Choosing SourcifyChina for custom automotive parts ensures high-quality products at competitive prices. Their extensive network of reliable factories guarantees efficient production and timely delivery, meeting the stringent requirements of the automotive industry.

SourcifyChina offers end-to-end procurement services, including sourcing, quality control, and logistics management. Their expert team manages every detail, ensuring a seamless and hassle-free purchasing experience for buyers.

With a strong commitment to transparency and communication, SourcifyChina provides regular updates and clear reporting throughout the procurement process. Buyers can trust them to handle complex projects with professionalism and accuracy.

SourcifyChina prioritizes customer satisfaction, tailoring their services to meet specific needs and preferences. Their flexible approach allows for customized solutions, ensuring that each buyer’s unique requirements are fully addressed.

By partnering with SourcifyChina, buyers benefit from reduced risks and improved cost efficiency. Their strategic sourcing and robust quality assurance processes ensure that products meet or exceed international standards.

In summary, choosing SourcifyChina for custom automotive parts procurement from China offers unparalleled quality, reliability, and customer-centric services, making them an ideal partner for buyers seeking excellence in their supply chain.

Custom automotive parts offer a wide range of options to personalize and enhance your vehicle’s performance, appearance, and functionality. These parts can be tailored to fit specific models and preferences, providing unique modifications to suit individual styles.

– Performance Enhancements:

– Turbochargers and superchargers

– High-performance exhaust systems

– Cold air intakes

– Performance chips and tuners

– Aesthetic Modifications:

– Custom paint jobs

– Body kits

– Custom wheels and rims

– LED lighting

– Interior Customizations:

– Custom upholstery

– Aftermarket steering wheels

– Personalized dashboard components

– High-end audio systems

– Suspension Upgrades:

– Lowering kits

– Lift kits

– Performance shocks and struts

– Air suspension systems

– Safety and Technology Additions:

– Advanced navigation systems

– Backup cameras

– Parking sensors

– Enhanced security systems

– Specialized Accessories:

– Roof racks and carriers

– Custom floor mats

– Unique grille designs

– Tailgate accessories

These custom parts not only improve the vehicle’s look and feel but can also significantly enhance its functionality and performance. From increased horsepower to luxurious interiors, the possibilities are nearly endless for car enthusiasts looking to make their vehicle truly one-of-a-kind.

Custom automotive parts are used to enhance vehicle performance, aesthetics, and functionality. These parts allow for personalized modifications to meet specific needs or preferences, ranging from improved speed to unique design features.

– Performance Enhancement: Upgraded engines, turbochargers, and exhaust systems for better speed and efficiency.

– Aesthetics: Custom paint jobs, body kits, and interior modifications for a unique look.

– Functionality: Specialized parts like suspension systems, brakes, and tires to improve handling and safety.

– Comfort: Enhanced seating, climate control systems, and soundproofing for a better driving experience.

– Technology Integration: Advanced navigation systems, audio setups, and connectivity features.

– Off-Road Capabilities: Lift kits, off-road tires, and reinforced frames for rugged terrain.

– Racing Applications: Lightweight materials, aerodynamic components, and performance tuning for competitive racing.

– Restoration: Custom parts to restore classic cars to their original or improved conditions.

– Eco-Friendly Upgrades: Parts for electric conversions and improving fuel efficiency.

– Personalization: Custom license plates, steering wheels, and shift knobs for a personal touch.

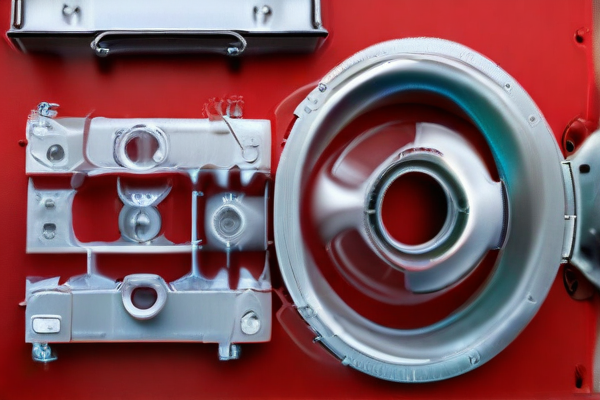

SourcifyChina offers custom automotive parts made from high-quality materials designed to meet industry standards. Their products often use durable metals like aluminum and stainless steel, which provide strength and resistance to corrosion.

In addition to metals, SourcifyChina also employs advanced plastics and composites. These materials offer flexibility, lightweight properties, and high impact resistance, making them suitable for various automotive applications.

The company ensures precision in manufacturing by utilizing cutting-edge technology and stringent quality control processes. This attention to detail guarantees that each part meets the specific requirements of their clients.

SourcifyChina’s commitment to using premium materials and advanced manufacturing techniques ensures that their custom automotive parts not only enhance vehicle performance but also maintain safety and longevity.

SourcifyChina employs rigorous quality control measures in its custom automotive parts manufacturing process. Each stage of production is meticulously monitored to ensure precision and adherence to specifications.

The process begins with a thorough inspection of raw materials, ensuring they meet the highest standards. Advanced testing equipment is used to detect any impurities or defects early on.

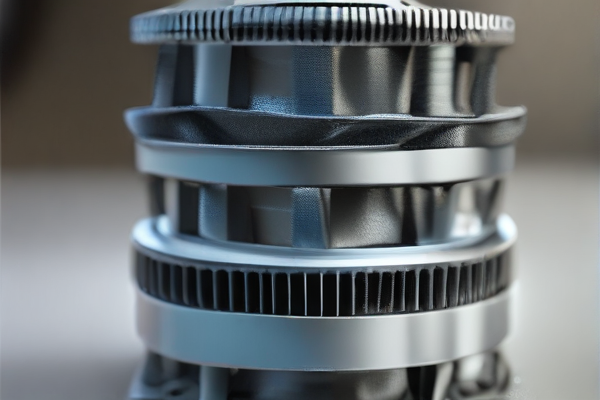

During production, state-of-the-art machinery and technology maintain consistency and accuracy. Skilled technicians oversee operations, performing regular checks to guarantee components meet design requirements.

Finished parts undergo comprehensive testing, including durability, performance, and safety assessments. This ensures each piece functions reliably under various conditions.

Finally, a detailed quality assurance review is conducted before packaging and shipment. This includes a final inspection and validation, ensuring every part that leaves the facility meets SourcifyChina’s stringent quality standards. This meticulous approach underscores the company’s commitment to delivering exceptional custom automotive parts.

SourcifyChina specializes in custom automotive parts, offering tailored solutions to meet the diverse needs of automotive manufacturers and enthusiasts. Their expertise includes precision engineering and advanced manufacturing techniques to produce high-quality components.

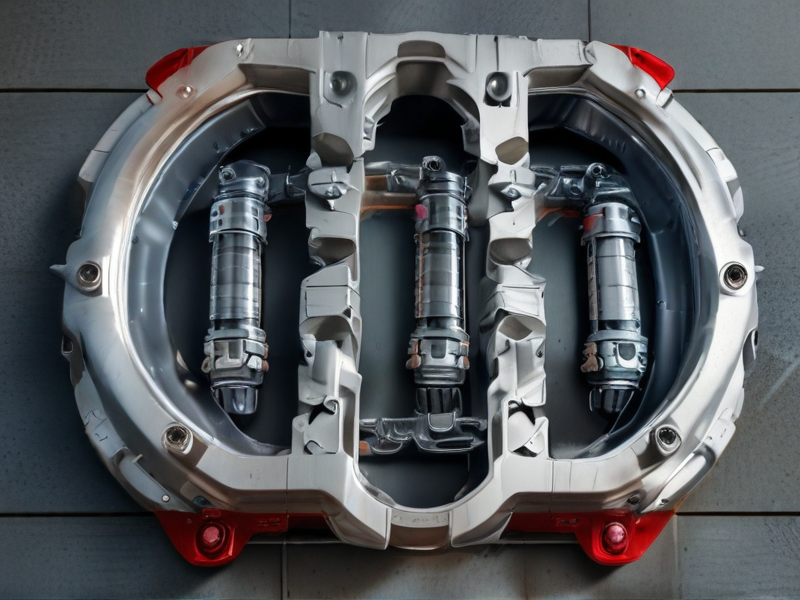

The company provides a wide range of custom parts, including engine components, suspension systems, and interior accessories. Each product is designed to enhance vehicle performance and aesthetics, ensuring optimal functionality and durability.

SourcifyChina uses state-of-the-art technology and rigorous quality control measures to ensure each part meets or exceeds industry standards. This commitment to excellence guarantees reliable and long-lasting products for their customers.

Their team of experienced engineers and designers collaborates closely with clients to develop bespoke solutions that align with specific requirements. This customer-centric approach ensures that every custom part is crafted to perfection.

Additionally, SourcifyChina offers competitive pricing and efficient production timelines, making them a preferred partner for automotive customization projects. Their global supply chain network ensures timely delivery and support for clients worldwide.

By combining innovation, quality, and customer service, SourcifyChina stands out as a leading provider of custom automotive parts. Their dedication to meeting and exceeding client expectations solidifies their reputation in the automotive industry.

Custom automotive parts offer numerous advantages, enhancing vehicle performance, aesthetics, and longevity. These benefits cater to both casual drivers and automotive enthusiasts.

– Improved Performance: Custom parts can significantly enhance engine power, fuel efficiency, and overall driving dynamics.

– Personalization: Allows vehicle owners to tailor their cars to their specific tastes and needs, making their vehicles unique.

– Enhanced Durability: High-quality custom parts often last longer than standard components, reducing maintenance costs over time.

– Increased Resale Value: Vehicles with well-chosen custom parts can fetch higher prices on the resale market.

– Better Fit and Function: Custom parts are designed to fit perfectly and function optimally, improving vehicle reliability.

– Aesthetic Appeal: Custom parts can dramatically improve the visual appeal of a vehicle, making it stand out.

– Technological Advancements: Many custom parts incorporate the latest technology, providing modern features not available in older models.

– Safety Improvements: Some custom parts can enhance vehicle safety by providing better handling, braking, and stability.

– Eco-Friendly Options: Custom parts often include eco-friendly alternatives that can reduce a vehicle’s environmental impact.

Custom automotive parts enhance vehicle performance, aesthetics, and personalization, allowing enthusiasts to tailor their cars to specific needs and preferences. Here are some notable features:

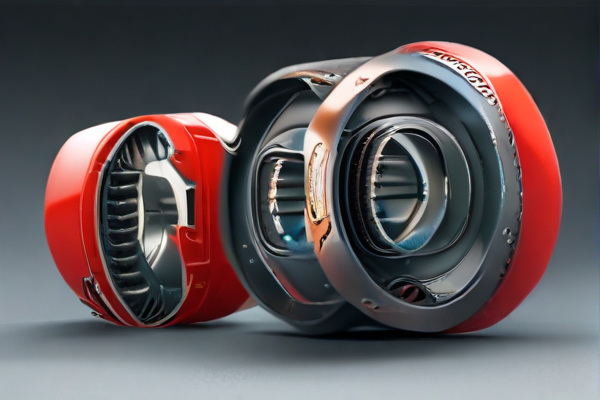

– Performance Enhancement: Custom parts like exhaust systems, turbochargers, and suspension kits improve power, handling, and overall vehicle performance.

– Aesthetics and Design: Unique body kits, paint jobs, and interior modifications provide a distinct look, reflecting the owner’s personal style.

– Durability and Quality: High-quality materials and precision engineering in custom parts often result in better durability and longevity compared to standard components.

– Functionality: Custom parts can add or improve functions, such as advanced lighting systems, enhanced braking components, and specialized tires.

– Fit and Compatibility: Designed to meet specific vehicle requirements, custom parts ensure a perfect fit and seamless integration with the vehicle’s existing systems.

– Innovation and Technology: Incorporation of the latest technologies, like smart sensors and aerodynamics, can give vehicles a cutting-edge advantage.

– Weight Reduction: Use of lightweight materials such as carbon fiber can significantly reduce vehicle weight, enhancing speed and efficiency.

– Sound Customization: High-performance mufflers and sound systems allow for personalized acoustic experiences.

– Eco-Friendliness: Some custom parts are designed to improve fuel efficiency or reduce emissions, contributing to a greener environment.

– Safety Enhancements: Advanced safety features, like roll cages and reinforced bumpers, provide additional protection in various driving conditions.

Overall, custom automotive parts offer a wide range of benefits, making them a popular choice among car enthusiasts and professionals alike.

SourcifyChina specializes in providing custom automotive parts, catering to the unique needs of car enthusiasts and manufacturers. Their extensive range includes tailored components for both performance and aesthetic enhancements, ensuring vehicles meet specific requirements.

Using advanced manufacturing techniques, SourcifyChina delivers high-quality parts that enhance vehicle performance and durability. Their custom products include engines, suspension systems, and exterior accessories designed to optimize driving experiences.

The company prides itself on its ability to manage complex projects, from concept to delivery. Their team collaborates closely with clients, ensuring every detail aligns with the customer’s vision and specifications.

SourcifyChina’s commitment to quality and innovation makes them a preferred partner for automotive customization. They consistently meet industry standards and exceed client expectations, providing reliable and efficient solutions. Whether it’s for personal use or commercial applications, SourcifyChina delivers custom automotive parts that drive excellence and satisfaction.

SourcifyChina Custom Automotive Parts is a distinguished company specializing in the procurement and production of tailored automotive components. Catering to a global clientele, SourcifyChina combines cutting-edge manufacturing technologies with rigorous quality control standards to deliver high-performance parts that meet the diverse needs of the automotive industry. From intricate engine components to sophisticated electronic systems, the company’s extensive product range is designed to enhance vehicle performance and reliability. By leveraging a robust supply chain network across China, SourcifyChina ensures cost-effective solutions without compromising on quality. Their commitment to innovation and customer satisfaction positions them as a trusted partner for automakers, aftermarket suppliers, and automotive enthusiasts worldwide, striving to exceed industry expectations and foster long-term client relationships.

In the aerospace, defense, and marine industries, custom automotive parts play a crucial role in enhancing performance, safety, and reliability. These sectors often require highly specialized components that can withstand extreme conditions and rigorous demands. Custom automotive parts are engineered to meet specific needs such as high strength-to-weight ratios, corrosion resistance, and precise dimensional tolerances. In aerospace applications, for instance, lightweight and durable materials are essential to improve fuel efficiency and overall aircraft performance. Similarly, in defense, custom parts are designed to endure harsh environments and heavy loads, ensuring the reliability and effectiveness of military vehicles and equipment.

The marine industry also benefits significantly from the use of custom automotive parts. Vessels operating in saltwater environments require parts that resist corrosion and maintain integrity over extended periods. Customization allows for the integration of advanced materials and coatings that enhance longevity and performance. Additionally, custom parts enable tailored solutions for propulsion systems, navigation, and other critical functions, ensuring that marine vessels can operate efficiently and safely in challenging conditions. By leveraging the expertise in custom automotive part manufacturing, these industries can achieve superior performance, extended operational life, and increased safety standards, meeting the stringent requirements of their respective fields.

Custom automotive parts play a pivotal role in enhancing vehicle performance, aesthetics, and functionality. These parts, tailored to meet specific requirements, enable car enthusiasts and manufacturers to push the boundaries of standard automotive capabilities. Performance-oriented custom parts, such as turbochargers, exhaust systems, and suspension components, are designed to optimize engine efficiency and handling characteristics, providing a significant boost to a vehicle’s power and agility. Additionally, aesthetic modifications like custom body kits, wheels, and interior trims allow owners to personalize their vehicles, reflecting individual style and taste. The integration of advanced materials and manufacturing techniques, such as 3D printing and CNC machining, has further revolutionized the creation of bespoke automotive components, ensuring precision and superior quality.

In the realm of automotive electronics, custom parts are equally transformative, contributing to the rapid advancement of vehicle technology. Custom electronic components, including advanced ECU (Engine Control Unit) tuning, bespoke infotainment systems, and specialized sensor arrays, enhance the driving experience by improving vehicle intelligence and connectivity. ECU tuning, for instance, allows for personalized engine performance settings, optimizing fuel efficiency and power output based on user preferences. Custom infotainment systems provide a tailored interface that integrates seamlessly with other smart devices, offering enhanced navigation, entertainment, and connectivity features. Furthermore, custom sensor arrays enable advanced driver-assistance systems (ADAS), increasing vehicle safety through precise detection and response mechanisms. As automotive technology continues to evolve, the demand for custom electronic parts is expected to grow, driving innovation and personalization in the automotive industry.

In the construction sector, custom automotive parts are pivotal in the development of specialized machinery and vehicles that cater to unique project needs. These parts are designed to enhance the performance, durability, and efficiency of construction equipment such as bulldozers, excavators, and cranes. Custom-engineered components can significantly reduce downtime and maintenance costs by ensuring compatibility and optimized performance for specific tasks. For instance, reinforced axles, bespoke hydraulic systems, and tailored suspension components are crucial in handling the rigorous demands of construction sites, leading to improved productivity and safety.

In the energy sector, custom automotive parts play a crucial role in the efficiency and reliability of vehicles and machinery used in energy production and distribution. Whether it’s for wind turbine maintenance vehicles, specialized trucks for transporting oil and gas, or electric utility service trucks, customized parts ensure these vehicles can operate under extreme conditions and fulfill their specific roles. Custom cooling systems, enhanced powertrains, and specialized drive systems are examples of how these parts contribute to the efficient operation of energy-related machinery. By optimizing these components for the unique demands of the energy sector, companies can achieve greater operational efficiency, reduce environmental impact, and enhance the overall reliability of their energy supply chains.

The industrial equipment industry significantly benefits from the application of custom automotive parts, primarily in the manufacturing and maintenance of specialized machinery. Custom automotive parts are designed to meet specific requirements, enhancing the performance and longevity of industrial equipment. For instance, heavy-duty vehicles used in construction and mining often require robust and reliable components that can withstand extreme conditions. Custom parts ensure these machines operate efficiently and safely, reducing downtime and maintenance costs. Additionally, custom parts can be tailored to improve fuel efficiency and reduce emissions, aligning with regulatory standards and sustainability goals.

Moreover, the integration of custom automotive parts into industrial equipment facilitates innovation and adaptation to new technologies. Advanced materials and precision engineering in custom parts enable the development of high-performance machines capable of executing complex tasks with greater accuracy and speed. Industries such as agriculture, logistics, and manufacturing rely on these tailored solutions to enhance productivity and maintain a competitive edge. Customization also allows for the seamless incorporation of modern technologies like IoT sensors and automation systems, further optimizing equipment performance. Consequently, the use of custom automotive parts not only enhances the functionality and durability of industrial equipment but also drives technological advancement and operational efficiency across various sectors.

Custom automotive parts, traditionally associated with the enhancement and modification of vehicles, have found significant applications in the medical devices industry. This intersection leverages advanced manufacturing techniques such as 3D printing and CNC machining, initially perfected for the automotive sector, to produce bespoke medical components. For example, precision engineering used in custom automotive parts ensures high accuracy and reliability, which is crucial for medical devices like prosthetics, implants, and surgical instruments. These devices must meet stringent regulatory standards, and the expertise gained from the automotive sector in producing durable, high-performance parts translates well into creating medical devices that require similar qualities of precision and endurance.

Moreover, the use of custom automotive parts technology in medical devices promotes innovation and patient-specific solutions. Just as custom automotive parts can be tailored to enhance the performance and aesthetics of a vehicle, medical devices can be customized to better fit the anatomical and physiological needs of individual patients. This is particularly beneficial in the development of orthopedic implants and dental prosthetics, where a precise fit is crucial for patient comfort and the success of the procedure. The adaptability of manufacturing techniques like 3D printing allows for rapid prototyping and production of medical devices, thereby accelerating the development process and enabling the creation of more effective and personalized medical solutions. This convergence of automotive and medical technologies not only improves patient outcomes but also fosters ongoing advancements in both fields.

Machining and manufacturing of custom automotive parts involve precision engineering to create components tailored to specific vehicle requirements, ensuring optimal performance and compatibility. Advanced machining techniques such as CNC (Computer Numerical Control) milling and turning are employed to produce high-quality, bespoke parts that meet exact specifications. These methods allow for intricate designs and tight tolerances, essential for parts like custom engine components, suspension systems, and brake assemblies. The use of high-grade materials, including aluminum, steel, and titanium, enhances durability and performance, while computer-aided design (CAD) software facilitates the creation of detailed blueprints that guide the manufacturing process.

The application of custom automotive parts in manufacturing extends beyond mere performance enhancement to include aesthetic customization and restoration projects. For enthusiasts and restorers, custom-machined parts provide the opportunity to recreate or improve upon original components that may be obsolete or unavailable. This capability is crucial for maintaining the authenticity and functionality of classic and vintage vehicles. Additionally, in the realm of motorsports, bespoke parts are engineered to withstand extreme conditions and deliver superior performance, giving teams a competitive edge. Overall, the integration of machining and manufacturing technologies in the production of custom automotive parts exemplifies the fusion of innovation and craftsmanship, driving advancements in both vehicle performance and design.

Here is a list of frequently asked questions (FAQ) along with answers for manufacturing custom automotive parts of quality work from SourcifyChina factory:

Q: What types of custom automotive parts does SourcifyChina manufacture?

A: SourcifyChina specializes in producing a wide range of custom automotive parts, including metal and plastic components, engine parts, body panels, and interior accessories. We cater to various customization needs, from design to material selection.

Q: How does SourcifyChina ensure the quality of its automotive parts?

A: We maintain strict quality control protocols throughout the manufacturing process. Our parts undergo rigorous testing and inspection, adhering to international standards such as ISO 9001 and TS 16949 to ensure they meet the highest quality requirements.

Q: What materials can be used for custom parts at SourcifyChina?

A: We offer a variety of materials including steel, aluminum, plastics, composites, and more. Our team can recommend the best material based on your specific requirements and application.

Q: How long does it take to manufacture and deliver custom automotive parts?

A: The lead time varies depending on the complexity and quantity of the order. Typically, the process takes between 4 to 8 weeks from design approval to delivery.

Q: Can SourcifyChina handle large volume orders for custom parts?

A: Yes, we have the capacity to manage both small and large volume orders. Our facilities are equipped to handle mass production while maintaining high quality standards.

Q: Does SourcifyChina offer design and prototyping services?

A: Yes, we provide comprehensive design and prototyping services. Our team works closely with clients to develop prototypes that meet their specifications and can be tested before full-scale production.

Q: How do I start a project with SourcifyChina?

A: To start a project, you can contact us through our website or email. Provide details about your requirements, and our team will guide you through the process, from initial consultation to final delivery.

Q: What are the payment terms for custom orders?

A: Payment terms typically include an initial deposit followed by payments at various stages of production. We offer flexible payment options to accommodate different client needs.

Q: Can SourcifyChina manufacture parts according to my CAD drawings?

A: Absolutely. We can manufacture parts directly from your CAD drawings, ensuring they meet your precise specifications and requirements.

Q: Is there a minimum order quantity for custom automotive parts?

A: We are flexible with order quantities and can accommodate both small and large orders. However, larger orders may benefit from cost efficiencies due to economies of scale.

Manufacturing custom automotive parts from a factory like SourcifyChina involves several critical steps and considerations to ensure high quality, efficiency, and cost-effectiveness:

1. Design and Prototyping: Start with detailed CAD designs and specifications of the custom part. Engage in prototyping to test the design’s functionality and fit. SourcifyChina can assist with refining these designs and producing prototypes using CNC machining, 3D printing, or other rapid prototyping methods.

2. Material Selection: Choose the appropriate materials for durability, performance, and cost-effectiveness. Discuss with SourcifyChina to understand the range of materials they offer and their suitability for different automotive applications.

3. Manufacturing Process: Determine the most suitable manufacturing process (e.g., injection molding, die casting, forging, machining). SourcifyChina offers a variety of processes and can provide guidance on the best method based on your part’s design, material, and required quantity.

4. Quality Control: Implement strict quality control measures. SourcifyChina provides comprehensive quality assurance services, including in-process inspections, final inspections, and testing (e.g., stress tests, material analysis) to ensure the parts meet your specifications and standards.

5. Cost Management: Work closely with SourcifyChina to manage costs. This includes optimizing design for manufacturability (DFM), selecting cost-effective materials, and choosing the right production process. SourcifyChina can provide detailed quotes and suggest cost-saving measures without compromising quality.

6. Logistics and Supply Chain: Plan for efficient logistics and supply chain management. SourcifyChina can assist with packaging, labeling, and shipping, ensuring that your custom parts are delivered on time and in perfect condition.

7. Compliance and Certifications: Ensure that the manufactured parts comply with relevant automotive standards and certifications. SourcifyChina can help navigate regulatory requirements and provide necessary documentation.

By leveraging SourcifyChina’s expertise, you can achieve high-quality custom automotive parts while maintaining cost efficiency and meeting delivery schedules.

1. What types of custom automotive parts can SourcifyChina produce?

SourcifyChina specializes in manufacturing a wide range of custom automotive parts, including but not limited to engine components, transmission parts, suspension systems, braking systems, and body parts. They can handle both metal and plastic components and cater to both OEM and aftermarket specifications.

2. How do I start the process of sourcing parts from SourcifyChina?

To begin, you need to provide detailed specifications, including drawings or CAD files, material requirements, and quantities. Contact their sales team through their website or email to discuss your project. They will provide a quote and timeline based on your needs.

3. What is the typical lead time for custom parts?

Lead times vary depending on the complexity and volume of the parts ordered. Generally, prototypes can be delivered in 2-4 weeks, while full production runs might take 6-12 weeks. SourcifyChina offers expedited services for urgent projects.

4. Can SourcifyChina handle large-scale production?

Yes, SourcifyChina is equipped to handle both small batch orders and large-scale production runs. Their facilities are scalable and can manage high-volume manufacturing efficiently.

5. How does SourcifyChina ensure the quality of the parts?

Quality is assured through stringent inspection processes, including material testing, dimensional inspections, and functional testing. SourcifyChina adheres to ISO and other relevant international quality standards to ensure that all parts meet or exceed customer specifications.

6. Are there minimum order quantities (MOQs) required?

MOQs depend on the complexity and type of part being manufactured. SourcifyChina strives to be flexible and can accommodate both small and large orders, although pricing may be more favorable for higher quantities.

7. How are the parts shipped to customers?

SourcifyChina offers several shipping options, including air, sea, and express courier services. The choice depends on the urgency, cost, and destination. They provide comprehensive logistics support to ensure timely and safe delivery.

8. What payment terms does SourcifyChina offer?

Payment terms are typically negotiable and can include options such as T/T (bank transfer), L/C (letter of credit), and other standard international trade payment methods. Terms will be specified in the quotation and contract.

9. Can SourcifyChina help with design and development of custom parts?

Yes, SourcifyChina has an experienced engineering team that can assist with design, prototyping, and development of custom parts. They offer design-for-manufacturing (DFM) services to optimize parts for production and cost-efficiency.

10. How can I get a quote for my project?

To get a quote, provide detailed project requirements, including design files, material specifications, and estimated quantities. You can submit this information via SourcifyChina’s website or email their sales team. They typically respond with a detailed quote within a few business days.

Sourcing custom automotive parts from SourcifyChina factory can be streamlined with the following tips:

1. Clear Specifications:

– Detailed Designs: Provide precise technical drawings, material specifications, and quality standards.

– Samples: If possible, send physical samples to ensure accurate replication.

2. Communication:

– Regular Updates: Establish a communication schedule for updates on production progress.

– Point of Contact: Ensure you have a dedicated contact person who is fluent in your language to avoid misunderstandings.

3. Quality Assurance:

– Pre-production Samples: Request samples before full production to verify quality and specifications.

– Inspections: Arrange for third-party inspections at various production stages.

4. Factory Visits:

– On-Site Visits: If feasible, visit the factory to assess their capabilities and production environment.

– Virtual Tours: Use video calls to get a real-time look at the manufacturing process if visiting isn’t possible.

5. Pricing and Contracts:

– Transparent Pricing: Ensure all costs are outlined clearly, including any potential hidden fees.

– Clear Contracts: Draft detailed contracts that specify delivery times, payment terms, and quality standards.

6. Logistics and Shipping:

– Reliable Shipping: Choose reliable logistics partners for timely and safe delivery.

– Customs and Duties: Be aware of import regulations and duties in your country to avoid delays.

7. Payment Terms:

– Secure Payments: Use secure payment methods, such as letters of credit or escrow services, to protect both parties.

– Milestone Payments: Consider milestone payments aligned with production stages to mitigate risk.

8. Cultural Understanding:

– Cultural Sensitivity: Understanding Chinese business etiquette can foster better relationships and smoother negotiations.

Following these steps will help ensure a successful and efficient sourcing process from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.