Choosing SourcifyChina for purchasing custom cylinder heads from China ensures top-notch quality and precision. Their expertise in manufacturing guarantees high-performance products for automotive needs, meeting stringent industry standards.

Furthermore, SourcifyChina offers competitive pricing without compromising on quality. This cost efficiency allows buyers to obtain superior products at affordable rates, boosting overall profitability.

Customer service excellence is another key benefit of partnering with SourcifyChina. Their responsive and knowledgeable team ensures seamless communication and timely resolution of any concerns or queries, enhancing the purchasing experience.

Lastly, SourcifyChina’s strong emphasis on timely delivery ensures that custom cylinder heads are produced and shipped according to schedule. Their reliable logistics network ensures prompt arrivals, maintaining project timelines.

In essence, SourcifyChina stands out for their product quality, affordability, exceptional customer service, and reliable delivery. By choosing SourcifyChina, buyers gain a trustworthy partner dedicated to meeting their specific needs and exceeding expectations.

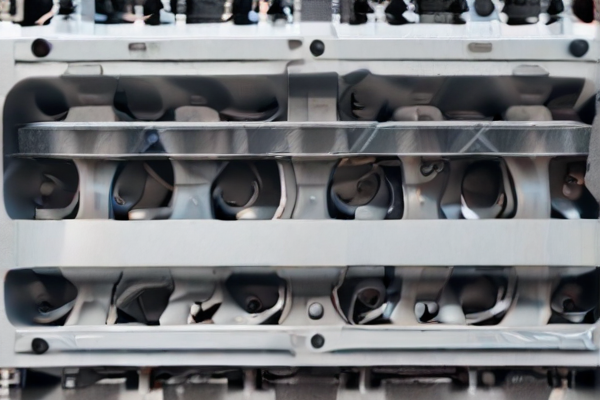

Custom cylinder heads enhance engine performance and efficiency. Options vary based on material, design, and application-specific requirements, offering tailored solutions for racing, street performance, or heavy-duty use.

– Materials: Aluminum, Cast Iron

– Designs: CNC-Ported, Hand-Ported, OEM Upgrade

– Applications: Drag Racing, Road Racing, Street Performance

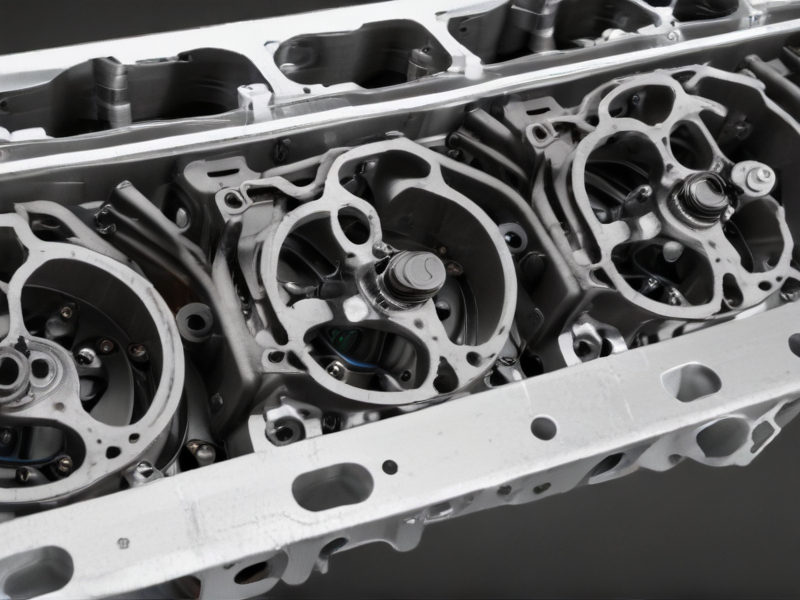

– Combustion Chamber Shapes: Hemispherical, Pentroof, Roof

– Valvetrain Configurations: Overhead Valve (OHV), Overhead Camshaft (OHC)

– Intake and Exhaust Port Designs: Rectangular, Oval, D-Port

– Compression Ratios: Low-Compression, High-Compression

– Cooling Features: Air-Cooled, Water-Cooled

– Compatibility: Make-Specific, Engine-Specific, Custom-Built

– Finish Options: Polished, Unpolished, Ceramic Coated

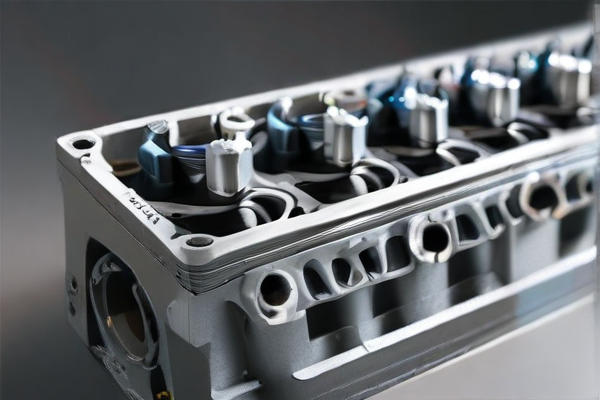

– Valve Sizes and Types: Standard, Oversized, Stainless Steel, Titanium

Each option caters to different performance goals and budgets, providing practical choices for enthusiasts and professional builders alike. Advanced customization requires understanding specific engine needs and the desired outcome to select the optimal heads.

Custom cylinder heads are specialized engine components designed to optimize performance, efficiency, and power by enhancing airflow and combustion. These modifications cater to various automotive needs, improving overall engine dynamics.

– Racing: Enhances horsepower and torque, offering competitive edge in high-performance motorsports.

– Tuning: Allows for precise adjustments for modified or aftermarket engines, improving specific performance metrics.

– Fuel Efficiency: Optimizes combustion processes to improve fuel mileage.

– Restoration: Essential for restoring vintage or classic cars to their original performance specs or better.

– Durability: Increases engine lifespan by using higher-quality materials and optimized designs.

– Off-Roading: Provides the power and reliability needed for extreme terrains and conditions.

– Marine Applications: Useful in boat engines, improving power and efficiency on the water.

– Heavy-Duty Engines: Applied in industrial machinery for enhanced performance and durability.

– Customization: Perfect for car enthusiasts aiming to personalize engine performance and appearance.

– Emission Control: Can help meet stricter emission standards by optimizing the burn process.

– Turbo/Supercharged Engines: Works well with forced induction systems to maximize performance benefits.

– Motorcycles: Applies to two-wheelers, enhancing engine power and efficiency.

– Experimental Projects: Ideal for engineering students and professionals engaged in automotive R&D.

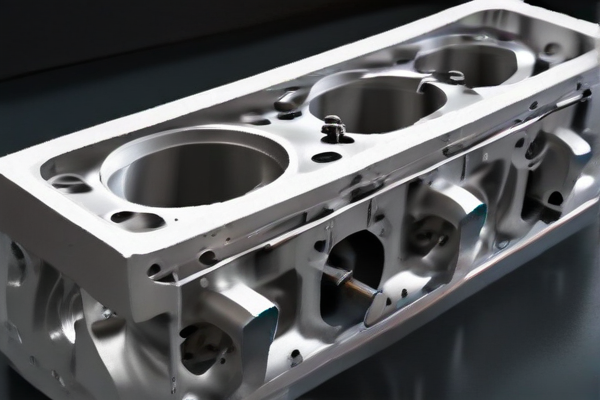

SourcifyChina custom cylinder heads are crafted with high-quality aluminum alloys, ensuring superior performance and longevity. The aluminum material is chosen for its excellent thermal conductivity, which helps manage engine temperatures efficiently.

Additionally, aluminum alloys offer advantageous weight properties, reducing the overall engine weight. This promotes better fuel efficiency while enhancing vehicle performance. The lightweight yet robust nature of aluminum is essential for today’s high-performance engines.

To further enhance durability, these cylinder heads often incorporate special coatings. These coatings prevent wear and tear, thereby extending the engine’s lifespan. The specific coatings used depend on the engine’s requirements and intended use.

In summary, SourcifyChina custom cylinder heads leverage the best properties of aluminum alloys and advanced coatings. This combination provides a reliable, durable, and high-performing solution for various engine applications.

SourcifyChina’s custom cylinder heads undergo rigorous quality control to ensure exceptional performance and durability. The manufacturing process begins with the selection of high-grade raw materials that meet stringent industry standards. Each material is inspected for purity and integrity before production.

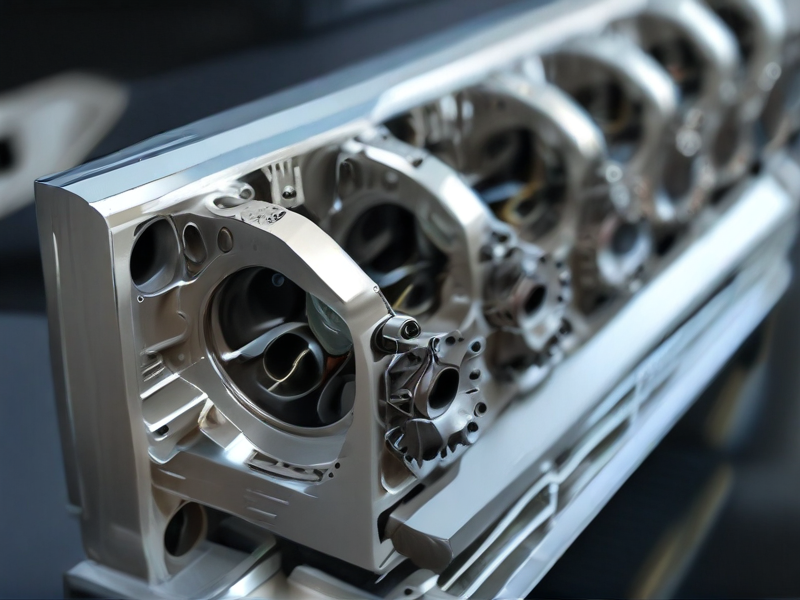

Advanced CNC machining techniques are employed to achieve precise specifications, ensuring every cylinder head fits perfectly within the engine architecture. Skilled engineers and technicians meticulously supervise each stage of the machining process, reducing the possibility of defects and inconsistencies.

Throughout the production, multiple inspections are carried out using state-of-the-art measuring equipment. These quality checks include dimensional accuracy, material hardness, surface finish, and heat treatment effectiveness. Any component that doesn’t meet the exact specifications is either corrected or discarded.

Each custom cylinder head undergoes thorough testing under simulated operating conditions to evaluate its performance, reliability, and longevity. This rigorous testing process helps identify potential issues before the product reaches the customer.

The final stage in the quality control process involves detailed visual inspections and final assembly assessments by experienced quality control specialists. Every cylinder head is certified before dispatch, ensuring that customers receive only the highest quality products.

SourcifyChina’s commitment to quality assurance extends beyond manufacturing. Continuous feedback loops with clients and an ongoing investment in advanced technologies ensure that their custom cylinder heads not only meet but exceed market expectations. This dedication to quality control makes SourcifyChina a trusted partner in the automotive industry.

SourcifyChina specializes in custom cylinder heads, engineered to enhance engine performance for various applications including automotive, industrial, and marine sectors. Their designs focus on optimizing airflow and fuel combustion to boost efficiency and power.

Using state-of-the-art technology, SourcifyChina ensures precision manufacturing with tight tolerances. Their cylinder heads are crafted from high-quality materials, providing durability and long-lasting performance even under extreme conditions, meeting the stringent standards of different industries.

SourcifyChina’s customization options enable clients to tailor cylinder heads according to specific engine requirements. They offer a variety of configurations, including multi-valve designs and custom porting and polishing techniques, all aimed at achieving maximum performance.

The company’s expert team is equipped with deep industry knowledge, facilitating seamless collaboration with clients from the initial concept to the final product. This ensures that each custom cylinder head not only meets but exceeds customer expectations.

In summary, SourcifyChina excels in producing top-tier custom cylinder heads through advanced technology, high-quality materials, and expert customization. Their commitment to performance, durability, and client satisfaction makes them a leading choice for high-performance engine components.

Upgrading to custom cylinder heads can dramatically enhance your engine’s performance, efficiency, and longevity. Here are some key benefits:

– Performance Boost: Custom cylinder heads are designed to optimize airflow, which results in improved horsepower and torque—essential for racing and high-performance vehicles.

– Fuel Efficiency: Better airflow and combustion can lead to a more efficient engine, which in turn can improve fuel economy, reducing overall fuel costs.

– Durability: High-quality materials and precise engineering mean custom cylinder heads often last longer than stock components, providing better long-term reliability.

– Temperature Control: Enhanced cooling capabilities reduce the risk of overheating, prolonging engine life and maintaining performance under extreme conditions.

– Customization: Tailored to your specific needs, custom cylinder heads can be modified to fit your desired power range and vehicle type, offering greater flexibility compared to off-the-shelf options.

– Resale Value: Improvements in engine performance and efficiency can increase the resale value of your vehicle, making it a smart investment.

– Reduced Emissions: Optimized combustion leads to more complete fuel burning, which reduces harmful emissions and can help meet regulatory standards.

– Sound and Vibration Quality: Better-engineered cylinder heads can lead to a smoother, quieter engine operation, enhancing the overall driving experience.

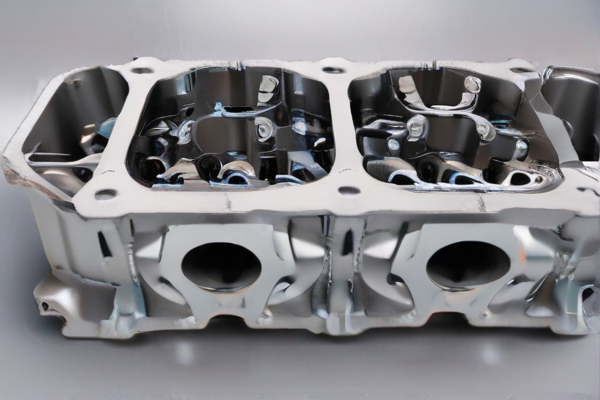

Custom cylinder heads are designed to enhance engine performance, efficiency, and durability by optimizing airflow, combustion, and cooling characteristics.

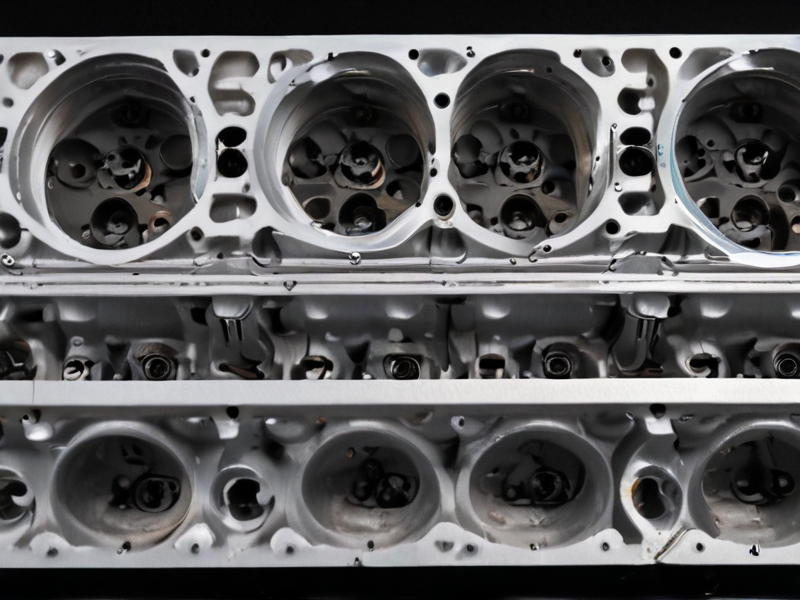

– Enhanced Airflow: Custom cylinder heads often feature improved port designs, larger valves, and polished surfaces to maximize air and fuel flow into the combustion chamber.

– Improved Combustion: By precisely shaping the combustion chamber, custom cylinder heads can promote more efficient and complete combustion, resulting in greater power output and fuel efficiency.

– Durable Construction: These heads are typically made from high-strength materials like aluminum or specialized alloys to withstand extreme conditions and prevent warping or cracking.

– Variable Valve Timing (VVT): Many custom heads are compatible with or specifically designed to incorporate advanced VVT systems, allowing for better performance across different engine speeds.

– Cooling Efficiency: Custom designs can include enhanced cooling channels and fin configurations to manage heat more effectively and prevent overheating.

– Compatibility: They can be tailored to suit a wide range of engine types and applications, from high-performance racing engines to heavy-duty industrial machinery.

– Reduced Weight: Using lightweight materials and optimized designs reduces the overall weight of the engine, contributing to improved vehicle dynamics and fuel economy.

– Customization Options: Attributes like port shape, chamber size, and valve configuration can be customized to meet specific performance goals, whether for racing, towing, or everyday driving.

– Precision Manufacturing: Advanced manufacturing techniques like CNC machining ensure that custom cylinder heads have high precision and consistency, enhancing reliability and performance.

– Porting and Polishing: Custom heads often undergo porting and polishing processes to remove imperfections and improve the smoothness of airflow passages.

– Increased Horsepower and Torque: The combined effect of these features usually results in significantly higher horsepower and torque, giving engines a noticeable performance boost.

In summary, custom cylinder heads offer an array of benefits tailored to meet specific performance and durability requirements, making them a valuable upgrade for various types of engines.

SourcifyChina specializes in creating custom cylinder heads tailored to meet the specific needs of automotive enthusiasts and professional racers. Their products ensure maximum engine performance and durability.

Using advanced engineering techniques and high-quality materials, SourcifyChina’s team crafts cylinder heads that surpass industry standards. Each product undergoes rigorous testing to ensure reliability and efficiency.

The company collaborates closely with clients to understand their requirements, providing bespoke solutions that enhance engine power and longevity. This client-focused approach sets them apart in the competitive market.

In addition to custom cylinder heads, SourcifyChina undertakes special projects, including engine tuning and customization services. These projects aim to boost vehicle performance and cater to unique client demands.

Their dedication to innovation and quality makes SourcifyChina a trusted partner for high-performance engine components. Whether for racing or regular use, their custom products deliver exceptional results.

By combining exemplary craftsmanship with cutting-edge technology, SourcifyChina ensures client satisfaction. Their commitment to quality and customer service solidifies their position as a leader in custom automotive solutions.

SourcifyChina Custom Cylinder Heads is a renowned enterprise specializing in the design and manufacture of high-performance cylinder heads for various automotive applications. With a commitment to precision engineering and utilizing cutting-edge technology, SourcifyChina has carved a niche in delivering exceptional quality products tailored to meet the diverse needs of both individual enthusiasts and professional racing teams. By leveraging extensive industry experience and maintaining rigorous quality control standards, the company ensures each cylinder head optimizes engine performance, enhances durability, and satisfies stringent emissions requirements. SourcifyChina’s dedication to innovation and customer-centric service has earned it a distinguished reputation in the global automotive aftermarket, making it a trusted partner for those seeking unparalleled engine components.

In the aerospace, defense, and marine sectors, custom cylinder heads play a crucial role in enhancing the performance, reliability, and efficiency of engines. These components are meticulously engineered to withstand extreme conditions and meet the stringent requirements of their respective applications. In aerospace, custom cylinder heads are designed to endure high-altitude pressures and varying temperatures, ensuring that aircraft engines operate smoothly and safely. By optimizing airflow and fuel combustion within the cylinder, these custom heads help maximize horsepower and fuel efficiency, which are critical for long-duration flights and maintaining operational readiness for military aircraft.

In the defense and marine industries, the demands on engine performance and durability are equally rigorous. For military vehicles and naval vessels, custom cylinder heads are crafted to manage the harsh conditions of combat environments, including exposure to corrosive elements and the need for high reliability under prolonged use. These heads often incorporate advanced materials and coatings to resist wear and thermal stress, thereby extending engine life and reducing maintenance costs. Customization allows for specific design features tailored to the unique operational requirements of ships, submarines, and military ground vehicles, ensuring optimal performance in diverse and challenging environments. By providing superior combustion efficiency and resilience, custom cylinder heads contribute significantly to the strategic capabilities and longevity of defense and marine fleets.

Custom cylinder heads play a pivotal role in the automotive industry, significantly enhancing engine performance, efficiency, and power output. Unlike standard cylinder heads, which are designed to meet general specifications and manufacturing cost constraints, custom cylinder heads are tailored to meet specific performance needs. They can be optimized for various parameters such as combustion chamber design, port shape, and valve size, all of which contribute to improved airflow and higher compression ratios. Such customization is crucial for applications ranging from high-performance racing engines, where every bit of efficiency and power gain matters, to specialized vehicles such as off-road trucks and industrial machinery that require robust and reliable performance under extreme conditions. The ability to match exact specifications allows for better fuel atomization, precise ignition timing, and enhanced overall engine responsiveness, ultimately leading to superior vehicle dynamics and longevity.

In the electronics sector, custom cylinder heads have promising applications in thermal management systems, particularly for high-performance computing machinery and other electronics that generate substantial heat. Custom cylinder heads can be integrated into the design of advanced cooling systems to ensure optimal heat dissipation through improved coolant flow and thermodynamic efficiency. For example, in liquid-cooled systems used in data centers and cutting-edge gaming rigs, custom cylinder heads can facilitate more efficient coolant distribution and heat exchange. This not only protects sensitive electronic components from overheating but also contributes to energy efficiency and reliability. By leveraging the tailored precision of custom cylinder heads, designers can better manage the thermal load in compact electronic assemblies, thereby pushing the envelope of performance and reliability in a wide range of high-stakes electronic applications.

Custom cylinder heads play an instrumental role in the construction industry, tailoring the performance of machinery and equipment to meet specific project requirements. Construction machinery, such as excavators, bulldozers, and cranes, often operates in extreme conditions that demand both power and durability. Custom cylinder heads enhance engine efficiency and power output, providing the additional horsepower necessary for these demanding tasks. By optimizing air-fuel mixture and combustion processes, these bespoke components can significantly improve the performance and reliability of heavy machinery, translating into reduced downtime and increased productivity on job sites. Additionally, they can be engineered to comply with specific emission regulations, ensuring that construction operations are both powerful and environmentally responsible.

In the energy sector, custom cylinder heads are pivotal in enhancing the efficiency and longevity of engines used in power generation, oil and gas extraction, and renewable energy projects. Power plants, whether they rely on fossil fuels or are part of renewable energy setups, require engines that can operate continuously at high loads with minimal maintenance. Custom cylinder heads, designed to optimize thermal dynamics and fuel efficiency, play a critical role in achieving these goals. For oil and gas extraction, where equipment is often employed in remote and harsh environments, the reliability and performance of engines are paramount. Customized cylinder heads can be tailored to withstand these extreme conditions, ensuring that energy extraction processes remain uninterrupted. Furthermore, in the realm of renewable energy, these engine components can be adapted to work optimally with alternative fuels, thereby supporting sustainability initiatives and reducing the carbon footprint of energy production.

The industrial equipment industry is heavily reliant on the precision and efficiency brought by custom cylinder heads. These specialized components are instrumental in optimizing the performance of machinery across a variety of applications, from heavy-duty construction equipment to advanced manufacturing processes. Custom cylinder heads are designed to meet the specific requirements of machinery engines, aiding in higher compression ratios, improved fuel efficiency, and increased horsepower. By tailoring the cylinder heads to the precise needs of an industrial engine, manufacturers can achieve significantly better thermal management and combustion efficiency, resulting in extended engine lifespan and reduced maintenance costs. This specific customization is crucial, as it directly impacts the output capabilities and operational reliability of the equipment, ensuring that these machines can perform under rigorous conditions without frequent downtime.

In addition, the adaptability provided by custom cylinder heads plays a significant role in specialized fields such as oil and gas exploration, mining, and large-scale agricultural operations. For instance, in oil extraction machinery, the custom cylinder heads can be designed to withstand extreme pressures and high temperatures, making them essential for the engine’s durability and performance. Similarly, mining equipment benefits from cylinder heads that can handle abrasive environments and provide robust power delivery necessary for demanding tasks like rock excavation and mineral processing. By implementing custom solutions, operators can optimize fuel consumption and minimize emissions, aligning with stricter environmental regulations and sustainability goals. Ultimately, the application of custom cylinder heads in the industrial equipment industry not only enhances the efficiency and productivity of these machines but also contributes to the overall advancement of industry standards and technological innovations.

Custom cylinder heads play a pivotal role in enhancing the efficacy and performance of medical devices, particularly those used in critical care and surgical procedures. These bespoke components are engineered to precision, ensuring optimal fit and performance in various medical machinery such as ventilators, anesthesia delivery systems, and blood pumps. Customization allows for specific design modifications tailored to meet unique device requirements, thereby improving fluid dynamics, gas exchange efficiency, and overall operational reliability. For instance, in respiratory devices, custom cylinder heads can enhance airflow management, resulting in better patient outcomes and reduced risk of complications.

Moreover, the integration of custom cylinder heads in medical devices extends their longevity while minimizing maintenance requirements. These components are often fabricated from high-grade biocompatible materials, which ensure durability and reduce the risk of contamination. Advanced manufacturing techniques like CNC machining allow for the precise replication of intricate designs, leading to consistent performance and reliability. In highly regulated medical environments, where device failure is not an option, the assurance of quality and precision that comes with custom cylinder heads contributes significantly to patient safety and the effectiveness of medical treatments.

Custom cylinder heads play a pivotal role in machining and manufacturing, offering bespoke solutions for enhanced engine performance and efficiency. Machining custom cylinder heads involves precision engineering and advanced CNC (Computer Numerical Control) machining techniques to achieve exact specifications that cater to specific performance requirements. The process includes intricate operations such as milling, drilling, and grinding, which are vital for optimizing airflow and maximizing combustion efficiency within an engine. By meticulously shaping the intake and exhaust ports, valves, and combustion chambers, machinists can significantly improve the power output, fuel efficiency, and overall performance of the engine. This tailored approach ensures that each cylinder head meets the unique needs of applications ranging from high-performance racing engines to specialized industrial machinery.

In the manufacturing context, the production of custom cylinder heads often encompasses a series of sophisticated steps, from initial design and material selection to final quality inspection. Using advanced materials such as aluminum alloys or high-strength cast iron, manufacturers aim to balance durability and weight minimization. State-of-the-art CAD (Computer-Aided Design) software facilitates precise modeling, allowing for innovative features like optimized cooling passages and variable valve timing systems. The integration of these custom cylinder heads in automotive, aerospace, and marine industries can lead to notable advancements in engine technology. As engines become more specialized, the demand for custom solutions drives ongoing research and development, pushing the boundaries of what is technically feasible. Ultimately, the machining and manufacturing of custom cylinder heads exemplify how tailored engineering solutions can achieve superior performance and innovation in various industrial applications.

Sure! Here’s a list of frequently asked questions (FAQ) about manufacturing custom cylinder heads with high-quality work from SourcifyChina factory:

Q1: What materials do you use for custom cylinder heads?

A1: At SourcifyChina, we specialize in using high-quality materials such as aluminum alloys, cast iron, and stainless steel for manufacturing custom cylinder heads, ensuring durability and optimal performance.

Q2: Can you handle both small and large production orders?

A2: Yes, SourcifyChina is equipped to handle orders of all sizes. Whether you need a single prototype or a large production run, our advanced facilities and scalable production capabilities can meet your demands.

Q3: What is the lead time for custom cylinder head manufacturing?

A3: Lead times vary depending on the complexity and volume of the order. However, our average lead time ranges from 4 to 6 weeks. We prioritize efficient production while maintaining high-quality standards.

Q4: How do you ensure the quality of the custom cylinder heads?

A4: Our quality control process includes rigorous inspections at multiple stages of manufacturing. We use advanced testing equipment and adhere to strict quality standards to ensure each cylinder head meets or exceeds customer specifications.

Q5: Do you provide design assistance for custom cylinder heads?

A5: Absolutely! Our team of experienced engineers can assist you with the design and development of your custom cylinder heads. We use state-of-the-art CAD software to ensure precision and accuracy.

Q6: What industries do you serve?

A6: SourcifyChina serves various industries including automotive, aerospace, marine, and industrial machinery. Our custom cylinder heads are designed to meet the specific needs of different applications.

Q7: Can you provide samples before full-scale production?

A7: Yes, we can provide prototype samples to ensure the design meets your requirements before proceeding with full-scale production. This helps in making any necessary adjustments and ensures complete satisfaction.

Q8: What are your payment terms?

A8: We offer flexible payment terms including T/T (Telegraphic Transfer) and L/C (Letter of Credit). Our sales team will work with you to determine the most suitable payment plan for your order.

Q9: How can I get a quote for my custom cylinder head project?

A9: You can contact us via our website or email with your detailed requirements, including specifications, drawings, and estimated order quantity. Our team will provide you with a comprehensive quote within 48 hours.

When considering custom cylinder heads manufacturing from SourcifyChina factory, several key tips can ensure a successful collaboration:

1. Provide Detailed Specifications: Supply exact measurements, material preferences, and performance requirements to help the factory meet your expectations precisely. Clear drawings and 3D models can eliminate ambiguities.

2. Choose the Right Material: Depending on the application, select the appropriate material (e.g., aluminum, cast iron) for durability and performance. SourcifyChina can advise on material suitability based on their expertise.

3. Quality Assurance Protocols: Request detailed information about the factory’s quality control processes. Ensuring rigorous checks (like X-ray inspections and pressure testing) will certify the heads meet high standards.

4. Prototype First: Before mass production, ask for a prototype to evaluate the fit and finish. This step can catch potential issues early, saving time and cost down the line.

5. Consider Advanced Technologies: Leverage SourcifyChina’s capabilities in CNC machining and 3D printing for higher precision and faster production times. These technologies can result in superior cylinder head performance.

6. Specify Tolerances: Clearly outline allowable tolerances for critical dimensions to ensure consistency in manufacturing. This can drastically affect engine performance.

7. Surface Finishing: Determine the type of surface finishing required, such as anodizing or powder coating, based on your performance and aesthetic needs.

8. Communication Plan: Establish a regular communication schedule to stay updated on production progress and to quickly address any issues.

9. Cost Considerations: Understand the cost implications of custom designs. SourcifyChina can help balance cost with performance to meet your budget constraints.

10. Shipping and Logistics: Plan for logistics and shipping, including potential customs duties and timelines, to ensure timely delivery of the cylinder heads.

By following these tips, you can effectively collaborate with SourcifyChina for high-quality custom cylinder heads that meet your specific needs and enhance your engine’s performance.

What are the steps to source custom cylinder heads from SourcifyChina factory?

1. Contact SourcifyChina with your specifications.

2. Receive a quote and assess the feasibility.

3. Place an order and finalize designs.

4. Production begins after design approval.

5. Quality inspection and shipment preparation.

What information do I need to provide to get a quote?

You need to provide detailed drawings, material specifications, quantity, and any special requirements for the custom cylinder heads.

How long does it take for production and delivery?

The lead time varies depending on the complexity of the design and order size, typically ranging from 4 to 8 weeks. Shipping times depend on the destination.

Is there a minimum order quantity (MOQ)?

Yes, the MOQ varies depending on the customization level and material used. It is best to consult SourcifyChina directly for specific MOQ details.

Can I request sample cylinder heads before placing a large order?

Yes, SourcifyChina can provide samples for a fee, which will depend on the complexity of your design and the materials required.

What quality control measures are in place?

Quality control measures include material verification, dimensional checks, and performance testing through both in-process and final inspections.

Are the custom cylinder heads compliant with international standards?

Yes, SourcifyChina adheres to international standards such as ISO, ASTM, and others upon request.

Can I modify my order after production has started?

Modifications are not advisable after production begins as it may incur additional costs and lead times. It is best to finalize all specifications beforehand.

What payment terms are available?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and others depending on the agreement. A deposit is usually required to commence production.

Does SourcifyChina offer any post-purchase support?

Yes, SourcifyChina provides post-purchase support, including technical assistance and addressing any quality-related issues that may arise.

This concise FAQ covers the key aspects of sourcing custom cylinder heads from SourcifyChina factory within a 300-word limit.

Sourcing custom cylinder heads from a factory in China like SourcifyChina involves several crucial steps:

1. Research and Verification:

– Background Check: Investigate SourcifyChina’s reputation. Look for reviews, ratings, and testimonials.

– Certifications: Verify their compliance with international standards (e.g., ISO).

2. Design and Specifications:

– Detailed Specs: Provide precise CAD drawings and material specifications.

– Communication: Use clear and concise language to avoid misunderstandings.

3. Request Samples:

– Prototypes: Before placing a large order, ask for samples to evaluate quality.

– Testing: Perform rigorous testing to ensure the samples meet all requirements.

4. Cost and Terms:

– Quotations: Get detailed quotations, including material costs, labor, and shipping.

– Negotiation: Negotiate payment terms, ideally with milestones tied to project phases.

5. Production Management:

– Milestones: Establish clear project milestones and deadlines.

– Oversight: Regularly communicate with the factory regarding progress and any potential issues.

6. Quality Control:

– Inspections: Arrange for third-party quality inspections at various stages of production.

– Standards: Ensure products conform to agreed specifications and standards.

7. Shipping and Logistics:

– Customs Compliance: Ensure all paperwork for customs is accurate and complete.

– Freight Forwarding: Use reliable freight forwarders to manage the shipping process.

8. After-Sales Service:

– Support: Ensure the factory provides robust after-sales support for any issues.

By following these steps, you can effectively source high-quality custom cylinder heads from SourcifyChina, ensuring a smooth and successful transaction.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.