Selecting SourcifyChina Factory for purchasing CNC water jet cutting machines from China ensures top-quality products and advanced technology. Renowned for precision and durability, their machinery meets diverse customer needs.

SourcifyChina offers competitive pricing, making high-end CNC water jet cutting machines affordable. Their transparent pricing model and cost-effective solutions drive significant savings for buyers.

Customer satisfaction is a priority at SourcifyChina Factory. They provide comprehensive after-sales support and excellent customer service, ensuring your machinery remains in peak condition for years.

In addition to high standards, SourcifyChina boasts an efficient delivery system, promising timely and secure shipping. This reliability minimizes downtime and enhances production efficiency.

Choosing SourcifyChina Factory is a smart investment for any buyer seeking superior CNC water jet cutting machines, backed by professional support and reliable performance.

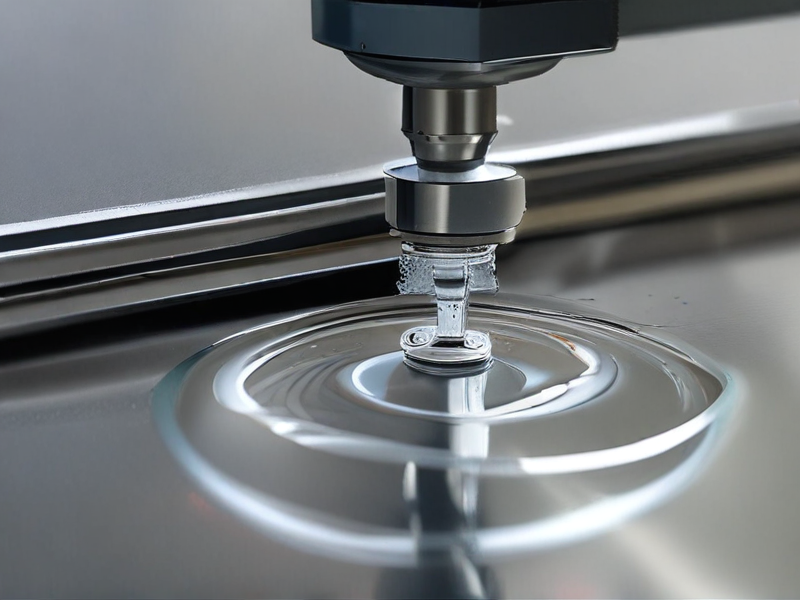

CNC water jet cutting is a versatile and precise method used to cut various materials using a high-pressure water jet. The process can be enhanced by adding abrasive particles for cutting harder substances.

Types of CNC Water Jet Cutting:

– Pure Water Jet Cutting

– Abrasive Water Jet Cutting

Options for CNC Water Jet Cutting:

– Pump Types:

– Direct Drive Pumps

– Intensifier Pumps

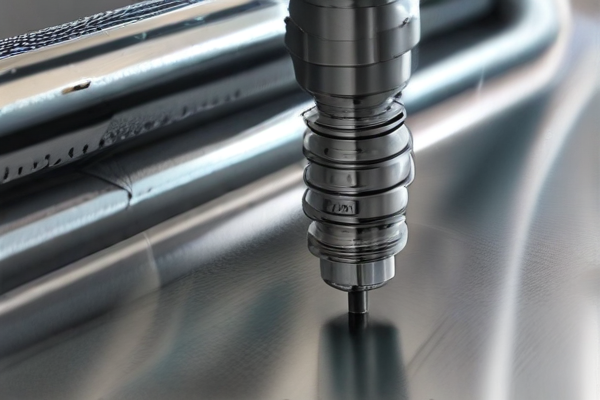

– Cutting Heads:

– Standard Cutting Head

– Abrasive Cutting Head

– Materials:

– Metals (steel, aluminum)

– Stone (marble, granite)

– Plastics

– Glass

– Composites

– Applications:

– Precision Engineering

– Aerospace

– Automotive

– Architectural

– Art and Design

– Speed and Efficiency Controls:

– Variable Speed Settings

– Automated Adjustments

– Software Integration:

– CAD/CAM Software Compatibility

– Real-time Monitoring and Adjustments

CNC water jet cutting provides numerous customizable options to suit specific needs in various industries, offering unparalleled precision and versatility in material processing.

CNC water jet cutting is a versatile fabrication method used to cut various materials with high precision using a high-pressure stream of water mixed with abrasive particles.

Applications for CNC water jet cutting include:

– Custom automotive parts

– Aerospace components

– Architectural designs

– Metal fabrication

– Glass cutting

– Stone and tile work

– Composite materials

– Gasket production

– Prototype development

– Electronics enclosures

– Medical instruments

– Signage and artwork

– Industrial machinery parts

– Food processing equipment

– Marine parts and accessories

– Textile and leather cutting

– Educational projects

– Sporting goods

– Energy and utility tools

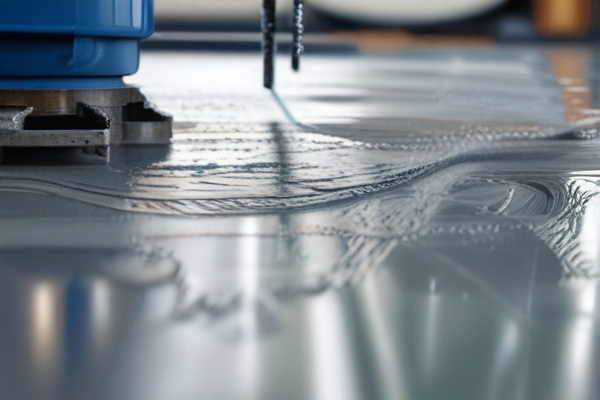

SourcifyChina’s CNC water jet cutting utilizes a fine jet of water, often combined with abrasive materials, to cut through a wide variety of materials with precision. This method is known for its high accuracy and ability to produce complex shapes.

Materials commonly cut using this technique include metals like aluminum, steel, and titanium, as well as non-metals such as glass, ceramics, and composites. The versatility of water jet cutting makes it suitable for both industrial applications and intricate artistic designs.

In addition to metal and non-metal materials, water jet cutting is also effective for softer substances like rubber, foam, and textiles. The cold cutting process ensures that there is no thermal distortion or material degradation.

Furthermore, materials like stone, granite, and marble are also frequently processed using CNC water jet cutting. This method preserves the integrity and aesthetic qualities of the material, making it ideal for architectural and decorative purposes.

SourcifyChina ensures the highest quality cuts by utilizing advanced CNC technology and skilled operators. Their commitment to precision and efficiency makes them a trusted partner for industries ranging from aerospace to custom manufacturing.

SourcifyChina’s CNC water jet cutting quality control process begins with meticulous material selection. Only high-grade, certified raw materials are used to ensure optimal performance and durability. This foundational step minimizes quality issues down the line.

Before initiating the cutting process, the engineering team conducts thorough CAD/CAM design verifications. These checks ensure precision and compliance with client specifications, reducing the likelihood of defects during production.

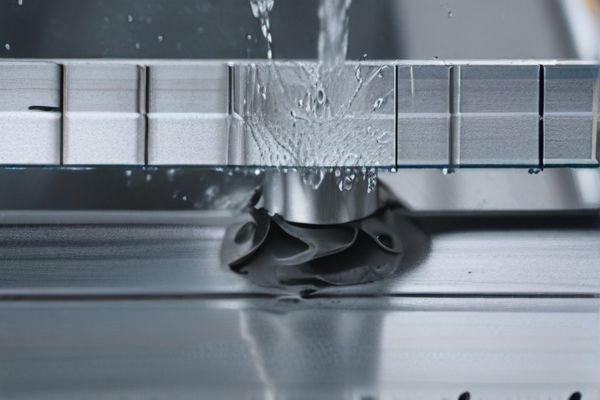

State-of-the-art CNC water jet cutters are employed for the actual cutting, minimizing material stress and thermal deformation. This advanced machinery guarantees tight tolerances and pristine edges, essential for high-quality output.

Post-cutting, each piece undergoes a rigorous inspection, including dimensional checks and surface finish assessments. Automated and manual inspections catch any deviations, ensuring each component meets stringent quality benchmarks.

Final quality control includes functional tests and trials, especially for parts with critical applications. These tests validate that the components perform reliably under specified conditions, reassuring end-user satisfaction.

By investing in robust quality control measures at every stage, SourcifyChina ensures that its CNC water jet cutting services deliver exceptional precision and reliability. The outcome is a higher degree of client trust and long-lasting business relationships.

SourcifyChina’s CNC water jet cutting capabilities are renowned for their precision and versatility. Utilizing advanced technology, their systems can create intricate designs on a variety of materials, including metal, glass, stone, and composites.

This cutting method is particularly advantageous as it maintains the structural integrity of materials by eliminating heat-affected zones. The cold-cutting process ensures no warping or discoloration, which is vital for high-quality outputs in industrial and creative applications.

The CNC water jet cutting services offered by SourcifyChina also boast exceptional accuracy, with tolerances as tight as ±0.001 inches. This precision is crucial for industries such as aerospace, automotive, and electronics, where even the smallest deviation can result in significant issues.

Moreover, SourcifyChina’s technology provides an eco-friendly cutting solution. The water jet cutting process uses only water and abrasive materials, producing no hazardous fumes and reducing the environmental footprint.

Clients benefit from the company’s ability to handle both small-batch and large-scale production runs efficiently. The flexibility to switch quickly between different projects ensures prompt delivery times and cost-effective solutions.

In addition to the technical advantages, SourcifyChina offers excellent customer service. Clients can rely on thorough consultations and tailored approaches to meet specific project requirements.

In summary, SourcifyChina’s CNC water jet cutting capabilities combine precision, versatility, eco-friendliness, and superior customer service, making them a leader in the manufacturing and cutting industry. Their technology and expertise enable businesses to achieve high-quality results, ensuring strategic advantages in various competitive markets.

CNC water jet cutting is a highly versatile and efficient machining process that offers numerous benefits across various industries. It allows for precision cutting of nearly any material without generating heat or mechanical stress.

– Versatility: Can cut virtually any material, including metal, stone, glass, and composites.

– Precision: Achieves tight tolerances and intricate designs with a smooth finish.

– No Heat-Affected Zone (HAZ): Eliminates the need for secondary operations as there is no thermal distortion.

– Eco-Friendly: Uses water and abrasive materials that can often be recycled.

– Minimal Material Waste: Reduces waste with its precise cutting capability, leading to cost savings.

– Safety: Low risk of fire hazards since it doesn’t generate heat or sparks.

– Quick Setup: Reduces production time with fast initial setup and programming.

– No Tool Wear: Uses a high-pressure water stream rather than a physical cutting tool, resulting in longer-lasting equipment.

CNC water jet cutting offers precise and versatile material processing without the thermal distortion seen in traditional cutting methods. It’s suitable for a wide range of materials such as metals, stone, and glass.

– Precision Cutting: Achieves high tolerances, often within ±0.005 inches, suitable for intricate designs.

– Versatility: Cuts a variety of materials including metals, composites, stone, glass, and plastics, with thicknesses up to several inches.

– No Heat Affect Zone (HAZ): Unlike laser cutting, it avoids thermal distortion and material warping.

– Eco-Friendly: Uses water and abrasive materials like garnet, which are non-toxic and recyclable.

– Minimal Material Waste: Narrow kerf width and efficient nesting reduce scrap material and optimize resource usage.

– Complex Shapes: Capable of cutting complex geometric shapes and detailed patterns with ease.

– User-Friendly Software: Advanced CAD/CAM software ensures easy design input and precise control over cutting paths.

– Smooth Edges: Produces clean edges that often require no further finishing, saving time and costs.

– Multi-Head Configurations: Allows simultaneous cutting of multiple parts, boosting productivity.

– Non-Contact Process: Prevents mechanical stress on the material, ideal for delicate and brittle substances.

In summary, CNC water jet cutting stands out for its precision, versatility, and environmentally friendly nature, making it an excellent choice for various industrial applications.

SourcifyChina specializes in CNC water jet cutting services, providing precision and versatility for custom products and projects. Utilizing high-pressure water mixed with abrasives, this technology ensures clean, accurate cuts on various materials, from metals to composites.

The company’s expertise extends to both small-scale personal projects and large-scale industrial applications. By leveraging advanced CNC machinery, SourcifyChina is capable of producing intricate designs and complex geometries, meeting the exact specifications of its clients.

Innovation and quality control are at the core of SourcifyChina’s operations. Each project undergoes meticulous planning and quality checks, ensuring that the final products meet stringent standards and exceed customer expectations.

Clients from diverse industries, such as aerospace, automotive, and construction, rely on SourcifyChina for their water jet cutting needs. The company’s commitment to customer satisfaction is evident in its prompt delivery and cost-effective solutions.

SourcifyChina’s CNC water jet cutting services not only save time but also reduce material waste. This eco-friendly approach aligns with modern sustainability goals, making the company a preferred choice for environmentally conscious clients.

In summary, SourcifyChina’s CNC water jet cutting services offer unparalleled precision and quality for a broad range of custom products and projects. By combining cutting-edge technology with exceptional customer service, SourcifyChina continues to set industry standards, making it the go-to solution for all CNC water jet cutting needs.

SourcifyChina CNC Water Jet Cutting is an industry leader in precision manufacturing and engineering services. Specializing in the advanced technique of CNC water jet cutting, the company caters to a broad spectrum of industries, including automotive, aerospace, and architectural sectors. Utilizing state-of-the-art technology, SourcifyChina provides unparalleled accuracy in cutting a diverse array of materials such as metal, glass, stone, and composites. Their water jet cutting solutions are not only precise but also eco-friendly, as they eliminate the need for hazardous chemicals and produce minimal waste. With a strong commitment to quality and customer satisfaction, SourcifyChina ensures that each project meets stringent industry standards and client specifications. Professionalism, technical prowess, and innovative approaches make SourcifyChina an indispensable partner for businesses seeking reliable, high-precision cutting solutions.

CNC water jet cutting technology has revolutionized the aerospace and defense industries by enabling the precise fabrication of complex components from a variety of materials. The aerospace sector requires parts made from advanced materials such as titanium, aluminum, and composites, all of which can be efficiently cut with water jets without compromising their structural integrity. The precision and flexibility of CNC water jet cutting ensure that even the most intricate geometries are realized with minimal waste, enhancing both performance and cost-effectiveness. Moreover, the absence of thermal distortion during the cutting process is particularly critical for aerospace applications, where the integrity of materials must be maintained to endure extreme operational conditions. Additionally, the technology supports rapid prototyping and customized manufacturing, allowing for quicker iteration cycles and deployment of innovative designs.

In the defense and marine sectors, CNC water jet cutting is similarly transformative. These applications often require robust, corrosion-resistant materials that must be adapted to precise specifications. For defense, whether fabricating vehicle armor, intricate surveillance equipment, or missile components, CNC water jet cutting provides unmatched precision and repeatability. In the marine environment, where exposure to salt water and high mechanical stress is a given, materials like stainless steel and aluminum alloys are commonly used; water jet cutting ensures these materials are processed without inducing stress or heat-affected zones that could lead to premature failure. Furthermore, the ability to cut thick materials and complex shapes with high accuracy is particularly beneficial for producing custom parts for submarines, ships, and underwater exploration equipment. Overall, the versatility and precision of CNC water jet cutting make it an essential tool in advancing the capabilities and reliability of aerospace, defense, and marine technologies.

CNC water jet cutting has significantly transformed the automotive industry by enabling the precise and efficient fabrication of complex parts. This technology utilizes highly pressurized water streams, often mixed with abrasive materials, to seamlessly cut through metal, glass, and composite materials with minimal waste. Automotive manufacturers leverage this technique to produce intricate engine components, chassis parts, and interior panels with superior accuracy, ensuring optimal fit and performance. The cold cutting process inherent to water jets prevents thermal distortion and material hardening, which is crucial in maintaining the structural integrity of automotive components. Furthermore, the flexibility and precision of CNC water jet cutting help reduce production time and costs, making it an indispensable tool for both prototyping and mass production in car manufacturing.

In the realm of electronics, CNC water jet cutting plays a pivotal role in producing components with exceptional precision and intricate detailing, crucial for modern electronic devices. This cutting-edge technology is employed to create circuit boards, housings, and various intricate parts that are essential in devices such as smartphones, laptops, and industrial electronics. The capability to cut through a wide range of materials, including metals, ceramics, and plastics, without inducing thermal stress, ensures the integrity and functionality of delicate electronic components. Moreover, the integration of CNC technology allows for automated, highly accurate cutting processes, which is essential for achieving the fine tolerances and repeatability demanded by the electronics industry. By facilitating rapid prototyping and high-quality production, CNC water jet cutting greatly contributes to the advancement and innovation within the electronics sector.

CNC water jet cutting is revolutionizing the construction industry by providing unparalleled precision and efficiency in cutting various materials. This technology employs high-pressure water, often mixed with abrasive particles, to slice through materials such as metal, glass, stone, and ceramics with ease. Its versatility allows construction professionals to create complex geometric shapes, intricate designs, and precise cuts that would be challenging to achieve with traditional cutting methods. Moreover, CNC water jet cutting minimizes material waste, reduces dust and hazardous fumes, and prevents heat-induced warping, ensuring a safer and more eco-friendly construction process. This advanced cutting technique accelerates project timelines and enhances the quality of architectural elements, from custom tiles and countertops to structural steel components.

In the energy sector, CNC water jet cutting plays a crucial role in manufacturing and maintenance operations, particularly in the production of components for renewable energy sources such as wind turbines and solar panels. The ability to cut through thick metals and composite materials with high precision ensures that each component meets strict specifications and performance standards. This accuracy is essential for the efficient operation of energy systems, where even minor deviations can lead to significant performance issues. Additionally, CNC water jet cutting is invaluable in the fabrication of parts for oil and gas pipelines, nuclear reactors, and other critical infrastructure, ensuring durability and reliability. By incorporating CNC water jet cutting, the energy industry can achieve higher levels of efficiency, sustainability, and safety, driving forward the adoption of advanced technologies in power generation and distribution.

The industrial equipment industry has witnessed significant advancements with the application of CNC water jet cutting technology. CNC (Computer Numerical Control) water jet cutting utilizes high-pressure streams of water, often combined with abrasive materials, to precisely cut through a variety of materials such as metals, composites, stone, and ceramics. This technique offers unparalleled precision and versatility, making it essential for industries requiring intricate designs and high tolerances. One key advantage is that the cold cutting process eliminates the thermal stresses that can cause material deformation or structural changes, ensuring the integrity of both delicate and robust materials. Additionally, CNC water jet cutting provides a clean finish, reducing the need for secondary processing and enhancing overall manufacturing efficiency.

Another significant application of CNC water jet cutting in the industrial equipment sector is its role in custom fabrication and prototyping. As industries push for rapid innovation and product development, the need for flexible and adaptable cutting solutions has never been greater. CNC water jet cutting allows manufacturers to quickly produce prototype components with complex geometries, enabling faster design iterations and reducing time-to-market. Moreover, its ability to handle a broad spectrum of materials means that it can seamlessly integrate with various stages of the production process, from initial concept to final assembly. This versatility and precision, combined with cost-efficient operation, position CNC water jet cutting as a critical tool in modern industrial manufacturing, driving both innovation and quality in the production of industrial equipment.

CNC water jet cutting is revolutionizing the manufacturing of medical devices by providing unparalleled precision, versatility, and material compatibility. This technology uses a high-pressure stream of water, often mixed with abrasive particles, to cut through materials with extreme accuracy. For medical devices, where precision is paramount, CNC water jet cutting is particularly beneficial. It can create intricate designs and complex geometries required for modern medical tools, ensuring that each device meets the stringent quality standards necessary for healthcare applications. This capability is crucial for the production of surgical instruments, orthopedic implants, and other specialized equipment, where even the slightest deviation can significantly impact performance and safety.

Moreover, CNC water jet cutting is incredibly versatile and capable of handling a wide range of materials, including metals, plastics, composites, and even delicate materials like laminates and ceramics. This adaptability is essential in the medical device industry, where devices often incorporate multiple material types to enhance functionality and biocompatibility. Additionally, the cold cutting process eliminates the risk of thermal distortion and material hardening, which is vital for maintaining the integrity of sensitive components. By streamlining the manufacturing process and ensuring high-quality, consistent outputs, CNC water jet cutting significantly contributes to the advancement of medical technology, ultimately leading to better patient outcomes and more efficient healthcare solutions.

CNC water jet cutting, a process that harnesses the power of high-pressure water streams mixed with abrasive materials, has revolutionized the machining and manufacturing industries. This method provides unparalleled precision and versatility, enabling manufacturers to cut a wide range of materials, including metals, composites, glass, and ceramics, without introducing any thermal stress. The CNC (Computer Numerical Control) aspect allows for intricate and complex designs to be executed with high repeatability, minimizing waste and maximizing efficiency. This cold-cutting technique is particularly beneficial in applications where the integrity of the material’s properties must be maintained, such as in aerospace, automotive, and medical device manufacturing.

In the realm of manufacturing, CNC water jet cutting is celebrated for its ability to produce high-quality cuts with smooth edges, reducing the need for secondary finishing processes. This not only saves time but also cost, making it an attractive option for both prototyping and large-scale production runs. The technology is environmentally friendly as it eliminates the need for harmful chemicals and reduces material waste. Additionally, its capability to handle a diverse array of materials and thicknesses makes it a versatile tool for custom job shops as well as large-scale industrial applications. The adoption of CNC water jet cutting aligns with the ongoing trend towards precision engineering and sustainable manufacturing practices, setting new benchmarks in productivity and quality assurance.

#### 1. What materials can be cut using CNC water jet cutting at SourcifyChina?

SourcifyChina’s CNC water jet cutting can handle a wide variety of materials including metals (like aluminum, steel, and titanium), plastics, ceramics, glass, stone, and composites. The versatility of the water jet system makes it suitable for diverse applications across different industries.

#### 2. What is the maximum thickness that can be cut with CNC water jet cutting?

Our CNC water jet cutting system can cut materials up to 6 inches thick. However, the optimal thickness for maintaining precision and quality typically ranges up to 2 inches, depending on the material type.

#### 3. How precise is the CNC water jet cutting process?

The CNC water jet cutting process is highly precise, with tolerances as fine as ±0.003 inches. This high level of accuracy ensures detailed and intricate cuts, making it ideal for precision components.

#### 4. Does the water jet cutting process cause any material deformation?

No, the water jet cutting process does not cause thermal deformation because it is a cold cutting process. This makes it ideal for heat-sensitive materials and components.

#### 5. Are custom designs and prototypes possible?

Yes, SourcifyChina specializes in custom designs and prototyping. Our advanced CNC software can accurately replicate complex geometries and designs, catering to bespoke project requirements.

#### 6. What is the lead time for CNC water jet cutting projects?

The lead time for projects varies depending on the size and complexity of the order. Generally, we aim for a turnaround time of 1-3 weeks. For urgent requests, expedited services are available upon request.

#### 7. How do you ensure the quality of the cuts?

Quality is ensured through rigorous process controls, advanced CNC machinery, and thorough inspections. Each project undergoes detailed review and quality checks to meet the highest standards.

#### 8. Can you handle large volume orders?

Yes, SourcifyChina is equipped to handle both small and large volume orders efficiently. Our scalable production capabilities ensure timely delivery without compromising on quality.

#### 9. How do I request a quote or place an order?

When considering CNC water jet cutting manufacturing from SourcifyChina factory, there are several key tips to ensure a successful partnership and high-quality results:

1. Understand Cutting Capabilities: CNC water jet cutting can handle a wide range of materials, from metals and composites to stone and glass. Ensure SourcifyChina’s equipment is suitable for the materials and thicknesses you require.

2. Precision and Tolerances: Water jet cutting offers high precision. Confirm with SourcifyChina the tolerance levels they can achieve and how this aligns with your project’s demands.

3. Material Efficiency: Since water jet cutting minimizes waste, discuss with SourcifyChina how to optimize material usage. This can reduce costs and improve sustainability.

4. Complex Designs: If your project involves intricate patterns or shapes, ensure the factory has experience with complex designs and can provide examples of similar past projects.

5. Surface Quality: Water jet cutting often results in smoother edges compared to other cutting methods. Verify the finish quality from SourcifyChina to avoid additional post-processing.

6. Turnaround Time: Clarify lead times with SourcifyChina, especially if your project has tight deadlines. Reliable delivery schedules are crucial for maintaining project timelines.

7. Cost Factors: Discuss the pricing structure in detail. Factors such as material, complexity, and quantity can affect costs. Transparent quotes help avoid unexpected expenses.

8. Technical Support and Communication: A responsive communication channel with SourcifyChina is vital. Ensure they offer technical support throughout the process, from design to final production.

9. Quality Assurance: Check if SourcifyChina has quality control measures in place, including inspections and certifications. This ensures your parts meet all specifications and standards.

10. Sustainability Practices: Inquire about SourcifyChina’s environmental policies. Water jet cutting is eco-friendly; ensure their practices align with your sustainability goals.

By considering these tips, you can capitalize on the capabilities of CNC water jet cutting from SourcifyChina factory for precise, efficient, and cost-effective manufacturing solutions.

Sure, here are some frequently asked questions (FAQ) with their answers for sourcing CNC water jet cutting services from SourcifyChina factory:

1. What is CNC water jet cutting?

CNC water jet cutting is a process that uses a high-pressure stream of water, often mixed with an abrasive material, to cut a variety of materials with precision. It is controlled by a computer to ensure accuracy and consistency.

2. Why should I choose CNC water jet cutting from SourcifyChina factory?

SourcifyChina factory offers state-of-the-art CNC water jet cutting technology, skilled technicians, and a robust quality assurance process, ensuring high precision, quick turnaround times, and competitive pricing.

3. What materials can be cut using CNC water jet cutting at SourcifyChina factory?

Our CNC water jet cutting service can handle a wide range of materials, including metals (steel, aluminum, titanium), composites, plastics, glass, ceramics, stone, and more.

4. What is the maximum thickness of materials that can be cut?

SourcifyChina’s CNC water jet cutting can cut materials up to 200 mm (approximately 8 inches) thick, depending on the material type.

5. What are the tolerances and precision levels of your CNC water jet cutting?

Our CNC water jet cutting achieves high precision with tolerances typically within ±0.1 mm, making it suitable for detailed and complex parts.

6. How do I submit a project for CNC water jet cutting to SourcifyChina factory?

You can submit your project by contacting us through our website, providing your design files and specifications. We accept various file formats such as CAD, DXF, and DWG.

7. What is the lead time for CNC water jet cutting projects?

Lead times vary based on project complexity and volume. Typically, we aim to complete orders within 1-2 weeks after receiving all necessary information and materials.

8. Are there any minimum order requirements?

We cater to both small and large orders. There are no strict minimum order requirements, allowing flexibility for prototypes, small batches, and large-scale production.

9. How is the pricing for CNC water jet cutting determined?

Pricing is based on factors such as material type and thickness, cutting complexity, project volume, and lead time. We provide detailed quotes upon reviewing project specifications.

10. Do you offer post-processing services?

Sourcing CNC water jet cutting services from SourcifyChina factory requires careful planning and diligence. Here are some tips to guide you:

1. Detailed Requirements: Start with a clear and detailed list of your requirements, including material specifications, tolerances, sizes, and quantities.

2. Research Suppliers: Check SourcifyChina’s reputation. Look for reviews, ratings, and past project experiences. This can help you identify reliable suppliers.

3. Request Quotes: Get quotes from multiple vendors within SourcifyChina. This can help you compare prices, services, and timelines.

4. Sample Order: If possible, request a sample order to assess the quality and precision of their CNC water jet cutting services.

5. Communication: Maintain clear and consistent communication with the supplier. Discuss your project’s detailed specifications and expected delivery timelines.

6. Quality Assurance: Inquire about their quality assurance processes. Ensure they have measures to check for accuracy and defects.

7. Certifications: Verify any industry-related certifications the factory holds to assure compliance with international standards.

8. Payment Terms: Discuss and agree on payment terms upfront. Consider split payments, with an initial deposit and final payment upon completion or delivery.

9. Lead Time: Confirm the lead times for production and delivery. Factor in potential delays and find out how they handle such situations.

10. Legal Documentation: Ensure all agreements, including costs, timelines, quality expectations, and delivery schedules, are documented in a formal contract.

11. Site Visit: If feasible, arrange a visit to the factory to understand their operational capabilities and quality control processes.

12. Logistics: Plan the logistics for shipping and potential customs duties. Choose reliable shipping partners to avoid delays and damage.

Following these tips can help streamline the process and ensure you secure high-quality CNC water jet cutting services from SourcifyChina.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.