Reliable Sheet Metal Factory Design: Partnering with SourcifyChina for Excellence

In today’s competitive market, ensuring the quality and precision of manufacturing processes is pivotal. SourcifyChina stands as a reputable partner in designing sheet metal factories, offering unparalleled expertise and reliability to meet your production needs efficiently.

Choosing SourcifyChina Factory for sheet metal design purchases offers numerous advantages. Their advanced technology ensures precision and high-quality products. Clients benefit from cost-effective solutions, thanks to efficient production methods and competitive pricing.

SourcifyChina Factory’s extensive experience in sheet metal fabrication means they understand diverse customer needs. They provide tailored solutions, ensuring each project meets specific requirements. This customization enhances client satisfaction and fosters long-term partnerships.

Additionally, SourcifyChina Factory emphasizes stringent quality control measures. They implement thorough inspections and use top-grade materials, guaranteeing reliable and durable products. This commitment to excellence builds trust and credibility among buyers.

Moreover, their robust customer support system ensures smooth communication and prompt resolution of issues. Clients enjoy a seamless purchasing experience, supported by a responsive and knowledgeable team.

In summary, SourcifyChina Factory is an ideal choice for sheet metal design purchasing due to their advanced technology, tailored solutions, stringent quality control, and exceptional customer support. These attributes make them a reliable partner for buyers seeking high-quality, cost-effective products from China.

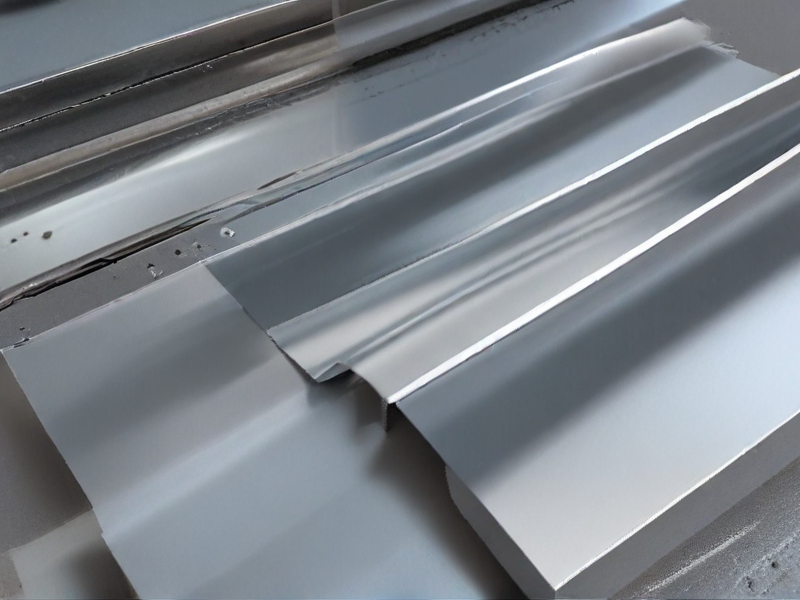

Designing with sheet metal offers versatility, enabling the creation of diverse structures and shapes. Key techniques include bending, welding, and cutting, allowing for functional and aesthetic results in various applications.

– Bending: Using brake presses or roll forming machines to create angles or curves.

– Cutting: Laser cutting, water jet cutting, or shearing for precise shapes.

– Welding: Joining metal pieces together using TIG, MIG, or spot welding.

– Stamping: Mass-producing with consistent accuracy using dies for shapes and forms.

– Forming: Creating three-dimensional shapes from flat sheets.

– Punching: Making holes or shapes using punching machines.

– Deburring: Smoothing rough edges after cutting or punching.

– Surface Finishing: Adding coatings or treatments for corrosion resistance and aesthetics.

– Prototyping: Creating models to test and refine designs before mass production.

– CNC Machining: Using computerized controls for precision and repeatability in complex designs.

By utilizing these methods and options, designers can harness sheet metal’s flexibility and durability for innovative projects across industries.

Designing with sheet metal is integral to various industries due to its versatility and strength. It is used for creating durable, lightweight, and cost-effective components in multiple sectors.

– Automotive Industry: Produces car bodies, chassis, and other crucial components.

– Aerospace Engineering: Creates aircraft parts, including wings and fuselage sections.

– Electronic Enclosures: Ideal for fabricating protective cases for electronic devices.

– Construction Materials: Utilized in roofing, siding, and structural elements.

– HVAC Systems: Essential for making ducts, vents, and other air management components.

– Medical Devices: Constructing housings for medical equipment and surgical instruments.

– Home Appliances: Manufacturing parts for refrigerators, ovens, and washing machines.

– Furniture Design: Crafting ergonomic and aesthetic metal furniture frames.

– Agricultural Equipment: Building strong yet lightweight machinery parts.

– Signage: Producing durable and weather-resistant signs and displays.

– Renewable Energy: Fabricating components for wind turbines and solar panels.

– Marine Industry: Used in the construction of ships and boat parts.

– Material Handling: Creating storage racks, conveyor belts, and other handling equipment.

– Packaging: Manufacturing specialized metal containers for various industries.

– Decorative Elements: Designing intricate art pieces and architectural details.

– Tool Boxes and Storage: Making robust storage solutions for various tools.

– Military and Defense: Constructing armored vehicles and secure facilities.

– Lighting Fixtures: Producing durable and effective lighting enclosures and components.

– Food Processing: Designing hygienic and corrosion-resistant equipment.

Sheet metal’s adaptability makes it valuable across industries, providing efficient and innovative solutions for modern manufacturing requirements.

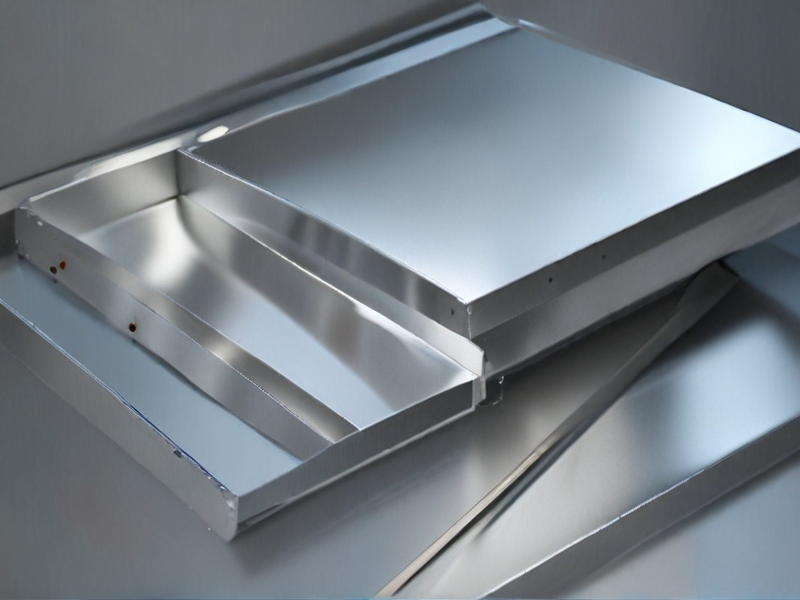

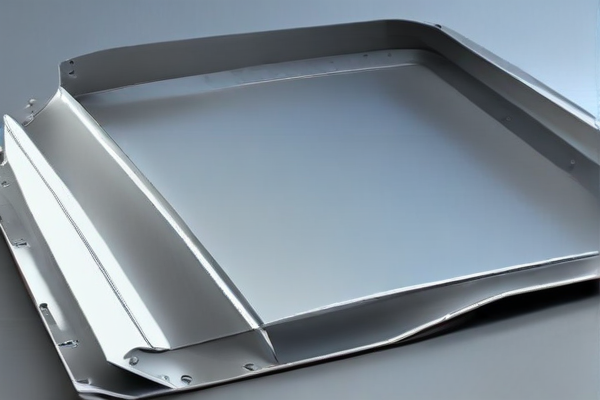

“SourcifyChina” specializes in creating innovative designs utilizing sheet metal. Their expertise lies in transforming flat sheets of metal into practical, stylish products through processes like cutting, bending, and welding. The precision in these methods ensures the creation of durable and functional components.

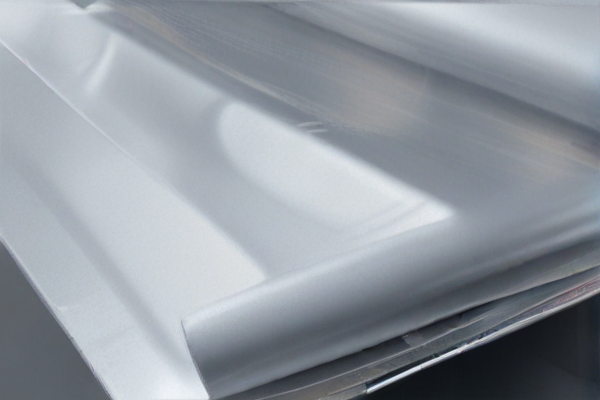

The company prides itself on using high-quality metals such as stainless steel, aluminum, and galvanized steel. These materials offer robustness, corrosion resistance, and malleability, making them ideal for a variety of applications. The choice of material impacts both the durability and aesthetic appeal of the finished product.

In the design phase, SourcifyChina employs advanced software tools for accurate modeling and simulation. This technology allows for meticulous planning, identifying potential issues before production. The software also aids in optimizing material use, reducing waste, and ensuring cost-effectiveness.

SourcifyChina’s focus on sustainability drives their commitment to efficient material use and waste reduction. They recycle scrap metal and adhere to environmentally conscious practices throughout their production processes. This dedication to green manufacturing helps minimize their carbon footprint.

They offer custom designs tailored to meet specific client requirements. Their skilled designers collaborate closely with clients, ensuring the final product aligns with the vision and functional needs. Their versatility in sheet metal design makes them a preferred choice across various industries.

In conclusion, SourcifyChina’s innovative approach to sheet metal design sets them apart in the industry. By leveraging high-quality materials, advanced technology, and a commitment to sustainability, they create solutions that are both functional and visually appealing. Their ability to customize projects to meet individual client needs further underscores their reputation as a leader in sheet metal design.

SourcifyChina specializes in designing with sheet metal, combining precision and innovation. The company integrates advanced technology to ensure the highest quality in its products. Their design team meticulously plans each project, ensuring optimal functionality and aesthetics.

Quality control is pivotal at SourcifyChina. Each step, from initial design to final production, undergoes rigorous inspections. This multi-tiered scrutiny guarantees that every piece meets stringent industrial standards and customer expectations.

The manufacturing process involves state-of-the-art machinery, enhancing precision, and reducing waste. SourcifyChina leverages automation and skilled craftsmanship to maintain consistent product quality, essential in the competitive market.

To ensure top-notch quality, SourcifyChina implements stringent testing protocols. These tests, including stress, durability, and accuracy checks, ensure that each product can withstand real-world applications. Only products that pass these rigorous tests are delivered to customers.

SourcifyChina values customer feedback and continuous improvement. Post-production, products are carefully reviewed for any potential defects or improvements. This attention to detail not only ensures high-quality products but also fosters trust and long-term relationships with clients.

In conclusion, SourcifyChina’s commitment to quality control in designing with sheet metal is evident in every aspect of their manufacturing process. Their rigorous quality checks, advanced technology, and dedication to continuous improvement ensure that clients receive the best possible products. This meticulous approach not only upholds industry standards but also sets SourcifyChina apart as a leader in sheet metal design and manufacturing.

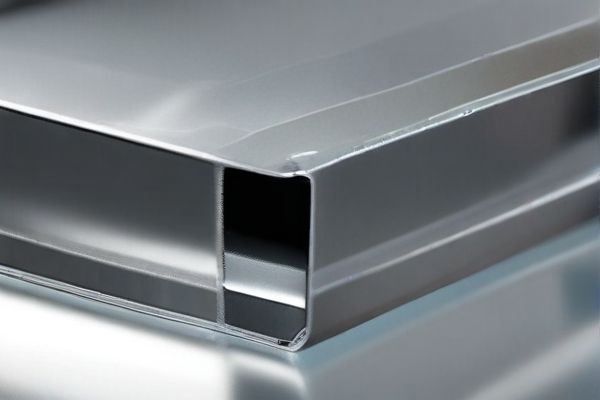

SourcifyChina brings extensive expertise in designing with sheet metal, crafting intricate components with precision and efficiency. Utilizing advanced CAD software, their designs ensure optimal material usage, reducing waste while maintaining structural integrity.

Their proficiency extends to a variety of metals, including aluminum, steel, and stainless steel. This versatility allows them to cater to diverse industries, from automotive to electronics, delivering components that meet stringent requirements and standards.

SourcifyChina’s state-of-the-art machinery, including CNC laser cutters and press brakes, ensures consistently high-quality outputs. By integrating automated processes, they achieve remarkable accuracy and repeatability in large-scale production runs.

Beyond manufacturing, SourcifyChina offers comprehensive support in prototype development and testing. Their iterative approach guarantees that every design is thoroughly vetted before mass production, minimizing potential issues and ensuring customer satisfaction.

The company’s commitment to continuous improvement and innovation keeps them at the forefront of sheet metal design and fabrication. By leveraging the latest technologies and industry best practices, they provide cost-effective, reliable solutions tailored to each client’s unique needs.

Additionally, SourcifyChina prioritizes sustainability throughout their operations. They adopt eco-friendly practices, such as recycling scrap metal and employing energy-efficient technologies, to minimize their environmental impact.

Finally, their experienced team of engineers and designers collaborates closely with clients, ensuring clear communication and seamless project execution from concept to final product. This client-centric approach is integral to their success and reputation for delivering exceptional sheet metal designs.

SourcifyChina demonstrates unparalleled capabilities in sheet metal design, from conceptualization to production. Their technical prowess, coupled with a commitment to quality and customer satisfaction, makes them a trusted partner for any business seeking high-performance sheet metal components.

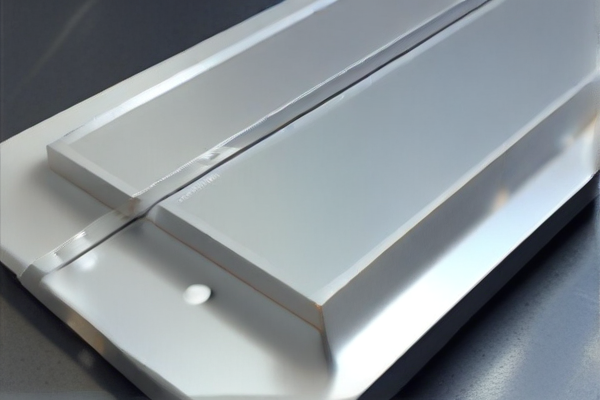

Designing with sheet metal offers numerous advantages, making it a preferred choice in various industries. Its versatility, cost-effectiveness, and durability make it ideal for diverse applications.

– Versatility: Sheet metal can be easily molded into various shapes, allowing for complex designs.

– Cost-Effective: It is relatively inexpensive and available in abundance, reducing material costs.

– Strength and Durability: Offers high strength-to-weight ratio, ensuring robust and long-lasting structures.

– Ease of Fabrication: Techniques such as cutting, bending, and welding are straightforward.

– Lightweight: Suitable for industries where weight is a critical factor, such as automotive and aerospace.

– Recyclability: Sheet metal is recyclable, contributing to environmental sustainability.

– Consistency: High precision and consistency are achievable, essential for mass production.

– Corrosion Resistance: Certain types of sheet metal, like stainless steel, offer excellent corrosion resistance.

– Thermal Conductivity: Good for applications requiring heat dissipation, such as heat sinks.

– Aesthetic Flexibility: Can be finished in various ways, including painting, plating, and anodizing, for enhanced appearance.

These benefits demonstrate why sheet metal design remains a cornerstone in modern engineering and manufacturing.

Designing with sheet metal offers numerous advantages such as durability, lightweight properties, and cost-effectiveness, making it ideal for a variety of industrial applications.

– Material Strength and Durability: Sheet metal is strong and resistant to wear and tear, offering long-lasting performance.

– Lightweight: Despite its durability, sheet metal is lightweight, reducing overall project weight and transportation costs.

– Cost-Effective: It offers an economical solution, balancing quality and expenses.

– Flexibility in Design: Sheet metal can be easily cut, bent, and shaped into complex geometries.

– High-Precision: Modern techniques like CNC machining ensure high-precision results.

– Ease of Joining: Various methods such as welding, riveting, and bolting can be used for assembly.

– Surface Treatment: Options like powder coating and galvanization enhance durability and aesthetics.

– Recyclability: Sheet metal is highly recyclable, making it an environmentally friendly option.

– Thermal Conductivity: Its good thermal conductivity makes it useful for heat dissipation purposes.

– Corrosion Resistance: Certain types of sheet metal, like stainless steel, offer excellent corrosion resistance.

SourcifyChina excels in designing custom products and projects using sheet metal. Their expertise allows for the creation of intricate and durable metal components tailored to client specifications. This capability ensures high-quality, bespoke solutions for diverse needs.

Utilizing advanced technology, SourcifyChina’s design process focuses on precision. They employ computer-aided design (CAD) software and cutting-edge machinery to fabricate detailed and exact metal sheets. This approach guarantees that every project meets exacting standards and performs reliably over time.

One key strength is their ability to handle a variety of metals, including aluminum, stainless steel, and copper. Each material is meticulously chosen based on project requirements, ensuring optimal performance, durability, and cost-efficiency. This versatility helps cater to a wide array of industries.

Additionally, SourcifyChina emphasizes sustainability in their design practices. They aim to minimize waste and utilize eco-friendly materials whenever possible. This commitment not only benefits the environment but also aligns with modern industry trends toward greener manufacturing.

Quality control is a paramount focus for SourcifyChina. Every sheet metal product undergoes rigorous testing and inspection before delivery. This commitment to quality ensures that clients receive products that meet or exceed their expectations, enhancing long-term satisfaction and reliability.

Customer collaboration is another cornerstone of SourcifyChina’s methodology. They work closely with clients through every stage of the design and production process, from initial concept to final product. This partnership ensures that the end results perfectly match the client’s vision and functional needs.

In conclusion, SourcifyChina’s expertise in sheet metal design enables them to create custom products and projects that stand out for their precision, quality, and sustainability. Their commitment to client collaboration and rigorous quality control ensures exceptional results and high client satisfaction.

SourcifyChina, a distinguished name in the engineering and manufacturing sector, excels in designing with sheet metal, delivering top-notch solutions that meet diverse client needs. Renowned for its precision and innovation, the company specializes in transforming raw sheet metal into high-performance components and products across various industries, including automotive, electronics, and heavy machinery. By leveraging advanced CAD software and state-of-the-art machinery, SourcifyChina ensures that every design is meticulously crafted to achieve optimal functionality and durability. The company prides itself on its ability to provide end-to-end services, from initial concept and prototyping to full-scale production, all while maintaining stringent quality standards. Their team of skilled engineers and designers collaborates closely with clients, ensuring that each project aligns seamlessly with specific requirements and industry standards. Sustainable practices are also at the core of their operations, as they continually strive to minimize waste and maximize efficiency, reflecting their commitment to environmental responsibility. In essence, SourcifyChina stands as a beacon of excellence in sheet metal design and manufacturing, consistently delivering innovative and reliable solutions to its global clientele.

Designing with sheet metal holds critical importance in the aerospace, defense, and marine industries due to its balance between strength, weight, and versatility. In aerospace, sheet metal components are utilized extensively in the construction of aircraft elements such as fuselage skins, wing structures, and internal brackets. The ability to form complex shapes while maintaining structural integrity is essential for both performance and safety. Advanced alloys and precision fabrication techniques allow engineers to optimize aerodynamics, reduce fuel consumption, and meet stringent regulatory requirements. Moreover, the adaptability of sheet metal design supports rapid prototyping and iterative development, which is crucial for innovation in aerospace technologies.

In the defense and marine sectors, sheet metal’s resilience and adaptability are invaluable for crafting a wide array of components ranging from armor plating in military vehicles to structural parts of naval vessels. The materials used in these applications are often chosen for their durability and resistance to harsh environments, including extreme temperatures, corrosive conditions, and mechanical wear. The design flexibility offered by sheet metal allows for the integration of complex geometries and reinforced structures, which are imperative for the protection and longevity of defense and marine equipment. Additionally, the ability to produce custom components quickly and cost-effectively ensures that these industries can adapt to evolving technological and tactical needs, maintaining readiness and operational efficiency.

Designing with sheet metal is integral to the automotive industry due to its versatility, strength, and cost-effectiveness. Automakers extensively employ sheet metal in the creation of car body panels, chassis, and various structural components. The ease of forming sheet metal into complex shapes allows for intricate designs that meet aesthetic and aerodynamic requirements while maintaining vehicle safety standards. Moreover, advancements in technologies such as hydroforming and laser cutting have further enhanced the precision and efficiency of sheet metal fabrication, enabling manufacturers to produce lightweight yet sturdy components that contribute to improved fuel efficiency and performance. The recyclability of sheet metal also aligns with the industry’s growing focus on sustainability and environmental conservation.

In the electronics sector, sheet metal’s adaptability is equally significant. It is commonly used for creating enclosures, chassis, and brackets for a wide range of devices, from consumer electronics like computers and smartphones to industrial machinery and telecommunications equipment. The precision that sheet metal fabrication offers ensures the production of parts that meet tight tolerances, essential for the assembly of intricate electronic components. Techniques such as stamping, bending, and punching are essential for producing custom parts that enhance functionality and durability. Furthermore, the ability to add protective coatings to sheet metal helps in shielding electronic components from electromagnetic interference (EMI) and physical damage, thus extending their operational lifespan. Consequently, sheet metal design is crucial for both optimizing product performance and ensuring the reliability of electronic devices.

Designing with sheet metal has revolutionized the construction industry, bringing a blend of durability, adaptability, and aesthetics to modern architectural projects. In construction, sheet metal is often employed for roofing, facade cladding, and structural support due to its lightweight yet sturdy nature. The material allows architects to create sleek, contemporary designs while ensuring long-lasting performance against environmental stressors. Moreover, advanced fabrication techniques, such as laser cutting and CNC bending, enable precise, custom designs that can be efficiently mass-produced, significantly reducing construction time and costs. The versatility of sheet metal also makes it ideal for creating complex geometries and seamless integrations, further enhancing the architectural possibilities and the overall resilience of buildings.

In the realm of energy applications, sheet metal plays a crucial role in the manufacturing and efficiency of various systems. It is extensively used in the production of wind turbines, solar panels, and HVAC systems, where its properties contribute to optimized energy capture and thermal management. For instance, the aerodynamic design of sheet metal components in wind turbines allows for better airflow and higher energy conversion efficiency. Similarly, the reflective and absorptive characteristics of sheet metal are essential in solar panel fabrication, enhancing their ability to harness solar energy. In HVAC systems, sheet metal ducts and enclosures not only ensure efficient air distribution but also contribute to thermal insulation and noise reduction. By leveraging the unique features of sheet metal, these energy applications maximize performance and sustainability, driving advancements in renewable energy and energy-efficient technologies.

The industrial equipment industry heavily leverages the practice of designing with sheet metal due to its versatility, durability, and cost-effectiveness. Sheet metal is used in creating robust structural components, enclosure systems, brackets, and complex shapes that require precise tolerances and high strength-to-weight ratios. Industries such as automotive, aerospace, HVAC, and heavy machinery take advantage of sheet metal for crafting components like chassis, panels, ductwork, and protective covers. Its ability to be easily cut, bent, and welded enables the design of intricate parts that can be mass-produced with consistent quality. Moreover, the wide range of available metals, including steel, aluminum, and copper, each offering unique properties, allows designers to tailor material choices to specific functional requirements like corrosion resistance, thermal conductivity, or weight considerations.

Advancements in Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies have further enhanced the application of sheet metal in the industrial equipment sector. With CAD software, engineers can simulate and optimize the design for manufacturability, ensuring that components can be easily created using processes like laser cutting, punching, and CNC bending. Additionally, these digital tools allow for the efficient nesting of parts on large sheets, minimizing material waste and reducing costs. CAM technologies streamline production workflows, ensuring that the transition from virtual design to physical product is precise and efficient. This integration of design and manufacturing technologies not only accelerates time-to-market but also facilitates the customization of industrial equipment to meet specific client needs. As a result, designing with sheet metal remains a pivotal practice in the ongoing innovation and efficiency of the industrial equipment industry.

Designing with sheet metal in medical devices predominantly leverages the material’s versatility, strength, and malleability to create durable, sterile, and precise components essential for patient care and clinical environments. From enclosures for medical instruments like ECG machines to intricate components in surgical devices, sheet metal is invaluable. Its availability in various grades, including stainless steel and aluminum, ensures that it can meet rigorous hygiene standards while offering excellent resistance to corrosion and wear. The ability to be easily fabricated into complex shapes allows medical device designers to innovate ergonomic and functional designs that adhere to strict regulatory standards, facilitating better patient outcomes and ease of use by healthcare providers.

Moreover, the integration of sheet metal in the production of medical devices also enhances cost-efficiency and scalability. Techniques such as laser cutting, bending, and stamping enable the mass production of highly precise components with minimal material waste, which is crucial for both prototyping and full-scale manufacturing. Additionally, the ease of modifying and customizing sheet metal parts means that medical devices can rapidly evolve to incorporate the latest technological advancements and design improvements. This adaptability is key in a field where innovation can significantly impact patient health and treatment efficacy. Therefore, sheet metal’s role extends beyond just structural applications; it is fundamental in advancing the capability and reliability of contemporary medical devices.

Designing with sheet metal plays a critical role in modern machining and manufacturing applications due to its unparalleled versatility, cost-effectiveness, and adaptability. The process begins with selecting the appropriate type and thickness of metal, such as aluminum, steel, or copper, based on the product’s requirements. Sheet metal designs leverage computer-aided design (CAD) software, which enables engineers to create meticulously detailed models tailored to specific functions while minimizing material waste. This precision is vital for industries like automotive, aerospace, and consumer electronics, where structural integrity and performance are imperative. Techniques such as laser cutting, stamping, and bending are employed to transform flat sheets into complex shapes, ensuring high accuracy and repeatability across production runs.

In manufacturing, sheet metal design contributes significantly to rapid prototyping and scalability. By simplifying assembly processes and reducing the need for additional fasteners or welds, sheet metal components facilitate faster production times and lower costs. This method also makes it easier to produce lightweight yet durable structures, fostering innovation in product development. Moreover, the recyclability of sheet metal aligns with sustainable manufacturing practices, making it an environmentally friendly option. The integration of advanced technologies, like automated machinery and CNC bending, further enhances efficiency and consistency, enabling manufacturers to meet stringent quality standards while accommodating customizations and intricate designs. Overall, designing with sheet metal not only optimizes the production process but also drives advancements in various high-tech industries.

Sure! Here is a list of FAQs for manufacturing “designing with sheet metal quality work from SourcifyChina factory”:

Q1: What materials are available for sheet metal fabrication?

A1: We offer a variety of materials including stainless steel, aluminum, brass, copper, and galvanized steel. Our material options cater to different strength, conductivity, and corrosion resistance requirements.

Q2: What is the typical lead time for a sheet metal project?

A2: The lead time can vary based on the complexity and quantity of the order, but standard lead times range from 2 to 4 weeks. We also offer expedited services for urgent projects.

Q3: Can you assist with the design and prototyping stages?

A3: Yes, we offer comprehensive design and prototyping services. Our experienced engineers can work with your concepts to create detailed designs and prototypes for validation before full production.

Q4: What tolerance levels can you achieve in sheet metal fabrication?

A4: We can achieve tight tolerances based on your project requirements. Typically, we maintain tolerances within ±0.005 inches, but this can be adjusted according to specific needs.

Q5: Do you provide finishing services like painting or powder coating?

A5: Absolutely! We offer a wide range of finishing options including powder coating, anodizing, electroplating, and painting to provide both aesthetic appeal and additional protection to your products.

Q6: What quality control measures are in place?

A6: Our quality control process includes rigorous inspections at multiple stages—material selection, fabrication, and finishing. We utilize advanced measurement tools to ensure every product meets the specified standards.

Q7: Are there minimum order quantities (MOQs) for sheet metal fabrication?

A7: We cater to both small and large orders. MOQs depend on the complexity and customization of the project, but we are flexible and aim to accommodate your manufacturing needs.

Q8: What types of industries do you serve?

A8: We serve a wide range of industries including automotive, aerospace, electronics, consumer goods, and medical devices. Our versatile capabilities allow us to meet the varied demands of different sectors.

Q9: How do you handle shipping and logistics for international clients?

A9: We offer comprehensive shipping and logistics services. We manage everything from packaging to customs documentation to ensure a smooth delivery process to any location worldwide.

Designing with sheet metal manufacturing, particularly when partnering with a factory like SourcifyChina, requires a balance of creativity and practicality to ensure cost-efficiency, manufacturability, and quality. Here are some essential tips to guide your process:

1. Material Selection: Choose the appropriate type of sheet metal (e.g., aluminum, steel) based on your product’s requirements for strength, flexibility, corrosion resistance, and cost.

2. Thickness Consideration: Optimize the thickness of the sheet metal to balance durability and weight. Thicker metal increases strength but also cost and weight. Communicate with SourcifyChina to understand their standard thickness ranges and availability.

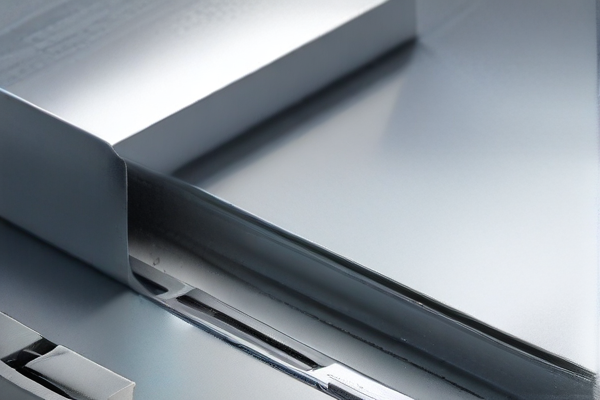

3. Bend Allowances: Factor in bend allowances in your design to account for material stretching. Sharp corners can lead to fractures; instead, use larger bend radii relative to the material thickness.

4. Tolerances and Clearances: Design with realistic tolerances in mind to ensure parts fit together properly. Overly tight tolerances can increase costs and manufacturing complexity.

5. Standardize Features: Use standardized hole sizes and patterns to take advantage of existing tooling at SourcifyChina. This can reduce costs and lead times.

6. Minimize Complexities: Simple designs are generally more cost-effective. Avoid overly complex shapes and designs that require multiple processes or specialty tooling.

7. Draft Angle Integration: When forming parts, integrate draft angles to facilitate easier removal from molds and dies, if applicable.

8. Surface Treatments: Specify surface treatments (e.g., anodizing, powder coating) early in the design phase to prevent corrosion and improve aesthetics, keeping in mind the additional production time and cost.

9. Communication: Maintain open communication with the engineering team at SourcifyChina. Their feedback can be invaluable for refining your design to better fit their manufacturing capabilities and limitations.

10. Prototype Testing: Create prototypes to test the design before full-scale production. This can reveal potential issues early and allow for adjustments without significant financial implications.

By adhering to these guidelines, you can achieve efficient, cost-effective, and high-quality sheet metal designs that leverage the capabilities of SourcifyChina’s manufacturing processes.

Sure! Here is a list of frequently asked questions (FAQs) with answers for sourcing “designing with sheet metal” from SourcifyChina factory:

Q1: What types of sheet metal materials does SourcifyChina work with?

A1: SourcifyChina works with a variety of materials including stainless steel, aluminum, galvanized steel, and copper. We can cater to specific material requirements based on the project needs.

Q2: What thicknesses of sheet metal can be processed?

A2: SourcifyChina can handle sheet metal thicknesses ranging from 0.5mm to 20mm, depending on the material type and specific project requirements.

Q3: What design formats does SourcifyChina accept?

A3: We accept multiple CAD file formats including DXF, DWG, and STEP. If you have other format preferences, let us know, and we can accommodate or convert your design files.

Q4: Can SourcifyChina help with the design process?

A4: Yes, our team offers design assistance to ensure manufacturability and cost efficiency. We provide DFM (Design for Manufacturability) reviews to help optimize your designs.

Q5: What finishing options are available?

A5: SourcifyChina provides various finishing options such as powder coating, anodizing, electroplating, and more. We can meet specific aesthetic and functional requirements.

Q6: What is the typical lead time for sheet metal projects?

A6: Lead times vary depending on project complexity and volume. Typically, our lead times range from 2 to 4 weeks after design approval. Expedited services are available upon request.

Q7: Do you provide prototypes?

A7: Yes, we offer prototyping services to help validate designs before full-scale production. This allows for any necessary adjustments to be made early in the process.

Q8: How does SourcifyChina ensure quality control?

A8: Quality is ensured through rigorous QC procedures, including material inspections, in-process checks, and final product evaluations. We adhere to international quality standards.

Q9: Can you handle high-volume production runs?

A9: Absolutely. SourcifyChina is equipped to handle both low and high-volume production runs, ensuring scalability to meet your needs.

Q10: How do I get a quote for my sheet metal project?

Sourcing “designing with sheet metal” from SourcifyChina factory requires meticulous planning and communication to ensure quality and efficiency. Here are some tips:

1. Research and Vetting:

– Company Background: Investigate SourcifyChina’s history, reputation, and customer reviews.

– Certifications: Check for relevant certifications in quality management (ISO 9001) and environmental standards (ISO 14001).

2. Detailed Specifications:

– Design Files: Provide detailed CAD drawings and 3D models.

– Materials: Specify the type, thickness, and grade of metal.

– Finishes and Treatments: Detail requirements for surface finishes, coatings, and treatments (e.g., anodizing, powder coating).

3. Prototyping:

– Initial Samples: Request prototypes to evaluate the quality before mass production.

– Feedback Loop: Provide feedback and ask for modifications if necessary.

4. Lead Times and Production Capacity:

– Production Schedules: Understand their production timelines and capacity to ensure they can meet your deadlines.

– Scalability: Assess if the factory can scale production based on your future needs.

5. Quality Assurance:

– Inspection Processes: Ensure they have robust quality control procedures at various stages of production.

– Third-Party Inspections: Consider hiring independent quality inspectors.

6. Communication:

– Clear Instructions: Provide concise and clear instructions to avoid misunderstandings.

– Regular Updates: Establish regular check-ins for progress updates.

7. Legal and Logistics:

– Contracts: Have a solid contract detailing terms of production, quality standards, delivery timelines, and penalties for non-compliance.

– Shipping and Customs: Plan for shipping logistics and understand customs regulations in your country.

8. Cost Considerations:

– Quotes: Get detailed quotes, including material costs, manufacturing fees, and shipping.

– Negotiation: Negotiate terms but ensure cost savings do not compromise quality.

By adhering to these tips, you can effectively source high-quality sheet metal designs from SourcifyChina, ensuring your projects meet the desired standards and timelines.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.