Technology and Applications of custom 3d printing

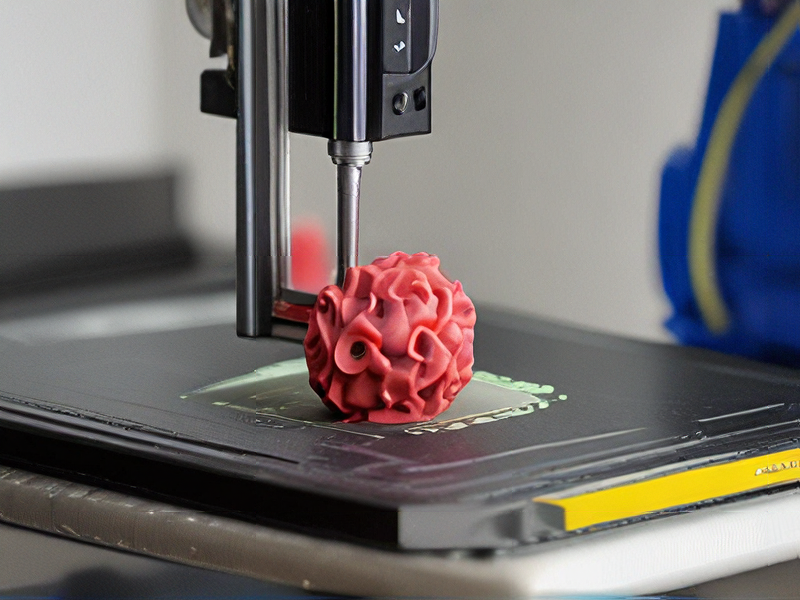

Custom 3D printing, also known as additive manufacturing, revolutionizes traditional manufacturing processes by enabling the creation of complex, bespoke objects from digital designs. This technology finds diverse applications across various industries:

1. Prototyping and Product Development: Companies use custom 3D printing to quickly iterate and refine prototypes. It allows designers to test concepts and functionalities before mass production, reducing time and costs.

2. Customized Consumer Goods: From personalized jewelry and fashion accessories to custom-fit prosthetics and medical implants, 3D printing enables the production of unique, tailored products that meet individual needs and preferences.

3. Healthcare and Biotechnology: In medicine, 3D printing is transforming healthcare with custom prosthetics, orthodontics, and anatomical models for surgical planning. Researchers also use it to create tissue and organ scaffolds for regenerative medicine.

4. Aerospace and Automotive: These industries utilize 3D printing for lightweight components, complex geometries, and rapid prototyping. It enables manufacturers to reduce weight, improve fuel efficiency, and customize parts for specific applications.

5. Construction and Architecture: 3D printing large-scale structures like houses and bridges is becoming feasible, offering faster construction times, reduced labor costs, and the ability to create intricate architectural designs.

6. Education and Research: Educational institutions use 3D printing to enhance learning experiences, allowing students to visualize complex concepts and create models for projects. Researchers explore new materials and applications, pushing the technology’s boundaries.

7. Sustainability: By enabling on-demand manufacturing and reducing material waste compared to traditional methods, 3D printing supports sustainability efforts in manufacturing and supply chains.

Advancements in materials science, software development, and printer technology continue to expand the capabilities and applications of custom 3D printing, making it a transformative force in modern industry and innovation.

Quality Testing Methods for custom 3d printing and how to control quality

Quality testing for custom 3D printing involves a mix of pre-print, in-process, and post-print assessments. Here’s a concise guide on methods and quality control measures:

Pre-Print Quality Control:

1. Design Verification: Ensure the digital model is optimized for 3D printing. Check for errors such as non-manifold edges and ensure the design meets the specifications.

2. Material Selection: Choose appropriate materials based on the intended use of the printed object. Verify the material properties and compatibility with the printer.

In-Process Quality Control:

1. Printer Calibration: Regularly calibrate the printer to maintain dimensional accuracy and proper layer adhesion.

2. Environmental Control: Maintain optimal temperature and humidity levels in the printing environment to prevent warping and other defects.

3. Monitoring: Use cameras and sensors to monitor the printing process. Implement automated systems to detect and correct issues like layer misalignment or extruder clogging.

Post-Print Quality Control:

1. Dimensional Accuracy: Measure the printed object against design specifications using tools like calipers or 3D scanners.

2. Surface Finish: Inspect the surface quality visually and through tactile examination to check for roughness, layer lines, and other defects.

3. Structural Integrity: Perform mechanical testing such as tensile, compression, and impact tests to ensure the printed part meets strength requirements.

4. Post-Processing: Implement post-processing steps like sanding, polishing, or heat treatment to improve the final product’s quality.

Quality Control Measures:

1. Standard Operating Procedures (SOPs): Develop and follow SOPs for all stages of 3D printing to ensure consistency.

2. Training: Provide comprehensive training for operators on machine maintenance, troubleshooting, and quality standards.

3. Documentation: Maintain detailed records of each print job, including material batch numbers, machine settings, and inspection results.

4. Regular Maintenance: Schedule regular maintenance for 3D printers to prevent unexpected failures and ensure optimal performance.

5. Statistical Process Control (SPC): Use SPC techniques to monitor and control the printing process, identifying trends and addressing issues before they lead to defects.

By integrating these methods, you can maintain high quality in custom 3D printing projects.

Tips for Procurement and Considerations when Purchasing from custom 3d printing

When engaging in procurement from custom 3D printing services, several key considerations can streamline your decision-making process:

1. Quality Standards: Ensure the provider meets your quality requirements by reviewing samples, testimonials, or previous work. Quality assurance protocols and certifications can also indicate reliability.

2. Technical Capabilities: Assess the range of materials, technologies, and printing capacities offered by the service. Compatibility with your project requirements (e.g., size, complexity, material properties) is crucial.

3. Cost and Value: Compare pricing structures and quotes from multiple providers. Consider not just the initial cost but also long-term value, including post-processing, finishing, and support services.

4. Lead Times and Flexibility: Evaluate turnaround times and the provider’s ability to accommodate changes or urgent orders. Clear communication channels and responsiveness are essential.

5. Intellectual Property and Confidentiality: Ensure that the provider respects your intellectual property rights and maintains confidentiality regarding your designs or proprietary information.

6. Customer Support and Communication: Opt for providers who offer robust customer support, clear communication channels, and proactive updates throughout the production process.

7. Sustainability and Ethics: Consider the environmental impact of materials used and the provider’s sustainability practices. Ethical considerations such as fair labor practices may also be important.

8. Prototyping and Iteration: If prototyping is part of your project, inquire about iterative processes, feedback incorporation, and the cost implications of revisions.

9. Post-Production Services: Determine if additional services like finishing, assembly, or packaging are offered and their costs.

10. References and Reviews: Seek references or read reviews from previous clients to gauge overall satisfaction and reliability.

By carefully considering these factors, you can make informed decisions when selecting a custom 3D printing service that aligns with your project’s needs and objectives.

FAQs on Sourcing and Manufacturing from custom 3d printing in China

FAQs on Sourcing and Manufacturing Custom 3D Printing in China

1. Why choose China for 3D printing manufacturing?

China offers competitive pricing, advanced technology, and a vast network of suppliers, making it an attractive option for 3D printing manufacturing.

2. How do I find reliable 3D printing suppliers in China?

Use platforms like Alibaba, Global Sources, or Made-in-China. Check supplier reviews, request samples, and verify certifications to ensure reliability.

3. What materials are available for 3D printing in China?

Common materials include PLA, ABS, nylon, resin, and metal alloys. Confirm material availability with your supplier based on your project needs.

4. What is the typical lead time for 3D printed parts?

Lead times vary depending on the complexity and quantity of the order but typically range from a few days to several weeks.

5. How do I ensure the quality of 3D printed parts?

Request prototypes, conduct quality inspections, and work with suppliers who have quality certifications such as ISO 9001.

6. Can I get customized designs manufactured?

Yes, Chinese manufacturers can handle custom designs. Provide detailed CAD files and clear specifications to ensure accurate production.

7. What are the costs involved in 3D printing manufacturing in China?

Costs include design, material, printing, post-processing, and shipping. Request detailed quotes from multiple suppliers for comparison.

8. How do I handle intellectual property (IP) concerns?

Sign non-disclosure agreements (NDAs) and work with reputable suppliers to protect your IP. Consider registering your design patents in China.

9. What are the shipping options and costs?

Shipping options include air freight for fast delivery and sea freight for cost savings. Costs depend on weight, volume, and delivery speed.

10. Are there any import duties or taxes?

Yes, import duties and taxes may apply. Check with your local customs office and include these costs in your budget.

11. How do I communicate effectively with Chinese suppliers?

Use clear, concise English, provide detailed instructions, and consider using translation services if necessary. Regular communication helps avoid misunderstandings.

These FAQs cover the essentials of sourcing and manufacturing custom 3D printing in China, ensuring a smooth and efficient process.