Choosing SourcifyChina for purchasing CNC woodturning lathes from China offers unmatched quality and reliability. Their factory produces equipment that meets international standards, ensuring durability and precision. Buyers benefit from competitive pricing, making high-quality machinery accessible without breaking the bank.

SourcifyChina’s expertise ensures you get a product tailored to your needs. Their team of engineers and technicians is dedicated to continuous improvement, integrating the latest technology and features into their lathes. Customer satisfaction is a priority, evidenced by their comprehensive after-sales support and warranty services.

Furthermore, SourcifyChina streamlines the procurement process, eliminating language barriers and reducing lead times. Their experienced logistics team ensures timely and hassle-free deliveries, so your production line faces no unnecessary delays. They provide transparent communication, keeping you informed about every step of your order.

Choosing SourcifyChina means partnering with a company committed to excellence. Their robust quality control processes ensure each lathe is rigorously tested before shipment. This dedication to quality translates to reliable, efficient machinery that helps boost your productivity and business profitability.

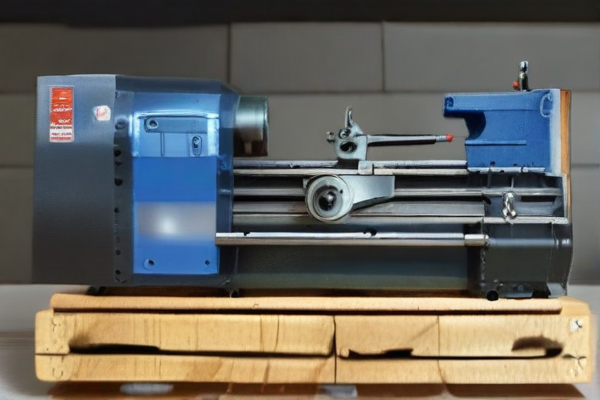

CNC woodturning lathes are essential for precision woodwork, offering various types and options tailored for professionals and hobbyists. These machines excel in creating intricate designs with minimal effort.

– 3-Axis CNC Lathe: Simple operations, perfect for beginners.

– 4-Axis CNC Lathe: More complex designs, suitable for intermediate users.

– 5-Axis CNC Lathe: High-precision, ideal for advanced and industrial applications.

– Table-Top CNC Lathe: Compact and portable, great for small spaces.

– Full-Size CNC Lathe: Robust and powerful, handles larger projects.

– Dual-Spindle CNC Lathe: Enables multi-tasking, boosts productivity.

– CNC Lathe with Live Tooling: Allows milling and drilling, versatile usage.

– Educational CNC Lathe: Designed for training, user-friendly software.

– CNC Combination Lathe: Combines lathe and milling functions, increases functionality.

These CNC woodturning lathes come with various features and options, catering to different skill levels and project requirements. They ensure accuracy, efficiency, and creativity in woodturning tasks.

CNC woodturning lathes offer precision and efficiency in crafting detailed wooden items, ideal for both complex production and unique designs. These machines streamline the woodworking process, enabling high-quality and consistent results.

– Furniture legs and spindles

– Intricate artistic sculptures

– Precision architectural moldings

– Custom wooden handles and grips

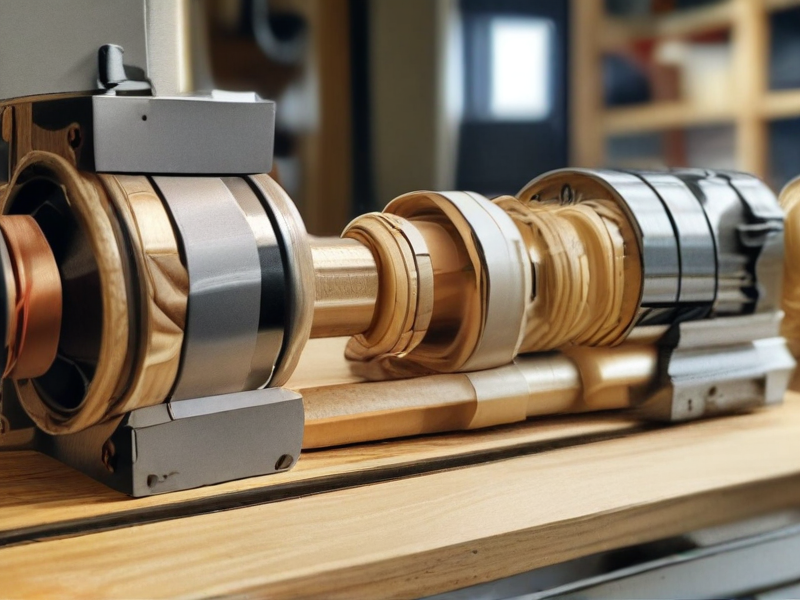

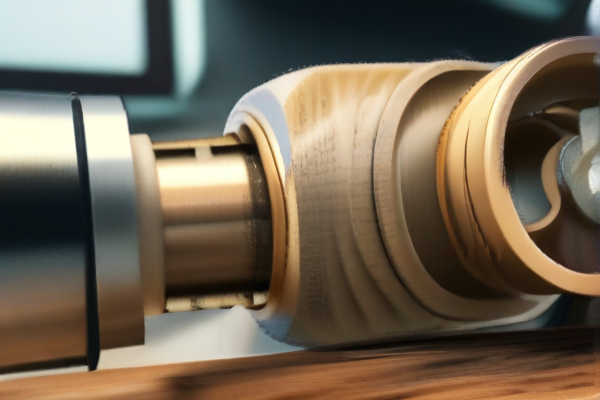

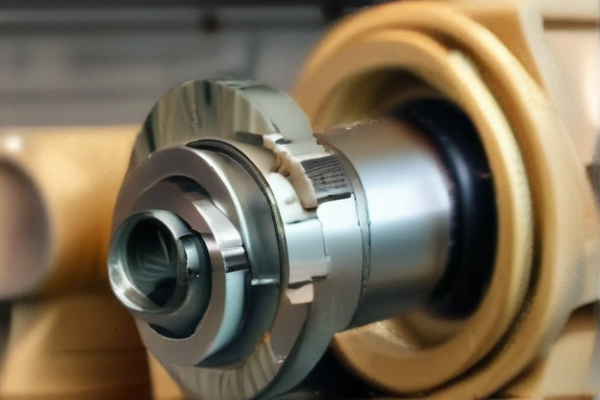

The “SourcifyChina CNC woodturning lathe” is constructed primarily from high-quality, precision-engineered metal alloys, ensuring long-lasting durability and consistent performance in demanding woodturning tasks. The robust metal frame reduces vibrations during operation, allowing for precise and smooth finishes on various wooden workpieces.

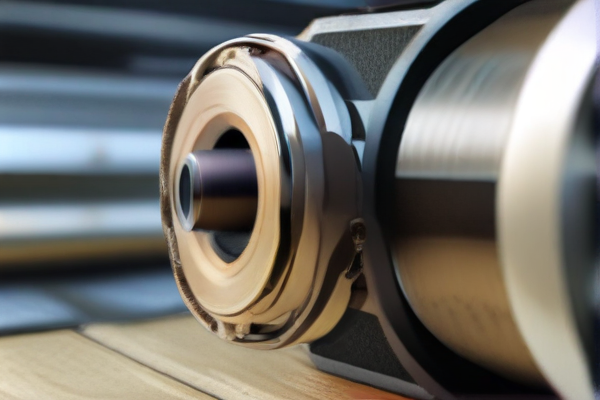

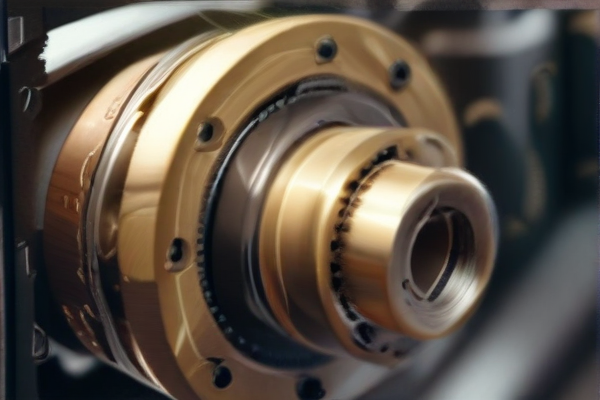

In addition to the metal framework, the machine integrates advanced electronic components made from reliable circuitry and durable materials. These elements include the CNC control unit, stepper motors, and servo drives, which collectively enable accurate and programmable operations. The use of high-grade materials in these components ensures minimal wear and enhances the machine’s lifespan.

Another critical material aspect is the cutting tools, often made from high-speed steel (HSS) or carbide. These materials offer superior hardness and heat resistance, crucial for maintaining sharp edges and achieving clean cuts on wood. The replaceable and adjustable nature of these cutting tools contributes to operational efficiency and flexibility.

Finally, the lathe incorporates essential safety features crafted from high-quality materials. Safety shields, emergency stop buttons, and other protective elements are typically made from impact-resistant plastics and metals. These ensure user safety while maintaining the machine’s overall performance and reliability.

Overall, the “SourcifyChina CNC woodturning lathe” blends top-tier metal alloys, durable electronic components, robust cutting tools, and reliable safety features to offer a high-performing, long-lasting woodturning solution. The thoughtful selection of materials maximizes efficiency, safety, and precision, making it an invaluable asset for professional and hobbyist woodworkers alike.

SourcifyChina employs stringent quality control measures in its CNC woodturning lathe manufacturing process. Each lathe undergoes rigorous inspection at various stages, ensuring precision and reliability.

Raw materials are meticulously chosen for their durability and performance. Suppliers undergo a stringent vetting process to guarantee the highest standard of input materials, contributing significantly to the final product quality.

Advanced CNC machinery is used, which ensures precise adherence to design specifications. Regular calibration of machines ensures each lathe meets exacting standards, minimizing defects and ensuring consistent output.

Skilled technicians closely monitor the assembly process. Each step is documented, and quality checks are performed at critical points to ensure that any potential issues are identified and rectified promptly.

Finished lathes undergo comprehensive testing, including operational trials to ensure they meet the high-performance criteria. Any deviations from the optimal performance are corrected before the product is cleared for dispatch.

Finally, each lathe is packaged carefully to prevent damage during transportation. Customer feedback is actively sought and analyzed, forming the basis for continuous improvement in the manufacturing and quality control processes. This holistic approach underscores SourcifyChina’s commitment to excellence.

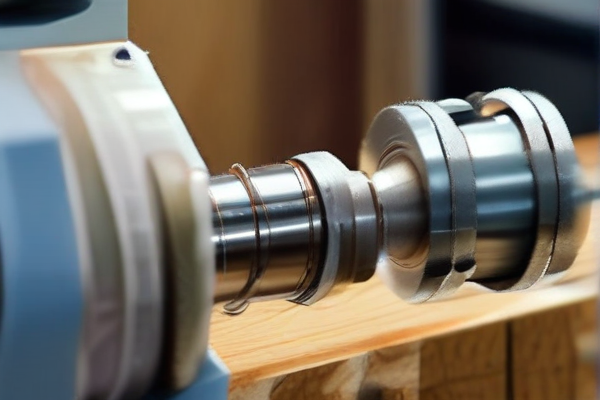

The SourcifyChina CNC woodturning lathe offers precise and efficient woodturning capabilities. This advanced machine uses computer numerical control (CNC) technology to automate the woodturning process, ensuring consistent results with minimal manual intervention.

Designed for both small and large-scale operations, the lathe can handle a variety of wood types and shapes. This flexibility allows artisans to create intricate designs, from custom furniture legs to detailed wooden spindles, with remarkable accuracy.

The machine’s robust construction ensures durability and long-lasting performance. It can operate continuously under demanding conditions, maintaining quality and precision even during extended production runs, which boosts overall efficiency.

With intuitive software, users can easily program complex patterns and designs. The user-friendly interface simplifies the learning curve, making it accessible for both experienced craftsmen and beginners alike. Its high-speed capabilities also reduce production time.

In addition, the SourcifyChina CNC woodturning lathe incorporates safety features to protect both the operator and the machine. Emergency stop buttons, automatic shutoff functions, and safety guards are standard, ensuring a secure working environment.

Overall, the SourcifyChina CNC woodturning lathe stands out for its precision, reliability, and user-friendliness. Whether you’re crafting one-of-a-kind pieces or mass-producing components, this lathe can meet your needs, adding significant value to any woodworking shop.

A CNC woodturning lathe offers precision and efficiency in woodworking, transforming raw materials into finely crafted pieces with minimal manual intervention.

– Precision and Consistency: CNC woodturning lathes provide superior accuracy, ensuring each piece is crafted with exact dimensions and uniformity.

– Increased Efficiency: Automated operations reduce production time and allow for completing complex designs quickly.

– Versatility: The machinery can handle various wood types and complex shapes with ease.

– Reduced Labor Costs: Less manual work is required, thus lowering labor costs and reducing the likelihood of human error.

– Complex Designs: Capable of producing intricate and detailed designs that are difficult to achieve with manual tools.

– Material Conservation: Precision cutting ensures optimal use of wood, minimizing waste.

– Repeatability: The ability to produce identical items consistently, ideal for mass production.

– Safety: Enhanced safety features protect operators, reducing the risk of injury.

– Scalability: Ideal for both small-scale custom projects and large-scale production runs.

– User-friendly Software: CNC machines often come with advanced software that is easy to operate, even for those with limited experience.

– Minimal Maintenance: Modern CNC lathes are designed to require minimal maintenance, enhancing longevity and reliability.

Overall, CNC woodturning lathes are indispensable tools for enhancing productivity and quality in woodworking.

CNC Woodturning Lathe Features

A CNC woodturning lathe is a state-of-the-art device designed to offer precision, efficiency, and versatility in woodworking. Below are some of its key features:

– Precision and Accuracy: Utilizes computer-controlled operations to ensure consistent and precise cuts.

– Automation: Capable of performing complex turning operations automatically, reducing manual intervention.

– Versatility: Can handle a wide variety of woodturning tasks, from simple spindles to intricate designs.

– Ease of Use: User-friendly interfaces and software make it accessible even to beginners.

– Speed: High-speed operation decreases production time significantly.

– Customization: Provides the ability to upload custom designs directly from CAD software.

– Durability: Built with robust materials and components for long-lasting performance.

– Repeatability: Ensures identical outputs in mass production runs.

– Safety Features: Equipped with safety guards, emergency stop buttons, and other protective measures.

– Low Waste: Enhanced precision and control minimize material waste.

– Integrated Dust Collection: Often includes or can be connected to a dust collection system to maintain a clean work area.

– Multi-Axis Control: Some models offer multi-axis capabilities for more complex designs.

– Flexibility: Easily switch between different types of wood and cutting tools.

– Maintenance: Require less frequent maintenance compared to manual lathes.

– Software Integration: Compatible with various design and modeling software for greater flexibility.

These features make CNC woodturning lathes a valuable addition to any woodworking shop, enhancing both the quality and efficiency of production.

SourcifyChina’s CNC woodturning lathe excels in creating customized products and projects for various industries. Their sophisticated machinery allows for intricate detailing and high-precision craftsmanship, ensuring top-quality results.

Projects ranging from furniture components to bespoke art pieces benefit from the lathe’s advanced capabilities. The technology allows for swift, uniform production while maintaining the ability to create unique, one-of-a-kind items.

SourcifyChina employs a team of skilled technicians who are adept at turning client visions into tangible creations. From initial design to final product, they offer a seamless, collaborative process.

In addition to standard offerings, SourcifyChina provides tailored solutions to meet specific project requirements. Whether you’re looking for mass production or limited runs, their CNC woodturning lathes can adapt to your needs.

Customer satisfaction is a priority, evidenced by their dedicated service and attention to detail. With a focus on quality and precision, SourcifyChina continues to be a trusted name in custom CNC woodturning projects.

Their commitment to innovation and excellence ensures that each product not only meets but exceeds client expectations. Invest in their expertise for your next project and experience the difference quality craftsmanship can make.

SourcifyChina CNC Woodturning Lathe specializes in providing advanced, precision-engineered CNC woodturning lathes tailored to meet the diverse needs of woodcraft enthusiasts and industrial manufacturers alike. Known for their unwavering commitment to quality and innovation, SourcifyChina leverages cutting-edge technology and robust industrial practices to deliver machinery that excels in both performance and reliability. Each lathe is meticulously designed to execute complex woodturning tasks with unparalleled accuracy and efficiency, ensuring consistent results for high-volume production runs or intricate custom projects. The company’s dedication to customer satisfaction goes beyond machinery, offering comprehensive support, including training, troubleshooting, and maintenance services. SourcifyChina’s impressive portfolio of state-of-the-art CNC woodturning lathes positions it as a trusted leader in the woodworking machinery market, making it the go-to choice for professionals seeking excellence and durability in their woodworking endeavors.

In the aerospace and defense sectors, CNC woodturning lathes play a niche yet critical role. These lathes are employed for crafting complex, precision wooden prototypes and molds, essential in the early stages of design and testing. For instance, wooden models of aerodynamic surfaces, like wings or fuselage sections, are turned to exact specifications to study airflow dynamics and other physical properties. Furthermore, in defense applications, CNC woodturning lathes are used to create intricate wooden patterns for casting metal parts, ensuring that critical components are produced with high fidelity. This capability is vital for the development of prototypes and testing equipment where precision and accuracy are paramount.

In the marine industry, CNC woodturning lathes are indispensable for producing both functional components and aesthetic elements of watercraft. These lathes facilitate the creation of detailed wooden components such as propeller models, tillers, and custom handles for nautical instruments, ensuring that they meet the exacting standards required for marine environments. Additionally, they are used to turn wooden parts for traditional shipbuilding, including the production of spars, masts, and decorative elements like figureheads and trim. By automating the turning process, CNC woodturning lathes enhance precision and repeatability, which is crucial for maintaining the structural integrity and aesthetic appeal of both modern and classical vessels.

CNC woodturning lathes have found diverse applications in the automotive industry, where precision and efficiency are paramount. These computer-controlled machines excel at producing intricate wooden parts that mimic or complement metallic car components, such as custom dashboard inlays, shift knobs, and steering wheel trims. Automotive designers often seek bespoke and luxurious interiors; CNC woodturning lathes provide the flexibility to craft unique, high-quality wood parts with exact specifications. By automating the turning process, manufacturers can maintain consistent quality while significantly reducing production times and labor costs. Moreover, CNC technology allows for rapid prototyping and seamless modifications, ensuring that automotive parts meet evolving design and functional requirements.

In the realm of electronics, CNC woodturning lathes also play a pivotal role. With the rise of custom-designed electronic gadgets, such as high-end audio equipment and handcrafted computer peripherals, the demand for precision-crafted wooden components has surged. CNC lathes enable the creation of perfectly shaped wooden casings and knobs that not only offer aesthetic appeal but also provide durability and a tactile quality superior to plastic counterparts. For instance, audiophiles often prefer wooden speaker housings for their acoustic properties, and CNC woodturning lathes ensure these housings are crafted to exacting standards. The use of CNC technology in electronics manufacturing thus bridges the gap between artisanal craftsmanship and modern precision, catering to niche markets that value both functionality and luxury.

CNC woodturning lathes have revolutionized the construction industry by significantly enhancing precision and efficiency. In construction, exact measurements and flawless execution are paramount to ensure structural integrity and aesthetic appeal. CNC woodturning lathes facilitate the creation of intricate architectural elements like balusters, columns, and ornate wooden fixtures with unparalleled accuracy. Traditional craftsmanship demands considerable manual effort and time, whereas CNC technology automates the process, reducing both labor costs and production time. This automation not only ensures uniformity in each piece but also allows for rapid prototyping and bulk production, making it indispensable in modern construction projects where time and precision are critical.

In the realm of energy applications, CNC woodturning lathes contribute to the sustainable manufacturing of wooden components used in renewable energy technologies, such as wind turbines. The precise machining capabilities of CNC lathes are essential for producing aerodynamic and robust turbine blades that optimize energy capture. Wood, being a renewable resource with a lower carbon footprint than metals and composites, offers an eco-friendly alternative when sourced sustainably. Additionally, CNC lathes can be instrumental in crafting parts for bioenergy systems, where wooden composites are often used. This advanced technology thereby supports the transition to more sustainable energy solutions by facilitating the efficient, high-quality production of key wooden components in renewable energy infrastructure.

The industrial equipment industry has greatly benefited from the application of CNC (Computer Numerical Control) woodturning lathes, revolutionizing the process of wood machining. These advanced machines are programmed to execute precise, repetitive movements, enabling the mass production of intricate wooden components with high precision and consistency. This automation reduces the reliance on manual labor and minimizes human error, which in turn boosts efficiency and lowers production costs. CNC woodturning lathes are widely used in manufacturing wooden furniture, decorative items, and bespoke architectural elements, providing the capability to produce complex designs that would be challenging and time-consuming to create by hand.

Furthermore, CNC woodturning lathes have expanded the creative possibilities for designers and manufacturers in the industrial equipment sector. The ability to quickly switch between different programs and tool configurations allows for greater flexibility in production runs, from small batches of custom pieces to large-scale operations. This adaptability is crucial for meeting diverse market demands and staying competitive. Additionally, the precision of CNC technology ensures that each piece is produced to exact specifications, which is particularly important for components that must fit together perfectly in larger assemblies. Overall, the integration of CNC woodturning lathes into industrial processes enhances product quality, reduces waste, and accelerates production timelines, fostering innovation and efficiency in the woodworking industry.

A CNC woodturning lathe, conventionally used in woodworking to craft intricate designs, is ingeniously repurposed in the medical devices industry. These advanced machines bring precision and repeatability to the production of various medical apparatus components. By using computer numerical control (CNC) technology, these lathes turn raw materials, often biomedical-grade polymers and certain metals, into highly accurate, complex shapes required for medical implants, prosthetics, and surgical instruments. The ability to execute fine, meticulous cuts ensures that each piece adheres to stringent healthcare standards, essential for patient safety and effective treatment outcomes.

The transition of CNC woodturning lathes into the medical field highlights a trend towards versatile manufacturing processes that combine automation with high precision. With the addition of specialized tooling and adjusted machine parameters, these lathes can produce consistent, high-quality parts with minimal manual intervention, reducing the risk of human error. This scalability is crucial in meeting the growing demand for medical devices, particularly in personalized medicine, where customized implants and prosthetics are increasingly in demand. As technology continues to advance, the application of CNC woodturning lathes in the medical devices sector exemplifies how innovative repurposing of existing technology can meet evolving healthcare needs efficiently.

CNC woodturning lathes have revolutionized the machining and manufacturing industry by offering unparalleled precision and efficiency in crafting wooden components. Unlike traditional lathes, which require manual intervention and expert skill, CNC (Computer Numerical Control) lathes operate based on pre-set computer programs, allowing for high levels of accuracy and consistency. These machines can produce intricate designs and complex shapes with ease, making them indispensable for applications ranging from furniture manufacturing to architectural detailing. The ability to replicate designs precisely means that manufacturers can produce large volumes of identical parts, reducing waste and ensuring a uniform quality that meets stringent industry standards.

In addition to their precision, CNC woodturning lathes also significantly enhance productivity. The automation of the turning process means that once a design is programmed, the machine can work independently, albeit under supervision, allowing operators to focus on other tasks. This efficiency not only speeds up production but also brings down labor costs, making it a cost-effective solution for small and large-scale manufacturing operations. Furthermore, the versatility of CNC lathes means they can easily switch between different tasks or projects, providing flexibility to meet varying demands without substantial downtime or retooling. From custom-designed furniture components to standardized industrial products, CNC woodturning lathes represent a critical technology in modern manufacturing.

Certainly! Below is an FAQ list focusing on CNC woodturning lathes from SourcifyChina factory. Each question is highlighted with bold tags and the responses are concise.

Q: What types of wood can the CNC woodturning lathe from SourcifyChina handle?

A: The lathe can process various types of wood, including hardwoods like oak and maple, and softwoods like pine and cedar.

Q: What is the maximum diameter and length of wood that the lathe can accommodate?

A: The CNC woodturning lathe can handle wood pieces with a maximum diameter of up to 300mm and a length of up to 1000mm.

Q: How precise is the CNC woodturning lathe in terms of tolerance?

A: The machine offers high precision with tolerances within ±0.01mm, ensuring quality and consistency in every piece.

Q: Is it easy to operate the CNC woodturning lathe?

A: Yes, the lathe comes with an intuitive user interface and detailed manuals, making it easy for both beginners and experienced operators.

Q: What kind of software compatibility does the CNC woodturning lathe have?

A: The lathe is compatible with major design and CNC software like AutoCAD, ArtCAM, and Fusion 360, allowing for versatility in project designs.

Q: How does SourcifyChina ensure the quality of the CNC woodturning lathes?

A: The machines undergo rigorous quality control checks and are manufactured using high-grade materials to meet international standards.

Q: Are there any customization options available?

A: Yes, SourcifyChina offers customization options to meet specific customer requirements, including tailored dimensions and additional features.

Q: What are the maintenance requirements for the CNC woodturning lathe?

A: Regular maintenance includes lubrication, cleaning of the work area, and periodic checks on machine parts to ensure optimal performance.

Q: Does SourcifyChina provide after-sales support and warranty?

A: Absolutely, the company offers comprehensive after-sales support and a one-year warranty on all CNC woodturning lathes.

Q: Can I view a demonstration of the CNC woodturning lathe before purchasing?

A: Yes, SourcifyChina provides demonstrations either in person at their factory or via live video sessions to showcase the machine’s capabilities.

This brief FAQ should provide essential insights into CNC woodturning lathes from SourcifyChina factory.

When considering CNC woodturning lathe manufacturing from a factory like SourcifyChina, several key tips can ensure a smooth and efficient process:

1. Research the Manufacturer: Verify SourcifyChina’s reputation and reliability through customer reviews, certifications, and industry references.

2. Specify Your Requirements: Clearly communicate your specifications such as lathe size, motor power, spindle speed, and additional features like auto-feeding or advanced software integration.

3. Quality Assurance: Ensure the factory adheres to international quality standards, such as ISO certifications. Request material certifications and regular quality checks.

4. Customization Options: Check if they offer customization to cater to unique requirements, whether in machine design or software compatibility.

5. Request Samples: Before bulk manufacturing, request samples or prototypes to evaluate the craftsmanship, tolerance levels, and performance consistency.

6. Evaluate Technology: Ensure the factory uses the latest technology in CNC machinery to guarantee precision, efficiency, and reduced production times.

7. Cost Analysis: Conduct a cost-benefit analysis, factoring in the price, shipping, tariffs, and potential maintenance costs. Cheap isn’t always better – focus on value.

8. After-Sales Support: Inquire about the after-sales service including warranty, technical support, and availability of spare parts.

9. Lead Time & Delivery: Confirm production lead times and delivery schedules. Understand their logistics to avoid delays.

10. Legal Agreements: Draft clear contracts detailing the manufacturing terms, quality expectations, timelines, and payment schedules to safeguard your interests.

11. Sustainable Practices: Opt for factories with sustainable manufacturing practices to ensure environmental compliance and corporate responsibility.

By adhering to these tips, you can achieve efficient and high-quality CNC woodturning lathe manufacturing with SourcifyChina, ultimately enhancing your production capabilities and product quality.

Sure, here are some frequently asked questions (FAQ) with answers for sourcing a CNC woodturning lathe from SourcifyChina factory:

Q1: What types of CNC woodturning lathes does SourcifyChina offer?

A1: SourcifyChina offers a variety of CNC woodturning lathes, including single-axis, multi-axis, and fully-automated lathes. These machines are designed for precision, durability, and various levels of production capacity.

Q2: Can I customize the CNC woodturning lathe to meet specific requirements?

A2: Yes, SourcifyChina provides customization options based on your specific needs, including size, power, software compatibility, and additional features such as enhanced safety mechanisms and automated tool changers.

Q3: What is the lead time for delivery?

A3: The typical lead time ranges from 4 to 8 weeks, depending on the complexity and customization options of the CNC woodturning lathe. Discussing specifics with the factory will provide a more accurate timeline.

Q4: What are the payment terms?

A4: SourcifyChina generally accepts multiple payment methods, including wire transfers, L/C (Letter of Credit), and PayPal. Standard payment terms are usually 30% upfront and 70% upon shipment.

Q5: How is shipping handled?

A5: The factory handles both domestic and international shipping, ensuring your CNC woodturning lathe is securely packaged and reaches you in optimal condition. Shipping costs vary based on the destination, size, and weight of the shipment.

Q6: Is there a warranty or after-sales support?

A6: Yes, SourcifyChina provides a standard one-year warranty on most CNC woodturning lathes. They also offer after-sales support including remote troubleshooting, replacement parts, and maintenance services.

Q7: Are there any certifications for quality assurance?

A7: SourcifyChina’s CNC woodturning lathes are manufactured in compliance with international standards such as ISO and CE certifications, ensuring high quality and reliability.

Q8: Can I visit the factory to inspect the machines?

A8: Absolutely, factory visits can be arranged. It is recommended to schedule an appointment in advance to ensure that a representative is available to provide a detailed tour and demonstration.

This FAQ should help address most common inquiries when sourcing a CNC woodturning lathe from SourcifyChina factory.

Sourcing a CNC woodturning lathe from SourcifyChina Factory can be streamlined with the following tips:

1. Research and Shortlist: Start by researching potential manufacturers on SourcifyChina. Look for factories specializing in CNC woodturning lathes. Pay attention to their experience, product range, and reviews from past clients.

2. Check Certifications: Ensure the factory has necessary certifications such as ISO, CE, and RoHS. This confirms adherence to international quality standards.

3. Assess Quality: Request detailed product specifications, materials used, and any available quality assurance processes. High-quality CNC lathes should have precision components and durable build.

4. Request Samples: If feasible, ask for a sample purchase to check the product’s quality firsthand. This can be a critical step in verifying that the equipment meets your requirements.

5. Compare Prices: Obtain quotes from multiple sources. Analyzing cost against quality and features will help you find the most value-for-money option. Beware of prices that seem too good to be true – they often are.

6. Evaluate Communication: Effective communication is crucial. Assess how promptly and clearly the factory responds to your inquiries. This also gives hints about their future customer service.

7. Visit the Factory: If possible, arrange a visit to the factory. This can provide insights into their production capabilities and working conditions. If visiting isn’t an option, a virtual tour could be a substitute.

8. Check Payment and Delivery Terms: Discuss payment options, manufacturing timelines, and delivery conditions. Ensure they are clear and mutually agreeable to avoid future misunderstandings.

9. Negotiate Contracts: Where possible, negotiate a detailed contract outlining specifications, timelines, payment terms, and warranties to safeguard both parties’ interests.

10. Monitor Performance: Post-purchase, monitor the lathe’s performance and maintain regular communication with the supplier for any support or additional purchases.

By following these steps, you can effectively source a reliable CNC woodturning lathe from SourcifyChina Factory, ensuring quality and efficiency in your operations.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.