Reliable

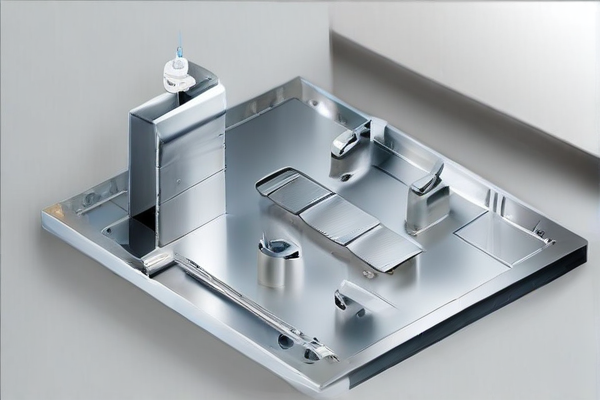

Custom Sheet Metal Fabrication with SourcifyChina: Your Trusted Factory Partner

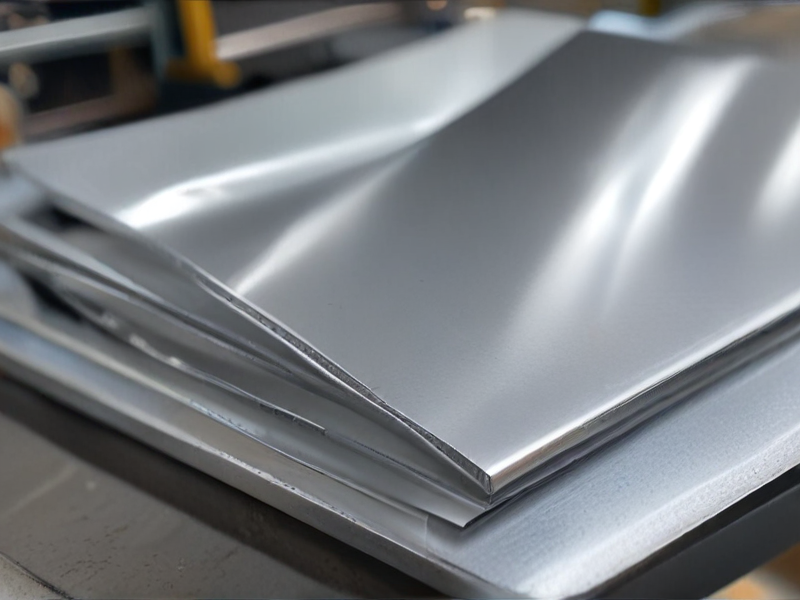

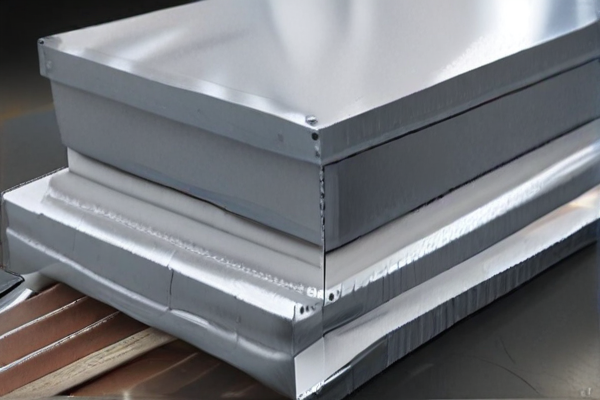

Discover top-tier, reliable custom sheet metal fabrication services with SourcifyChina, your dependable factory source, ensuring high-quality manufacturing and precision engineering tailored to your specifications and industry needs.

Superior Quality and Precision

SourcifyChina Factory prides itself on superior quality and precision in custom sheet metal fabrication. Using state-of-the-art equipment and rigorous quality control processes, they consistently deliver products that meet or exceed client expectations.

Competitive Pricing

Affordability is a key advantage when choosing SourcifyChina. By leveraging cost-effective manufacturing practices and local supply chains, they offer competitive pricing without compromising on quality, making them ideal for businesses on a budget.

Custom Solutions and Flexibility

SourcifyChina offers a high degree of customization, tailoring each project to the specific needs of the client. Their flexible approach allows for modifications and adaptations, ensuring that the final product perfectly aligns with the client’s vision and requirements.

Experienced and Skilled Workforce

Their team comprises highly skilled and experienced professionals who are experts in the field of sheet metal fabrication. This extensive expertise guarantees efficient production processes, innovative solutions, and reliable results every time.

Advanced Technology

Utilizing cutting-edge technology, SourcifyChina stays ahead of industry trends and innovations. Their investment in advanced machinery and software ensures high precision, consistency, and faster turnaround times, making them a preferred choice for complex projects.

Export Expertise

With vast experience in international trading and export regulations, SourcifyChina ensures smooth shipping and handling. Their knowledgeable staff manage logistics efficiently, reducing potential delays and ensuring that products reach their destinations on time and in perfect condition.

By choosing SourcifyChina Factory, buyers gain access to top-tier custom sheet metal fabrication services that blend quality, affordability, and innovation. Their dedicated team, advanced technology, and extensive export experience make them a reliable partner for global businesses looking to source high-quality metal products from China.

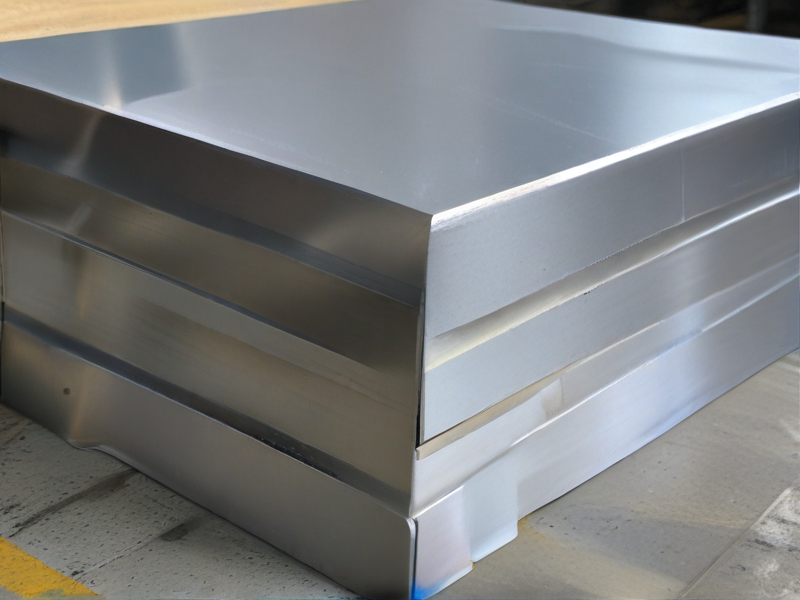

Custom sheet metal fabrication involves various processes to transform flat metal sheets into specific shapes and designs. Its applications span numerous industries, offering flexibility and precision for both small and large-scale projects.

Types

and Options for Custom Sheet Metal Fabrication:

– Cutting

– Laser Cutting

– Plasma Cutting

– Waterjet Cutting

– Shearing

– Bending

– Press Braking

– Roll Bending

– Hand Bending

– Forming

– Deep Drawing

– Stretch Forming

– Hydroforming

– Joining

– Welding (MIG/TIG)

– Riveting

– Adhesive Bonding

– Finishing

– Powder Coating

– Anodizing

– Electroplating

– Polishing

– Materials

– Stainless Steel

– Aluminum

– Copper

– Brass

– Mild Steel

– Prototyping

– Quick Turnaround Prototypes

– Small Batch Production

– Design Support

– CAD/CAM Software Integration

– 3D Modeling

Custom sheet metal fabrication has diverse applications, allowing for tailored solutions in various industries, such as automotive, aerospace, medical, and construction, to create bespoke components and structures.

– Automotive: Manufacturing custom car parts, including chassis components, panels, and brackets.

– Aerospace: Crafting specialized aircraft components that meet stringent safety and performance standards.

– Medical: Producing precise medical equipment and devices tailored to specific applications.

– Construction: Fabricating building facades, supports, and other architectural elements.

– Electronics: Creating housing and enclosures for electronic devices and systems.

– HVAC Systems: Developing custom ductwork and cooling systems for optimal performance.

– Agriculture: Custom equipment and machinery parts designed to enhance productivity.

– Renewable Energy: Fabricating components for solar panels, wind turbines, and other sustainable energy systems.

– Furniture: Creating bespoke metal furniture pieces with unique designs and specifications.

– Marine: Manufacturing durable ship and boat parts resistant to harsh marine environments.

– Signage: Producing weather-resistant, custom signage for commercial and industrial use.

– Food Processing: Crafting sanitary and durable equipment complying with industry standards.

– Tool and Die Making: Producing custom tools and dies for manufacturing processes.

– Prototyping: Facilitating the development of prototypes for new products and innovations.

– Military: Creating specialized equipment and vehicle parts for defense applications.

– Household Appliances: Manufacturing custom components for appliances, enhancing aesthetics and functionality.

– Infrastructure: Custom parts for bridges, railways, and other critical infrastructure projects.

– Robotics: Components for custom-built robots and automation systems.

– Art and Sculpture: Metalwork for custom art installations and sculptures.

– Lighting: Designing and fabricating custom lighting fixtures tailored to specific needs.

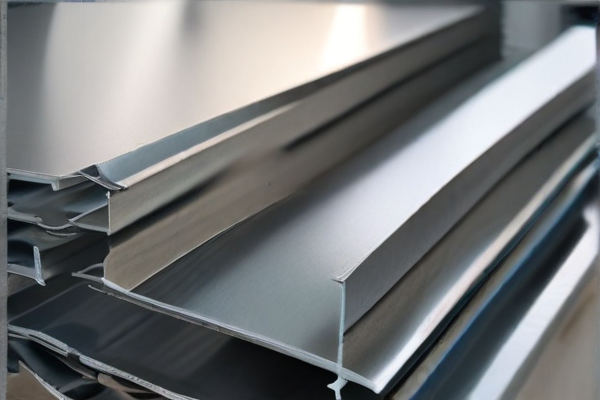

SourcifyChina custom sheet metal fabrication offers a wide array of materials tailored to meet specific project requirements. Stainless steel, known for its durability and resistance to corrosion, is a popular choice.

Another common material is aluminum, prized for its lightweight nature and excellent thermal conductivity. Aluminum is often used in applications requiring both strength and reduced weight.

Mild steel is utilized for projects requiring flexibility and cost-efficiency. Known for its malleability and weldability, mild steel is widely used in structural and automotive industries.

Copper is also employed for its excellent electrical and thermal conductivity. It’s ideal for specialized components that require high precision and reliability.

All these materials ensure that SourcifyChina’s custom sheet metal fabrication delivers quality, durability, and specialized solutions for diverse industrial applications.

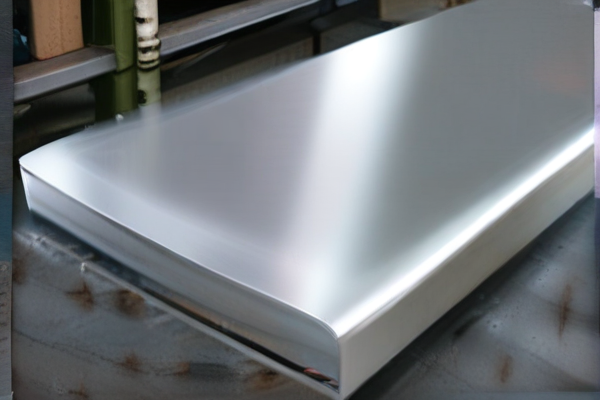

SourcifyChina’s custom sheet metal fabrication quality control manufacturing process ensures high standards through meticulous planning and precision engineering. State-of-the-art technology and skilled technicians collaborate to deliver top-tier products with consistent accuracy and durability.

The process begins with a thorough analysis of material specifications to meet customer requirements. Advanced computer-aided design (CAD) systems are employed to create precise blueprints, which guide every stage of production, minimizing errors.

Quality control checkpoints are strategically placed throughout the fabrication process. Each component undergoes rigorous inspections, including dimensional verification and stress testing, ensuring that parts adhere to stringent industry standards.

Post-fabrication, all items are subject to final quality assessments. This includes detailed visual inspections and functional tests to verify that the end products meet the specified criteria. Any discrepancies are addressed promptly, ensuring superior craftsmanship.

SourcifyChina also implements continuous improvement initiatives to enhance quality. Feedback from inspections and customers is analyzed to identify areas for process optimization, further boosting reliability and efficiency.

In addition, SourcifyChina’s team is highly trained and committed to excellence. Regular training sessions and certifications ensure that technicians stay updated with the latest industry best practices, contributing to overall product quality.

SourcifyChina is dedicated to sustainability and ethical manufacturing practices. By incorporating eco-friendly materials and processes, they not only meet regulatory standards but also contribute to environmental preservation, reflecting their commitment to corporate responsibility.

In conclusion, SourcifyChina’s custom sheet metal fabrication quality control manufacturing process is a comprehensive system designed to deliver superior products. From initial design to final inspection, every step is meticulously planned and executed, ensuring that customer expectations are not just met, but exceeded.

SourcifyChina is renowned for its custom sheet metal fabrication capabilities, addressing diverse industrial needs with precision and efficiency. Utilizing advanced technology and CNC machinery, SourcifyChina ensures high-quality metal components.

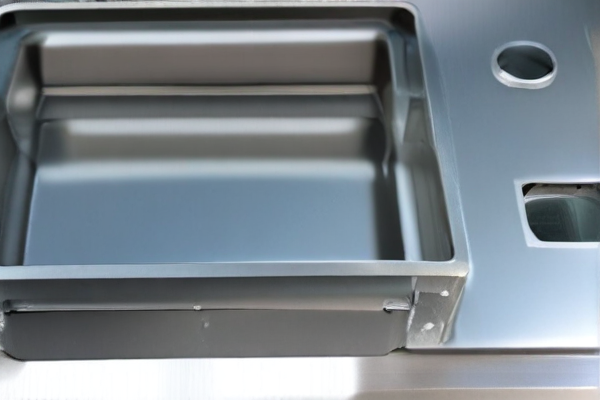

The company offers various services, including cutting, bending, welding, and assembly of sheet metals. Each process is tailored to meet specific customer requirements, guaranteeing satisfaction through detailed craftsmanship and state-of-the-art equipment.

SourcifyChina handles a variety of materials such as stainless steel, aluminum, and carbon steel. Their expertise extends across multiple industries, including automotive, electronics, and construction, showcasing versatility in metal fabrication.

Rigorous quality control measures are implemented at every production stage to ensure consistent results. The skilled workforce and stringent inspection protocols contribute to delivering products that meet international standards and client expectations.

In addition to fabrication, SourcifyChina provides design consulting, helping clients optimize their designs for manufacturability and cost-efficiency. This collaborative approach underscores their commitment to innovation and customer service.

Their logistics solutions ensure timely delivery of finished products, minimizing downtime and enhancing project timelines. SourcifyChina’s efficient supply chain management underscores its capability to handle both small-scale and large-scale production runs.

SourcifyChina’s investment in research and development drives continuous improvement in fabrication techniques. By staying at the forefront of technology, they maintain a competitive edge and offer clients cutting-edge solutions.

Environmental sustainability is a core focus, with eco-friendly practices integrated into their operations. This commitment reflects their responsibility towards sustainable manufacturing and reducing environmental impact.

With a reputation built on reliability and technical excellence, SourcifyChina is a trusted partner in custom sheet metal fabrication. Their comprehensive capabilities and dedication to quality and innovation make them a preferred choice across various industries.

Custom sheet metal fabrication offers numerous advantages, enabling businesses to meet specific requirements and achieve precision in their projects.

– Tailored Solutions: Custom fabrication allows for the creation of parts and components tailored to specific needs, ensuring exact fit and function.

– High Precision: Advanced techniques and tools used in custom metal fabrication ensure high precision and accuracy, vital for intricate designs and applications.

– Material Versatility: A wide range of metals, including steel, aluminum, and copper, can be fabricated to meet diverse project requirements.

– Enhanced Strength and Durability: Custom metal components often exhibit superior strength and durability, making them suitable for heavy-duty applications.

– Cost-Effectiveness: By providing exactly what is needed, custom fabrication can reduce material waste and lower overall project costs.

– Turnaround Time: Modern fabrication shops can offer quick turnaround times, crucial for meeting tight deadlines without compromising quality.

– Quality Control: Custom fabrication facilities often have stringent quality control measures in place, guaranteeing high-quality output.

– Design Flexibility: Engineers and designers can implement more complex and creative designs through custom metal fabrication.

– Integration: Custom parts can be seamlessly integrated into existing systems, enhancing compatibility and performance.

– Prototyping and Testing: Custom fabrication supports prototyping and testing stages, allowing for modifications and improvements before full-scale production.

Custom sheet metal fabrication facilitates efficient, cost-effective, and high-quality production, making it an invaluable process across various industries.

Custom sheet metal fabrication offers tailored solutions, enabling the creation of unique metal components to meet specific requirements. The process boasts several noteworthy features:

– Precision and Accuracy: Advanced machinery and technologies ensure high precision in cutting, bending, and shaping metal parts.

– Versatility: Works with a wide range of metals including steel, aluminum, copper, and brass to create diverse products.

– Customization: Enables the design and creation of unique geometries and complex structures to meet particular needs.

– Rapid Prototyping: Facilitates quick turnaround in producing prototypes for testing and validation purposes.

– Cost-Effective Production: Reduces material waste and labor costs through efficient manufacturing methods.

– Strength and Durability: Utilizes robust materials that ensure the resulting products are strong and long-lasting.

– Finishing Options: Offers a variety of surface treatments like painting, anodizing, and powder coating to enhance appearance and resistance.

– Scalability: Capable of scaling production from small runs to large batches efficiently.

– Integration of Technology: Incorporates CAD/CAM software for precise designs and CNC machinery for exact execution.

– Compliance: Adheres to industry standards and regulations ensuring quality and safety.

These features make custom sheet metal fabrication a go-to choice for industries ranging from automotive and aerospace to construction and electronics.

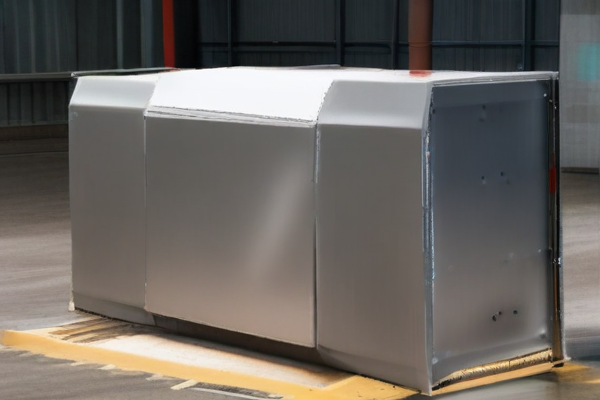

SourcifyChina specializes in custom sheet metal fabrication, offering tailored solutions for various industries. From elaborate enclosures to intricate brackets, their craftsmanship meets rigorous standards. Each project is designed to meet customer specifications and ensures enhanced durability and functionality.

Clients benefit from their state-of-the-art technology and skilled workforce, which enable precise cutting, bending, and welding. This tech-centric approach promises efficient production cycles and impeccable detail, delivering high-quality products every time.

SourcifyChina’s comprehensive range of services includes prototyping, production runs, and post-production finishing. They provide powder coating, painting, and galvanizing to extend the lifecycle of metal components.

Their transparent project management fosters seamless communication and timely deliveries. Whether a small bespoke order or a large-scale operation, SourcifyChina’s commitment to excellence ensures impeccable quality and client satisfaction.

Overall, SourcifyChina excels in transforming sheet metal into functional, high-performance components. Their dedication to innovation and quality makes them a reliable partner in the custom fabrication industry, paving the way for future advancements and customer success.

SourcifyChina is a premier custom sheet metal fabrication company known for its cutting-edge technology and precision engineering. With a strong foothold in the manufacturing industry, the company specializes in providing tailored sheet metal solutions for diverse industrial applications. Leveraging advanced machinery and a highly skilled workforce, SourcifyChina delivers high-quality products, from prototypes to large-scale production runs, ensuring stringent adherence to client specifications and timelines. Their comprehensive services include laser cutting, bending, welding, and finishing, all executed with a commitment to excellence and innovation. By emphasizing customer satisfaction and efficient project management, SourcifyChina has established itself as a trusted partner in the global market, catering to a wide array of sectors including automotive, aerospace, electronics, and construction. The company’s dedication to quality and continuous improvement echoes through its robust quality control processes and ISO certifications, making SourcifyChina a reliable choice for custom sheet metal fabrication needs.

Custom sheet metal fabrication plays a critical role in the aerospace, defense, and marine industries, offering tailored solutions to meet the stringent demands of each sector. In aerospace, precision and reliability are paramount. Custom-fabricated sheet metal components are utilized in constructing aircraft fuselages, wings, and internal structures due to their lightweight yet robust nature. These parts must withstand extreme stress, temperature variations, and high-speed aerodynamic forces, necessitating rigorous specifications and manufacturing standards. Advanced materials, such as titanium and aluminum alloys, are often chosen for their excellent strength-to-weight ratios, enhancing fuel efficiency and overall performance.

In the defense sector, custom sheet metal fabrication is essential for building resilient and versatile military equipment. Armored vehicles, missile systems, and defense communications hardware benefit from the robust and adaptable nature of sheet metal. These components must endure harsh environments and challenging operational conditions, such as exposure to ballistic impacts, extreme temperatures, and corrosive elements. Similarly, the marine industry relies heavily on custom-fabricated sheet metal parts for constructing ship hulls, structural frameworks, and specialized marine equipment. These components require corrosion resistance and durability to perform reliably in saltwater environments. Overall, custom sheet metal fabrication enables these industries to produce high-performance, mission-critical components that meet exacting standards and contribute to operational success.

Custom sheet metal fabrication plays a pivotal role in the automotive industry by providing tailored solutions that meet specific design and performance criteria for vehicles. Manufacturers rely on precisely fabricated metal parts for chassis, engine components, body panels, and exhaust systems. The capability to produce lightweight yet strong and durable parts is crucial for improving fuel efficiency and vehicle safety. Furthermore, custom sheet metal fabrication allows for rapid prototyping and iterative design adjustments, which accelerates innovation and reduces time to market. This adaptability is essential in an industry consistently pushing the boundaries of technology and aesthetics to meet consumer and regulatory demands.

In the electronics sector, custom sheet metal fabrication is indispensable for producing enclosures, brackets, and structural elements that house sensitive components. The fabrication process ensures that these metal parts offer optimal protection against environmental factors, electromagnetic interference, and physical damage. Additionally, precision is paramount in creating parts that align perfectly with circuit boards and other internal components, promoting effective thermal management and overall device reliability. Custom metal fabrication also supports the development of bespoke designs for consumer electronics, allowing manufacturers to differentiate their products through sleek, functional casings. This capability is vital in a competitive market where design innovation and product robustness are key determinants of consumer preference and brand success.

Custom sheet metal fabrication plays an essential role in the construction industry, providing tailored solutions for various structural and architectural needs. By using advanced techniques such as laser cutting, bending, and welding, fabricators can create precise components that fit specific project requirements. Custom sheet metal offers unparalleled versatility, allowing architects and engineers to design unique building facades, intricate roofing systems, and robust support structures. The durability of metal materials such as steel, aluminum, and stainless steel ensures these components can withstand harsh environmental conditions and deliver long-term performance. Moreover, the rapid turnaround time for custom parts helps keep construction schedules on track, reducing downtime and optimizing resource utilization.

In the realm of energy applications, custom sheet metal fabrication is indispensable for creating efficient and reliable components used in power generation and distribution systems. Renewable energy projects, such as solar and wind farms, benefit significantly from fabricated metal parts tailored to enhance performance and durability. Custom enclosures, brackets, and mounting systems are crucial for protecting sensitive equipment and ensuring optimal alignment of solar panels and wind turbines. Additionally, in traditional energy sectors like oil and gas, custom sheet metal components are used for constructing pipelines, storage tanks, and heat exchangers. The precision and customization offered by sheet metal fabrication allow for the manufacturing of parts that can withstand high pressures and corrosive environments, thereby enhancing safety and efficiency. Thus, the role of custom sheet metal fabrication in the energy sector is pivotal for both advancing renewable energy technologies and maintaining the reliability of conventional energy systems.

Custom sheet metal fabrication plays a crucial role in the industrial equipment industry by enabling the creation of precisely tailored components that meet specific operational requirements. This process involves cutting, bending, and assembling sheet metal to form various parts that are essential for the functionality of industrial machinery. Through techniques like laser cutting, CNC punching, and robotic welding, custom sheet metal fabrication allows for high precision and consistency, ensuring that each component fits perfectly within the overall system. This level of customization is vital for industries that demand rigorous standards, such as aerospace, automotive, and manufacturing, where even minor deviations can lead to significant operational inefficiencies or safety concerns.

Moreover, custom sheet metal fabrication supports innovation and rapid prototyping in the industrial equipment sector. Companies can quickly develop and test new designs, allowing them to stay ahead in a competitive market where technological advancements are continually redefining industry standards. By leveraging custom sheet metal fabrication, manufacturers can produce small batches of parts for trial and validation before committing to full-scale production. This agility reduces developmental risks and accelerates the time-to-market for new equipment. Additionally, the ability to create bespoke solutions tailored to unique operational challenges enhances overall efficiency, durability, and performance of industrial machinery, directly contributing to higher productivity and lower downtime in complex industrial environments.

Custom sheet metal fabrication plays an instrumental role in the medical devices industry by enabling the precise and tailored construction of various healthcare equipment. The process involves cutting, bending, and assembling sheet metal to create parts and enclosures that meet stringent hygienic standards and specific design criteria. For instance, surgical instruments, diagnostic equipment, and hospital furniture often rely on custom sheet metal components for their durability, sterility, and structural integrity. The ability to produce bespoke parts ensures that the equipment can be fine-tuned to match the unique requirements of different medical procedures, enhancing overall efficiency and patient care.

Moreover, the adaptability of custom sheet metal fabrication allows for rapid prototyping and iterative development, which is crucial in the fast-paced medical field. When developing new medical devices, manufacturers can quickly produce and test prototypes, making necessary adjustments before moving to large-scale production. This not only accelerates the innovation cycle but also ensures that the final products are optimized for performance and safety. Additionally, the options for various finishing treatments in sheet metal fabrication, such as powder coating or anodizing, help meet the stringent regulatory standards for medical devices by providing protective layers that resist corrosion and facilitate cleaning. Thus, custom sheet metal fabrication is vital in delivering high-quality, reliable, and compliant medical devices tailored to the evolving needs of healthcare.

Custom sheet metal fabrication plays a crucial role in machining and manufacturing by enabling the production of precise and complex components tailored to specific project needs. This process involves cutting, bending, and assembling sheet metal to create parts or structures that meet exact specifications. Techniques such as laser cutting, water jet cutting, and CNC (Computer Numerical Control) machining are often employed to achieve high precision and repeatability. Customization allows for the creation of unique designs and prototypes that are essential in industries like aerospace, automotive, and consumer electronics, where exact dimensions and functionality are paramount. The ability to fabricate bespoke parts ensures that manufacturers can stay competitive by quickly adapting to new requirements and innovations.

In the manufacturing setting, custom sheet metal fabrication enhances production efficiency and flexibility. By using advanced software and machinery, engineers can swiftly transition from design to production, minimizing downtime and reducing material waste. This adaptability is particularly advantageous for low-volume or specialized production runs, enabling manufacturers to cater to niche markets while maintaining high standards of quality. Additionally, sheet metal parts can undergo various finishing processes such as powder coating, anodizing, or electroplating to meet aesthetic and functional requirements. In essence, custom sheet metal fabrication not only supports the creation of functional components but also contributes to an efficient manufacturing process that is capable of meeting the ever-evolving demands of modern industry.

Q1: What materials can SourcifyChina factory work with for custom sheet metal fabrication?

A1: SourcifyChina factory specializes in working with a wide range of materials including stainless steel, aluminum, galvanized steel, and brass to meet various customer needs.

Q2: What industries does SourcifyChina serve with their custom sheet metal fabrication?

A2: We serve multiple industries, including automotive, consumer electronics, aerospace, telecommunications, and industrial equipment, among others.

Q3: What is the lead time for a custom sheet metal fabrication project?

A3: Lead times vary depending on the complexity and size of the project, but generally, our turnaround time is between 2 to 6 weeks.

Q4: Can SourcifyChina handle both small and large production runs?

A4: Yes, we are equipped to handle both small-scale prototyping and large-scale production runs to accommodate different customer requirements.

Q5: What quality control measures are in place at SourcifyChina to ensure high-quality work?

A5: We implement rigorous quality control measures, including inspections at every stage of production, adherence to international standards, and use of advanced testing equipment to ensure top-notch quality.

Q6: Does SourcifyChina offer design assistance for custom sheet metal fabrication projects?

A6: Absolutely. Our experienced engineering team provides design assistance and consultations to help optimize your designs for manufacturability and cost-efficiency.

Q7: How does SourcifyChina ensure accurate and precise fabrication?

A7: We utilize advanced CNC machinery, laser cutting, and other state-of-the-art technologies to ensure precise and accurate fabrication for all projects.

Q8: Can SourcifyChina handle complex designs and specifications?

A8: Yes, our skilled technicians and modern equipment are capable of handling intricate and complex designs, ensuring that your specifications are met with high precision.

Q9: What types of finishing options are available for sheet metal parts?

A9: We offer a variety of finishing options including powder coating, anodizing, plating, painting, and sandblasting to meet your specific aesthetic and functional requirements.

Q10: How can I get a quote for a custom sheet metal fabrication project from SourcifyChina?

Custom sheet metal fabrication is a crucial process in various industries including automotive, aerospace, electronics, and construction. SourcifyChina factory is renowned for its reliable and high-quality custom metal fabrication services. Here are a few tips to optimize your experience:

1. Define Requirements Clearly: Ensure you have detailed specifications, including dimensions, materials, tolerances, and finishes, to avoid misunderstandings.

2. Choose the Right Material: Different projects require different metals. Common choices include aluminum, stainless steel, and carbon steel. Your material choice affects durability, weight, and cost.

3. Prototyping: Consider creating a prototype before large-scale production. This helps in identifying potential design flaws and making necessary adjustments without a major financial outlay.

4. Leverage CAD Software: Utilize Computer-Aided Design (CAD) software to create detailed designs. This not only improves accuracy but also facilitates easier communication with the factory.

5. Understand Capabilities: SourcifyChina offers a range of fabrication techniques such as laser cutting, bending, welding, and stamping. Familiarize yourself with these methods to utilize them effectively.

6. Quality Control: Ensure the factory has rigorous quality control processes in place. Request details about their inspection methods, certifications, and past quality performance.

7. Cost Management: Obtain detailed quotes and understand all costs involved, including materials, labor, tooling, and shipping. Don’t compromise on quality for the sake of reducing costs.

8. Lead Times: Clarify lead times upfront to ensure your project timeline is met. Factor in potential delays especially if custom tooling or special materials are required.

9. Sustainability: If applicable, discuss sustainable practices and materials with the factory to minimize environmental impact.

10. Effective Communication: Maintain open and clear communication lines with the factory. Use visual aids, regular updates, and in some cases, site visits to ensure everything is on track.

By following these tips, you can leverage SourcifyChina’s expertise to achieve high-quality, cost-effective, and timely custom sheet metal fabrication.

Here are some frequently asked questions (FAQ) with answers for sourcing custom sheet metal fabrication from SourcifyChina factory:

1. What services do you offer in custom sheet metal fabrication?

SourcifyChina provides a comprehensive range of services, including cutting, bending, welding, stamping, and assembly. We cater to various industries such as automotive, aerospace, electronics, and construction.

2. What materials can you work with?

We handle various materials, including stainless steel, aluminum, copper, brass, and other metal alloys. Our team can help you choose the best material for your specific project needs.

3. What is your lead time for custom sheet metal projects?

Lead times can vary depending on the complexity and volume of your order. Generally, prototypes can take 1-2 weeks, while full production runs may take 4-6 weeks. We strive to meet your deadlines and keep you informed throughout the process.

4. How do you ensure the quality of fabricated parts?

We adhere to strict quality control standards, including ISO certifications. Our quality assurance team conducts rigorous inspections at every stage of production to ensure your parts meet the specified tolerances and requirements.

5. Can you provide design assistance?

Yes, we offer design assistance to optimize your designs for manufacturability. Our experienced engineers use advanced CAD/CAM software to create accurate and reliable models, ensuring your final product meets your expectations.

6. Do you offer prototyping services?

Absolutely. We provide rapid prototyping services to help you validate and refine your designs before full-scale production. This allows you to make necessary adjustments and save on costs.

7. What is your minimum order quantity (MOQ)?

Our MOQ varies based on the project requirements. We cater to both small and large orders, ensuring flexibility to meet your needs.

8. How do I get started with a custom sheet metal fabrication order?

Simply contact us with your project details, including drawings, specifications, and quantity requirements. Our team will review your information and provide you with a detailed quote and project timeline.

9. What are your payment terms?

We offer flexible payment terms, typically requiring a deposit before production and the balance upon completion. Specific terms will be detailed in our quotation and contract.

10. How do you handle shipping and delivery?

Sourcing custom sheet metal fabrication from a reliable factory like SourcifyChina can be a streamlined process if you follow these key tips:

Clearly specify your custom sheet metal requirements, including material type, thickness, tolerances, and finish. Detailed drawings and CAD designs will help communicate your needs effectively.

Check SourcifyChina’s credentials, certifications (like ISO 9001), and history of past projects. Client reviews and ratings can offer insights into their reliability and quality of work.

Submit an RFQ with all the specifics of your project. Include quantities, deadlines, and any special requirements. This helps avoid misunderstandings and ensures you get accurate quotes.

Compare quotes not just on cost but also on added services such as prototyping, lead times, and the capability to handle complex designs. Consider the total value offered.

If possible, request a prototype before committing to mass production. This enables you to inspect the quality, fit, and finish of the fabrication work and make necessary adjustments.

Maintain clear and continuous communication throughout the process. Regular updates and prompt responses can prevent delays and ensure that the project stays on track.

Inquire about the factory’s quality assurance processes. Ensure they have robust inspection protocols to meet international standards, preventing defects and ensuring consistency.

Discuss logistics early on. Understand shipping options, costs, and timelines to avoid surprises. Also, clarify the incoterms to determine who bears the risk at different stages of shipping.

Check if SourcifyChina offers after-sales support, including handling defects, replacements, or any other post-production issues. This can be crucial for long-term partnerships.

By following these tips, you can effectively source high-quality custom sheet metal fabrication from SourcifyChina, ensuring your project is completed to your specifications and on time.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.