Reliable SourcifyChina Factory: Premium Cut Sheet Metal Tool Solutions for Precision and Durability

Discover the unparalleled reliability of SourcifyChina Factory’s advanced cut sheet metal tools, meticulously engineered for precision and durability to meet your industrial needs. Trust in our top-tier manufacturing to enhance your production efficiency.

Choosing “SourcifyChina” Factory for purchasing cut sheet metal tools from China offers unmatched value. They specialize in high-quality production and adhere to stringent global standards, ensuring durability and precision.

Additionally, “SourcifyChina” provides competitive pricing without compromising on quality. This cost-efficiency is highly advantageous for buyers, maximizing their investment value.

Furthermore, their prompt delivery and robust customer support set them apart. Timely responses and efficient logistics ensure that your operations remain uninterrupted, and issues are promptly resolved.

In conclusion, “SourcifyChina” Factory presents a synergistic blend of quality, affordability, and dependability. Their comprehensive approach to manufacturing and customer service makes them an ideal partner for acquiring cut sheet metal tools from China.

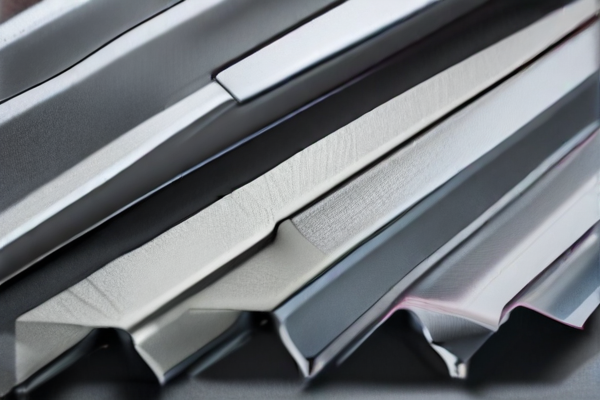

Cut sheet metal tools are essential for shaping and resizing metal sheets in various industrial and DIY projects. These tools come in multiple types, each tailored for specific tasks and material thicknesses.

– Tin Snips/Hand Shears: Ideal for straight cuts and curves in thinner sheets.

– Aviation Snips: Designed with compound leverage for cutting through thicker metals and making intricate cuts.

– Nibblers: Electric or pneumatic tools perfect for making rapid, complex cuts without deforming the sheet.

– Bench Shears: Lever-operated tools mounted on a bench for accuracy in cutting larger sheets.

– Angle Grinders: Equipped with cutting wheels for versatile, high-speed cutting applications.

– Plasma Cutters: Use electrically conductive gas to cut through thick sheets with precision and minimal distortion.

– Laser Cutters: Provide extremely precise cuts with minimal effort, suitable for both thin and thick sheets.

– Hydraulic Shears: Powerful machines that use hydraulic force for cutting through very thick metal sheets.

– Waterjet Cutters: Utilize high-pressure water mixed with abrasives to cut through various materials without heat affecting the integrity of the sheet.

– Electric/Pneumatic Shears: Offer significant power for efficient cutting, recommended for repetitive tasks involving thicker materials.

These tools accommodate a range of metalworking needs, ensuring both professionals and hobbyists can find the appropriate tool for their specific requirements.

A cut sheet metal tool is essential in various industries for precise cutting of metal sheets, enhancing efficiency and accuracy. It serves a multitude of applications across different trades and production processes.

– Automotive Industry: Fabricates car body parts, chassis, and custom modifications.

– Construction: Creates roofing panels, HVAC components, architectural elements, and framework.

– Manufacturing: Produces machinery parts, industrial equipment, and consumer goods.

– Electrical Industry: Crafts electrical enclosures, switchgear, and panel boards.

– Aerospace: Develops aircraft components, structural frames, and custom aerospace parts.

– Art and Sculpture: Helps in creating intricate metal artworks and sculpture pieces.

– Prototyping: Facilitates rapid prototyping for product development and testing.

– Furniture Design: Produces metal furniture parts and decorative elements.

– Home Appliances: Manufactures casing and parts for various home appliances.

– Signage and Display: Cuts materials for customized signs and display structures.

– Marine Industry: Used in fabricating boat hulls, decks, and other marine components.

– Medical Device Production: Assists in manufacturing surgical instruments and medical equipment.

– Agriculture Equipment: Creates parts for farming machinery and tools.

– Defense and Military: Produces vehicle armor, weapon parts, and protective barriers.

– Renewable Energy: Fabricates parts for solar panels, wind turbines, and other renewable energy systems.

The versatility and precision of cut sheet metal tools make them indispensable across these various sectors, contributing significantly to innovation and production efficiency.

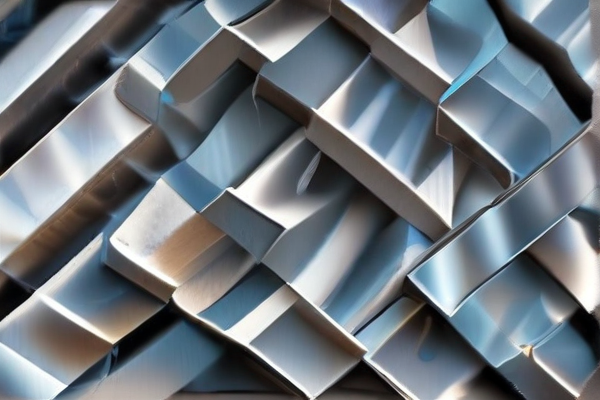

SourcifyChina’s cut sheet metal tool utilizes high-grade stainless steel for its primary structure. Stainless steel is chosen for its exceptional durability and resistance to corrosion, ensuring a long-lasting and reliable tool.

For added precision in cutting, the tool incorporates hardened steel blades. Hardened steel is specifically treated to enhance its toughness, allowing for cleaner cuts and prolonged blade life, essential for high-frequency industrial use.

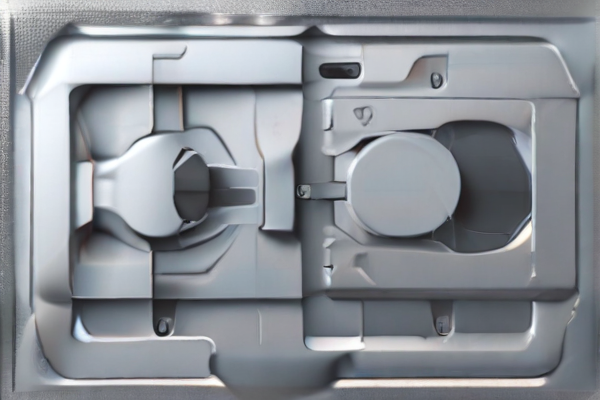

The handle of the cut sheet metal tool is ergonomically designed and typically made of rubber-coated plastic. This material combination provides a comfortable grip, reducing hand fatigue during extended periods of operation.

An additional feature of the tool includes a locking mechanism crafted from reinforced steel. This adds another layer of safety by securing the blades when not in use, making it safe for transport and storage.

Overall, the meticulous selection of materials ensures that SourcifyChina’s cut sheet metal tool is both robust and efficient. Its construction aims to meet the demanding requirements of industrial settings while offering ease of use and enhanced safety features.

The quality control manufacturing process for SourcifyChina’s cut sheet metal tool begins with meticulous material selection. Only the highest-grade metal sheets are chosen to ensure durability and precision during the cutting process.

During production, sophisticated machinery is employed to cut the metal sheets to exact specifications. Continuous monitoring by experienced technicians ensures that each piece maintains uniformity and adheres to the design criteria.

Once the initial cutting is complete, each metal sheet undergoes rigorous inspection. Advanced measurement tools and inspection protocols are used to detect any deviations or defects, ensuring each tool meets stringent quality standards.

Finishing touches are applied to the cut metal sheets, including deburring and edge smoothing. These processes eliminate rough edges and enhance the overall aesthetic and functional quality of the tool.

Finally, a comprehensive quality assessment is carried out, involving both manual checks and automated scanning. Each tool is validated against predefined quality benchmarks before being approved for packaging and shipment.

By adhering to this meticulous quality control process, SourcifyChina guarantees that every cut sheet metal tool delivers exceptional performance and reliability, meeting the highest industry standards. This dedication to quality assures customer satisfaction and long-term durability of their tools.

The SourcifyChina Cut Sheet Metal Tool exemplifies precision in metal fabrication processes. It allows for intricate designs to be cut with high accuracy and minimal waste, streamlining production. Laser cutting technology ensures clean edges and precise dimensions.

Robust in its performance, this tool handles various metals, from mild steel to aluminum and stainless steel, accommodating diverse industry applications. Its versatility caters to both small-scale prototypes and large production runs, making it ideal for custom and standardized projects alike. Plus, sophisticated programming features enhance efficiency.

Operator-friendly features include an intuitive interface, facilitating ease of use even for those with limited technical expertise. The automated nature of the tool further reduces labor costs and errors, contributing to overall production efficiency. Safety protocols are embedded, ensuring a secure operational environment.

Maintenance of the SourcifyChina tool is straightforward, thanks to robust build quality and accessible component layout. Scheduled upkeep prolongs the tool’s lifespan and maintains optimal performance. The tool’s efficiency not only boosts productivity but also aids in meeting stringent deadlines without quality compromise.

Providing comprehensive support, SourcifyChina offers training, troubleshooting, and customization services to ensure optimal tool utilization. A customer-centric approach guarantees businesses can adapt the tool to specific needs, ensuring maximum return on investment. The SourcifyChina Cut Sheet Metal Tool is therefore a indispensable asset in modern metalworking operations.

Using a cut sheet metal tool offers numerous advantages, enhancing productivity and precision in metalworking projects.

– Increased Efficiency: These tools significantly speed up the cutting process, saving valuable time in various applications.

– Enhanced Precision: Cut sheet metal tools deliver clean, accurate cuts, reducing errors and waste.

– Versatility: They can handle different types of metals and thicknesses, making them suitable for diverse projects.

– Reduced Labor Costs: Automation in cutting tools minimizes manual labor, resulting in lower operational expenses.

– Improved Safety: Modern cut sheet metal tools come with safety features that protect operators from accidents.

– Consistent Quality: These tools ensure uniform cuts, maintaining high-quality standards across production.

– Ease of Use: Advanced designs and technologies make these tools user-friendly, even for those with minimal experience.

– Durability: High-quality materials and engineering extend the lifespan of these tools, offering long-term reliability.

– Cost-Effective: Investing in cut sheet metal tools proves economical over time as they reduce waste and increase efficiency.

– Customization Options: These tools allow for tailored cutting solutions, accommodating specific project requirements.

– Eco-Friendly: Accurate cuts reduce material waste, contributing to environmentally sustainable practices.

Incorporating cut sheet metal tools into your workflow can transform your operations, providing a blend of efficiency, precision, and safety, while also being cost-effective and versatile.

Cut sheet metal tools offer precision and efficiency in metalworking, streamlining the cutting process for various applications. Ideal for producing intricate shapes and edges, these tools cater to both industrial and DIY projects.

– Precision Cutting: Achieve clean, accurate cuts with minimal edge distortion.

– Versatility: Compatible with various metals, including aluminum, steel, and copper.

– Durability: Built to withstand rigorous use, ensuring long-term reliability.

– Ease of Use: User-friendly designs enhance operational efficiency, even for novices.

– Adjustable Settings: Customize cut depth and angle to suit specific project requirements.

– Safety Features: Integrated guards and automatic shutoff mechanisms minimize injury risks.

– Portability: Lightweight and compact options available for on-site work.

– Cost-Effective: Reduces material wastage and speeds up production, lowering overall costs.

These features make cut sheet metal tools essential for achieving high-quality results in metal fabrication.

SourcifyChina specializes in providing custom sheet metal tools tailored to specific project needs. Utilizing advanced technology, they create precise, durable tools that meet exacting industry standards.

Their expert team collaborates with clients to design, prototype, and produce custom metal tools that enhance productivity and efficiency. This collaborative approach ensures the final product aligns perfectly with the project’s requirements.

SourcifyChina’s commitment to quality ensures each tool undergoes rigorous testing. By doing so, they guarantee reliability and performance, vital in demanding environments like automotive, aerospace, and construction industries.

In addition to custom tools, SourcifyChina offers end-to-end project management, from initial consultation to final delivery. Their comprehensive services ensure smooth project execution, adhering to both timelines and budgets.

What sets them apart is their ability to handle complex, high-spec orders while maintaining stringent quality controls. Their innovation and dedication make them a preferred partner for businesses needing bespoke sheet metal solutions.

Ultimately, SourcifyChina not only delivers superior products but also empowers clients through expert guidance and support. Their holistic approach has earned them a reputation for excellence in sheet metal tool production.

SourcifyChina Cut Sheet Metal Tool Company stands at the forefront of precision engineering and manufacturing, specializing in the production of high-quality sheet metal tools. Leveraging advanced technologies and state-of-the-art equipment, the company has consistently delivered products that meet stringent international standards. With a robust supply chain and a highly skilled workforce, SourcifyChina ensures that each tool is crafted with unparalleled accuracy and durability, catering to a diverse range of industries including automotive, aerospace, and electronics. Their commitment to innovation is evidenced by continuous investments in research and development, ensuring that they remain competitive in an ever-evolving market. By focusing on customer satisfaction, SourcifyChina has built strong, long-lasting relationships with clients worldwide, establishing itself as a reliable partner in sheet metal fabrication solutions. Their comprehensive suite of services, from conceptual design through to final production, underscores their capability to meet the most complex and specialized needs, making them a leader in the industry.

In the Aerospace, Defense, and Marine industries, precision and reliability are paramount, making the application of cut sheet metal tools indispensable. These tools are employed in the fabrication of essential components such as airframes, bulkheads, and brackets in aircraft. The high precision cutting capabilities ensure tight tolerances and reduce the risk of structural failures by guaranteeing exact dimensions and high-quality finishes. Advanced materials, including titanium and aluminum alloys often used in aerospace applications, require specialized cutting tools that can handle their unique properties without compromising integrity. The repeatability and accuracy of cut sheet metal tools thus play a critical role in maintaining the robustness and safety of aerospace structures.

Similarly, in the Defense sector, the rigorous demands for durability, resilience, and precision are met through the use of advanced cut sheet metal tools. Components for armored vehicles, naval ships, and missile systems require exacting standards to ensure performance under extreme conditions. Cut sheet metal tools are vital in crafting intricate parts swiftly and accurately from hardened alloys and composite materials, which are essential for both offensive and defensive applications. The Marine industry also benefits significantly from these tools, where they are used to create components for submarines, commercial ships, and offshore platforms. Given the harsh maritime environment, cut sheet metal tools help in manufacturing parts that resist corrosion, withstand pressure, and ensure longevity, contributing to the overall durability and safety of marine vessels and structures.

Cut sheet metal tools are indispensable in the automotive industry, where precision and efficiency are paramount. These tools facilitate the fabrication of various car components by enabling the accurate cutting and shaping of metal sheets. From body panels to intricate components like brackets and reinforcements, cut sheet metal tools ensure that each piece is crafted to exact specifications. This precision is crucial for maintaining structural integrity and ensuring proper assembly of parts, which directly impacts the vehicle’s performance and safety. Additionally, the efficiency of cut sheet metal tools helps manufacturers maintain consistent production speeds and reduces material waste, thus optimizing both cost-effectiveness and sustainability in automotive production processes.

In the realm of electronics, cut sheet metal tools are equally vital. They play a critical role in creating the enclosures and chassis that house delicate electronic components. The precision machining of these housings ensures that all internal elements are protected from external damage and electromagnetic interference. Furthermore, the fine cutting capabilities of these tools allow for the incorporation of intricate design features such as ventilation slots and mounting holes, which are essential for the functionality and assembly of electronic devices. Thus, cut sheet metal tools contribute significantly to the durability, functionality, and aesthetic appeal of electronics, from consumer gadgets to sophisticated industrial equipment.

Overall, cut sheet metal tools embody a cornerstone of modern manufacturing processes in both the automotive and electronics sectors, driving forward advancements in design and production efficiency.

In the construction industry, the cut sheet metal tool is indispensable for fabricating and customizing various architectural components. Whether it’s creating intricate shapes for building facades, ductwork for HVAC systems, or framing for doors and windows, this tool enables precise and efficient cutting of sheet metal to meet specific design requirements. Its versatility simplifies the construction process, reducing the need for multiple tools and minimizing material wastage. With the ability to produce clean, accurate cuts, the cut sheet metal tool ensures components fit perfectly, which is critical for maintaining the structural integrity and aesthetics of any building project. Consequently, it enhances productivity on-site, allowing construction teams to meet tight deadlines and maintain high-quality standards.

In the energy sector, particularly in renewable energy applications like solar panel manufacturing and wind turbine assembly, the cut sheet metal tool plays a crucial role in material fabrication. Solar panels, for instance, require precise metal frames and mounts, which are efficiently produced using this tool. Similarly, components for wind turbines, such as nacelle covers and support structures, rely on accurately cut metal parts to ensure optimal performance and durability. Moreover, in the production of batteries and electrical enclosures for energy storage systems, the cut sheet metal tool ensures that each component meets stringent specifications, which is vital for safety and efficiency. By enhancing the precision and speed of production, this tool contributes significantly to advancing renewable energy technologies and supporting the global shift towards more sustainable energy solutions.

The industrial equipment sector significantly benefits from the application of cut sheet metal tools, which are pivotal in manufacturing and construction processes. These tools are engineered to slice through various metals such as steel, aluminum, and copper with precision and efficiency. The use of cut sheet metal tools in industrial applications spans a multitude of tasks, ranging from producing automotive components to constructing large-scale industrial machinery. High productivity and reduced material wastage are notable advantages, leading to cost-efficiency in mass production. By leveraging technologies such as CNC (Computer Numerical Control) cutting, these tools offer unparalleled accuracy and repeatability, essential for maintaining high quality in finished products.

Moreover, cut sheet metal tools play a critical role in enhancing customization and flexibility in manufacturing. Industries, particularly automotive and aerospace, require components that meet detailed specifications and rigorous standards. Advanced cut sheet metal tools enable manufacturers to swiftly adapt to design changes and custom orders without extensive downtime. They support intricate designs and complex geometrical shapes, broadening the scope of innovation. This adaptability combined with the ability to process diverse metal types ensures that industries can continually meet evolving market demands. Thus, cut sheet metal tools not only bolster operational efficiency but also drive advancements in industrial manufacturing capabilities.

Medical devices often require precise and complex components that cater to stringent safety and functionality standards. The cut sheet metal tool is indispensable in the production of these components, enabling the fabrication of intricate parts such as enclosures, brackets, and surgical instruments with high accuracy. Employing computer-aided design (CAD) software, manufacturers can program the tooling machines to cut sheet metal to exact specifications, ensuring consistency and quality across batches. The ability to work with diverse metals, including stainless steel, aluminum, and titanium, further enhances the versatility of this tool, making it a cornerstone in producing a wide array of medical devices that meet rigorous industry standards.

Additionally, the cut sheet metal tool aids in rapid prototyping and iterative design processes, allowing for swift adjustments and improvements in medical device manufacturing. This agility is crucial for developing innovative solutions to meet emerging healthcare needs. The precision of cut sheet metal tools minimizes material waste and optimizes the use of resources, aligning with sustainable manufacturing practices. With advancements in technology, modern cut sheet metal tools are increasingly incorporating automation and robotic systems, which enhance production speed and reduce the likelihood of human error. This evolution continues to improve the efficiency and reliability of medical device production, ultimately aiding in the delivery of high-quality medical care.

Cut sheet metal tools are indispensable in both machining and manufacturing sectors due to their precision and efficiency in processing sheet metal materials. In the machining realm, these tools are used to achieve high-accuracy cuts and complex shapes, optimizing the material usage and minimizing waste. They enable the fabrication of intricate parts for various industries, ranging from automotive to aerospace. The precision offered by these tools reduces the need for subsequent machining processes, thus shortening the production cycle and lowering costs. Machinists rely on these tools to create prototypes and custom components with exacting tolerances, ensuring the final products meet stringent industry standards.

In the manufacturing sector, cut sheet metal tools are integral to mass production lines. They enhance productivity by enabling high-speed and automated cutting operations, contributing significantly to the efficiency of assembly processes. The versatility of these tools allows manufacturers to work with a wide range of materials, including aluminum, steel, and titanium, tailoring products to specific requirements. Automated cut sheet metal systems can be integrated with Computer Numerical Control (CNC) machines and robotic arms, providing seamless and continuous production capabilities. This integration enables real-time adjustments and quality control, ensuring consistent output and reducing the margin for errors. As a result, products ranging from household appliances to industrial machinery can be manufactured with precision, reliability, and uniformity.

Certainly! Here is a list of frequently asked questions (FAQs) with answers regarding manufacturing cut sheet metal tools from SourcifyChina factory:

Q1: What types of sheet metal tools do you manufacture?

A1: SourcifyChina manufactures a range of sheet metal tools including cutting tools, bending tools, punching tools, and forming tools, tailored to meet different industrial requirements.

Q2: What materials can you work with?

A2: Our factory works with various materials such as steel, aluminum, copper, brass, and stainless steel to produce high-quality sheet metal tools.

Q3: How do you ensure the quality of the sheet metal tools?

A3: We employ stringent quality control measures including material inspection, in-process checks, and final product testing, adhering to international standards to ensure top-notch quality.

Q4: Can you customize tools according to specific requirements?

A4: Yes, we offer customization services. You can provide your designs or specifications, and our engineers will work closely with you to create the tools that meet your specific needs.

Q5: What is the typical lead time for manufacturing?

A5: The lead time varies depending on the complexity and quantity of the order. Generally, it ranges from 2 to 6 weeks. We strive to meet your deadlines while maintaining high quality.

Q6: Do you offer sampling services?

A6: Yes, we can provide sample tools before mass production to ensure you are satisfied with the design and quality.

Q7: What certifications do you hold?

A7: SourcifyChina holds ISO 9001, CE, and various other certifications that attest to our quality management systems and manufacturing processes.

Q8: Can you support large-scale production runs?

A8: Absolutely. Our factory is equipped with advanced machinery and technology to handle both small and large-scale production runs efficiently.

Q9: How do you handle shipping and logistics?

A9: We offer comprehensive shipping and logistics support, working with reliable freight forwarders to ensure timely and safe delivery of your orders worldwide.

Q10: What are your payment terms?

A10: Our standard payment terms are flexible and include options such as T/T, L/C, and other secure methods. We will work with you to find a suitable payment arrangement.

For further inquiries, please contact our customer support team.

When sourcing cut sheet metal tools from SourcifyChina Factory, it’s essential to focus on several key aspects to ensure quality, efficiency, and cost-effectiveness.

1. Supplier Verification: Confirm the credentials and quality certifications (ISO, CE) of SourcifyChina Factory. Check for reviews and past customer experiences to gauge reliability.

2. Material Quality: Discuss material specifications with the factory. High-quality metals like stainless steel or aluminum ensure durability and precision in tools.

3. Customization: If you require specific designs or customizations, ensure that SourcifyChina Factory is equipped with advanced machinery like CNC machines and laser cutters to handle intricate details.

4. Prototyping: Request a prototype before mass production. This will help you evaluate the tool’s performance and make any necessary adjustments.

5. Communication: Establish clear communication channels. Ensure that there is a dedicated point of contact who speaks your language or has proficient language skills to avoid misunderstandings.

6. Quality Control: Set up a robust quality control process. Discuss the factory’s in-house inspection procedures and consider third-party inspections if needed.

7. Lead Times: Inquire about production and shipping lead times to align with your project timelines. Ensure that the factory can meet your deadlines without compromising quality.

8. Cost Transparency: Understand all cost elements, including raw materials, labor, tooling, and shipping. Request a detailed quotation to avoid hidden charges.

9. Sustainability: If sustainability is crucial to your business, discuss the factory’s environmental policies and practices.

10. After-Sales Support: Ensure that SourcifyChina Factory provides after-sales support, including warranties and technical assistance.

Building a strong relationship with SourcifyChina Factory, grounded in thorough research and clear agreements, will ensure successful production of high-quality cut sheet metal tools.

Sure! Here is a simple FAQ for sourcing cut sheet metal tools from SourcifyChina factory:

1. What is SourcifyChina?

SourcifyChina is a professional sourcing company that partners with reputable Chinese factories to provide high-quality manufacturing solutions, including cut sheet metal tools, to global clients.

2. How can I place an order?

To place an order, visit SourcifyChina’s website or contact their sales team. You’ll need to provide specifications, quantities, and any other relevant details of your cut sheet metal tool requirements.

3. What information do I need to provide for a quote?

Provide as much detail as possible, including material types, thickness, dimensions, tolerances, finishes, and quantities. Drawings or CAD files are highly beneficial.

4. What is the lead time for production?

Lead times vary depending on the complexity and size of the order. Typically, production can range from a few weeks to a few months. Confirm with SourcifyChina for precise timings.

5. Can you provide samples before full-scale production?

Yes, SourcifyChina can provide samples or prototypes for approval before proceeding to full-scale production. This ensures that the products meet your specifications.

6. What quality control measures are in place?

SourcifyChina employs stringent quality control processes, including material verification, in-process inspections, and final product testing. They can also provide QC reports on request.

7. What are the payment terms?

Payment terms typically include a deposit upon order placement and the balance before shipment. Specific terms can be negotiated directly with SourcifyChina.

8. Do you handle shipping and logistics?

Yes, SourcifyChina can manage shipping and logistics, including customs clearance and delivery to your designated location. They offer various shipping options to accommodate different needs.

9. What if I have issues with my order?

SourcifyChina has a customer service team to handle any issues or concerns. They work closely with clients to resolve any problems swiftly and efficiently.

10. How can I contact SourcifyChina?

You can contact SourcifyChina via their website, email, or by phone. They also offer live chat support for immediate assistance.

The provided answers reflect general procedures and information and may vary based on specific circumstances or custom arrangements.

Sourcing a cut sheet metal tool from SourcifyChina factory can seem daunting, but following these steps can ensure a smooth procurement process:

1. Research & Verification:

– Visit SourcifyChina’s official website or trusted platforms like Alibaba.

– Verify the factory’s credentials, certifications, and customer reviews to ensure reliability.

2. Clear Requirements:

– Specify detailed requirements: material type, thickness, tool dimensions, and tolerances.

– Include intended application to help them recommend the best tool.

3. Request for Quotes (RFQs):

– Send RFQs to multiple manufacturers to compare prices, quality, and lead times.

– Ensure the RFQs include all necessary details to get accurate quotes.

4. Samples:

– Request sample tools to evaluate quality firsthand before placing a bulk order.

– Verify that the samples meet your requirements and standards.

5. Quality Assurance:

– Inquire about their quality control processes and any third-party testing.

– Ask for Inspection Certificates or Quality Reports for the materials and finished tools.

6. Negotiation:

– Negotiate terms such as pricing, payment terms, delivery times, and warranty.

– Discuss potential for future discounts or bulk order benefits.

7. Secure Contract:

– Draft a detailed contract including all terms and conditions, which protects both parties’ interests.

– Make sure clauses on quality assurance, delivery deadlines, and penalties for delays or defects are included.

8. Logistics:

– Coordinate with the factory and a reliable shipping provider for the best logistics solutions.

– Consider delivery times, customs duties, and insurance coverage.

9. Communication:

– Maintain regular communication with the supplier for updates on the production and shipping status.

– Resolve any issues promptly and document all communications.

Following these steps can help you source quality cut sheet metal tools efficiently and effectively from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.