Technology and Applications of d2 metal

Technology and Applications of D2 Tool Steel

D2 tool steel is a high-carbon, high-chromium air-hardening steel known for its wear resistance, hardness, and toughness. Its composition includes approximately 1.5% carbon and 12% chromium, which enhances its hardness and corrosion resistance. The steel is typically hardened through heat treatment processes.

#### Key Technologies

1. Heat Treatment: D2 tool steel is subjected to heat treatment processes such as annealing, quenching, and tempering to achieve desired mechanical properties. This makes it extremely hard and durable.

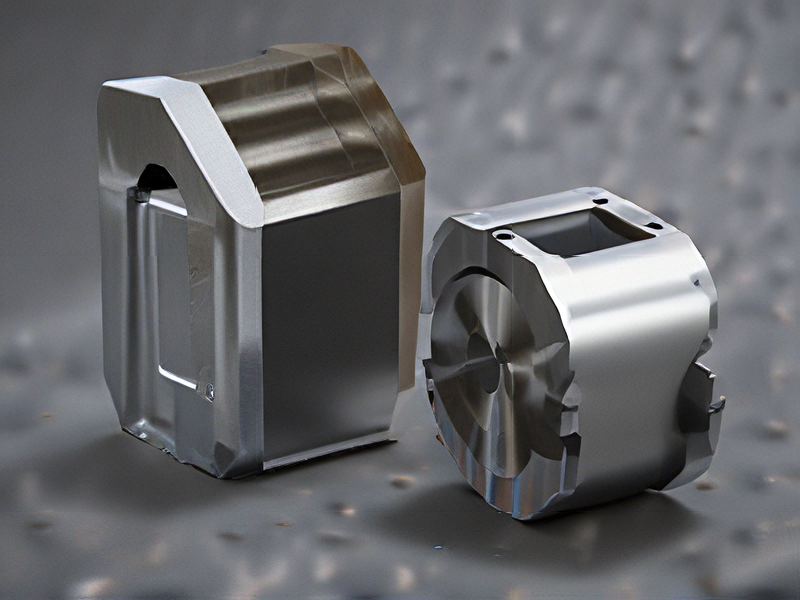

2. Machining: Advanced machining techniques, including CNC machining, are used to shape D2 steel into precise tools and components. Given its hardness, machining D2 can be challenging, requiring specialized equipment and techniques.

3. Cryogenic Treatment: This involves cooling the steel to extremely low temperatures to improve its wear resistance and dimensional stability. It reduces the retained austenite in the steel, enhancing its overall performance.

#### Applications

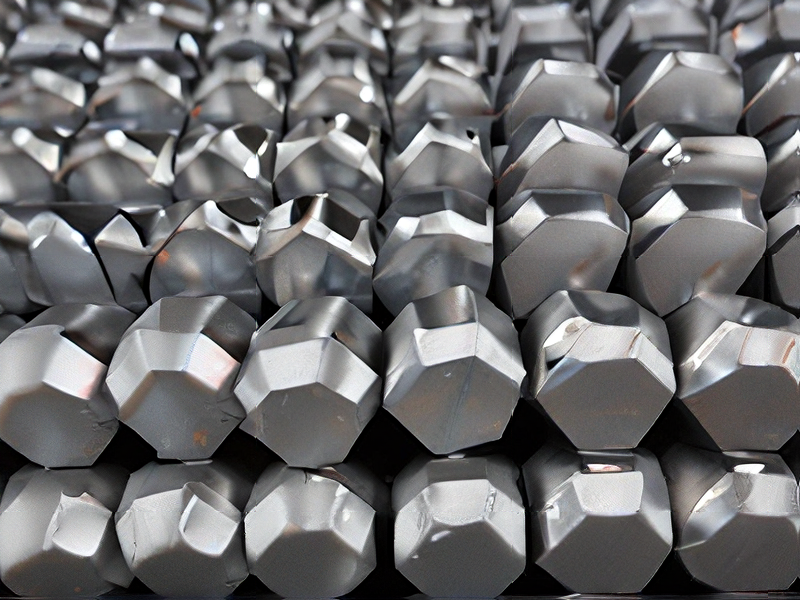

1. Tool and Die Making: D2 is widely used in the manufacturing of dies for stamping, cutting, and forming. Its wear resistance ensures long tool life, reducing downtime and costs in production environments.

2. Industrial Blades: The steel’s hardness and wear resistance make it ideal for industrial blades used in paper, plastic, and metal cutting applications. D2 blades maintain sharp edges longer, increasing efficiency.

3. Injection Molding: D2 is used for molds in the plastic injection molding industry. Its toughness and resistance to abrasive wear allow for high-volume production runs without significant tool degradation.

4. Knives and Cutlery: High-end knives, including kitchen and hunting knives, often use D2 steel for their blades. The steel provides a sharp, durable edge that withstands heavy use.

5. Bearings and Bushings: D2 steel is used in applications requiring high wear resistance and low friction, such as bearings and bushings in heavy machinery.

In summary, D2 tool steel is essential in industries requiring durable, wear-resistant components, leveraging advanced heat treatment and machining technologies to maximize its performance in demanding applications.

Quality Testing Methods for d2 metal and how to control quality

Quality Testing Methods for D2 Tool Steel:

1. Chemical Composition Analysis:

– Method: Optical Emission Spectroscopy (OES) or X-ray Fluorescence (XRF).

– Purpose: Ensures the metal’s chemical composition meets specifications for elements like carbon, chromium, and vanadium.

2. Hardness Testing:

– Method: Rockwell Hardness Test (HRC).

– Purpose: Verifies hardness levels, typically ranging from 55-62 HRC for D2 steel after heat treatment.

3. Microstructure Examination:

– Method: Metallographic Analysis using Optical or Electron Microscopy.

– Purpose: Checks for uniformity, grain size, and distribution of carbides, ensuring optimal mechanical properties.

4. Tensile Testing:

– Method: Universal Testing Machine (UTM).

– Purpose: Measures tensile strength, yield strength, and elongation to determine the material’s mechanical performance.

5. Impact Testing:

– Method: Charpy Impact Test.

– Purpose: Evaluates toughness, especially important for applications requiring high resistance to fracture.

6. Non-Destructive Testing (NDT):

– Method: Ultrasonic Testing (UT) or Magnetic Particle Inspection (MPI).

– Purpose: Detects internal and surface defects without damaging the material.

Quality Control Measures:

1. Raw Material Verification:

– Conduct thorough inspection and testing of incoming raw materials to ensure compliance with required standards.

2. Process Control:

– Implement strict process controls during manufacturing, such as maintaining precise temperature and timing during heat treatment.

3. In-Process Inspection:

– Regular inspections and tests at various production stages to detect and correct defects early.

4. Final Inspection:

– Comprehensive testing of finished products, including dimensional checks and mechanical property verification.

5. Documentation and Traceability:

– Maintain detailed records of all tests and inspections for traceability and quality audits.

6. Continuous Improvement:

– Analyze test data to identify trends and areas for improvement, implementing corrective actions to enhance quality continuously.

These methods and measures ensure D2 tool steel’s reliability and performance, meeting stringent industry standards.

Tips for Procurement and Considerations when Purchasing from d2 metal

Tips for Procurement and Considerations When Purchasing D2 Metal

1. Understand the Material: D2 steel is a high-carbon, high-chromium tool steel known for its hardness and wear resistance. It’s crucial to understand these properties to ensure it meets your specific needs.

2. Supplier Reliability: Choose suppliers with a strong reputation and proven track record in providing high-quality D2 metal. Check reviews, ask for certifications, and possibly conduct audits.

3. Quality Assurance: Ensure the supplier provides thorough quality assurance measures. Look for ISO certifications and inquire about their quality control processes.

4. Technical Specifications: Verify the chemical composition and mechanical properties of the D2 metal. Ensure it matches the specifications required for your application.

5. Cost vs. Quality: While cost is a critical factor, don’t compromise on quality. Cheap D2 steel may lack the necessary durability and performance, leading to higher costs in the long run.

6. Sample Testing: Request samples for testing before placing large orders. This helps in verifying the material’s quality and suitability for your needs.

7. Lead Times and Supply Chain: Confirm lead times and ensure the supplier has a reliable supply chain. Delays can impact your production schedule.

8. Customization Options: Check if the supplier offers customization options like specific dimensions, heat treatments, or surface finishes to meet your precise requirements.

9. Post-Purchase Support: Evaluate the supplier’s customer service and post-purchase support. Reliable after-sales service can be crucial for addressing any issues that arise.

10. Sustainability and Compliance: Ensure the supplier complies with environmental regulations and sustainability practices. Ethical sourcing is increasingly important in today’s market.

11. Payment Terms: Negotiate favorable payment terms to manage cash flow effectively. Be clear on terms like delivery schedules, payment timelines, and penalties for delays.

By considering these factors, you can make informed decisions when procuring D2 metal, ensuring you get high-quality material that meets your requirements and supports your project’s success.

FAQs on Sourcing and Manufacturing from d2 metal in China

FAQs on Sourcing and Manufacturing from D2 Metal in China

1. What is D2 Metal?

– D2 steel is a high-carbon, high-chromium tool steel known for its excellent hardness and wear resistance. It’s commonly used for cutting tools, dies, and punches.

2. Why source D2 metal from China?

– China offers competitive pricing, a wide range of suppliers, and significant manufacturing capabilities. This makes it cost-effective and efficient for high-volume production.

3. How to find reliable D2 metal suppliers in China?

– Use verified online platforms like Alibaba, Made-in-China, or Global Sources. Attend trade shows, seek recommendations, and perform due diligence by checking certifications and customer reviews.

4. What are the quality standards for D2 metal in China?

– Ensure suppliers adhere to international standards such as ASTM A681 or DIN 1.2379. Request mill test certificates (MTC) to verify chemical composition and mechanical properties.

5. What is the typical lead time for D2 metal production in China?

– Lead times vary but generally range from 4 to 8 weeks, depending on order size and complexity. Custom requirements may extend this period.

6. How to ensure the quality of D2 metal products?

– Conduct factory audits, request samples, and use third-party inspection services like SGS or BV. Establish clear quality control processes and specifications.

7. What are the shipping options and costs from China?

– Shipping options include sea freight, air freight, and express couriers. Costs depend on the shipment size, weight, and delivery time. Incoterms like FOB, CIF, or DDP determine additional charges.

8. Are there any import duties or tariffs?

– Import duties and tariffs depend on the destination country’s regulations. Check with local customs authorities for accurate information.

9. What payment terms are commonly used?

– Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and escrow services. Negotiating favorable terms can mitigate risks.

10. How to handle communication and potential language barriers?

– Use clear, concise communication. Many Chinese suppliers employ English-speaking staff. Utilize translation services if necessary and maintain regular contact via email or messaging apps.

For further assistance, consider consulting sourcing agents or professional advisory services familiar with the Chinese manufacturing landscape.