Reliable

Custom Metal Fabricating by SourcifyChina Factory: Quality You Can Trust for Precision Manufacturing

Choosing SourcifyChina for your custom metal fabricating needs ensures unparalleled craftsmanship, reliability, and quality. Built on years of industry experience, our factory provides precision manufacturing solutions tailored to your specifications. Partner with us for guaranteed satisfaction.

SourcifyChina Factory has established a robust reputation for quality and precision in custom metal fabricating. Their extensive experience ensures that every piece meets stringent international standards, which is critical for buyers seeking reliable and high-quality products.

The factory employs state-of-the-art technology to deliver precise and efficient production. This commitment to advanced machinery means that they can handle both large-scale and intricate custom projects, providing versatility for buyers with diverse needs.

Moreover, SourcifyChina prioritizes customer service, offering thorough consultations and transparent communication throughout the manufacturing process. This approach ensures buyers are kept informed and can make adjustments as needed, fostering a collaborative relationship.

Another key advantage is their competitive pricing without compromising on quality. By leveraging local resources and streamlined operations, SourcifyChina provides cost-effective solutions that benefit buyers seeking to maximize value.

Finally, their rigorous quality control measures ensure that every product leaving the factory meets the highest standards. From initial material selection to final inspection, SourcifyChina’s comprehensive quality assurance processes guarantee that buyers receive only the best custom metal fabrications.

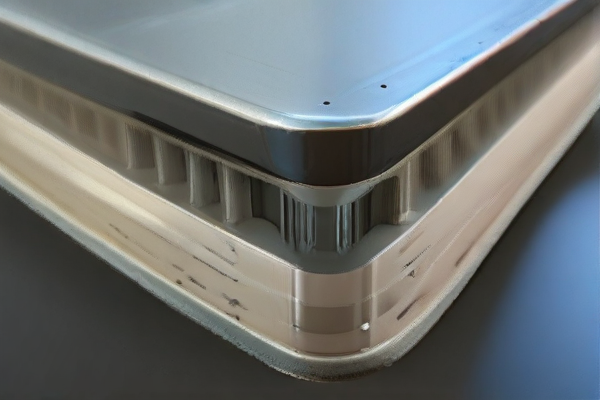

Custom metal fabricating involves creating bespoke metal structures tailored to specific needs. It encompasses a variety of techniques and materials, offering numerous options to suit diverse applications across industries.

– Sheet Metal Fabrication: Cutting, bending, and assembling flat metal sheets.

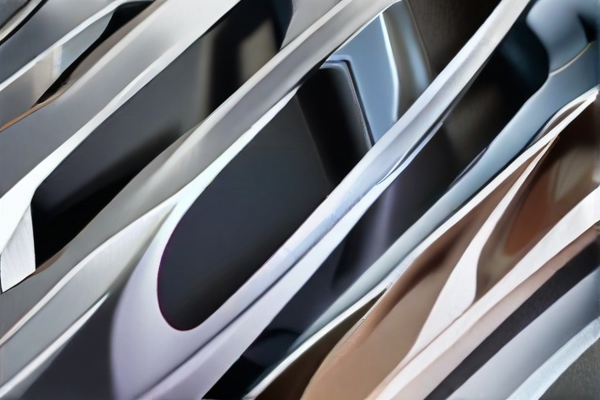

– CNC Machining: Precision cutting using Computer Numerical Control machines.

– Welding: Various welding techniques to join metal parts.

– Laser Cutting: Using lasers for precise cuts and intricate designs.

– Metal Stamping: Forming metal components using a stamping press.

– Tube Bending: Shaping metal tubes without compromising their integrity.

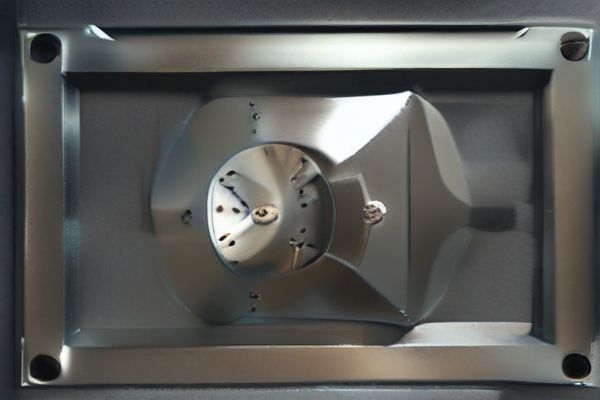

– Casting: Pouring molten metal into molds to form complex shapes.

– Water Jet Cutting: High-pressure water jets to cut through metal.

– Punching: Making holes or shapes in metal through mechanical or hydraulic punches.

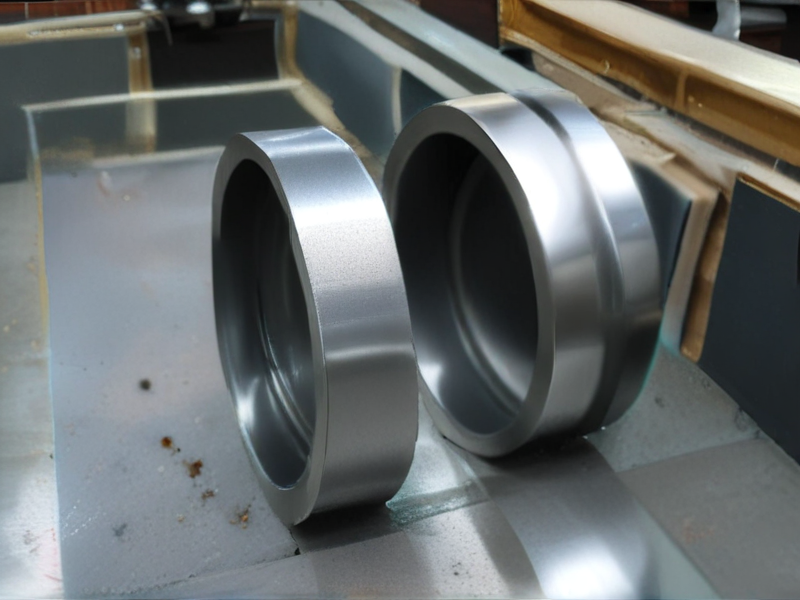

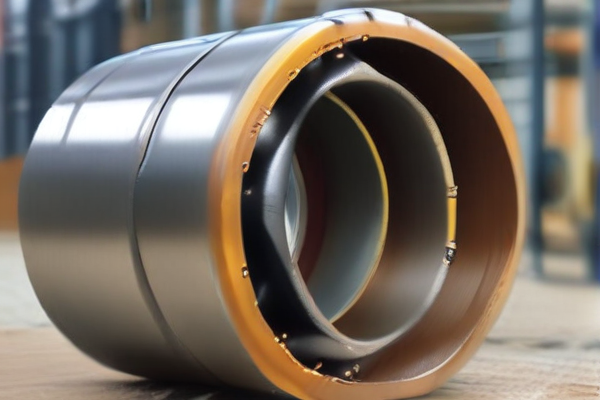

– Rolling: Creating cylindrical shapes by rolling metal sheets.

– Forging: Shaping metal through compressive forces.

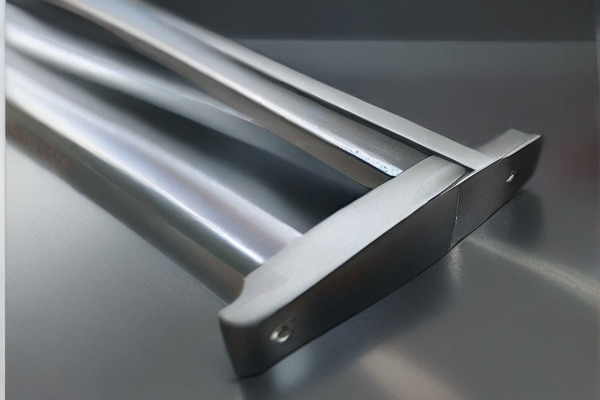

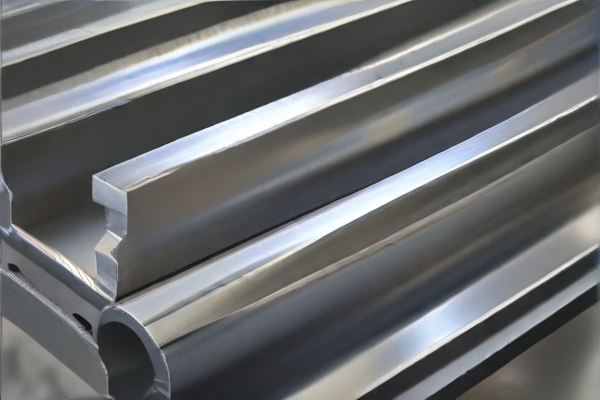

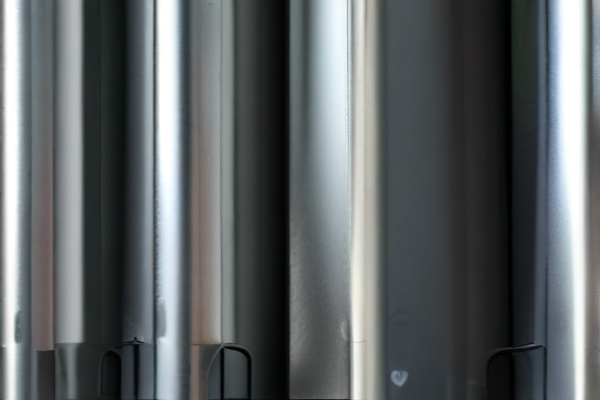

– Extrusion: Pushing metal through a die to create long shapes with uniform cross-sections.

– Powder Coating: Applying a protective and decorative finish to metal.

– Anodizing: Increasing corrosion resistance and enhancing appearance.

– Electroplating: Coating metal by electrochemical process for increased durability.

– Heat Treatment: Altering properties of metal by controlled heating and cooling.

– Prototype Fabrication: Creating preliminary models for testing and refinement.

By choosing the right combination of these methods, businesses can achieve highly specific and effective metal solutions tailored to their unique requirements.

Custom metal fabricating offers tailored solutions for various industries, providing precision-crafted components to meet specific needs. From architectural projects to automotive parts, custom fabrication enhances performance and design.

– Architectural Projects: Unique metal structures, facades, and decorative elements.

– Automotive Industry: Custom engine components, chassis parts, and accessories.

– Construction: Specialized beams, columns, and support structures.

– Aerospace: Precision-crafted parts for aircraft and spacecraft.

– Medical Equipment: Custom-designed surgical tools and medical devices.

– Industrial Machinery: Specialized gears, brackets, and machine parts.

– Electronics: Custom enclosures and heat sinks.

– Agricultural Equipment: Durable and specific farming tools and parts.

– Renewable Energy: Components for solar panels, wind turbines, and other green technology.

– Food and Beverage Industry: Custom stainless steel equipment for processing and packaging.

– Marine Applications: Corrosion-resistant parts for boats and ships.

– Public Art Installations: Unique metal sculptures and constructions.

– HVAC Systems: Custom ductwork and metal components.

– Tool and Die Making: Precision dies and molds for manufacturing.

– Signage: Custom metal signs and displays.

– Telecommunications: Structural components for antennas and towers.

– Military and Defense: Custom armor, vehicle components, and infrastructure parts.

– Robotics: Custom frames, arms, and components for robots.

– Healthcare Facilities: Custom infrastructure components for hospitals.

– Plumbing and Waterworks: Specialized pipes and fittings.

Using custom metal fabricating, industries can achieve higher precision, enhanced durability, and innovative designs that meet specific functional and aesthetic requirements.

SourcifyChina specializes in custom metal fabricating services, offering a comprehensive range of materials. They excel in using stainless steel, aluminum, brass, and copper, ensuring durability and precision in each custom project.

Stainless steel is a popular choice for its corrosion resistance and strength, making it ideal for industrial applications. Aluminum is favored for its lightweight and excellent conductivity, suitable for both structural and electrical components.

Brass, known for its malleability and attractive appearance, is often utilized in decorative elements and fittings. Copper, with its superior thermal and electrical properties, is essential in electrical wiring and heat exchangers.

SourcifyChina’s meticulous attention to material quality and their advanced fabricating techniques guarantee that each project meets stringent industry standards. Their expertise ensures client-specific solutions, delivering products that consistently surpass expectations in performance and reliability.

SourcifyChina is renowned for its custom metal fabricating prowess, leveraging advanced quality control processes to ensure every product meets stringent standards. Their precision craftsmanship is a testament to their dedication to excellence.

At SourcifyChina, quality control begins at the initial stages of raw material selection. By procuring high-grade materials, they lay the foundation for superior and durable metal products, ensuring longevity and reliability in every project.

The manufacturing process includes state-of-the-art machinery and technology. SourcifyChina employs cutting-edge CNC machines and employs rigorous in-line inspections to ensure accurate dimensions and tolerances are consistently met throughout production.

Skilled technicians and engineers at SourcifyChina bring a wealth of experience, conducting thorough inspections at each manufacturing stage. This expertise ensures that every piece adheres to the specified design and functional requirements, mitigating potential defects or deviations.

Final inspections are rigorous, encompassing comprehensive tests and evaluations. Products undergo stress tests, precision checks, and surface finish assessments to verify their quality, durability, and aesthetic appeal before they are approved for shipment.

SourcifyChina’s commitment to quality control extends beyond the factory floor. They incorporate client feedback and continuously refine their processes, ensuring each batch meets evolving industry standards and client expectations.

By prioritizing a meticulous quality control process, SourcifyChina not only enhances product integrity but also fosters trust and reliability with their global clientele. This commitment to excellence positions them as a leader in custom metal fabricating.

SourcifyChina is renowned for its custom metal fabricating capabilities, offering tailored solutions to meet diverse client needs. Our state-of-the-art machinery and skilled workforce ensure high precision in production.

Adhering to stringent quality standards, we handle projects of varying complexities, from intricate prototypes to large-scale manufacturing. Our expertise spans multiple industries including automotive, aerospace, and consumer goods.

With a strong focus on innovation, we utilize advanced techniques such as CNC machining, laser cutting, and welding. Our capability to work with various metals like aluminum, steel, and titanium sets us apart.

Customer satisfaction is paramount, and we work collaboratively to provide efficient, cost-effective solutions without compromising on quality. Our commitment to excellence has earned us a loyal client base and a reputation for reliability.

Finally, our comprehensive service package includes design assistance, prototyping, and full-scale production, ensuring a seamless journey from concept to completion. SourcifyChina’s robust infrastructure and unwavering dedication make us a leader in custom metal fabrication.

Custom metal fabricating offers businesses the flexibility to create precise, high-quality metal components tailored to meet specific needs and requirements, boosting efficiency and performance.

– Precision: Custom metal fabricating allows for high levels of accuracy and detail, ensuring components fit perfectly within their intended applications.

– Durability: Custom-fabricated metal components are usually made from high-quality materials, offering enhanced strength and longevity.

– Versatility: Custom fabrication can accommodate a wide range of designs and materials, allowing for diverse applications across different industries.

– Cost-Effective: Reduces waste and optimizes material usage, ultimately saving money in the long run.

– Rapid Prototyping: Facilitates quicker development of prototypes, allowing for faster product iteration and testing.

– Customization: Tailored solutions can be designed to meet unique and complex project requirements.

– Improved Aesthetics: Custom fabrication offers the ability to create aesthetically pleasing designs that match specific visual and functional criteria.

– Quality Assurance: Custom metal fabricators often adhere to stringent quality control measures, ensuring high standards are maintained.

In summary, custom metal fabricating provides businesses with precise, durable, and versatile solutions that can adapt to specific needs while being cost-effective and supporting rapid innovation.

Custom metal fabricating is a process that transforms raw metal into specific shapes and designs based on client specifications. This offers multiple advantages such as precision, durability, and versatility.

– Precision Engineering: Custom metal fabricating allows for highly accurate and detailed designs tailored to specific requirements, ensuring a perfect fit for any project.

– Material Variety: Various metals such as steel, aluminum, and copper can be fabricated, offering economical and performance benefits.

– Advanced Technology: Utilizes cutting-edge machinery like CNC machines, laser cutters, and robotic welders for flawless output.

– Customization: Enables unique designs that are not achievable with standard metal components, offering bespoke solutions.

– Durability and Strength: Custom-fabricated metals are designed to meet exact specifications and can therefore endure stress and environmental conditions better than off-the-shelf parts.

– Efficiency: Offers streamlined production processes that can reduce waste and lower costs through precise material usage.

– Aesthetic Appeal: Capable of creating visually appealing metal components that enhance the overall design of the project.

– Scalability: Suitable for both small-batch and large-scale production, adapting to various business needs.

– Compliance: Meets industry standards and specifications, ensuring safety and reliability.

– Versatility: Applicable in diverse industries including automotive, aerospace, construction, and consumer goods.

In summary, custom metal fabricating is a multi-faceted service that brings a range of benefits from improved durability and precision to design versatility and cost-efficiency. Leveraging advanced technology and a variety of high-quality materials, it meets the specific needs of any demanding project.

SourcifyChina specializes in custom metal fabrication services to create unique products tailored to customer specifications. Utilizing advanced technologies and high-quality materials, they ensure precision and durability in every project.

Their offerings range from intricate metal components to large-scale constructions, serving a variety of industries including automotive, construction, and consumer goods. Whether it’s custom brackets, frames, or enclosures, SourcifyChina delivers exceptional craftsmanship.

Clients benefit from comprehensive project management, from initial design consultation to final production, ensuring seamless execution and timely delivery. Their team collaborates closely with clients to meet specific requirements and exceed expectations.

SourcifyChina’s commitment to innovation and sustainability means they continually explore new techniques and eco-friendly materials. This dedication positions them as leaders in the custom metal fabrication industry, providing reliable solutions that cater to both current and future market demands.

With a strong focus on customer satisfaction, SourcifyChina offers after-sales support, ensuring all client needs are met. Their reputation is built on consistent quality, making them a trusted partner for custom metal projects worldwide.

SourcifyChina Custom Metal Fabricating is a premier manufacturing firm specializing in high-quality, custom metal fabrication solutions tailored to meet diverse industrial needs. Based in China, the company leverages advanced technology and skilled craftsmanship to produce precision-engineered metal components that adhere to stringent international standards. Offering a broad spectrum of services, including laser cutting, welding, CNC machining, and metal stamping, SourcifyChina caters to a wide array of industries such as automotive, aerospace, electronics, and construction. The company’s commitment to innovation, combined with a customer-centric approach, ensures seamless integration of their metal products into clients’ projects, irrespective of complexity or scale. Reliable, efficient, and dedicated to excellence, SourcifyChina has positioned itself as a global leader in custom metal fabrication, continuously setting benchmarks in quality and service delivery.

Custom metal fabricating plays a crucial role in the aerospace, defense, and marine industries by providing tailored solutions that meet stringent performance and safety standards. In aerospace, precision and reliability are paramount. Custom fabrication ensures components like airframe structures, engine parts, and landing gear are manufactured to exact specifications, maintaining the balance between weight and strength. Advanced techniques such as CNC machining, laser cutting, and 3D metal printing enable the production of complex geometries and fine details that are essential for modern aircraft performance and sustainability. Additionally, the use of lightweight yet durable materials, often specific alloys, is optimized through custom processes, contributing to fuel efficiency and reducing emissions in the aerospace sector.

In the defense and marine fields, the demand for robust and long-lasting components is equally critical. Custom metal fabricating allows for the creation of specialized parts used in military vehicles, naval ships, and submersible vessels, ensuring they can withstand harsh environments and operational stresses. Armor plating, weapon mounts, and propulsion systems benefit from custom fabrication techniques designed to meet strict defense standards. Similarly, marine applications require components that resist corrosion and perform reliably under marine conditions, such as saltwater exposure and high pressures. Custom metal fabricating techniques allow for the use of specific materials like stainless steel and titanium, which provide the needed corrosion resistance and strength. By enabling the production of precision-engineered components, custom metal fabricating supports mission-critical operations across these sectors, enhancing their overall performance and durability.

Custom metal fabricating plays a critical role in the automotive industry, where precision and durability are paramount. This process involves designing and manufacturing metal components tailored to specific vehicle requirements, enabling the creation of parts that perfectly fit various models and afford superior performance. Custom metal fabrication is employed to produce a wide array of automotive parts, from engine components to chassis and body panels, ensuring that each element meets strict industry standards for safety and efficiency. Advances in techniques such as laser cutting, CNC machining, and TIG welding enhance the precision and quality of fabricated parts, contributing to the overall reliability and longevity of vehicles. Moreover, the ability to fabricate metal components custom-tailored to unique specifications enables automakers to innovate and improve vehicle design, pushing the boundaries of automotive technology and performance.

In the electronics industry, custom metal fabricating is indispensable for creating components that support and protect sensitive electronic devices. The fabrication process is crucial in manufacturing enclosures, brackets, heat sinks, and housings, which safeguard electronic circuits from environmental hazards and physical damage while simultaneously ensuring optimal functioning. The precision required in the electronics sector often necessitates the use of advanced fabrication techniques like photochemical machining and micro-welding, which accommodate the intricate designs and tight tolerances needed for modern electronic devices. Custom metal fabricating also allows for rapid prototyping, enabling electronics manufacturers to quickly iterate and refine their designs. This capability is essential in an industry characterized by rapid technological progression and the constant need for innovation. Custom metal components help enhance the performance, durability, and aesthetic appeal of electronic products, driving the industry forward with each new development.

Custom metal fabricating plays a crucial role in the construction industry by enabling the creation of unique, precise, and durable structural components. From beams and columns to intricate metal frameworks for architectural designs, custom fabrication ensures that each piece meets exact specifications and regulatory standards. This flexibility allows for innovative designs and the construction of complex structures that standard off-the-shelf metal components could not achieve. Additionally, custom metal fabricating supports the integration of modern building technologies, such as energy-efficient window frames and curtain walls, which are crucial for sustainable construction practices. The ability to tailor materials to the specific needs of a project minimizes waste and improves construction efficiency, ultimately enhancing the overall quality and longevity of the structures.

In the realm of energy applications, custom metal fabricating is indispensable for the development and maintenance of energy infrastructures, including renewable energy systems and traditional power plants. Precision-fabricated metal components are essential for constructing wind turbine blades, solar panel mounts, and hydroelectric dam parts, all of which are crucial for harnessing renewable energy sources. Additionally, in the oil and gas sector, pipelines, storage tanks, and refinery components rely heavily on custom metal fabrication to meet stringent safety and performance standards. The adaptability of custom fabrication allows engineers to design system-specific solutions that maximize efficiency and minimize downtime. Furthermore, the use of advanced metal alloys and fabrication techniques can enhance the durability and corrosion resistance of these components, ensuring long-term reliability and reducing maintenance costs. Through custom metal fabricating, the energy sector can develop more robust, efficient, and sustainable infrastructures to meet the growing global demand.

Custom metal fabricating plays a pivotal role in the industrial equipment industry, offering tailored solutions that address specific needs and challenges within various sectors. By leveraging advanced techniques such as cutting, welding, and forming, manufacturers can produce bespoke components that enhance the functionality, durability, and efficiency of industrial machinery. For instance, in the automotive industry, custom metal parts are essential for creating specialized tools and equipment that streamline production processes. Similarly, in the aerospace sector, custom metal fabricating ensures the creation of high-precision parts that meet stringent safety and performance standards. This bespoke approach allows industries to optimize their operations, reduce downtime, and maintain a competitive edge by incorporating specialized machinery and components that are tailored to their unique requirements.

Moreover, custom metal fabricating enhances the sustainability and adaptability of industrial equipment. With increasing environmental regulations and the need for sustainable practices, industries are turning to custom metal solutions to improve energy efficiency and reduce waste. For example, in the renewable energy sector, custom-fabricated metal components are crucial for constructing robust and efficient wind turbines and solar panels. These custom parts ensure that machinery can withstand harsh environmental conditions while maintaining peak performance. Additionally, the flexibility offered by custom metal fabricating allows industries to quickly adapt to technological advancements and evolving market demands. By investing in custom solutions, companies can extend the lifespan of their equipment, minimize maintenance costs, and ensure that their machinery remains relevant and efficient in a rapidly changing industrial landscape.

Custom metal fabricating plays a pivotal role in the medical devices industry, revolutionizing the way medical tools and equipment are designed, manufactured, and utilized. Tailored fabrication techniques enable the production of specialized components with unparalleled precision and adaptability, addressing the unique needs of medical practitioners and patients. For instance, surgical instruments such as scalpels, forceps, and retractors can be custom-designed to meet specific surgical requirements, enhancing their efficacy and safety. Furthermore, this level of customization ensures that devices can be optimized for the unique anatomical and physiological characteristics of individual patients, thereby improving clinical outcomes. The bespoke nature of custom metal fabricating also supports the development of innovative medical technologies, such as minimally invasive surgical devices, which demand intricate designs and exact specifications to function correctly within the human body.

Additionally, custom metal fabricating contributes significantly to the production and refinement of implantable devices like stents, orthopedic implants, and dental prosthetics. These devices must meet stringent biocompatibility, durability, and functionality standards, which are achievable through precise fabrication processes. By utilizing advanced techniques such as CNC machining, laser cutting, and additive manufacturing, medical device manufacturers can produce complex, high-quality components that meet rigorous regulatory requirements. Moreover, the ability to quickly prototype and iterate on designs allows for rapid innovation and adaptation to emerging medical needs. This agility is crucial in a field where technology and medical knowledge continually evolve. Consequently, custom metal fabricating not only enhances the performance and reliability of medical devices but also fosters advancements in medical science and patient care.

Custom metal fabricating serves as a cornerstone in modern machining and manufacturing, allowing for the production of bespoke metal components tailored to specific applications. In the machining realm, custom fabricating enables precise cutting, shaping, and assembly of metals, enhancing the ability to produce parts with tight tolerances and intricate geometries. Techniques such as CNC machining, laser cutting, and water jet cutting are often employed to achieve high levels of precision and repeatability. These technologies are essential in industries like aerospace, automotive, and medical devices, where the demand for intricate and robust components is ever-growing. By leveraging advanced machining processes, custom metal fabricating aids in minimizing material waste and maximizing production efficiency, ultimately reducing costs and improving the overall quality of the final product.

In the broader scope of manufacturing, custom metal fabricating contributes significantly to the development of unique and application-specific products. This goes beyond mere aesthetic customization to include functional adaptations that meet the exact needs of various industrial processes. For example, custom metal enclosures and structural supports are frequently produced for use in electronic devices, machinery, or infrastructure projects. By utilizing metal forming, welding, and assembly techniques, custom fabricators can create complex assemblies and sub-assemblies that integrate seamlessly into larger systems. This versatility is particularly advantageous in sectors such as renewable energy, construction, and telecommunications, where custom solutions often translate into improved performance and reliability. Overall, the ability to fabricate custom metal parts allows manufacturers to innovate continuously and respond swiftly to market demands and technological advancements.

Q: What services does SourcifyChina offer for custom metal fabricating?

A: SourcifyChina specializes in providing high-quality custom metal fabricating services, including laser cutting, CNC machining, welding, stamping, and assembly. We cater to various industries such as automotive, aerospace, electronics, and more.

Q: What materials can SourcifyChina work with?

A: We work with a wide range of metals, including stainless steel, aluminum, carbon steel, brass, and copper. If you have specific material requirements, please let us know, and we will source and fabricate accordingly.

Q: How does SourcifyChina ensure the quality of its custom metal fabricating?

A: Quality is our top priority. We implement strict quality control measures, including thorough inspections, advanced testing equipment, and adherence to international standards like ISO 9001. Our skilled technicians and engineers ensure each product meets the specified requirements.

Q: Can SourcifyChina handle large-scale production runs?

A: Yes, SourcifyChina is equipped to manage both small and large-scale production runs. Our state-of-the-art facilities and efficient processes allow us to handle high-volume orders without compromising on quality or delivery times.

Q: What is the typical lead time for custom metal fabricating projects?

A: Lead times vary depending on the complexity and volume of the project. Generally, prototype orders take about 2-3 weeks, while full production runs can take 4-6 weeks. We always strive to meet customers’ deadlines and will provide accurate timeframes upon project confirmation.

Q: How do I get a quote for my custom metal fabricating project?

A: To get a quote, please provide detailed specifications, including material type, dimensions, quantity, and any necessary drawings or designs. You can submit this information via our online form or contact our sales team directly. We will review your requirements and provide a competitive quote promptly.

Q: Does SourcifyChina offer design assistance or consultation?

A: Yes, we provide design assistance and consultation services to ensure your project is optimized for manufacturing. Our experienced engineers can help you refine your designs for improved functionality, cost-effectiveness, and manufacturability.

Q: What is SourcifyChina’s minimum order quantity (MOQ)?

A: Our MOQ varies depending on the project’s specifications and complexity. However, we are flexible and can accommodate both low and high-volume orders. Please contact us to discuss your specific needs.

When considering custom metal fabricating manufacturing from SourcifyChina factory, it’s essential to approach the process methodically to ensure you receive high-quality products that meet your specifications. Here are some tips to help you navigate the process effectively:

1. Define Specifications Clearly:

– Provide detailed drawings or CAD files. Precision in your specifications avoids costly mistakes and ensures the final product matches your expectations.

2. Material Selection:

– Specify materials accurately. SourcifyChina offers a variety of metals including stainless steel, aluminum, and carbon steel. Choose based on the application and required properties.

3. Prototype and Testing:

– Start with prototyping. It helps in verifying the design and material before mass production. Ensure rigorous testing of the prototype to identify and rectify any issues early.

4. Quality Standards:

– Confirm that the factory adheres to international quality standards like ISO 9001. This guarantees a consistent manufacturing process and product quality.

5. Technical Capabilities:

– Assess the factory’s technical capabilities. SourcifyChina is equipped with advanced machinery for cutting, welding, bending, and finishing. Ensure they have the equipment necessary for your project.

6. Communication and Language:

– Ensure clear communication. Language barriers can result in misunderstandings. Use simple and clear English and consider having a Chinese-speaking consultant if necessary.

7. Lead Times and Delivery:

– Discuss lead times upfront. Understand their production capacity and ensure they can meet your deadlines. Factor in shipping time to your location.

8. Inspection and Quality Control:

– Implement stringent quality inspections. Use third-party inspection firms if needed to verify the quality of the final products before shipment.

9. Cost Management:

– Request detailed quotations. Compare with other suppliers but also consider quality and reliability over just price.

10. After-Sales Support:

– Ensure they provide good after-sales support. A dependable factory will offer help with any post-delivery issues.

By keeping these tips in mind, you can optimize your custom metal fabrication manufacturing process with SourcifyChina and ensure high-quality, timely, and cost-effective production.

FAQs for Sourcing Custom Metal Fabricating from SourcifyChina Factory

1. What types of custom metal fabricating services does SourcifyChina offer?

SourcifyChina provides a wide range of services including cutting, bending, welding, stamping, and finishing. They work with various types of metals such as steel, aluminum, and brass to produce custom parts according to your specifications.

2. How do I get a quote for my custom metal project?

To get a quote, you’ll need to submit a detailed project description, drawings or CAD files, material specifications, and the required quantities. You can send this information via their website or directly to their customer service email.

3. What is the typical lead time for custom metal fabricating orders?

Lead times can vary depending on the complexity and size of the order. Generally, it ranges from 2 to 6 weeks. Rush orders may be accommodated upon request, subject to an additional fee.

4. Does SourcifyChina offer prototyping services?

Yes, SourcifyChina offers prototyping services to help you validate your design before committing to full-scale production. This ensures your final product meets all your specifications and quality standards.

5. Can SourcifyChina provide certification for the materials used?

SourcifyChina can provide material certifications and comply with international standards such as ISO, ASTM, and RoHS upon request. Be sure to mention your certification needs when placing your order.

6. What quality control measures are in place at SourcifyChina?

SourcifyChina employs stringent quality control processes, including in-process inspections, material testing, and final inspections. They also offer third-party quality checks if required.

7. How do you handle shipping and delivery?

SourcifyChina offers various shipping options including air freight, sea freight, and express courier services. They handle customs documentation and ensure all shipments comply with international trade regulations.

8. What payment methods does SourcifyChina accept?

SourcifyChina accepts multiple payment methods including bank transfers, PayPal, and major credit cards. Payment terms are usually negotiated based on order size and customer relationship.

9. Is there a minimum order quantity (MOQ) requirement?

Sourcing custom metal fabricating services from SourcifyChina factory can greatly benefit your project through efficiency and cost-effectiveness. Here are some concise yet essential tips to guide you:

1. Research and Vetting:

– Verify the factory’s credentials, certifications, and experience in custom metal fabricating.

– Look for reviews and testimonials from other businesses that have used their services.

2. Clear Specifications:

– Provide detailed drawings, material specifications, and tolerances.

– Ensure your designs are clear and comprehensive to avoid misunderstandings.

3. Quality Control:

– Request information on their quality control processes.

– Consider third-party inspections or audits to verify product quality.

4. Sample Requests:

– Ask for prototypes or samples before committing to large orders.

– Evaluate the samples for precision, quality, and finish.

5. Communication:

– Maintain clear and consistent communication with the factory.

– Address any potential issues or concerns promptly to prevent delays.

6. Payment Terms:

– Negotiate favorable payment terms, such as partial payments tied to production milestones.

– Understand their payment policies, including options for deposits and final payments.

7. Lead Times:

– Confirm realistic lead times for production and delivery.

– Factor in potential delays and ensure they are manageable within your project timeline.

8. Logistics and Shipping:

– Clarify shipping logistics, including handling, packaging, and transport.

– Understand international shipping regulations and tariffs to avoid unexpected costs.

9. Sustainability:

– Verify if the factory employs eco-friendly practices and sustainable sourcing of materials.

10. Legal Agreements:

– Draft and agree on a comprehensive contract detailing responsibilities, deadlines, and quality standards.

– Include clauses for dispute resolution to safeguard against potential issues.

Following these tips can lead to a smooth partnership and high-quality custom metal fabrication from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.