production processes, suitable for a wide range of applications.

– Automotive Industry: CNC machines are used to produce parts like engines, gearboxes, and other intricate components with high precision.

– Aerospace Industry: CNC technology is crucial for crafting complex geometries in aircraft parts, ensuring safety and performance.

– Medical Field: Production of surgical instruments, prosthetics, and customized implants are made possible with high accuracy using CNC machining.

– Electronics: CNC machining aids in manufacturing components like circuit boards and electronic enclosures, ensuring precise tolerances.

– Furniture Manufacturing: Custom furniture and intricate designs are produced efficiently with the help of CNC routers.

– Jewelry Making: CNC machines allow for the detailed and precise crafting of intricate jewelry pieces.

– Prototyping: Rapid prototyping and small-scale production runs benefit greatly from the flexibility and precision of CNC technology.

– Tool and Die Making: The production of molds, dies, and tooling components is streamlined and made more accurate.

– Textile Industry: CNC technology is used in the cutting and detailing of fabrics for fashion and upholstery.

– Marine Industry: CNC machines produce components for boats and ships, including propellers and engine parts.

– Woodworking: Custom woodworks, carvings, and fixtures are produced with high precision using CNC routers and machines.

– Construction: CNC technology helps in producing formworks, construction parts, and even complex architectural elements.

– Signage: Custom signs and displays are manufactured with high detail and consistency using CNC machines.

– Agriculture: Production of agricultural machinery parts and tools is enhanced using CNC technology.

– Energy Sector: CNC machining is used in producing components for wind turbines, solar panels, and other energy infrastructure.

This range of applications showcases the versatility and essential role of CNC technology in modern production and manufacturing sectors.

SourcifyChina CNC technology primarily utilizes high-quality metals such as aluminum, stainless steel, and titanium in its precision machining processes. These materials are chosen for their durability, strength, and corrosion resistance, making them ideal for a wide range of industrial applications.

In addition to metals, SourcifyChina also works with advanced plastics and composites. These materials offer unique benefits like lightweight properties and chemical resistance, which are essential for specific sectors like aerospace and medical devices, where specialized performance is required.

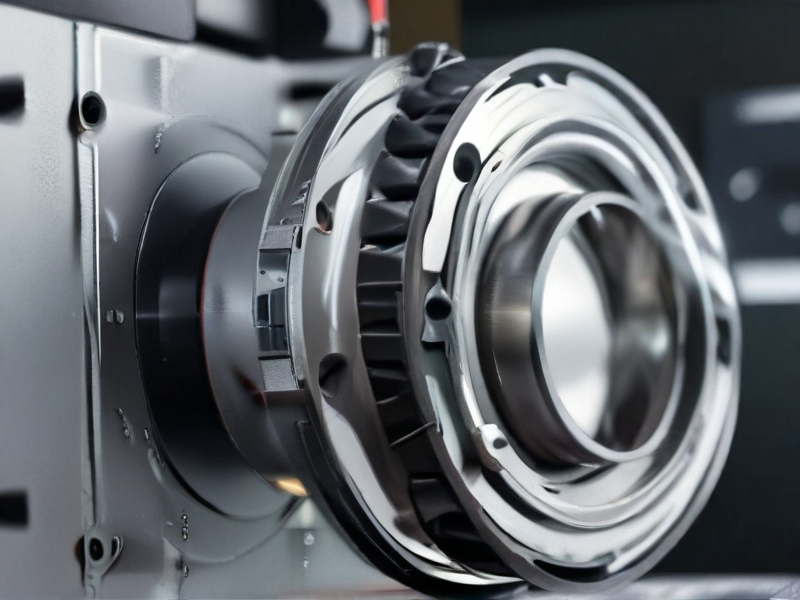

High precision and tight tolerances are achieved through the use of state-of-the-art CNC machines. This technology allows for intricate designs and consistent quality in mass production, ensuring that every component meets exact specifications and industry standards.

SourcifyChina’s commitment to sustainable practices is reflected in their material sourcing. They prioritize eco-friendly materials and processes, promoting environmental responsibility while delivering high-performance parts. This balance of quality and sustainability helps clients meet their own sustainability goals.

SourcifyChina employs cutting-edge CNC technology to ensure precision and consistency in manufacturing. Their state-of-the-art machinery allows for intricate designs and tight tolerances, ensuring high-quality outputs for diverse industrial needs.

Quality control is a cornerstone of SourcifyChina’s operations. They implement rigorous inspections at each production stage, utilizing advanced measurement tools and techniques to verify dimensions and surface finishes.

The company maintains strict adherence to international standards. By following ISO certifications and other industry benchmarks, they ensure products meet global quality requirements, fostering trust and reliability among clients.

Continuous improvement is a key focus. SourcifyChina invests in regular training for its workforce and upgrades to its CNC technology, keeping pace with the latest advancements. This commitment to excellence in quality control and manufacturing processes positions SourcifyChina as a leader in the CNC machining industry.

SourcifyChina is a leader in CNC technology, providing precise and efficient manufacturing solutions. Their advanced CNC machinery ensures high-quality, accurate production for a variety of industries, including automotive, aerospace, and electronics.

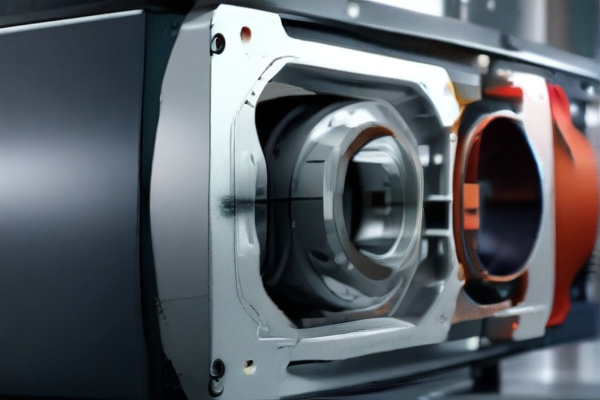

Their capabilities include multi-axis machining, which allows for the creation of complex parts with tight tolerances. This level of precision reduces the need for additional processing, saving time and costs.

SourcifyChina also offers rapid prototyping, enabling quick turnaround times for product development. This service is crucial for companies looking to innovate and bring new products to market faster.

The company employs state-of-the-art CAD/CAM software, ensuring seamless design-to-production processes. This integration streamlines operations and enhances overall manufacturing efficiency.

In addition to machining, SourcifyChina provides services like milling, turning, and grinding. Their comprehensive suite of capabilities makes them a one-stop shop for all CNC machining needs.

SourcifyChina is committed to quality, using rigorous inspection protocols to ensure every part meets stringent standards. Their dedication to excellence has earned them a reputation for reliability and precision.

Furthermore, SourcifyChina emphasizes sustainability by employing eco-friendly practices and reducing waste. Their commitment to the environment aligns with the growing demand for responsible manufacturing.

Overall, SourcifyChina’s CNC technology capabilities make them a top choice for businesses seeking high-quality, efficient, and innovative manufacturing solutions. Their comprehensive services, advanced machinery, and commitment to quality and sustainability set them apart in the competitive CNC machining industry.

CNC (Computer Numerical Control) technology has revolutionized modern manufacturing by enhancing precision, efficiency, and consistency. The integration of CNC machines in various industries offers substantial benefits.

– Enhanced Precision: CNC machines work with unparalleled accuracy, producing precise cuts and shapes consistently.

– Increased Productivity: Automation allows for continuous operation, maximizing output and reducing downtime.

– Consistency and Repeatability: High replication accuracy ensures uniform production, crucial for mass production industries.

– Reduced Human Error: Automated processes minimize the risk of mistakes, improving overall product quality.

– Flexibility: CNC machines can be reprogrammed quickly for different tasks, offering versatility in production.

– Efficient Use of Materials: Precision machining reduces waste, optimizing material usage and lowering costs.

– Improved Safety: Minimizing human involvement in hazardous tasks enhances workplace safety.

– Lower Long-term Costs: Despite high initial investment, CNC technology reduces labor costs and increases efficiency, leading to long-term savings.

Computer Numerical Control (CNC) technology revolutionizes manufacturing by automating precise control of machining tools using computer programming. This innovation brings several advantages to the industry.

– Precision and Accuracy: CNC machines execute operations with high precision, significantly reducing human error and ensuring consistent product quality.

– Efficiency and Speed: Automation speeds up production processes, minimizing manual intervention and enhancing throughput.

– Versatility: CNC technology can handle a variety of materials and complex designs, making it suitable for diverse manufacturing needs.

– Repeatability: It ensures consistent replication of designs, crucial for mass production.

– Safety: CNC machines enhance workplace safety by reducing direct human involvement in potentially hazardous processes.

– Cost-Effectiveness: Despite initial investment, CNC technology reduces labor costs and waste, leading to long-term savings.

– Flexibility: Easy reprogramming allows for quick adjustments to product designs, adapting to changing requirements without significant downtime.

– Integration with CAD/CAM: Seamless integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) software streamlines the design-to-production workflow.

SourcifyChina specializes in CNC technology, delivering high-precision custom products for diverse industries. Their advanced machinery ensures precise and consistent production, meeting exact specifications and maintaining high quality standards.

Their custom products range from intricate components to large-scale machinery parts, serving sectors like aerospace, automotive, and electronics. SourcifyChina’s expertise allows them to tackle complex projects with tailored solutions.

Their project management approach integrates design, prototyping, and manufacturing, ensuring seamless transitions from concept to completion. This holistic process minimizes errors and enhances efficiency.

Client satisfaction is paramount at SourcifyChina. By leveraging cutting-edge CNC technology and a dedicated team, they provide exceptional custom solutions, making them a trusted partner for manufacturing needs.

SourcifyChina CNC Technology is a leading industrial firm specializing in precision CNC (Computer Numerical Control) machining services and advanced manufacturing solutions. Established with a vision to revolutionize the manufacturing landscape, this company has quickly gained a reputation for its high-quality, reliable, and cost-effective production processes. SourcifyChina leverages state-of-the-art CNC technology to serve a diverse clientele across various industries, including aerospace, automotive, medical devices, and consumer electronics. By integrating rigorous quality control standards with cutting-edge machinery, the company ensures that each product meets stringent international specifications. Moreover, their expert team of engineers and technicians work collaboratively with clients from the initial design phase through to final production, enabling customized solutions tailored to specific requirements. This commitment to excellence, combined with strategic sourcing and logistics capabilities, positions SourcifyChina CNC Technology as a preferred partner for companies seeking to enhance their operational efficiencies and competitive edge in the global market.

Computer Numerical Control (CNC) technology has revolutionized the Aerospace, Defense, and Marine industries by providing a high level of precision and efficiency in manufacturing components. In aerospace, the demand for lightweight yet robust components is critical. CNC machines are capable of fabricating complex geometries and intricate designs from materials like aluminum, titanium, and advanced composites, ensuring high performance and reliability of aircraft parts. The accuracy of CNC machining significantly reduces waste and allows for tighter tolerances, which are essential for components subjected to the extreme stresses and environments encountered during flight. This technology supports the production of engine components, airframe structures, and intricate avionics parts with a high degree of repeatability and quality control.

In the Defense sector, CNC technology plays an instrumental role in the manufacturing of weapons systems, precision-guided munitions, and other defense-related equipment. The high precision of CNC machines is indispensable for producing parts that must meet stringent military specifications and operate reliably in harsh conditions. This ensures the effectiveness and safety of defense systems, from firearms to missile components. Similarly, the Marine industry benefits from CNC technology in the production of ship components, propulsion systems, and underwater exploration equipment. CNC machining allows for the creation of complex parts that can withstand the corrosive marine environment and the physical stresses of deep-sea operations. By enabling precise, efficient, and repeatable manufacturing processes, CNC technology enhances the performance and durability of vessels and marine equipment, contributing to safer and more efficient operations at sea.

CNC (Computer Numerical Control) technology plays a pivotal role in the automotive industry, enabling the precision manufacturing of complex components. In engine production, CNC machines are employed to craft parts such as cylinder heads, engine blocks, and transmission housings with exacting tolerances, ensuring optimal performance and reliability. The high precision of CNC technology allows for the creation of lightweight components, which are crucial for enhancing fuel efficiency and reducing emissions. Additionally, the automotive industry leverages CNC machining for prototyping new designs, allowing engineers to iterate quickly and bring innovations to market faster. This capability supports the development of advanced automotive technologies, including electric and autonomous vehicles, which require highly specialized and intricate parts.

In the electronics sector, CNC technology is indispensable for producing components with the high precision required in modern electronic devices. CNC machines are used to fabricate printed circuit boards (PCBs), which form the backbone of all electronic gadgets, from smartphones to medical devices. The technology allows for the precise drilling of holes and routing of conductive pathways, ensuring reliable performance and miniaturization of components. CNC machining is also critical in the manufacture of enclosures and heat sinks for electronic assemblies, providing robust and thermally efficient solutions. Moreover, the adaptability of CNC machines supports rapid prototyping and low-volume production runs, enabling electronics manufacturers to respond swiftly to market demands and technological advancements. This capability is essential for maintaining competitiveness in the fast-paced electronics industry.

CNC (Computer Numerical Control) technology has revolutionized the construction industry by enhancing precision, efficiency, and customization. In construction, CNC machines are used to fabricate components such as beams, columns, and panels with remarkable accuracy. This precision reduces material wastage and ensures that parts fit together perfectly, which is critical for large-scale projects. CNC technology also facilitates the creation of complex architectural designs and custom elements that would be difficult to achieve with traditional methods. Additionally, the automation of cutting, drilling, and milling processes speeds up production, lowers labor costs, and improves safety by reducing the need for manual handling of heavy and dangerous materials.

In the energy sector, CNC technology plays a crucial role in the manufacturing and maintenance of equipment used in power generation and distribution. For instance, CNC machines are essential for producing turbine blades, engine components, and other critical parts with high precision and consistency. This ensures optimal performance and longevity of energy systems. CNC technology is also pivotal in the fabrication of solar panels and wind turbine components, where precise cutting and assembly are required to maximize efficiency and reliability. Moreover, the ability to quickly produce custom parts using CNC machines supports the rapid prototyping and innovation needed to advance renewable energy technologies, contributing to a more sustainable energy future.

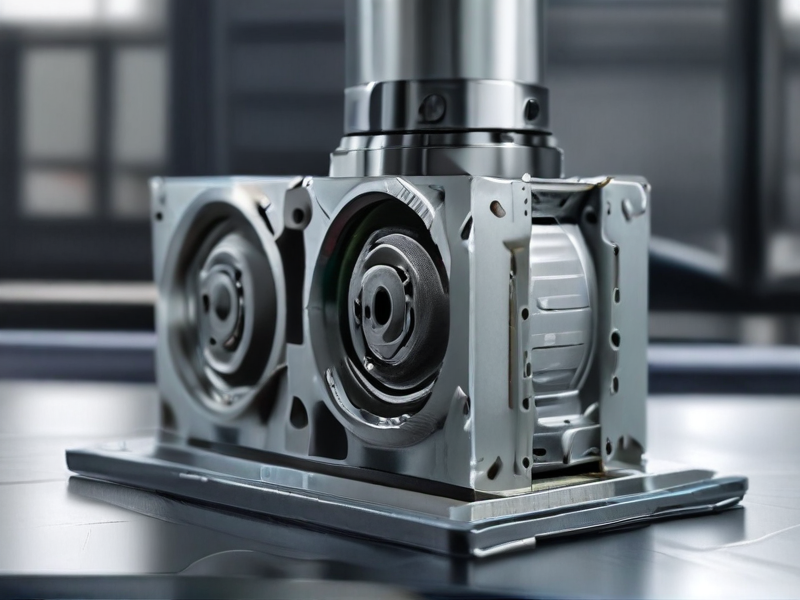

The industrial equipment industry has experienced a transformative shift with the integration of Computer Numerical Control (CNC) technology, substantially elevating both efficiency and precision in manufacturing processes. CNC allows for the automation of machine tools through the use of computers executing pre-programmed sequences of machine control commands. This technology has made it possible to produce complex parts with exceptional accuracy and repeatability, which is pivotal in industries where precision is critical, such as aerospace, automotive, and medical device manufacturing. With CNC, human error is significantly minimized, leading to higher quality and consistency in the production of industrial components. Additionally, CNC machines can operate continuously, facilitating high-volume production runs and thereby optimizing throughput.

Moreover, the application of CNC technology in the industrial equipment sector extends beyond mere manufacturing; it also encompasses customization and rapid prototyping. The agility of CNC machines allows for quick adjustments in production parameters, enabling manufacturers to swiftly respond to market demands and customer specifications. This is particularly beneficial in producing specialized machinery or parts required in industries such as oil and gas, mining, and renewable energy, where bespoke solutions are often necessary. Furthermore, the digitization of design and manufacturing processes through CNC technology fosters innovation by allowing engineers to experiment with new materials and designs with fewer constraints and risks. In summary, CNC technology has revolutionized the industrial equipment industry by enhancing precision, efficiency, and flexibility, thereby driving competitiveness and growth.

Computer Numerical Control (CNC) technology has revolutionized the manufacturing of medical devices, allowing for unprecedented precision, consistency, and efficiency. CNC machines are capable of producing extremely intricate components required for various medical applications, such as prosthetics, implants, and surgical instruments. These machines are programmed via software to execute highly detailed designs, ensuring that each part meets exact specifications. For medical devices, where even the smallest deviation can have significant consequences, CNC technology offers the reliability and precision necessary to meet stringent industry standards. This level of accuracy is crucial for the creation of custom implants tailored to individual patients, thereby enhancing the effectiveness of treatments and improving patient outcomes.

Moreover, CNC technology has streamlined the production process, reducing lead times and enabling faster innovation in the medical field. Traditional manufacturing methods often involved multiple manual steps, increasing the potential for errors and inconsistencies. In contrast, CNC machines can execute complex tasks in a single automated operation, significantly reducing human error and production time. This method also facilitates rapid prototyping, allowing medical device manufacturers to quickly develop and test new designs. As a result, advancements in medical technology can be brought to market more swiftly, accelerating the development of life-saving devices and treatments. Overall, the integration of CNC technology into the medical device industry has not only improved the quality and reliability of medical tools but has also driven innovation, ensuring that healthcare professionals have access to the most advanced and effective instruments available.

CNC (Computer Numerical Control) technology revolutionizes machining and manufacturing by automating the control of machine tools through computers. In machining, CNC technology ensures high precision, consistency, and efficiency. It allows the production of complex geometries that are difficult or impossible to achieve with manual machining. CNC machines can execute detailed and intricate designs with exact specifications repeatedly, reducing human error and waste. This technology is critical in industries such as aerospace, automotive, and medical device manufacturing, where precision is paramount. By using CAD (Computer-Aided Design) software to create digital designs, CNC machines can produce components with tight tolerances and exceptional surface finishes.

In the broader scope of manufacturing, CNC technology enhances productivity and scalability. It enables rapid prototyping and flexible production processes, allowing manufacturers to quickly adapt to design changes and market demands. CNC machines can operate continuously with minimal supervision, significantly increasing output and reducing labor costs. Moreover, CNC technology supports the integration of advanced manufacturing techniques, such as additive manufacturing and multi-axis machining, which further expand the capabilities and applications of manufacturing systems. By improving speed, accuracy, and adaptability, CNC technology plays a crucial role in advancing modern manufacturing, making it more efficient, reliable, and capable of meeting the stringent requirements of today’s industrial landscape.

FAQ:

CNC Technology Quality Work from SourcifyChina Factory

Q: What CNC technology does SourcifyChina use?

A: SourcifyChina utilizes advanced CNC machining technologies, including 3-axis, 4-axis, and 5-axis CNC machines. This ensures precision and efficiency in manufacturing complex parts.

Q: How does SourcifyChina ensure quality in CNC machining?

A: Quality is maintained through rigorous quality control processes. This includes in-process inspections, use of high-quality raw materials, and final product evaluations using advanced metrology tools like CMM (Coordinate Measuring Machines).

Q: What materials can be processed using CNC technology at SourcifyChina?

A: SourcifyChina can process a wide range of materials, including metals like aluminum, stainless steel, and titanium, as well as plastics such as ABS, POM, and PVC.

Q: Can SourcifyChina handle both low-volume and high-volume production?

A: Yes, SourcifyChina is equipped to manage both low-volume prototyping and high-volume production runs, offering flexibility to meet various customer needs.

Q: What industries does SourcifyChina serve with its CNC machining services?

A: SourcifyChina serves a diverse range of industries, including automotive, aerospace, medical devices, electronics, and consumer goods.

Q: How does SourcifyChina ensure timely delivery of CNC machined parts?

A: By optimizing production schedules and maintaining an efficient workflow, SourcifyChina ensures timely delivery. They also use advanced project management tools to track progress and meet deadlines.

Q: What certifications does SourcifyChina hold to guarantee quality?

A: SourcifyChina is ISO 9001:2015 certified, demonstrating their commitment to quality management systems and continuous improvement.

Q: Can SourcifyChina provide custom CNC machining solutions?

A: Yes, SourcifyChina offers custom CNC machining solutions tailored to specific requirements, including bespoke designs and complex geometries.

Q: How can I get a quote for CNC machining services from SourcifyChina?

A: You can obtain a quote by contacting their sales team through their website, providing details about your project requirements, and any specific tolerances or materials needed.

Q: Does SourcifyChina offer post-processing services?

A: Yes, SourcifyChina offers a variety of post-processing services, including anodizing, powder coating, and heat treatment, to meet specific finish and functional requirements.

When it comes to CNC (Computer Numerical Control) technology in manufacturing, SourcifyChina Factory offers some distinct advantages. Here are key insights and tips for leveraging CNC manufacturing from SourcifyChina:

1. Precision and Consistency: CNC technology ensures high precision and repeatability in manufacturing processes. SourcifyChina utilizes state-of-the-art CNC machines that can produce complex parts with tight tolerances, crucial for industries like aerospace, automotive, and medical devices.

2. Versatility: CNC machines at SourcifyChina can work with a wide range of materials, including metals (like aluminum, steel, and titanium) and plastics. This versatility allows for the production of diverse components across various industries.

3. Scalability: Whether you need a small batch of prototypes or large-scale production, SourcifyChina’s CNC capabilities can scale to meet your needs. Their facilities are equipped to handle both low-volume and high-volume production runs efficiently.

4. Cost-Effectiveness: CNC manufacturing reduces manual labor and minimizes waste, resulting in cost savings. SourcifyChina offers competitive pricing, particularly beneficial for businesses looking to outsource production while maintaining high quality.

5. Customization and Complexity: CNC technology supports complex designs and customization. SourcifyChina’s experienced engineers can assist in optimizing designs for CNC manufacturing, ensuring that even intricate parts are produced accurately.

6. Quality Assurance: SourcifyChina places a strong emphasis on quality control. Each CNC-machined part undergoes rigorous inspection to meet stringent quality standards, ensuring reliability and performance.

7. Rapid Turnaround: The automated nature of CNC machining allows for faster production cycles. SourcifyChina leverages this efficiency to provide quicker turnaround times, crucial for meeting tight deadlines and accelerating time-to-market.

8. Global Standards Compliance: SourcifyChina adheres to international manufacturing standards, making it a reliable partner for global clients seeking high-quality CNC-manufactured parts.

By partnering with SourcifyChina for CNC technology manufacturing, businesses can benefit from precision, versatility, and cost-effectiveness, all while ensuring high-quality outcomes and efficient production timelines.

Q: What types of CNC machines does SourcifyChina factory offer?

SourcifyChina factory provides a wide range of CNC machines including CNC milling machines, CNC lathes, CNC routers, and CNC plasma cutters. These machines cater to various industrial needs from precision parts manufacturing to large-scale production.

Q: Can I request custom CNC machine designs?

Yes, SourcifyChina offers customization services for CNC machines. You can specify your requirements, and the factory will work to design and produce a machine that meets your specific needs.

Q: What is the typical lead time for CNC machine orders?

The lead time varies depending on the complexity and customization of the CNC machine. Standard models typically have a lead time of 30-45 days, while customized machines might take longer, usually around 60-90 days.

Q: Does SourcifyChina factory provide installation and training services?

Yes, SourcifyChina offers comprehensive installation and training services. Technicians can be sent to your location to ensure proper installation and to train your staff on the operation and maintenance of the CNC machines.

Q: How does SourcifyChina ensure the quality of their CNC machines?

Quality assurance is a top priority at SourcifyChina. The factory implements stringent quality control measures, including multiple inspection stages and rigorous testing of each CNC machine before shipment.

Q: What are the payment terms for purchasing CNC machines from SourcifyChina?

The typical payment terms are 30% advance payment upon order confirmation and 70% balance before shipment. SourcifyChina also offers flexible payment options, which can be discussed during the negotiation phase.

Q: Can SourcifyChina handle large volume orders?

Yes, SourcifyChina is equipped to handle large volume orders. Their manufacturing capacity and scalable production processes ensure timely delivery of bulk orders without compromising quality.

Q: How can I get a quote for a CNC machine from SourcifyChina?

To get a quote, you can contact SourcifyChina directly via their website, email, or phone. Provide details about your requirements, and they will furnish a detailed quotation including pricing, lead time, and shipping costs.

Q: Are there warranties available for CNC machines purchased from SourcifyChina?

Yes, all CNC machines from SourcifyChina come with a warranty. The standard warranty period is one year, covering parts and labor. Extended warranties can also be arranged upon request.

Sourcing CNC technology from SourcifyChina factory can be a streamlined process if you follow these tips:

1. Define Your Needs:

Clearly specify the type of CNC machines or technology you require, including precision levels, materials, and specific functionalities.

2. Research Suppliers:

Utilize platforms like SourcifyChina to identify reputable suppliers. Check their credentials, certifications, and previous client reviews.

3. Request for Quotation (RFQ):

Send detailed RFQs to potential suppliers. Ensure that your requests are comprehensive, covering technical specifications, quantities, delivery schedules, and any special requirements.

4. Assess Capabilities:

Evaluate the technical capabilities of the factories. Ask about their experience with similar projects, machinery, and quality control processes.

5. Sample Testing:

Request samples or prototypes. Inspect these samples critically to verify that they meet your standards and specifications.

6. Quality Assurance:

Ensure the factory has robust quality assurance processes. Look for ISO certifications or other relevant quality standards.

7. Negotiate Terms:

Discuss and negotiate terms of payment, delivery timelines, and after-sales service. Ensure that there are clear agreements on these points to avoid misunderstandings.

8. Visit the Factory:

If possible, visit the factory in China. This allows you to see their operations firsthand and build relationships with the suppliers.

9. Logistics and Compliance:

Plan logistics carefully. Make sure that shipment, customs clearance, and compliance with local regulations are well-managed to avoid delays and additional costs.

10. Ongoing Communication:

Maintain clear and ongoing communication with the supplier throughout the process. Regular updates can help address any issues promptly.

11. Use Sourcing Agents:

Consider employing sourcing agents like SourcifyChina. They have local expertise and can manage many aspects of the sourcing process for you.

By following these steps, you can effectively source high-quality CNC technology from SourcifyChina and enhance your production capabilities.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.