Technology and Applications of computer aided machining

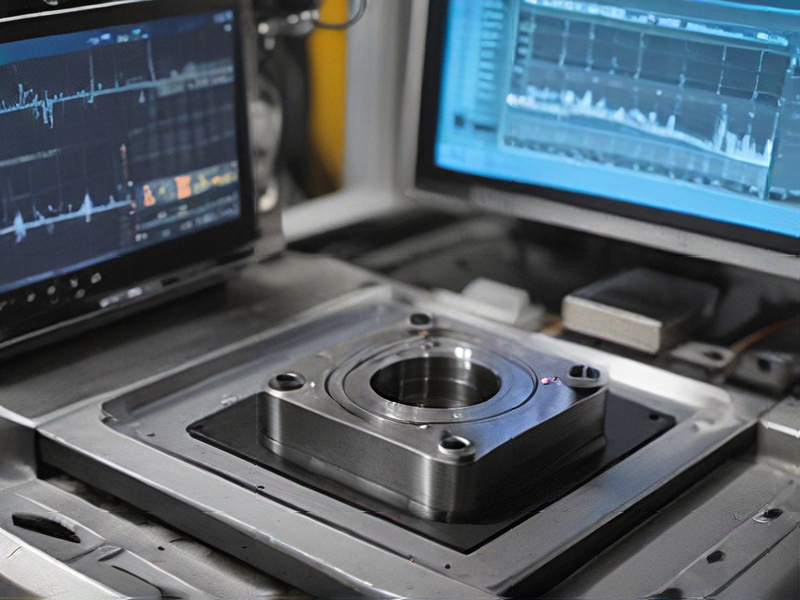

Computer-Aided Machining (CAM) encompasses technologies that automate and optimize manufacturing processes using computer software. CAM integrates with Computer-Aided Design (CAD) systems to convert CAD models into machine instructions, enhancing precision and efficiency in machining operations.

Key technologies in CAM include CNC (Computer Numerical Control) machining, which involves automated control of machinery through coded instructions. CNC allows for complex geometries and high repeatability, minimizing human error and reducing production time. Additionally, CAM software can simulate machining operations to anticipate potential issues, allowing for adjustments before physical machining begins.

Applications of CAM span various industries, including aerospace, automotive, and medical device manufacturing. In aerospace, for instance, intricate components can be machined with exacting standards, ensuring safety and performance. The automotive sector benefits from CAM in producing parts with high volume and stringent tolerances. Medical applications often require custom components, where CAM’s precision facilitates the production of implants and surgical tools tailored to individual patient needs.

Furthermore, advancements in CAM technologies, such as 5-axis machining, allow for the machining of complex shapes that were previously difficult or impossible to achieve. Additive manufacturing (3D printing) is increasingly incorporated into CAM processes, enabling the rapid prototyping of components while maintaining design flexibility.

Overall, CAM is integral to modern manufacturing, enhancing productivity, ensuring quality, and fostering innovation. By streamlining the transition from design to production, computer-aided machining plays a crucial role in the evolution of manufacturing techniques, driving efficiency and precision in creating today’s complex products.

Quality Testing Methods for computer aided machining and how to control quality

Quality testing in computer-aided machining (CAM) is crucial for ensuring the precision and reliability of machined components. Various methods can be employed to achieve the desired quality standards, including:

1. Dimensional Inspection: Utilize coordinate measuring machines (CMM) or laser scanners to verify the dimensions of components against CAD specifications. This ensures that parts meet the exact tolerances required.

2. Surface Finish Testing: Assess the surface quality using profilometers or surface roughness testers. This helps in evaluating the aesthetic and functional aspects of the finished parts.

3. Non-Destructive Testing (NDT): Methods like ultrasonic testing, radiographic inspection, or dye penetrant tests can identify internal flaws without damaging the parts. This is especially important for safety-critical components.

4. Tool Wear Monitoring: Implement sensors and software that monitor cutting tool conditions in real-time. This helps in predicting tool failures and initiating timely replacements, thus maintaining quality.

5. Statistical Process Control (SPC): Use SPC techniques to track process variability through control charts. This data-driven approach allows for early detection of quality issues, facilitating corrective actions.

6. First Article Inspection (FAI): Conduct thorough inspections of the first produced piece according to specifications before full-scale production. This verifies that the manufacturing process is capable of consistently producing acceptable parts.

7. Feedback Loops: Integrate feedback mechanisms between production and testing teams. Continuous monitoring and adjustments based on test results can improve machining processes and quality.

To control quality effectively, establish comprehensive quality management systems (QMS) that document procedures, train personnel, and ensure compliance with industry standards. Regular audits and reviews can further enhance the quality assurance process in CAM.

Tips for Procurement and Considerations when Purchasing from computer aided machining

When procuring computer-aided machining (CAM) equipment and services, consider the following tips and considerations to ensure you make the best choice for your organization:

1. Define Requirements: Clearly outline your machining needs, including materials, tolerances, production volume, and specific functionalities. This helps in selecting the right CAM system tailored to your operations.

2. Supplier Evaluation: Research potential suppliers thoroughly. Evaluate their reputation, experience, and customer feedback. Ensure they have a proven track record in delivering reliable CAM solutions.

3. Technical Support and Training: Choose a supplier that provides comprehensive technical support and training. Adequate training is essential for your staff to maximize the capabilities of the CAM software and hardware.

4. Integration Capabilities: Assess how the CAM system will integrate with existing design (CAD) and enterprise resource planning (ERP) systems. Smooth integration is vital for enhancing workflow and productivity.

5. Scalability: Consider whether the CAM system can grow with your business. As production needs evolve, the ability to scale up the software without major investments is crucial.

6. Cost-Benefit Analysis: Weigh the total cost of ownership against potential benefits. This includes initial costs, ongoing maintenance, software updates, and expected return on investment (ROI).

7. Trial Period: Whenever possible, request a trial or demonstration of the CAM software. This allows you to test functionality and determine if it meets your specific requirements before committing.

8. Stay Updated: The industry is rapidly changing. Choose suppliers who regularly update their technologies and can provide innovative solutions over time.

By keeping these considerations in mind, you can make informed procurement decisions that enhance your machining operations and contribute to overall efficiency.

FAQs on Sourcing and Manufacturing from computer aided machining in China

FAQs on Sourcing and Manufacturing from Computer-Aided Machining in China

1. What is computer-aided machining (CAM)?

CAM involves the use of software to control machine tools for manufacturing parts. It increases precision, reduces waste, and enhances production efficiency.

2. Why source CAM services from China?

China offers a vast network of manufacturers with advanced CAM technology, competitive pricing, and rapid production capabilities, making it an attractive option for businesses.

3. How do I select a reliable CAM supplier in China?

Look for suppliers with proven expertise, positive reviews, and relevant certifications (e.g., ISO 9001). Conduct due diligence through factory visits or online audits.

4. What are typical lead times for CAM projects?

Lead times can vary based on complexity and order size, typically ranging from 2 to 8 weeks. Discuss timelines with suppliers before placing orders.

5. How can I ensure quality control?

Implement a robust quality assurance plan, which includes pre-production samples, in-process inspections, and final quality checks. Collaborating with a local quality control team may also be beneficial.

6. Are there language barriers when sourcing from China?

Language barriers can exist, but many manufacturers employ English-speaking staff. Using clear, concise language and visual aids can help mitigate misunderstandings.

7. What are the shipping options from China?

Shipping methods include air freight, sea freight, and express delivery services, each varying in cost and transit time. Consider the urgency and budget when selecting a method.

8. What should I know about intellectual property protection?

Ensure that non-disclosure agreements (NDAs) are in place and consider using legal protections relevant to your technology to safeguard intellectual property during the manufacturing process.

For further assistance, consult with sourcing agents or industry experts who can guide you through the process.