“Reliable Custom Metal Fabrication Services by SourcifyChina: Your Trusted Source for Quality Factory Solutions”

Get expertly crafted metal parts tailored to your specifications with SourcifyChina’s top-notch custom metal fabrication services. Partner with a reliable source known for precision, efficiency, and excellence in factory solutions.

Choosing “SourcifyChina” Factory for custom metal fabrication ensures top-notch quality and precision. Our state-of-the-art technology and skilled workforce guarantee products that meet exact specifications and industry standards.

SourcifyChina offers competitive pricing without compromising on quality. We leverage our extensive network of suppliers to keep costs low and pass those savings on to our customers.

Our factory provides comprehensive services, from initial design consultations to final product delivery. This end-to-end solution streamlines the manufacturing process, saving buyers time and effort.

Customer satisfaction is our top priority. We maintain open communication throughout the production cycle, ensuring that your requirements are met and any concerns are swiftly addressed.

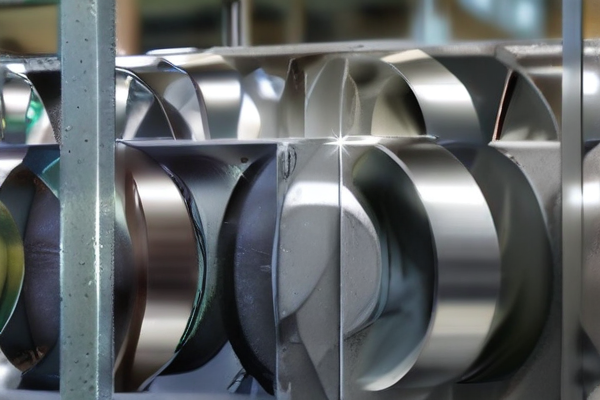

Timely delivery is crucial for our clients. SourcifyChina is committed to adhering to strict timelines, ensuring that your products reach you as scheduled, every time.

With years of experience in the industry, SourcifyChina has built a reputation for reliability and excellence. Our track record speaks volumes about our commitment to quality and customer service.

SourcifyChina also emphasizes sustainability in our manufacturing processes. We adopt eco-friendly practices and materials, contributing to a greener planet while maintaining high product standards.

Our multilingual support team bridges the communication gap, making it easier for international buyers to navigate the complexities of custom metal fabrication with ease and confidence.

Choose SourcifyChina for your custom metal fabrication needs and experience unparalleled quality, cost-effectiveness, and customer service. Partner with us to turn your visions into reality.

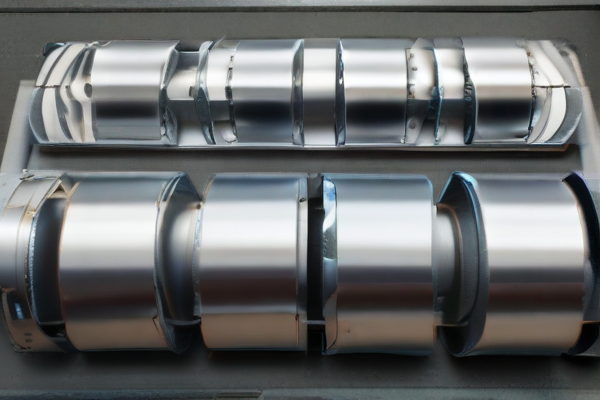

Custom metal fabrication involves crafting metal components tailored to specific requirements. Techniques include cutting, welding, and forming. Various metals such as steel, aluminum, and brass are used depending on the application.

Types and Options for Custom Metal Fabrication:

– Cutting:

– Laser Cutting

– Plasma Cutting

– Waterjet Cutting

– CNC Machining

– Welding:

– MIG Welding

– TIG Welding

– Stick Welding

– Spot Welding

– Forming:

– Bending

– Rolling

– Stamping

– Spinning

– Materials:

– Stainless Steel

– Aluminum

– Brass

– Copper

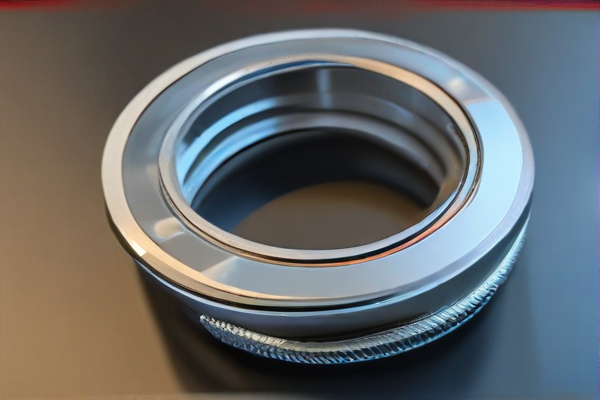

– Finishing:

– Powder Coating

– Anodizing

– Electroplating

– Polishing

– Applications:

– Automotive Parts

– Aerospace Components

– Industrial Machinery

– Architectural Structures

– Advantages:

– Precision and Accuracy

– Customization and Flexibility

– Durability and Strength

Custom metal fabrication involves creating metal parts tailored to specific needs and designs. It’s widely used across various industries for its precision and durability.

– Architectural Structures: Custom metal fabrication creates unique, durable, and complex designs for buildings and sculptures.

– Automotive Industry: Produces high-quality components for cars, trucks, and specialty vehicles.

– Aerospace: Crafts precise parts for aircraft, ensuring safety and performance.

– Medical Equipment: Essential for making surgical tools, hospital beds, and specialized medical devices.

– Electronics: Used to fabricate housings and chassis for electronic devices.

– Heavy Machinery: Produces parts that withstand heavy loads and harsh environments.

– Energy Sector: Creates components for wind turbines, solar panels, and oil rigs.

– Food Processing: Ensures sanitation and quality with custom stainless steel parts.

– Defense: Manufactures equipment and vehicles integral to national security.

– Art Installations: Allows artists to realize innovative metal sculptures and installations.

At its core, custom metal fabrication is indispensable for creating specific, high-precision components that cater to the unique requirements of various sectors, enhancing functionality and efficiency.

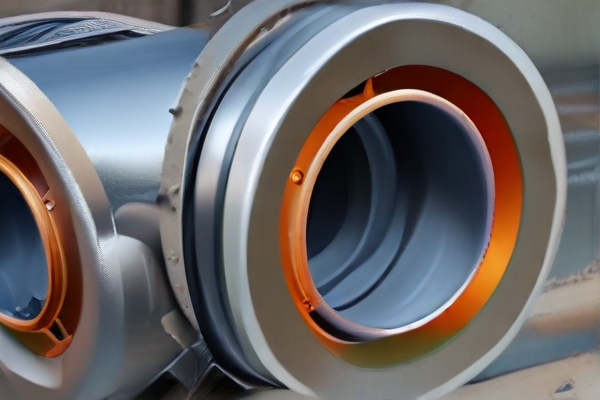

SourcifyChina specializes in custom metal fabrication, employing a range of high-quality materials to meet diverse client needs. Their expertise spans across stainless steel, aluminum, brass, and other durable metals.

Stainless steel is often a go-to choice for its corrosion resistance and strength. It’s particularly favored in projects requiring long-lasting, maintenance-free components. Aluminum, on the other hand, is lightweight and highly flexible, making it suitable for applications where weight and malleability are critical.

Brass is frequently used for its anti-corrosion properties and appealing aesthetics, ideal for decorative items and plumbing fixtures. Additionally, SourcifyChina can handle other materials such as copper and titanium, ensuring they can meet virtually any custom metal fabrication requirement.

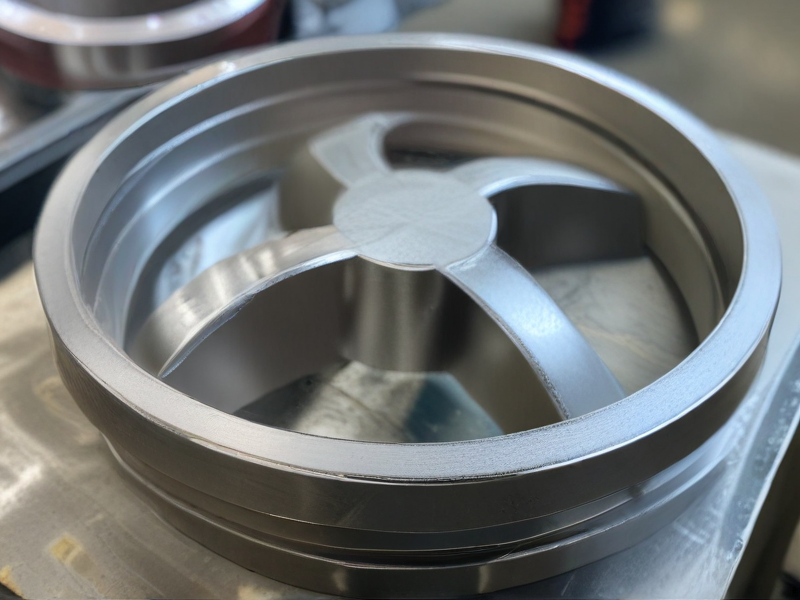

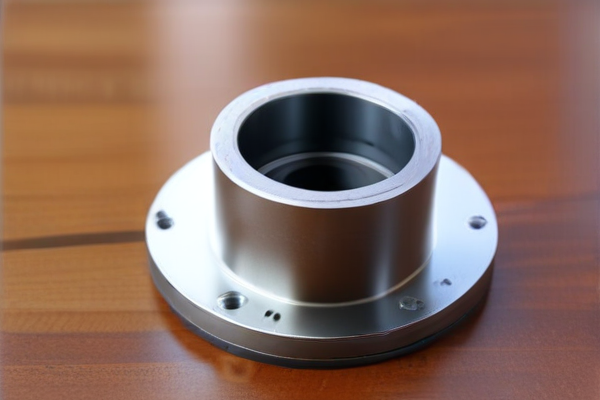

Their advanced manufacturing processes include cutting, bending, welding, and finishing, allowing for precise and intricate designs. State-of-the-art machinery and skilled technicians ensure that each piece meets rigorous quality standards.

Through careful selection of materials and techniques, SourcifyChina delivers top-notch, reliable custom metal fabrications. Their comprehensive approach and commitment to quality make them a preferred partner in the industry.

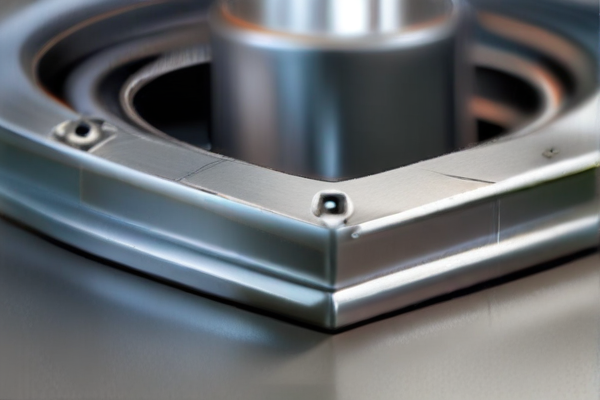

SourcifyChina custom metal fabrication ensures high-quality output through stringent quality control measures. From raw material inspection to final product evaluation, their process focuses on precision and consistency to meet client requirements.

The quality control begins with a thorough inspection of incoming raw materials. Each material batch is tested for composition, strength, and durability to ensure only the best materials are used in the fabrication process.

During fabrication, every stage is monitored meticulously. Skilled workers and advanced machinery collaborate to maintain the highest standards. Regular calibration and maintenance of equipment further enhance process accuracy.

Post-fabrication, products undergo rigorous testing to verify structural integrity and functionality. Dimensional checks, stress testing, and surface finish assessments are performed to ensure compliance with specifications.

Finally, before delivery, each product is subjected to a comprehensive quality assurance review. This includes documentation verification and final inspections to ensure the finished product meets SourcifyChina’s stringent quality standards and exceeds customer expectations.

SourcifyChina is renowned for its custom metal fabrication capabilities, ensuring precision and unparalleled quality in every project. They specialize in producing bespoke metal components tailored to clients’ exact specifications, no matter the complexity or scale.

Their state-of-the-art facility is equipped with advanced machinery and technology, including CNC machining, laser cutting, and welding techniques. This enables them to handle a vast range of materials, from aluminum and stainless steel to exotic alloys, providing flexible solutions.

SourcifyChina boasts a team of skilled engineers and technicians dedicated to delivering exceptional craftsmanship. Their expertise ensures optimal design and function, meeting stringent industry standards across various sectors such as automotive, aerospace, and construction.

They also prioritize efficient production processes and cost-effective solutions. By leveraging their extensive network of suppliers, they can source high-quality materials at competitive prices and maintain timely delivery schedules.

Additionally, SourcifyChina’s commitment to sustainability is evident in their eco-friendly practices. They utilize energy-efficient equipment and adhere to rigorous environmental regulations, striving to minimize their carbon footprint while maintaining top-tier quality.

The company’s robust quality control measures guarantee that every product undergoes rigorous inspections and testing. This exhaustive approach ensures that clients receive reliable and durable metal components, reinforcing their trust in SourcifyChina’s capabilities.

In summary, SourcifyChina stands out in the custom metal fabrication industry due to their technological prowess, skilled workforce, and unwavering commitment to quality and sustainability. Their ability to provide tailored solutions and adhere to deadlines makes them a preferred partner for businesses across diverse sectors.

Custom metal fabrication offers tailored solutions that meet specific project requirements, delivering unique benefits in terms of quality, durability, and functionality.

Benefits of Custom Metal Fabrication:

– Precision and Quality: Custom metal fabrication ensures high levels of precision, reducing errors and waste. This results in superior quality products tailored to exact specifications.

– Durability: Custom-fabricated metals are typically more resilient and long-lasting because they are designed to meet particular environmental and operational stresses.

– Flexibility in Design: Custom fabrication allows for the creation of unique and complex designs that standard off-the-shelf components cannot achieve.

– Cost Efficiency: Although initial costs may be higher, custom metal fabrication can be more cost-effective in the long run due to reduced material waste and improved productivity.

– Enhanced Performance: Customized metal components can be optimized for maximum performance, ensuring they work seamlessly within the intended application.

– Material Selection: Clients have the freedom to choose from a wide range of materials, including aluminum, steel, and exotic alloys, to fit specific needs and applications.

– Quick Turnaround Time: Advanced technologies in custom fabrication like CNC machining and laser cutting significantly reduce production times.

– Scalability: Custom metal fabrication can easily accommodate both small and large-scale projects, offering scalability that matches the scope of the project.

– Innovation: The custom process encourages innovation, allowing for the creation of prototypes and new products that push the boundaries of what standard parts can do.

– Personalized Service: Working closely with fabricators, clients receive personalized consultation and solutions, ensuring the end product meets their exact needs and preferences.

Custom metal fabrication stands out as an invaluable service for industries requiring precise, durable, and uniquely designed metal components.

Custom metal fabrication offers a tailored approach to creating metal products, utilizing advanced techniques for unique designs and specific requirements. It provides precision, durability, and versatility.

Key features of custom metal fabrication include:

– Precision and Accuracy: Leveraging CNC machines and laser cutting for exact measurements and intricate details.

– Material Variety: Works with diverse metals, such as steel, aluminum, and copper, catering to different needs.

– Customization: Enables bespoke designs to meet unique specifications and demands.

– Durability: Produces robust and long-lasting finished products.

– Advanced Techniques: Incorporates welding, bending, and stamping for complex structures.

– Prototyping: Allows for the creation of prototypes to test designs before full-scale production.

– Cost-Effectiveness: Reduces material waste and labor costs through efficient processes.

– Quality Control: Maintains high standards with thorough inspections and testing.

– Versatility: Applicable in various industries, from construction to automotive.

– Efficiency: Streamlines production, reducing lead times.

– Innovation: Adopts the latest technology and methods, staying ahead in the industry.

– Scalability: Capable of producing small batches or large-scale orders.

By integrating these features, custom metal fabrication ensures high-quality, reliable, and tailored solutions for diverse applications.

SourcifyChina provides exceptional custom metal fabrication services tailored to meet the unique requirements of each client. Their expertise covers a wide range of materials, including steel, aluminum, and brass, ensuring durability and precision in every project.

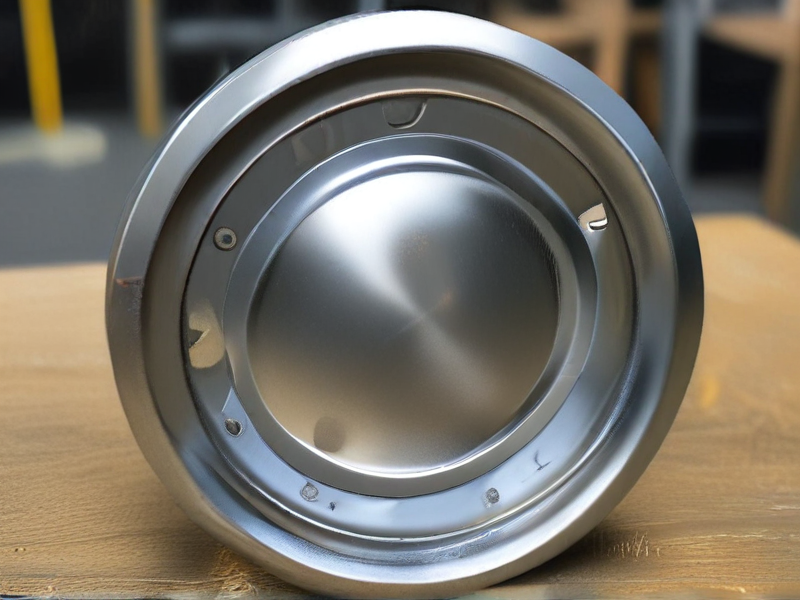

The company excels in producing high-quality custom metal products, such as brackets, enclosures, and structural components. Each item is fabricated with meticulous attention to detail, adhering to stringent quality standards and client specifications.

Innovative technology and state-of-the-art machinery enable SourcifyChina to tackle diverse projects, from small-scale prototypes to large production runs. Their team of skilled professionals is dedicated to delivering superior results efficiently and cost-effectively.

Client satisfaction is paramount, with SourcifyChina prioritizing clear communication and collaboration throughout the fabrication process. This ensures that every custom product perfectly aligns with the client’s vision and functional requirements.

SourcifyChina’s commitment to excellence and innovation sets them apart as a trusted partner in custom metal fabrication. Whether you need intricate designs or robust components, they are equipped to bring your projects to life with exceptional craftsmanship and reliability.

SourcifyChina Custom Metal Fabrication is a leading provider in the field of precision metal manufacturing, known for delivering exceptional quality and tailored solutions to meet diverse industrial needs. Located in China, this company capitalizes on state-of-the-art technology and a highly skilled workforce to produce a wide range of metal components and assemblies. SourcifyChina’s expertise extends to various processes including CNC machining, laser cutting, welding, and sheet metal forming, ensuring that every project meets stringent standards of accuracy and durability. The firm places a strong emphasis on collaboration and customer satisfaction, working closely with clients from the initial design phase through to final production. With a commitment to continuous improvement and innovation, SourcifyChina not only maintains competitive pricing but also ensures timely delivery, making it a trusted partner for businesses worldwide seeking reliable and efficient metal fabrication services.

Custom metal fabrication plays a pivotal role in the Aerospace, Defense, and Marine sectors, offering tailored solutions for complex engineering challenges. In aerospace applications, custom metal fabrication ensures the creation of highly precise components needed for aircraft and spacecraft, including wing structures, fuselage sections, and engine parts. The ability to fabricate parts to exact specifications using advanced techniques such as CNC machining, 3D printing, and laser cutting enhances the performance, safety, and reliability of aviation technology. Furthermore, custom solutions facilitate the integration of cutting-edge materials like titanium and carbon fiber composites, reducing weight while maintaining structural integrity—key factors in improving fuel efficiency and maneuverability of modern aircraft.

In the Defense and Marine sectors, the demand for bespoke metal components is equally critical, supporting the development of advanced weaponry, robust naval vessels, and specialized military equipment. Custom metal fabrication enables the production of combat-ready components and assemblies that can withstand extreme conditions and high stress, such as armored vehicle hulls, missile systems, and submarine pressure hulls. The precise fabrication of metal parts allows for the seamless integration of sophisticated electronic systems and defensive technologies. In marine applications, corrosion-resistant materials and high-strength alloys are often used to prolong the lifespan of ships and submarines, ensuring operational readiness and safety in harsh maritime environments. Thus, custom metal fabrication not only enhances the capabilities and durability of defense and marine assets but also contributes to national security and mission success.

Custom metal fabrication plays a pivotal role in the automotive industry, where precision and durability are paramount. This process involves cutting, shaping, and assembling metal to create high-strength components tailored to specific automotive needs. For instance, custom-fabricated parts can be used to develop chassis, exhaust systems, and suspension components that meet stringent safety and performance standards. The bespoke nature of this fabrication process allows manufacturers to optimize designs for weight reduction, fuel efficiency, and aesthetic appeal, ultimately enhancing vehicle performance and reliability. In an era where electric and autonomous vehicles are on the rise, custom metal fabrication is instrumental in creating advanced frameworks that support new technologies and ensure the seamless integration of electronic systems.

In the electronics industry, custom metal fabrication is equally indispensable, particularly for creating components that require high levels of precision and thermal management. Electronics enclosures, heat sinks, and circuit board components are often crafted through custom metal fabrication to ensure that they meet exact specifications and performance criteria. The process can accommodate the miniaturization trends in the industry by producing intricate, high-tolerance parts that are crucial for modern devices like smartphones, laptops, and medical equipment. Additionally, custom metal fabrication supports the development of robust housings and protective structures that shield delicate electronic components from environmental factors and mechanical stress. This tailored approach not only enhances the longevity and reliability of electronic products but also allows for innovative designs that keep pace with rapid technological advancements.

Custom metal fabrication plays a critical role in the construction industry, providing tailored solutions that enhance the structural integrity and aesthetic appeal of buildings. Through precise cutting, bending, and assembling of metal components, fabricators create bespoke elements such as beams, columns, and trusses that meet specific architectural and engineering requirements. This customization ensures that the metal parts fit perfectly within the design parameters, reducing the risk of structural failures and increasing the longevity of the buildings. Furthermore, custom metal fabrication allows for the integration of unique design features, such as intricate facades and decorative metalwork, giving architects and designers the flexibility to bring their creative visions to life. The precision and quality control inherent in custom metal fabrication also contribute to faster on-site assembly, saving time and reducing labor costs during construction projects.

In the energy sector, custom metal fabrication is indispensable for the development and maintenance of infrastructure critical to energy production and distribution. From oil rigs and pipelines to wind turbines and solar panel mounts, tailored metal components ensure that these systems operate efficiently and reliably. For instance, in the construction of offshore platforms, custom metal fabrication provides specialized steel components that can withstand harsh marine environments, ensuring the safety and durability of the structures. In renewable energy projects, fabricators create custom frames and supports for solar panels and wind turbines, optimizing their placement and energy capture. Additionally, custom metal fabrication enables the production of high-performance storage tanks and heat exchangers, essential for the efficient operation of power plants and refineries. By meeting the stringent standards and specifications of the energy industry, custom metal fabrication supports the advancement of technology and sustainability in energy production.

The industrial equipment industry relies heavily on custom metal fabrication to meet specific machinery requirements that off-the-shelf components simply cannot fulfill. Custom metal fabrication involves cutting, forming, and assembling metal components to precise specifications, enabling manufacturers to produce equipment that is uniquely tailored to their operational needs. Whether it’s heavy-duty conveyor systems, specialized machinery, or bespoke structural components, the ability to create custom-fitted parts ensures greater efficiency and performance. This is particularly critical in industries such as mining, manufacturing, and energy production, where the longevity and reliability of equipment can significantly impact productivity and operational costs.

Moreover, custom metal fabrication allows for greater innovation and optimization in design. Engineers and designers can collaborate to create components that enhance the functionality and durability of industrial equipment, addressing unique challenges faced in specific environments. For instance, heat-resistant alloys can be fabricated for equipment used in high-temperature settings, while corrosion-resistant materials can be crafted for operations exposed to harsh chemicals or marine conditions. By leveraging advancements in technology such as computer-aided design (CAD) and automated cutting techniques, the industrial equipment industry can achieve unparalleled precision and customization, ensuring that each piece of machinery not only meets but often exceeds industry standards. This adaptability not only extends the lifespan of the equipment but also provides a competitive edge by enabling companies to optimize their operational processes effectively.

Custom metal fabrication plays a pivotal role in the development and manufacturing of medical devices, as it allows for the creation of highly precise and specialized components necessary for advanced medical technologies. This field involves cutting, shaping, and assembling metal materials to produce parts that meet strict regulations and performance standards required in medical environments. For instance, surgical instruments made from high-grade stainless steel need to be durable, corrosion-resistant, and able to maintain sharpness over repeated uses. Custom metal fabrication facilitates the production of these instruments with exacting tolerances, ensuring they perform reliably in critical applications. Additionally, this level of precision is essential for the manufacture of components used in imaging equipment and life-support devices, where even the slightest deviation can affect functionality and patient outcomes.

Moreover, custom metal fabrication offers significant advantages in the innovation and personalization of medical devices. With advances in technology such as CAD (Computer-Aided Design) and CNC (Computer Numerical Control) machining, manufacturers can rapidly prototype and produce intricate parts tailored to specific medical needs. This is particularly beneficial for the development of custom implants or prosthetics, which must be designed to match the unique anatomy of individual patients. Tailoring these devices through customized metal fabrication not only improves the fit and comfort for patients but also enhances the overall success rates of medical procedures. By leveraging the capabilities of custom metal fabrication, the medical field continues to push the boundaries of what is possible, driving forward advancements that lead to better patient care and innovative treatment solutions.

Custom metal fabrication is a specialized manufacturing process that involves creating metal structures, components, and assemblies tailored to specific requirements and specifications. This process integrates various techniques such as cutting, welding, machining, and forming to shape raw metal materials into desired products. In machining applications, especially, custom metal fabrication allows for high precision in forming complex parts. Utilizing CNC (Computer Numerical Control) machines, manufacturers can produce intricate designs with tight tolerances, ensuring that each piece meets exact specifications. This precise control is crucial in industries like aerospace, automotive, and medical device manufacturing, where the reliability and accuracy of components can significantly impact performance and safety.

In the broader manufacturing context, custom metal fabrication supports the creation of both prototypes and large-scale production runs. It facilitates the development of unique components that are often vital for specialized machinery and equipment. For example, customized metal parts are essential in creating bespoke machinery for production lines in various industries, allowing businesses to enhance efficiency and productivity. Additionally, this fabrication technique is pivotal in the construction sector, where customized structural components are necessary to meet specific architectural and engineering demands. The flexibility offered by custom metal fabrication ensures that manufacturers can quickly adapt to design changes and innovations, maintaining a competitive edge in ever-evolving markets.

Sure, here is a list of FAQs with answers for manufacturing custom metal fabrication quality work at SourcifyChina factory:

Q1: What types of custom metal fabrication services does SourcifyChina offer?

A1: SourcifyChina offers a wide range of services, including cutting, bending, welding, assembly, and finishing. We specialize in creating high-quality custom metal parts tailored to your specifications.

Q2: How do you ensure the quality of your metal fabrication work?

A2: Quality is our top priority. We implement rigorous quality control processes, including thorough inspections and testing at every stage of production. We are also ISO certified, ensuring adherence to international standards.

Q3: Can you handle both small and large production runs?

A3: Yes, we have the capacity to handle both small and large-scale production runs. Our flexible manufacturing capabilities allow us to efficiently manage orders of any size.

Q4: What materials do you work with?

A4: We work with a variety of metals including steel, aluminum, stainless steel, and more. If you have specific material requirements, we can source and handle those as well.

Q5: How do I request a quote for my project?

A5: You can request a quote by providing detailed information about your project, including design specifications and quantity, through our website or contacting our customer service team directly. We aim to respond within 24 hours.

Q6: What is your typical lead time for custom metal fabrication projects?

A6: Lead times can vary depending on the complexity and size of the project. Generally, our lead times range from 2 to 6 weeks. We’ll provide a more accurate timeline upon reviewing your specific project details.

Q7: Do you offer design assistance or prototyping services?

A7: Yes, we offer design assistance and prototyping services to help you refine your product before full-scale production. Our team of experienced engineers can work with you to ensure your design is optimized for manufacturing.

Q8: Are there minimum order requirements?

A8: We do not have strict minimum order requirements. We aim to accommodate projects of all sizes and can discuss your specific needs during the initial consultation.

Q9: Can you provide references or examples of previous work?

A9: Absolutely. We can provide case studies and examples of previous custom metal fabrication projects upon request. This will give you an idea of our capabilities and quality of work.

When engaging with custom metal fabrication manufacturing from SourcifyChina factory, consider the following tips to ensure a successful partnership:

1. Define Specifications Clearly: Provide detailed drawings and specifications, including dimensions, materials, finishes, and tolerances. Clarity in your requirements minimizes errors and ensures the final product meets your expectations.

2. Quality Assurance: Inquire about the factory’s quality control processes. SourcifyChina typically implements rigorous inspection at various production stages. Request certificates and reports for quality assurance.

3. Material Selection: Discuss material options with the factory experts to choose the best one for your application. Factors like durability, weight, and cost need careful consideration.

4. Prototyping: Before full-scale production, prototype the design to iron out any potential issues. SourcifyChina often offers rapid prototyping services, allowing for adjustments before mass production.

5. Communication: Maintain open and frequent communication. Language barriers and time zone differences can pose challenges, but consistent updates help keep the project on track.

6. Lead Times and Delivery: Understand lead times and plan your project timeline accordingly. Consider logistics and shipping times to avoid delays.

7. Cost Management: Request detailed quotes that break down costs. This helps identify areas for potential savings and ensures transparency in pricing.

8. Factory Visit: If feasible, visiting the factory can provide invaluable insights into their capabilities, work culture, and production processes.

9. Compliance and Certifications: Ensure the factory complies with relevant industry standards and certifications like ISO. This adds a layer of reliability to their processes.

10. After-Sales Support: Discuss after-sales support and warranty policies to cover any issues that might arise post-production.

By focusing on these key areas, you can leverage SourcifyChina’s capabilities effectively for your custom metal fabrication needs, ensuring high-quality results and a smooth production process.

Certainly! Below is a list of frequently asked questions (FAQ) with answers for sourcing custom metal fabrication from SourcifyChina factory, each question marked in bold:

1. What is custom metal fabrication?

Custom metal fabrication involves designing, cutting, shaping, and assembling metal structures tailored to specific requirements.

2. Why choose SourcifyChina for custom metal fabrication?

SourcifyChina offers high-quality craftsmanship, advanced technology, experienced engineers, and competitive pricing to meet your specific metal fabrication needs.

3. What types of metals can SourcifyChina work with?

SourcifyChina specializes in various metals including steel, aluminum, copper, brass, and stainless steel.

4. What industries do you serve?

We cater to multiple industries including automotive, aerospace, construction, electronics, and machinery.

5. How do I get a quote for my custom metal fabrication project?

Submit your design specifications, material preferences, and quantity requirements through our website or contact our customer service for assistance.

6. What is the typical lead time for a custom metal fabrication order?

Lead times vary based on the complexity and volume of your order but generally range from 2 to 6 weeks.

7. Can you help with the design and prototyping of my project?

Yes, our experienced engineers can assist with design and prototyping to ensure your project meets all requirements.

8. Is there a minimum order quantity?

No, we can accommodate both small and large orders, but pricing may be more favorable for higher quantities.

9. What quality control measures are in place?

We have rigorous quality control procedures, including inspection of raw materials, in-process checks, and final product testing to ensure high standards.

10. What are your payment terms?

We typically require a deposit with the balance due upon completion. Specific terms can be discussed during the quotation process.

11. Do you ship internationally?

Yes, we provide international shipping options and handle all necessary export documentation.

12. How do I track my order?

Once your order is shipped, we will provide tracking information so you can monitor the delivery status.

Sourcing custom metal fabrication from SourcifyChina factory involves several key steps to ensure quality, cost-efficiency, and timely delivery. Here are some tips to guide you:

1. Define Requirements Clearly: Begin by specifying the exact dimensions, materials, tolerances, and finishing requirements for your custom metal parts. A detailed technical drawing or a prototype can be extremely helpful.

2. Research Factories: Use SourcifyChina’s platform to explore and shortlist potential factories. Look for those with experience in your specific industry or similar projects.

3. Verify Credentials: Check the factory’s certifications, such as ISO standards, and request samples of previous work to evaluate quality. Look for third-party audits and customer reviews.

4. Request Quotes: Contact your shortlisted manufacturers to request detailed quotes. Make sure the quotes include costs for materials, labor, tooling, finishing, and shipping. Be clear about your budget constraints and delivery timeline.

5. Negotiate Terms: Once you receive quotes, negotiate terms that align with your needs. Focus on factors like lead times, minimum order quantities, payment terms, and quality assurance processes.

6. Conduct Virtual or On-Site Visits: If possible, visit the factory in person or arrange for a virtual tour. This helps in assessing their operations, machinery, and overall capabilities.

7. Establish Clear Communication: Maintain regular communication with the factory through preferred channels like email, phone calls, or video conferences. Use platforms that support seamless translation if language barriers exist.

8. Sample Orders: Before committing to a large order, place a smaller sample order to validate the manufacturer’s capabilities and ensure they meet your quality standards.

9. Quality Control: Implement strict quality control measures. Ensure the factory has a rigorous QC process and consider hiring an independent inspector for additional validation.

10. Logistics Planning: Coordinate with the factory on shipping and logistics. Ensure all customs documentation and shipping arrangements are clear to avoid delays.

By following these steps, you can effectively source custom metal fabrication from SourcifyChina factory while minimizing risks and ensuring high-quality outcomes.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.