Choosing SourcifyChina Factory for CNC woodworking projects offers unparalleled expertise in precision manufacturing. Their skilled team ensures high-quality output, meeting exact specifications. Additionally, their commitment to customer satisfaction guarantees seamless communication and project updates.

SourcifyChina’s factories employ cutting-edge technology, ensuring efficient production processes. This technical advantage helps keep costs low, benefiting customers financially while maintaining superior quality standards.

Timely delivery is another reason to choose SourcifyChina. They have a robust logistics network, ensuring that projects are completed and delivered on schedule, vital for minimizing downtime and maintaining project timelines.

Excellent quality control measures are employed at SourcifyChina, ensuring each product undergoes rigorous testing and inspection before shipment. This focus on quality guarantees reliable and durable final products.

SourcifyChina prioritizes customer support, offering comprehensive assistance at every project stage. Their responsive team helps in addressing any concerns promptly, ensuring a smooth procurement experience from start to finish.

For buyers, SourcifyChina Factory offers a combination of expertise, advanced technology, cost-efficiency, and robust support, making them an ideal partner for CNC woodworking projects.

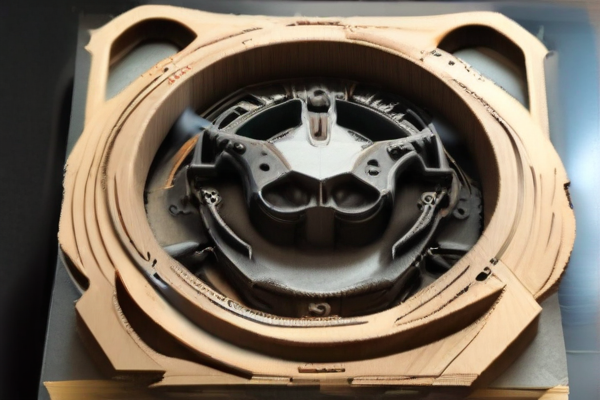

CNC woodworking projects offer endless creative possibilities, from intricate designs to functional furniture. These computerized machines allow for precision and complexity that are hard to achieve manually.

– Furniture: Chairs, tables, cabinets, and shelving units.

– Decorative items: Wall art, sculptures, and intricate patterns.

– Storage solutions: Custom drawers, boxes, and organizational kits.

– Signage: Personalized signs for homes and businesses.

– Toys and puzzles: Educational toys, jigsaw puzzles, and game boards.

– Kitchens: Cutting boards, utensils, and customized storage solutions.

– Airplanes and boat models: Detailed model kits with precise cuts.

– Architectural models: Scale models for builders and designers.

– Musical instruments: Guitar bodies and other wooden instruments.

– Frames: Custom picture and mirror frames.

CNC woodworking projects range from simple to complex, serving both beginners and professionals. The technology can greatly simplify the design and construction process, making it accessible for various skill levels. Additionally, the variety of materials that can be used allows for endless experimentation and innovation in woodworking.

Computer Numerical Control (CNC) woodworking projects have revolutionized the woodworking industry by offering precision, efficiency, and endless design possibilities. These machines are used in various applications, elevating craftsmanship and productivity to new heights.

– Furniture Manufacturing: CNC machines can precisely cut intricate designs, enabling the production of custom furniture and detailed cabinetry.

– Sign Making: They are widely used to carve detailed and intricate designs into wood for commercial and decorative signs.

– Architectural Elements: CNC technology allows for the creation of custom millwork, moldings, and other architectural components.

– Custom Wood Panels: These are used in interior design to create unique wall panels and decorative elements.

– Prototyping and Small Batch Production: CNC woodworking machines are ideal for producing prototypes and small production runs of wooden products.

– Instrument Making: They are used to create finely detailed components for musical instruments, such as guitars and violins.

– Art and Sculptures: Artists use CNC machines to carve intricate wooden sculptures and artwork.

– Engraving and Inlays: CNC technology allows for precise engraving and inlay work, adding detail and value to wooden objects.

– Wooden Toys and Games: These machines can produce safe, high-quality wooden toys and game pieces.

– Custom Decor: CNC woodworking is popular for making personalized wooden home decor items like plaques, frames, and coasters.

– Joinery and Dovetails: CNC machines can precisely cut complex joints like dovetails, making them strong and decorative.

– Sign Lettering and Carvings: Used for high-quality wooden signs with precision lettering and detailed carvings.

– Outdoor Structures: They can be employed to create components for outdoor furniture, pergolas, and other structures.

– Educational Models and Kits: CNC machines are used to produce educational models and DIY kits for learning and teaching purposes.

– Restoration Work: They are invaluable in restoring historic wooden pieces with exact replica parts.

SourcifyChina offers an array of CNC woodworking materials suitable for diverse projects. Their inventory includes high-quality hardwoods like oak, maple, and cherry, ensuring durability and a premium finish. The selection also features softwoods such as pine and cedar, ideal for budget-friendly endeavors.

For more specialized applications, SourcifyChina provides engineered woods such as plywood and MDF. These materials are perfect for intricate designs and large-scale productions due to their stability and uniformity. Additionally, their laser-cutting capabilities enhance precision in complex patterns, broadening the scope for creative projects.

Sustainable and eco-friendly materials are also a strong focus at SourcifyChina. They offer bamboo and reclaimed wood options, catering to environmentally conscious consumers. These materials not only reduce waste but also add unique aesthetic elements to woodworking projects.

SourcifyChina’s comprehensive selection ensures that hobbyists and professionals alike can find the perfect material for any CNC woodworking project. Their focus on quality and variety sets them apart, making them a go-to resource for all woodworking needs. With an emphasis on customer satisfaction and innovative solutions, SourcifyChina helps bring creative visions to life.

SourcifyChina ensures top-notch quality control in CNC woodworking projects through stringent oversight at various stages of production. From material selection to final assembly, each step is meticulously monitored.

Initial inspections involve rigorous testing of raw materials to confirm their integrity and suitability. This early scrutiny helps avoid future complications, guaranteeing a high-quality starting point for all products.

In-process inspections are conducted to monitor compliance with predetermined specifications. Skilled technicians utilize advanced measurement tools and techniques, ensuring that each component adheres to exact tolerances and dimensions.

Final quality checks involve comprehensive assessments of finished products. Visual inspections, functional tests, and surface quality evaluations are performed to validate the overall quality and durability.

This multifaceted approach to quality control ensures that CNC woodworking projects from SourcifyChina consistently meet or exceed industry standards, thereby delivering reliable and superior products to customers every time.

SourcifyChina, renowned for its CNC woodworking projects, showcases unparalleled expertise in precision and innovation. Utilising state-of-the-art CNC technology, the company transforms intricate designs into finely-crafted wooden masterpieces.

Their capabilities extend to intricate carvings, custom furniture, and detailed architectural elements, all benefiting from their high-quality machinery and skilled craftsmanship. This ensures every piece is not only unique but also a perfect fit for client specifications.

Furthermore, SourcifyChina’s CNC woodworking projects cater to both large-scale industrial needs and bespoke individual requirements. Their flexibility in project scale demonstrates their commitment to meeting diverse client demands without compromising on quality.

The integration of advanced software allows for meticulous design planning and seamless execution. This results in reduced waste and higher efficiency, translating into cost savings for clients while maintaining superior product standards.

Additionally, the company’s dedication to using sustainable materials aligns with global eco-friendly practices. This commitment reflects SourcifyChina’s role as a responsible industry leader in CNC woodworking projects, contributing positively to both their clients’ needs and the environment.

In conclusion, SourcifyChina’s CNC woodworking projects stand out for their precision, versatility, and commitment to sustainability. Their advanced capabilities and dedication to quality make them a top choice for anyone seeking exceptional woodworking solutions.

CNC woodworking projects offer numerous advantages that cater to both hobbyists and professionals, enhancing efficiency, precision, and creativity in woodworking.

– Precision and Consistency: CNC machines ensure high levels of accuracy, producing consistent results that are difficult to achieve with manual techniques.

– Increased Efficiency: Automated processes reduce production time, allowing for more complex designs to be created quickly and efficiently.

– Complex Designs: CNC technology enables the execution of intricate patterns and details that would be challenging and time-consuming to carve by hand.

– Reduced Waste: Precise cutting minimizes material waste, making projects more cost-effective and environmentally friendly.

– Versatility: CNC machines can work with various materials, including wood, plastic, and metal, offering greater creative flexibility.

– Scalability: Projects can be easily scaled to different sizes without compromising quality, perfect for both single and batch productions.

– Labor Savings: Automation reduces the need for manual labor, lowering labor costs and reducing the risk of human error.

– Increased Safety: CNC machines improve workplace safety by minimizing direct tool handling and exposure to sharp instruments.

– Customization: Personalize designs effortlessly with CAD software, allowing for unique, one-of-a-kind pieces.

– Skill Development: Working with CNC technology helps woodworkers develop new skills in CAD design and CNC programming.

Incorporating CNC technology into woodworking not only enhances productivity and precision but also unlocks a new level of creativity and customization.

CNC woodworking projects offer precision and efficiency unparalleled by traditional methods. The digitally-driven accuracy and repeatability allow for consistent, high-quality results.

– Precision: CNC machines can cut intricate designs with millimeter accuracy, ensuring flawless results every time.

– Efficiency: Speed up production times by automating repetitive tasks, reducing the time spent on manual labor.

– Customization: Design flexibility allows for unique, intricate designs that can be modified easily.

– Consistency: Produce identical parts in bulk with consistent quality and precision.

– Complexity: Create complex designs that are difficult or impossible to achieve by hand.

– Material Utilization: Optimize material usage, reducing waste and saving costs.

– Safety: Minimizes human intervention, reducing the risk of accidents and injuries.

– Scalability: Easily scale projects from prototypes to large production runs.

– Software Integration: Utilize advanced software for design and production, enhancing overall workflow.

– Versatility: Works with various materials including wood, composite, and plastics to diversify project outputs.

– Minimal Error: Reduced human error due to automated controls and precise execution.

– Cost-Effective: Lower labor costs and high material efficiency contribute to cost savings.

– Time-Saving: Reduces the project completion time by streamlining the cutting and carving processes.

– Maintenance: Regular maintenance keeps the machine in optimal working condition, ensuring long-term reliability.

– Reproducibility: Ability to reproduce exact copies of a design ensures consistency across multiple batches.

These features elevate CNC woodworking projects to an industry standard for high-quality, efficient production solutions.

SourcifyChina specializes in CNC woodworking projects, creating meticulously crafted products that combine traditional artistry with advanced technology. They cater to custom orders, ensuring that each piece meets the client’s unique specifications and expectations.

Their team of skilled artisans uses state-of-the-art CNC machinery to produce an array of items, from intricate décor pieces to robust furniture. This ensures precision and quality in every project they undertake.

SourcifyChina’s custom products are highly sought after for their durability and unique designs. They use a variety of woods and finishes to create pieces that suit diverse tastes and preferences.

Customer satisfaction is a top priority for SourcifyChina. They offer a collaborative design process, allowing clients to contribute to the creation of their custom pieces. This ensures that each product is truly unique.

Their comprehensive service doesn’t end at production. SourcifyChina also provides efficient logistics and delivery solutions, ensuring that their custom woodworking projects reach customers safely and on time.

In summary, SourcifyChina excels in combining advanced CNC technology with traditional woodworking craftsmanship to deliver high-quality, custom products. Their dedicated team ensures precision, quality, and customer satisfaction in every project they undertake.

SourcifyChina CNC Woodworking Projects stands out as a leader in precision-crafted woodworking solutions, seamlessly blending the latest CNC (Computer Numerical Control) technology with traditional artisanal craftsmanship. Based in China, the company specializes in producing high-quality custom furniture, intricate decorative items, and bespoke architectural components, catering to a global clientele. Their state-of-the-art CNC machinery ensures unparalleled accuracy and consistency, while their team of skilled artisans brings a human touch to each project, ensuring that every piece is not only technically flawless but also aesthetically captivating. What sets SourcifyChina apart is their commitment to sustainability; they employ eco-friendly practices and responsibly sourced materials in all their projects. Whether it’s a unique one-off piece or large-scale production, SourcifyChina’s dedication to quality and customer satisfaction has earned them a stellar reputation worldwide. The company’s ability to deliver customized solutions efficiently and affordably makes it a go-to destination for architects, designers, and woodworking enthusiasts seeking top-notch craftsmanship and innovation.

CNC woodworking projects have found a transformative role in aerospace, defense, and marine applications, carving out a niche where precision and customization are paramount. In the aerospace industry, the advanced capabilities of CNC machines allow for the creation of highly accurate wooden prototypes and models, which engineers use for aerodynamic testing and design validation. These wooden models are often larger, more cost-effective stand-ins for metal or composite parts, enabling rapid iteration and refinement of complex geometries before committing to expensive material options. This iterative process not only accelerates the design cycle but also reduces costs and material wastage, making CNC woodworking an invaluable tool in the preliminary stages of aerospace engineering.

Similarly, in the defense sector, CNC woodworking projects are instrumental in crafting precise mock-ups and training tools. For instance, wooden replicas of firearms, control panels, and operational elements are used in training exercises to simulate real-world scenarios without the associated risks or costs of using actual hardware. This allows for hands-on experience while maintaining safety and cost efficiency. In marine applications, CNC-machined wooden components are utilized for model testing in fluid dynamics labs, where accurate scale models of hulls and structural elements undergo rigorous testing. Furthermore, custom wooden parts are often employed in luxury yacht interiors, where CNC precision supports the creation of bespoke, high-quality furnishings and intricate design features, thereby enhancing both functionality and aesthetic appeal. Through these applications, CNC woodworking projects demonstrate their versatility and critical importance across these sophisticated and demanding sectors.

CNC woodworking projects have found significant applications in the automotive industry, enhancing both functionality and aesthetics. Within the automotive sector, CNC woodworking is employed to create custom interior panels, intricate dashboards, and ergonomic seating components. The precision of CNC machines ensures that each part fits perfectly, contributing to the car’s overall quality and luxury feel. Moreover, automakers utilize CNC woodworking to design prototype models and specialized components for high-performance vehicles. This approach facilitates rapid prototyping and iteration, helping to speed up the development cycle and improve product innovation. The versatility of CNC woodworking also allows for the integration of various materials like composites and polymers, which can be layered or inlaid into wooden components to meet specific performance and design criteria.

In the realm of electronics, CNC woodworking projects are increasingly being adopted to craft innovative and aesthetically pleasing enclosures for devices such as speakers, amplifiers, and home automation systems. The precision and versatility of CNC machines enable the creation of intricate designs that not only protect the electronic components but also enhance their visual appeal. CNC woodworking can accommodate the integration of various technological elements, such as touch screens, sensor arrays, and control knobs, into the wooden structure. This fusion of traditional materials with cutting-edge technology results in unique, high-quality products that stand out in the marketplace. Additionally, CNC woodworking facilitates small-scale production runs and customization, allowing electronics manufacturers to offer personalized products that cater to specific consumer preferences.

CNC woodworking projects have revolutionized the construction industry by significantly enhancing precision, efficiency, and versatility. Automated CNC machinery enables the production of intricate and large-scale components with exact specifications, reducing the margin for error and ensuring structural integrity. Custom elements such as trusses, beams, and decorative architectural details can be produced quickly, allowing for both standardization and unique design elements in construction projects. The time saved on complex cuts and shapes accelerates project timelines and reduces labor costs. Additionally, the integration of CNC technology in prefabricated construction systems simplifies on-site assembly, reducing the physical footprint and environmental impact associated with traditional construction methods.

In the energy sector, CNC woodworking projects contribute to the creation of high-efficiency structures and components essential for renewable energy solutions. For instance, precision-cut wooden elements are integral in constructing wind turbine blades and solar panel frames, where aerodynamics and structural integrity are crucial. The ability to produce these components to exact specifications results in better performance and longevity. Moreover, CNC woodworking supports sustainable practices by optimizing material usage and minimizing waste, aligning with the goals of green energy initiatives. The adaptability of CNC technology also facilitates the development of bespoke solutions for energy storage and distribution systems, thereby enhancing the overall efficiency and effectiveness of renewable energy infrastructures.

The industrial equipment industry has seen a significant transformation with the integration of CNC woodworking projects, enhancing both precision and efficiency. CNC (Computer Numerical Control) technology allows for the automated control of machining tools via computers, significantly reducing the likelihood of human error and enabling the production of intricate designs with high consistency. In woodworking, this translates to highly detailed carvings, joinery, and cuts that meet exact specifications, crucial for industries demanding precise and repetitive operations. Furniture manufacturing, for example, benefits immensely as CNC machines can handle complex patterns in wood, cuttings, and moldings, leading to high-quality products with reduced material wastage. Moreover, such precision minimizes the time needed for post-processing, contributing to overall increased productivity and cost efficiency.

Beyond traditional furniture, CNC woodworking has proven invaluable for custom woodwork in architecture and interior design. The ability to quickly prototype and produce custom components, from intricate paneling to bespoke cabinetry, allows manufacturers to offer tailored solutions to clients without extensive manual labor. This flexibility is critical in high-demand sectors such as luxury homes and commercial interiors, where unique designs are often required. Additionally, the integration of CNC technology facilitates the use of advanced software for design and simulation, enabling more innovative and complex project planning. Thus, manufacturers in the industrial equipment industry who invest in CNC woodworking technology can leverage these capabilities to expand their service offerings, improve their product quality, and maintain a competitive edge in a market increasingly driven by customized, precision-engineered products.

The application of CNC woodworking projects in the medical device industry represents a fascinating intersection of precision engineering and healthcare requirements. Computer Numerical Control (CNC) technology, originally developed for precise machining tasks in metalworking and woodworking, is now being adopted to create complex and highly accurate medical devices. These include surgical instruments, orthopedic components, and intricate parts for medical imaging machines. CNC woodworking offers unmatched precision, allowing for the creation of custom devices that meet the stringent requirements of medical standards. The technology’s ability to precisely cut, shape, and carve wood into detailed forms makes it a valuable tool for prototyping and producing small batches of highly customized medical tools.

Moreover, CNC woodworking can also play a role in creating ergonomic and patient-friendly medical devices. The use of wood, a biocompatible and aesthetically pleasing material, can enhance the design of assistive devices such as braces, prosthetics, and rehabilitation tools. These wooden components can be tailored to individual patient needs, providing both functionality and comfort. Furthermore, wood’s inherent properties, such as its lightweight and sustainability, add value in terms of reducing the environmental impact of medical device production. As healthcare facilities increasingly aim for sustainability, integrating CNC woodworking projects provides an innovative approach to developing practical, patient-specific, and environmentally responsible medical devices.

CNC (Computer Numerical Control) woodworking projects have revolutionized the machining and manufacturing industry by introducing unparalleled precision and efficiency. Unlike traditional woodworking, which relies heavily on manual operations and skilled artisans, CNC woodworking employs computer-controlled machines to execute intricate designs with exactitude. This technology enhances productivity by automating repetitive tasks, reducing the rate of human error, and enabling the creation of complex geometries that would be challenging to achieve manually. From custom furniture and cabinetry to intricate decorative panels and artistic sculptures, CNC machines can handle a wide variety of woodworking projects with remarkable speed and consistency. This level of precision also leads to superior product quality, which is critical in industries where accuracy and aesthetics are paramount.

In the manufacturing context, CNC woodworking offers significant advantages in terms of scalability and customization. Mass production is made simpler as identical pieces can be replicated with high fidelity, meeting stringent industry standards while reducing lead times. Additionally, the flexibility of CNC technology allows manufacturers to quickly switch between different production runs, facilitating bespoke and limited-edition pieces without significant downtime. This adaptability is particularly beneficial for small and medium-sized enterprises (SMEs) that may cater to niche markets or custom orders. Moreover, the integration of advanced software solutions enables seamless conversion of digital designs into physical products, streamlining the workflow from conceptualization to finished goods. As such, CNC woodworking not only boosts operational efficiency but also opens up new avenues for innovative design and functional applications in the ever-evolving landscape of machining and manufacturing.

Sure! Here are some frequently asked questions (FAQ) and answers about manufacturing CNC woodworking projects with quality work from SourcifyChina factory:

Q: What types of CNC woodworking projects can SourcifyChina handle?

A: SourcifyChina can handle a wide variety of CNC woodworking projects, including furniture, decorative items, cabinetry, and custom wood parts. Their advanced machinery and skilled technicians enable them to produce high-precision and intricate designs.

Q: How does SourcifyChina ensure the quality of their CNC woodworking projects?

A: SourcifyChina ensures quality through rigorous quality control procedures at every stage of production. They use high-grade materials, precision CNC machines, and conduct thorough inspections to meet international standards.

Q: Can SourcifyChina work with custom designs and specifications?

A: Yes, SourcifyChina specializes in custom designs and specifications. Clients can provide detailed drawings or CAD files, and the factory will produce the items exactly to those specifications.

Q: What is the typical lead time for a CNC woodworking project?

A: The lead time for a CNC woodworking project varies depending on its complexity and scale. Typically, SourcifyChina can complete projects within 2-4 weeks, but exact timelines will be provided after evaluating the project details.

Q: How does SourcifyChina handle project confidentiality?

A: SourcifyChina takes client confidentiality seriously. They are willing to sign non-disclosure agreements (NDAs) to ensure that all proprietary designs and project specifics remain confidential.

Q: What materials does SourcifyChina use for CNC woodworking?

A: SourcifyChina works with a wide range of materials including solid wood, plywood, MDF, and other engineered wood products. They source high-quality materials to meet client specifications and project requirements.

Q: How can I submit a project inquiry to SourcifyChina?

A: To submit a project inquiry, clients can visit the SourcifyChina website and fill out the inquiry form with project details, or they can contact their customer service via email or phone.

Q: Does SourcifyChina offer shipping and logistics support?

A: Yes, SourcifyChina provides comprehensive shipping and logistics support. They can handle everything from packaging to arranging international shipping, ensuring that finished products reach the client safely and on time.

Q: What is the cost structure for CNC woodworking projects at SourcifyChina?

SourcifyChina factory specializes in CNC woodworking projects manufacturing, providing precision and efficiency for custom designs. Here are some tips for optimizing your projects with them:

1. Design Optimization: Ensure your designs are optimized for CNC machining. Use CAD (Computer-Aided Design) software to create detailed digital plans, ensuring all dimensions and specifications are clear. This minimizes errors and maximizes accuracy.

2. Material Selection: Choose the right type of wood for your project. SourcifyChina can provide guidance on the best materials for durability and aesthetics, helping you select options like hardwoods, plywood, MDF, or specialty woods.

3. Prototyping: Before full-scale production, consider creating a prototype. This allows you to identify any design flaws or necessary adjustments, saving time and resources in the long run.

4. Precision and Tolerances: Communicate specific tolerance levels required for your project. CNC machines can achieve high precision, but ensuring all requirements are clear helps in maintaining quality and functionality.

5. Batch Production: Take advantage of CNC’s efficiency for batch production. Whether small or large-scale, batch manufacturing reduces costs and time, ensuring consistent quality across all units.

6. Surface Finishing: Plan for post-machining processes such as sanding, staining, or painting. SourcifyChina can provide these services or recommend suitable finishes to enhance the appearance and durability of your products.

7. Cost Management: Discuss cost-saving strategies with SourcifyChina. Factors like material efficiency, batch size, and complexity can influence prices. Optimize your design and production plan to balance cost and quality.

8. Communication: Maintain clear and consistent communication with the factory. This ensures your specifications, timelines, and quality expectations are met, leading to successful project outcomes.

By leveraging SourcifyChina’s expertise and advanced CNC technology, you can achieve high-quality woodworking projects efficiently and cost-effectively.

Sure, here is a list of FAQs with answers for sourcing CNC woodworking projects from SourcifyChina factory:

1. What types of CNC woodworking projects does SourcifyChina offer?

SourcifyChina provides a wide range of CNC woodworking projects, including furniture components, decorative items, custom engravings, cabinetry, and more. They can accommodate various designs and specifications according to your requirements.

2. How can I place an order with SourcifyChina?

To place an order, contact SourcifyChina through their official website or customer service hotline. Provide detailed specifications and designs for your project, and their team will assist you with the order process, including quotations and timelines.

3. What materials can SourcifyChina work with?

SourcifyChina can work with a variety of wood types, such as hardwoods (oak, maple, walnut), softwoods (pine, cedar), and engineered woods (plywood, MDF). Discuss your material preferences with their team for the best results.

4. Can SourcifyChina handle bulk orders?

Yes, SourcifyChina is equipped to handle both small and large-scale orders. Their advanced CNC machinery and skilled workforce enable them to manage bulk productions efficiently while maintaining quality standards.

5. What are the lead times for CNC woodworking projects?

Lead times vary based on the complexity and volume of the order. Typically, smaller projects may take a few weeks, while larger or more complex orders could take several months. It’s best to discuss timelines with their team during the initial consultation.

6. Can SourcifyChina provide custom designs?

Yes, SourcifyChina specializes in custom CNC woodworking projects. You can provide your own designs, or work with their in-house designers to create unique and tailored pieces that meet your specifications.

7. How does SourcifyChina ensure quality control?

SourcifyChina has a robust quality control process that includes detailed inspections at each stage of production. They use high-precision CNC machines and experienced craftsmen to ensure each piece meets stringent quality standards before shipment.

8. What are the payment terms and conditions?

Payment terms typically include a deposit upon order confirmation and the balance before shipment. Detailed terms and conditions can be discussed with SourcifyChina’s sales team to ensure transparency and mutual agreement.

9. Does SourcifyChina offer shipping services?

Sourcing CNC woodworking projects from SourcifyChina factory can be a streamlined process if approached correctly. Here are some tips to help you navigate it effectively:

1. Define Your Requirements: Clearly outline the specifications, materials, and finishes you need for your CNC woodworking projects. This includes dimensions, wood types, and any special features or detailed design elements.

2. Research the Factory: Gather information about SourcifyChina, including their production capabilities, experience in CNC woodworking, and past customer reviews. Ensure they have the expertise needed for your projects.

3. Request Samples: Before placing a large order, request samples of their work to evaluate the quality and craftsmanship. This can prevent misunderstandings and ensure the final product meets your standards.

4. Communicate Clearly: Ensure that all communications are clear and precise. Use visual aids like sketches or 3D models to convey your ideas. A language barrier can lead to misinterpretations, so be thorough and unambiguous.

5. Negotiate Terms: Discuss terms of production, payment, and delivery timelines upfront. Ensure that all details are agreed upon in writing to avoid any future discrepancies.

6. Quality Control: Establish quality control measures. Regularly check in during the production process and, if possible, hire a local inspector to perform quality control on-site before shipment.

7. Logistics and Shipping: Plan your logistics carefully. Work with SourcifyChina to understand the best shipping methods and costs. Factor in potential delays and customs clearance times to avoid disruptions.

8. Build Relationships: Foster a good relationship with the factory. Regularly communicate and provide feedback. A strong partnership can lead to better cooperation and potentially better terms in the future.

By following these steps, you can efficiently source high-quality CNC woodworking projects from SourcifyChina factory while minimizing risks and ensuring a smooth process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.