Title: “Reliable CNC Tools from China: SourcifyChina Connects You with Top-Quality Factory Supplies”

Discover the best CNC tools from trusted Chinese factories with SourcifyChina. Ensure reliability, precision, and cost-effectiveness for your machining needs by sourcing your tools through a proven platform.

“SourcifyChina” offers seamless access to high-quality CNC tools from China. Their rigorous selection process ensures that only reputable manufacturers are chosen, providing buyers with a broad range of reliable products.

Efficient and transparent, SourcifyChina simplifies procurement. With a dedicated team, they facilitate communication, negotiate prices, and manage logistics, allowing buyers to focus on their core business.

By leveraging their expertise, SourcifyChina minimizes risks associated with overseas purchases. They handle quality inspections and compliance checks, ensuring that clients receive products that meet international standards.

Moreover, SourcifyChina’s strong relationships with top-tier Chinese factories translate to competitive prices without compromising quality. Buyers benefit from lower production costs, enhancing their overall profitability.

Customer service is a priority at SourcifyChina. Their support team is readily available to address any concerns, providing personalized assistance and ensuring a smooth purchasing experience from start to finish.

In essence, choosing SourcifyChina for purchasing CNC tools from China means partnering with a reliable, cost-effective, and expert sourcing agent. Their comprehensive services streamline the procurement process, guaranteeing quality products and complete customer satisfaction.

CNC tools are essential for precise and efficient machining processes. Various types cater to different functions like cutting, drilling, and milling. Options include end mills, drill bits, reamers, and more.

– End Mills: Versatile tools used for milling and profile cutting. Available in different shapes, sizes, and materials.

– Drill Bits: Designed for drilling holes in various materials. Options include twist drills, center drills, and step drills.

– Reamers: Used to enlarge, finish, and align drilled holes with high precision.

– Taps and Dies: Essential for creating internal and external threads. Available in various sizes and thread pitches.

– Inserts: Replaceable cutting edges for turning, milling, and drilling. Made from carbide, ceramics, or diamond.

– Boring Tools: Designed to enlarge or refine holes with high accuracy.

– Cutting Blades: Used for cutting and shaping materials. Range includes straight, serrated, and circular blades.

– Face Mills: Large tools used for flat surface milling, improving both roughing and finishing operations.

– Broaches: Used for precision shaping, forming, and cutting, especially useful in keyway and spline cutting.

– Carbide-Tipped Tools: Known for their durability and wear resistance, suitable for high-speed applications.

– Thread Mills: Used for creating threads in complex and hard-to-reach areas, promotional over taps in some applications.

– Grinding Wheels: Used for precision grinding and finishing.

– Fly Cutters: Employed for creating flat surfaces, less used but very efficient for certain applications.

– Keyseat Cutters: Specifically designed for slotting and keyway cutting.

CNC tool selection depends on the material being machined, the type of CNC machine, and the specific requirements of the operation.

CNC tools are instrumental in modern manufacturing processes, offering precision and efficiency in tasks such as cutting, drilling, and milling across diverse industries.

– Automotive Industry: Creating engine parts, body components, and custom modifications.

– Aerospace Sector: Crafting intricate aircraft parts with high precision.

– Medical Field: Producing surgical instruments, implants, and prosthetics.

– Electronics Manufacturing: Fabricating intricate PCB boards and components.

– Woodworking: Shaping and cutting wood for furniture and cabinetry.

– Metalworking: Making detailed parts for machinery and industrial purposes.

– Jewelry Making: Crafting intricate designs with precious metals and stones.

– Defense Industry: Manufacturing parts for weapons, vehicles, and other defense equipment.

– Prototyping: Quickly creating prototypes for testing and development.

– Custom Manufacturing: Producing tailor-made components for various applications.

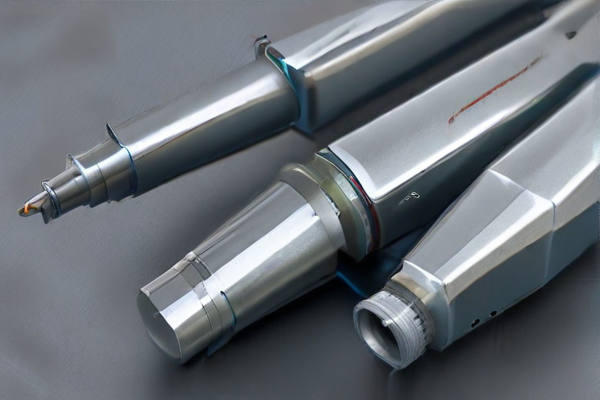

SourcifyChina CNC tools are renowned for their high-quality materials and precision engineering. This company specializes in producing an array of CNC tooling, from end mills to drill bits, tailored for various applications. Their materials range from high-speed steel (HSS) to carbide alloys, offering excellent durability and cutting performance.

HSS tools provide a good balance of toughness and cost-effectiveness, making them ideal for general-purpose machining. SourcifyChina refines this material to maximize its wear resistance and lifespan, ensuring consistent results in a variety of industrial settings.

For demanding applications, carbide tools from SourcifyChina are a preferred choice. These tools excel in high-speed and high-temperature operations, maintaining their cutting edge longer than HSS. Carbide’s hardness allows for faster material removal rates, increasing productivity while minimizing tool changeover.

Furthermore, SourcifyChina extends its expertise to coating technologies. Advanced coatings like titanium nitride (TiN) and aluminum titanium nitride (AlTiN) enhance tool performance by reducing friction and heat. These coatings significantly extend tool life and improve machining efficiency.

In conclusion, SourcifyChina stands out by offering CNC tools made from top-tier materials, from HSS to carbide, augmented with advanced coatings. Their commitment to quality and innovation in material selection ensures that customers receive durable, high-performance tools tailored to their specific machining needs.

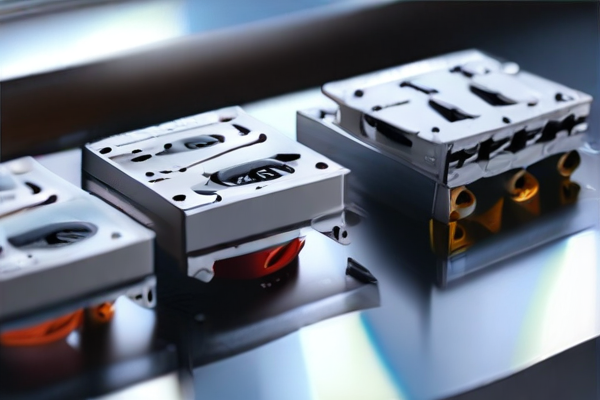

SourcifyChina CNC Tools employs a stringent quality control manufacturing process. Initially, raw materials are meticulously selected and tested to ensure they meet industry standards. This ensures the foundation of durable and reliable tools.

Subsequently, these materials undergo precise machining using state-of-the-art CNC equipment. Continuous monitoring during this phase helps maintain adherence to exact specifications, minimizing deviations and errors. Advanced software and skilled technicians work in tandem to optimize the machining process.

Post-machining, each tool is subjected to rigorous inspection procedures. Automated and manual checks confirm dimensional accuracy and surface finishes. This thorough vetting step guarantees each product meets high-quality standards before proceeding.

The final stage involves performance testing under simulated real-world conditions. This step verifies each tool’s reliability and durability, ensuring it can withstand varied operational demands. Tools that pass these tests are then packaged and prepared for shipment.

SourcifyChina prioritizes continual improvement through feedback and analysis. Customer feedback and performance data are regularly reviewed to refine processes and enhance product quality. This results in a consistent delivery of superior CNC tools to meet diverse market needs.

Ultimately, SourcifyChina’s stringent quality control process underscores their commitment to excellence. Consistent investment in advanced technology and skilled personnel ensures each CNC tool produced is of the highest quality, meeting and exceeding customer expectations.

SourcifyChina excels in providing top-notch CNC tools known for their exceptional precision and durability. They cater to various industries, including automotive, aerospace, and electronics, ensuring every project’s complexity is handled with expertise.

This company boasts a range of CNC equipment, from milling and turning tools to advanced multi-axis systems. Each tool is engineered to maintain high accuracy and efficiency, enhancing production processes and reducing downtime.

SourcifyChina’s commitment to quality is evident in their rigorous testing and inspection protocols. Every tool meets stringent international standards, ensuring clients receive reliable and consistent performance.

User-friendly design and innovative features characterize these CNC tools. Ergonomic interfaces and cutting-edge technology simplify operations, making them suitable for both seasoned professionals and newcomers in the CNC machining world.

Additionally, SourcifyChina offers excellent customer support and after-sales service. Their team of experts is always ready to assist with technical issues, providing swift resolutions to minimize operational disruptions.

By incorporating state-of-the-art technology and high-quality materials, SourcifyChina’s CNC tools represent a blend of reliability and performance. These tools empower businesses to achieve higher efficiency, precision, and productivity, ensuring they remain competitive in their respective markets.

Computer Numerical Control (CNC) tools offer significant advantages in manufacturing, including enhanced precision, improved efficiency, and reduced human error. These benefits make CNC tools essential in modern production environments.

– Enhanced Precision: CNC tools can perform highly intricate operations with exactness and repeatability, ensuring that each piece matches the design specifications perfectly.

– Increased Efficiency: Automation reduces the need for manual interventions, speeding up production processes and minimizing downtime.

– Consistency: CNC tools ensure that every product manufactured meets the same high standards, reducing variability and increasing overall product quality.

– Cost-Effectiveness: Though initial setup costs can be high, CNC tools eventually lower operational costs through reduced waste, fewer errors, and the need for less manual labor.

– Flexibility: CNC machines can be easily reprogrammed to produce different parts, making them ideal for short runs and custom manufacturing.

– Improved Safety: Operators interact less directly with machinery, reducing the risk of accidents and injuries.

– Scalability: CNC technology allows for easy scaling of production levels, accommodating fluctuations in demand without compromising on quality.

– Complex Task Execution: Capable of performing multiple, complex operations in a single setup, which would be difficult or impossible with conventional tools.

– Energy Efficient: Modern CNC machines are designed to be more energy-efficient, contributing to lower overall production costs.

– Data Integration: CNC systems can integrate with computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, streamlining the design-to-production workflow.

These benefits collectively make CNC tools indispensable in the landscape of contemporary manufacturing, offering a combination of precision, efficiency, and flexibility that traditional methods cannot match.

CNC (Computer Numerical Control) tools offer advanced machining capabilities, precision, and automation, contributing significantly to various manufacturing processes. Their features enhance productivity, reduce manual intervention, and improve the quality of the finished product.

– Precision and Accuracy: CNC tools provide high levels of precision and repeatability, ensuring consistent product quality.

– Automation: Capable of operating with minimal human intervention, which enhances efficiency and reduces labor costs.

– Complex Geometries: Ability to create intricate and complex shapes that would be difficult or impossible with manual machining.

– Programmable: Easily programmable using CAD/CAM software, allowing for quick adjustments and modifications.

– Multiple Axes: Advanced models can operate on multiple axes (such as 3, 4, or 5 axes), enabling complex and multi-directional machining.

– Tool Versatility: Can utilize various tools and attachments, making them suitable for multiple types of machining operations like drilling, milling, and turning.

– Material Versatility: Capable of working with a wide range of materials, including metals, plastics, and composites.

– High Speed and Efficiency: Enables high-speed machining, which significantly reduces production time.

– Safety Features: Equipped with advanced safety protocols and mechanisms to protect operators and the equipment.

– Remote Monitoring: Many modern CNC machines offer remote monitoring and diagnostics, enhancing maintenance efficiency.

– Energy Efficiency: Some models are designed to optimize energy consumption, contributing to cost savings and sustainability.

– Integrated Quality Control: Built-in quality control features such as automated measurement and defect detection improve the final product’s quality.

– Flexibility: Can quickly switch between different types of products or productions, enhancing flexibility and reducing setup time.

– Scalability: Suitable for both small-scale productions and large-scale manufacturing operations.

These features make CNC tools indispensable in modern manufacturing, optimizing processes, and ensuring high-quality output.

SourcifyChina specializes in providing high-quality CNC tools tailored to meet specific project needs. Their custom products are designed with precision to ensure optimal performance and durability for various industrial applications.

The company offers a wide range of CNC tools, including end mills, drills, and cutting inserts, crafted from premium materials. Each tool is engineered to deliver superior cutting efficiency and longevity, enhancing productivity.

SourcifyChina collaborates closely with clients to understand their unique requirements, ensuring the custom solutions are perfectly aligned with project goals. This personalized approach guarantees customer satisfaction and project success.

By leveraging advanced manufacturing technologies and rigorous quality control processes, SourcifyChina ensures that every custom CNC tool meets the highest standards. Their commitment to excellence drives innovation and reliability.

Overall, SourcifyChina’s custom CNC tools and project solutions stand out for their precision, durability, and tailored design, making them a trusted partner in the manufacturing industry. Their focus on client-specific needs ensures that each project achieves optimal results.

SourcifyChina CNC Tools is a premier provider of high-quality machining tools and solutions, enabling industries worldwide to achieve precision and efficiency in manufacturing processes. Based in China, the company leverages cutting-edge technology and a robust supply chain to offer a comprehensive range of CNC tooling products, including end mills, drills, inserts, and custom-made tools. SourcifyChina is dedicated to ensuring that their tools meet the stringent quality standards demanded by industries such as aerospace, automotive, and medical devices. They stand out by offering not only high-performance tools but also exceptional customer service, assisting clients with technical support and tailored solutions to optimize production. Their commitment to innovation and quality helps businesses streamline operations, reduce costs, and maintain a competitive edge in the global market. With a strong focus on research and development, SourcifyChina continues to push the boundaries of what’s possible in CNC tooling, establishing itself as a trusted partner in the manufacturing industry.

CNC (Computer Numerical Control) tools have revolutionized the Aerospace, Defense, and Marine industries by providing unprecedented precision, efficiency, and repeatability. In the aerospace sector, CNC machining plays a critical role in fabricating components such as turbine blades, airframes, and intricate engine parts. These components require exacting tolerances and superior surface finishes to ensure safety, performance, and fuel efficiency. Advanced CNC machines facilitate the simultaneous production of complex multi-axis parts from lightweight, high-strength materials such as titanium and composites, thereby reducing material waste and production time. The high degree of automation afforded by CNC technology minimizes human error and ensures consistency across large production runs, which is indispensable for meeting the stringent standards and certifications demanded in aerospace.

In the Defense and Marine sectors, CNC tools are equally transformative. Defense applications often deal with high-stakes components such as missile systems, armored vehicle parts, and firearm components, which require exceptional durability and precision. CNC machines enable the production of these critical components with outstanding accuracy, ensuring they meet the rigorous specifications necessary for operational effectiveness and safety. In the Marine industry, CNC machining is essential for creating robust, corrosion-resistant parts for ships and submarines, including engine components, propellers, and structural elements. The ability of CNC tools to work with a variety of materials, including exotic metals and specialized alloys, allows for the customization and optimization of parts that must withstand harsh marine environments. Overall, CNC tools enable these industries to achieve a higher standard of excellence, driving innovation and improving the reliability and performance of their critical applications.

Computer Numerical Control (CNC) tools have revolutionized the automotive industry by significantly improving precision, efficiency, and versatility in manufacturing processes. Automotive parts such as engine blocks, transmission cases, and intricate internal components require meticulously high levels of accuracy to ensure optimal performance and longevity. CNC machines, capable of executing complex instructions with minimal human intervention, streamline production and reduce the likelihood of human errors. This ensures a higher degree of uniformity and quality in mass-produced parts. Additionally, the use of CNC tools in prototyping enables automotive engineers to swiftly iterate and refine designs, expediting the development process for new car models and parts. CNC machining contributes to the automotive industry’s push towards automated production lines, paving the way for smart factories and Industry 4.0 advancements.

In the realm of electronics, CNC tools play a pivotal role in fabricating components such as printed circuit boards (PCBs), casings, and connectors. The miniature and intricate nature of electronic devices necessitates precision manufacturing to ensure functional reliability and compatibility. CNC machines are adept at handling delicate materials and can produce complex shapes and fine details which are essential for the compact designs prevalent in modern electronics. Moreover, the adaptability of CNC tools makes them an ideal choice for both high-volume production and small-scale custom electronics, such as prototypes and specialized equipment. The use of CNC machining aids in reducing material waste and accelerates the production cycle, enabling quicker time-to-market for electronic manufacturers. Thus, CNC technology not only enhances the quality and consistency of electronic components but also supports the fast-paced innovation cycle of the electronics industry.

CNC (Computer Numerical Control) tools have revolutionized the construction industry by enhancing precision, efficiency, and flexibility in various projects. In the context of construction, these tools are essential for creating high-precision components and complex structures, which are often required for modern architectural designs. CNC machines, including routers, milling machines, and plasma cutters, allow for the precise cutting, drilling, and shaping of materials like steel, aluminum, and wood. This precision minimizes material wastage and ensures that components fit perfectly, thereby accelerating the assembly process on-site. Furthermore, the automation capabilities of CNC tools minimize human error, reduce labor costs, and significantly shorten project timelines, leading to more cost-effective construction projects.

In the energy sector, CNC tools enable the production and maintenance of critical components used in various energy applications, such as wind turbines, solar panels, and nuclear reactors. The intricate parts required for these applications demand an exceptional level of precision and durability, which CNC machines can provide. For instance, the blades of wind turbines are often produced using CNC milling machines to achieve the aerodynamic efficiency crucial for energy generation. Similarly, the frames and supports for solar panels benefit from the precision cutting and drilling provided by CNC tools, ensuring optimal alignment and stability. Additionally, maintenance tasks, such as refurbishing turbine parts or producing replacement components, are expedited and made more reliable with CNC technology. By enhancing the manufacturing and upkeep of vital energy infrastructure, CNC tools play a significant role in improving efficiency and sustainability within the energy sector.

The industrial equipment industry has witnessed a significant transformation with the advent of computer numerical control (CNC) tools. CNC tools, which automate precise machining processes through computer programming, have revolutionized manufacturing by enhancing efficiency, accuracy, and repeatability. These tools are utilized in diverse applications, from producing intricate components for aerospace and automotive sectors to crafting large-scale machinery parts. By leveraging CNC technology, manufacturers can achieve complex geometries that would be challenging or impossible through traditional machining methods. The rigorous precision of CNC tools ensures that high-quality standards are consistently met, reducing material wastage and eliminating human error. This technological advancement has consequently optimized production cycles, leading to cost-effective operations and timely deliveries.

In addition to improving manufacturing processes, CNC tools have broadened the scope of design and customization in the industrial equipment sector. Engineers and designers can now rapidly prototype and iterate designs, leading to quicker innovations and advancements in machinery. The versatility of CNC machining allows for the production of both one-off bespoke parts and large batches of standardized components with equal ease. Moreover, the integration of CNC tools with computer-aided design (CAD) and computer-aided manufacturing (CAM) software facilitates seamless workflow automation, enhancing collaboration and operational efficiency. As a result, the industrial equipment industry not only benefits from heightened productivity but also from the ability to adapt swiftly to market demands and technological advancements. This integration underscores the pivotal role of CNC tools in driving forward the next generation of industrial manufacturing.

CNC (Computer Numerical Control) tools play a pivotal role in the medical device industry, transforming the landscape of modern healthcare with precision manufacturing. These tools enable the creation of complex, high-tolerance components that are essential for a variety of medical devices, including implants, prosthetics, surgical instruments, and diagnostic equipment. The ability to machine intricate geometries with micron-level accuracy ensures that parts are consistently reproducible, meeting the stringent quality standards required in medical applications. For instance, CNC machining allows for the production of custom prosthetic limbs that are tailored to each patient’s unique anatomical structure, enhancing both comfort and functionality. Additionally, CNC tools contribute to the development of minimally invasive surgical instruments, which are crucial for procedures that aim to reduce recovery times and improve patient outcomes.

Beyond the high precision and customization capabilities, CNC tools also offer significant benefits in terms of material compatibility and production efficiency. Medical devices often require biocompatible materials like titanium, stainless steel, and specialized polymers, which can be challenging to machine using conventional methods. CNC machining provides the versatility to work with these advanced materials while maintaining the required surface finishes and dimensional accuracy. The automation aspect of CNC tools also leads to higher production rates and consistent quality, which is critical in the high-demand healthcare sector. Moreover, the integration of advanced software in CNC systems facilitates rapid prototyping, allowing for quick iterations and adjustments during the development phase. This accelerates the innovation cycle for new medical devices, ultimately bringing life-saving technologies to market faster.

Computer Numerical Control (CNC) tools have revolutionized the machining and manufacturing industries by bringing a high level of precision, efficiency, and automation to the production process. In machining applications, CNC tools are employed to precisely cut, shape, and finish metal and other materials, often achieving complex geometries that would be difficult or impossible with traditional manual techniques. These tools are guided by computer programming languages, like G-code, which allow for precise control over the movement and operation of the machinery. This results in consistent and repeatable higher quality parts with minimal human error. CNC machining is widely used in producing components for a multitude of sectors such as aerospace, automotive, and medical devices, where precision and reliability are paramount.

In the broader manufacturing context, CNC tools enable mass production capabilities while maintaining flexibility in design and customizability. This adaptability allows manufacturers to quickly switch between producing different parts without significant downtime, making it ideal for both high-volume production runs and smaller batch orders. The automation aspect reduces labor costs and enhances production speed, thus offering better overall efficiency and cost-effectiveness. Furthermore, integration with other digital manufacturing technologies, such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems, ensures a seamless workflow from design to production. This integration not only accelerates the development process but also enables more complex and innovative product designs, pushing the boundaries of what’s possible in modern manufacturing.

Certainly! Here’s a list of FAQ with answers for manufacturing CNC tools quality work from SourcifyChina factory:

Q: What materials are used in your CNC tools?

A: Our CNC tools are made from high-grade materials such as tungsten carbide, high-speed steel (HSS), and various sophisticated alloys to ensure longevity and precision.

Q: How do you ensure the quality of your CNC tools?

A: We employ rigorous quality control procedures, including material inspection, dimensional accuracy checks, and performance testing. Additionally, our factory is ISO 9001 certified, ensuring adherence to international quality standards.

Q: What industries do you serve?

A: We cater to a wide range of industries including aerospace, automotive, medical, electronics, and general manufacturing that require precision machining.

Q: Can you produce custom CNC tools?

A: Yes, we offer custom manufacturing services where clients can specify dimensions, materials, and coatings. Our team works closely with you to meet your exact specifications.

Q: What is your production capacity?

A: Our factory is equipped with advanced machinery and skilled personnel, allowing us to handle both small-scale and large-scale orders efficiently.

Q: Do you offer any guarantees or warranties?

A: Yes, we provide a warranty on our CNC tools against manufacturing defects. The duration of the warranty may vary depending on the type of tool and its intended use.

Q: How long does it take to fulfill an order?

A: Lead times depend on the complexity and quantity of the order. Typically, standard orders are delivered within 2-4 weeks, while custom orders may take longer.

Q: What are your payment terms?

A: We accept various payment methods including wire transfer, credit card, and L/C. Payment terms are usually discussed during the quotation phase.

Q: Can you ship internationally?

A: Yes, we have extensive experience in exporting our products worldwide. We handle all shipping logistics to ensure your order arrives safely and on time.

Q: What makes SourcifyChina different from other manufacturers?

A: Our emphasis on quality, customization, and customer satisfaction sets us apart. We leverage state-of-the-art technology and experienced engineers to produce top-notch CNC tools.

Manufacturing CNC (Computer Numerical Control) tools at SourcifyChina factory can be a seamless process with the right approach and understanding. Here are some tips to ensure high-quality production:

1. Partner Selection: Choose SourcifyChina for their expertise in CNC tool manufacturing. Their vast experience ensures precision and reliability.

2. Material Quality: Use high-grade materials such as tungsten carbide, high-speed steel (HSS), and ceramic to ensure durability and performance.

3. Design Precision: Provide detailed CAD designs and specifications. Precise drawings minimize errors and ensure the tools meet your exact requirements.

4. Prototype Testing: Before mass production, create prototypes to test the designs. This allows for adjustments and ensures the final product meets quality standards.

5. Advanced Machinery: SourcifyChina utilizes state-of-the-art CNC machines. Be aware of their machinery capabilities to leverage the best technology.

6. Process Optimization: Collaborate with the factory’s engineers to optimize manufacturing processes. Efficient processes reduce costs and production time.

7. Quality Control: Implement stringent quality control measures. Inspect tools at various production stages to detect and rectify any imperfections early.

8. Communication: Maintain clear and constant communication with SourcifyChina’s team. This ensures your specifications are understood and followed precisely.

9. Volume Considerations: Determine the production volume. Bulk orders may qualify for discounts, but ensure the factory can handle the quantity without compromising quality.

10. Lead Time Management: Discuss and manage lead times effectively. Understanding the factory’s schedule helps in planning your supply chain efficiently.

11. After-Sales Support: Enquire about after-sales support and warranties. Reliable post-production services can address any issues that arise with the tools after delivery.

Following these tips can help you achieve optimal results while leveraging SourcifyChina’s capabilities in CNC tool manufacturing.

Sure, here is a concise FAQ for sourcing CNC tools from SourcifyChina factory:

1. What types of CNC tools does SourcifyChina factory offer?

SourcifyChina offers a wide range of CNC tools including milling cutters, drill bits, boring heads, and end mills. They also provide custom-made tools tailored to specific requirements.

2. How can I request a quote for CNC tools from SourcifyChina?

You can request a quote by visiting their website and filling out the inquiry form. Additionally, you can contact their sales team directly via email or phone for a more personalized service.

3. Is there a minimum order quantity (MOQ) for CNC tools at SourcifyChina?

Yes, the MOQ varies depending on the type of tool and specific customization needs. It is best to inquire directly with their sales team to get clear information based on your requirements.

4. What is the lead time for CNC tool orders?

The standard lead time ranges from 2 to 4 weeks, depending on the order size and complexity. For urgent orders, SourcifyChina offers expedited services.

5. Are samples available before placing a bulk order?

Yes, SourcifyChina provides sample CNC tools upon request. It’s a great way to assess the quality and conformity of the tools before committing to a larger order.

6. Do they provide international shipping services?

Yes, SourcifyChina ships CNC tools globally. They partner with reputable logistics companies to ensure timely and safe delivery.

7. What payment methods are accepted?

SourcifyChina accepts various payment methods including bank transfers, PayPal, and major credit cards. Specific payment terms can be discussed with their finance team.

8. How does SourcifyChina ensure the quality of their CNC tools?

SourcifyChina has a stringent quality control process that includes material inspection, dimensional accuracy checks, and performance testing to ensure all tools meet high standards.

9. Can I track my order once it has been shipped?

Yes, once your order is shipped, you will receive a tracking number and can follow the shipment through the logistics partner’s tracking portal.

10. What kind of customer support can I expect?

SourcifyChina offers comprehensive customer support, including pre-sale consultations, order updates, and post-sale assistance. Their support team is available via email, phone, and live chat.

These FAQs should help streamline the process of sourcing CNC tools from SourcifyChina factory.

Sourcing CNC tools from SourcifyChina factory can be streamlined by following these targeted tips:

1. Define Needs Clearly: Specify your exact requirements – tool types, materials, precision levels, and quantities. Detailed clarity prevents misunderstandings.

2. Research the Supplier: Verify SourcifyChina’s credentials and reliability. Check their certifications, customer reviews, and quality control measures.

3. Request Samples: Obtain samples of CNC tools to inspect quality and confirm they meet your standards before committing to a full order.

4. Compare Quotes: Gather quotes from SourcifyChina and other suppliers. Ensure you understand pricing structures, including any hidden fees or additional costs.

5. Evaluate Communication: Assess the responsiveness and language proficiency of their sales team. Effective communication is crucial for smooth transactions.

6. Inspect Manufacturing Capabilities: If possible, visit the factory or request a virtual tour. This shows the scale of operations and commitment to quality.

7. Negotiate Terms: Discuss payment terms, delivery schedules, and return policies to ensure they align with your business needs.

8. Check Logistics: Clarify shipping costs, delivery times, and customs regulations. Choose the best shipment method suited for your location and urgency.

9. Secure Agreement: Draft a clear contract outlining specifications, lead times, costs, and terms to safeguard both parties.

10. Ongoing Relationship: Build a long-term relationship with regular feedback loops to ensure consistent quality and service.

Following these tips will help ensure a smooth sourcing process with SourcifyChina for your CNC tool needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.