Technology and Applications of digital engraving machine

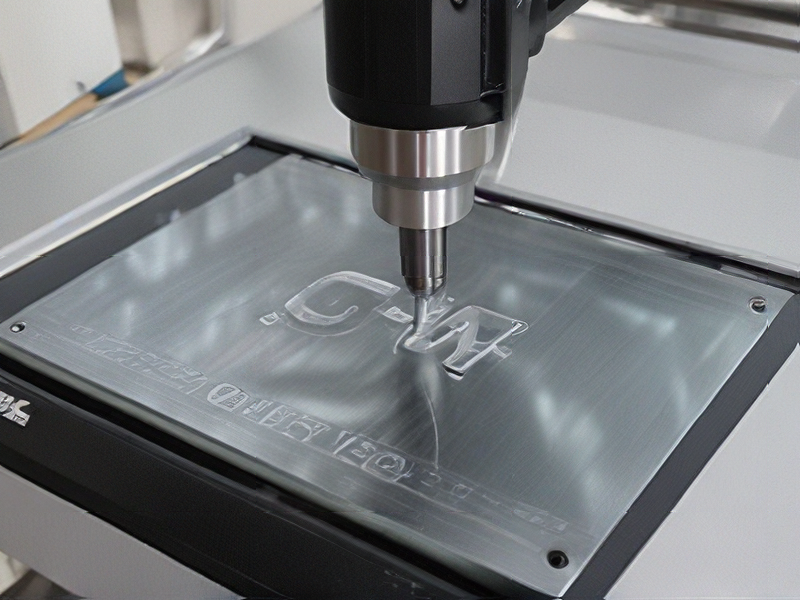

Digital engraving machines utilize advanced technologies, such as laser, rotary, and CNC (Computer Numerical Control) processes, to etch or cut designs into various materials including wood, metal, glass, and plastic. These machines are equipped with precision motors and software that control the engraving process, allowing for detailed and intricate designs with minimal human intervention.

One of the most significant applications of digital engraving machines is in personalized products. They are widely used for creating customized items like trophies, awards, jewelry, and gifts. Businesses often employ these machines for branding purposes, engraving logos or product information onto promotional items.

In the industrial sector, digital engraving machines enhance manufacturing processes by providing quality markings for components, ensuring traceability, and improving product information visibility. The automotive and aerospace industries utilize these machines for marking serial numbers and safety information on critical parts.

Additionally, in the art and design fields, digital engraving machines empower artists and designers to produce unique works by allowing for precise reproduction of complex patterns and textures. The integration of CAD (Computer-Aided Design) software with engraving machines streamlines the design-to-production workflow, enabling rapid prototyping and iterative design processes.

Digital engraving technology is also increasingly being adopted in educational settings, providing students with hands-on experience in design and manufacturing processes. The versatility and efficiency of these machines make them essential tools across various industries, contributing to both creativity and productivity in the modern manufacturing landscape.

Quality Testing Methods for digital engraving machine and how to control quality

Quality testing methods for digital engraving machines are essential to ensure precision, consistency, and durability of the engraved products. Here’s a concise overview of effective methods and quality control measures:

1. Calibration Checks

Regular calibration of the engraving machine is crucial. Use calibration tools to verify that the machine operates within specified tolerances. This involves checking the alignment, speed, depth, and precision of engravings.

2. Material Testing

Evaluate the engraving results on different materials (wood, plastic, metal). Conduct stress tests to assess the machine’s performance consistency across various substrates. This helps determine optimal settings for specific materials.

3. Visual Inspection

Conduct a thorough visual inspection of engraved samples for uniformity, clarity, and accuracy. Look for issues like missing details, uneven depths, or surface flaws. Use magnification tools if needed to identify minute discrepancies.

4. Dimensional Accuracy Checks

Utilize calipers and gauges to measure engraved dimensions. Compare measurements against specifications to ensure adherence to design requirements, particularly crucial for intricate designs.

5. Production Samples

Implement a sampling plan during production runs. Review a set number of samples from each batch to ensure consistent quality. Establish limits for acceptable defects to halt production if standards are not met.

6. User Feedback

Collect feedback from end-users regarding the durability and appearance of engraved products. This provides insights into potential issues not evident during the manufacturing process.

7. Data Logging and Analysis

Implement data logging to track machine performance and engraving quality. Analyze this data to identify trends, pinpoint recurring issues, and optimize processes.

By implementing these methods, one can maintain high standards of quality in digital engraving processes while ensuring customer satisfaction.

Tips for Procurement and Considerations when Purchasing from digital engraving machine

When procuring a digital engraving machine, consider the following tips to ensure a successful purchase:

1. Define Your Requirements: Assess your specific needs, including the types of materials you intend to engrave (e.g., wood, metal, glass), the engraving depth, and the size of the objects you’ll work with. This helps narrow down machine specifications.

2. Research Brands and Models: Look for reputable manufacturers and read customer reviews. Popular brands often have better support and reliability. Compare different models to find the best fit for your needs.

3. Evaluate Technology Types: Consider whether you need a CO2 laser, fiber laser, or rotary engraver. Each type has distinct advantages depending on the materials and engravings you plan to produce.

4. Check Software Compatibility: Ensure the machine is compatible with design software you intend to use. User-friendly software can significantly enhance productivity.

5. Assess Speed and Efficiency: Look for machines that offer quick engraving speeds, but also ensure they maintain quality. Balance speed with the resolution that meets your standards.

6. Consider Maintenance and Support: Investigate warranty terms, customer service, and the availability of replacement parts. A model with good support can save you time and costs in the long run.

7. Budget for Additional Costs: Don’t forget to account for ongoing costs like maintenance, replacement parts, and materials for engraving.

8. Training and Resources: Some models may require specific training. Ensure you or your team are prepared for operational processes.

9. Visit Demos or Trade Shows: If possible, see the machine in action. This can help you gauge its performance and usability.

10. Read Terms and Conditions: Carefully review purchase agreements, including return policies, to avoid unexpected issues.

By following these points, you can make an informed decision when purchasing a digital engraving machine.

FAQs on Sourcing and Manufacturing from digital engraving machine in China

FAQs on Sourcing and Manufacturing with Digital Engraving Machines in China

1. Why choose China for digital engraving machines?

China is a leading manufacturer, offering competitive prices, a wide range of products, and advanced technology. The country has established supply chains, making sourcing efficient.

2. What types of digital engraving machines are available?

You can find various types, including CO2 laser engravers, fiber laser engravers, CNC router engravers, and UV flatbed printers. Each type has its unique applications suited for materials like wood, glass, metal, and plastic.

3. How do I find reliable suppliers?

Utilize platforms like Alibaba, Made-in-China, or Global Sources. Verify suppliers through trade certifications, customer reviews, and factory audits. Visiting the manufacturer in person is also advisable for a thorough evaluation.

4. What is the MOQ (Minimum Order Quantity)?

MOQs can vary significantly among manufacturers. It’s essential to communicate your needs to suppliers, as some may accommodate smaller orders, especially for prototypes.

5. What are the payment terms?

Common payment methods include T/T (bank transfer), L/C (letter of credit), and PayPal. Ensure to negotiate favorable terms, especially for large orders.

6. How is quality assurance handled?

Request samples before placing a bulk order. Additionally, consider hiring a third-party inspection service to conduct quality checks during production and before shipping.

7. What about shipping and logistics?

Discuss shipping options with your supplier. They often have experience in international logistics. Factor in customs duties and potential delays in your timeline.

8. What support is available post-purchase?

Check for warranty terms and after-sales support, including spare parts availability, technical support, and maintenance services.

For further inquiries, consult with local sourcing agents or trade experts to navigate the process smoothly.