Choosing SourcifyChina Factory for purchasing a DIY milling machine from China ensures quality and reliability. The factory adheres to international standards, providing machines with precision engineering and durable components, meeting various buyer needs.

SourcifyChina Factory offers competitive pricing without compromising on quality. Their efficient manufacturing processes and strategic sourcing of raw materials contribute to cost savings, benefitting buyers with affordable yet high-quality products.

Additionally, the factory provides excellent customer service, from pre-purchase consultations to after-sales support. Their team of experts assists buyers in selecting the right milling machine, ensuring a smooth purchasing experience.

Moreover, SourcifyChina Factory emphasizes transparency and ethical practices. Buyers can trust that their machines are produced under fair labor conditions and environmentally responsible manufacturing processes.

In conclusion, choosing SourcifyChina Factory guarantees a combination of quality, affordability, superior customer service, and ethical considerations. Buyers investing in their DIY milling machines can expect unparalleled support and performance, making it a wise choice for both hobbyists and professionals.

DIY milling machines come in various types and options, allowing hobbyists and small workshops to customize them according to their needs and budget. These machines can range from simple, manual setups to more complex CNC (Computer Numerical Control) systems.

– Manual Milling Machines: Basic, cost-effective; ideal for beginners.

– CNC Milling Machines: Automated, precise; suitable for advanced users.

– Router-Based Milling Machines: Versatile; can be adapted for milling.

– 3D Printer Conversions: Dual-purpose; combines milling with 3D printing.

– DIY Kit Machines: Pre-packaged kits; easier assembly and customization.

– Repurposed Machines: Modified from old equipment; budget-friendly.

– Homemade Milling Machines: Built from scratch; highly customizable.

Options and considerations include:

– Material: Aluminum, steel, or wood frame.

– Spindle Power: Determines cutting capability.

– Axis Movement: Number of axes (typically 3 to 5).

– Software Compatibility: Open-source or proprietary CNC software.

– Build Size: Work area dimensions.

– Accuracy and Precision: Level of detail in milling.

– Cost: Budget constraints.

– Ease of Assembly: Pre-built vs. DIY assembly complexity.

– Upgradability: Potential for future enhancements.

Choosing the right DIY milling machine depends on the user’s specific needs, skills, and project requirements.

A DIY milling machine offers versatility for various applications in both home and professional settings, allowing hobbyists and engineers to execute precision tasks efficiently.

– Prototyping: Ideal for creating prototype parts for engineering projects.

– Custom Engineering: Fabricating custom parts that are not readily available.

– Jewelry Making: Crafting intricate designs with precision.

– Model Making: Building detailed scale models for architecture or hobbies.

– Maintenance and Repair: Reproducing or repairing worn-out machine parts.

– Woodworking: Shaping and detailing wooden components accurately.

– Metalworking: Machining metals for custom tools, parts, or art.

– Educational Projects: Teaching machining principles and practices.

– Engraving: Engraving text or designs onto various materials.

– PCB Fabrication: Milling custom circuit boards for electronics projects.

– 3D Sculpting: Creating three-dimensional objects from material blocks.

– Automotive Customization: Producing custom car parts or modifications.

– Furniture Making: Carving detailed woodwork for furniture pieces.

– Home Improvement: Crafting bespoke parts for household repairs or enhancements.

– Restoration Work: Reproducing antique mechanical parts with high accuracy.

– Musical Instruments: Shaping components for custom musical instruments.

– Art and Sculpture: Crafting detailed artwork from metal, wood, and other materials.

– RC Models: Producing precise parts for remote-controlled models.

– Aerospace Prototyping: Creating components for model aircraft or drones.

– Customization Projects: Tailoring parts for unique and personalized creations.

DIY milling machines unlock a world of crafting and machining possibilities, making them a valuable tool for both amateurs and professionals.

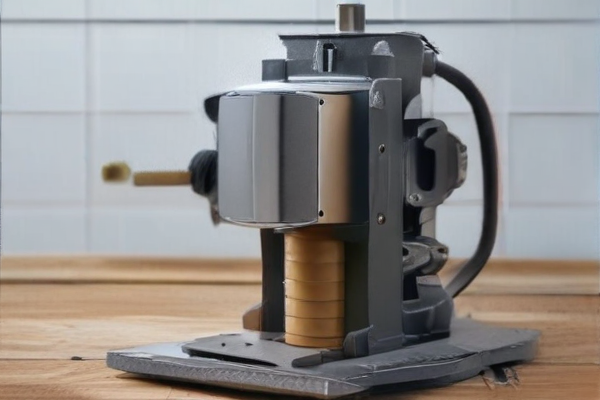

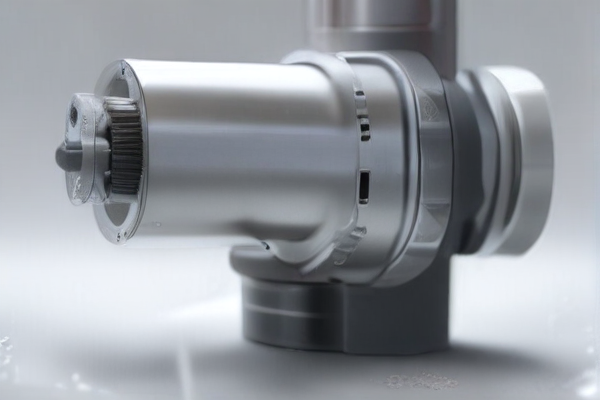

The SourcifyChina DIY milling machine is primarily constructed from high-quality aluminum. This material offers excellent durability while maintaining a lightweight structure, which is essential for precision tasks in milling projects.

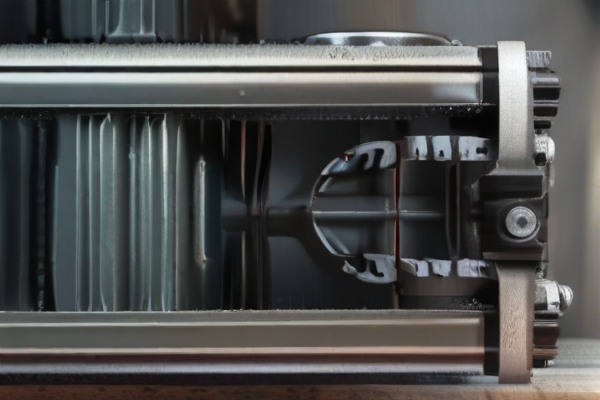

To further enhance stability and performance, the machine incorporates steel components. Steel adds the necessary rigidity to the milling process, reducing vibrations and ensuring smoother, more precise cuts on various materials such as wood, plastic, and metal.

The milling machine’s working bed is often made from a combination of aluminum and steel, allowing it to support heavy-duty operations. This blend ensures a strong foundation for any project, making it suitable for both hobbyists and professionals.

In addition to the metal components, various parts of the machine may use industrial-grade plastic, particularly in non-load-bearing areas. This choice of material helps reduce overall weight and cost without sacrificing reliability or functionality.

Overall, the choice of materials in the SourcifyChina DIY milling machine balances between cost efficiency, durability, and precision. This makes it a versatile tool suitable for a wide range of milling applications.

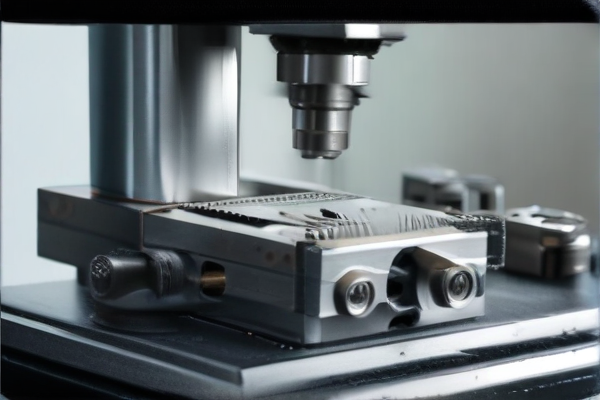

SourcifyChina implements a rigorous quality control process for its DIY milling machines. Their process begins with the selection of high-grade raw materials, ensuring the foundation is robust and reliable.

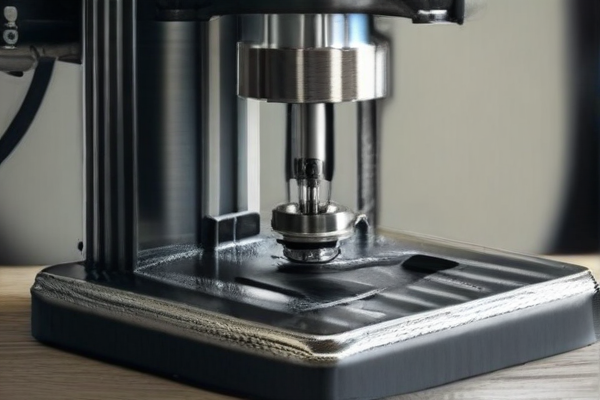

Precision is key in manufacturing. CNC machines are employed to produce parts within tight tolerances, minimizing errors. Each component undergoes several inspections to guarantee uniformity and precision.

Subsequent assembly stages are carried out by skilled technicians. Every assembled unit undergoes functional checks, calibration, and fine-tuning to meet predefined standards. This stage ensures machines operate seamlessly.

Finally, each milling machine undergoes thorough performance testing. Simulated real-life operations evaluate durability and functionality. Any unit not meeting the optimal thresholds is reworked or discarded, guaranteeing end-user satisfaction.

By implementing these stringent quality control measures, SourcifyChina delivers reliable and high-performance DIY milling machines to its customers, ensuring consistent manufacturing excellence and customer satisfaction.

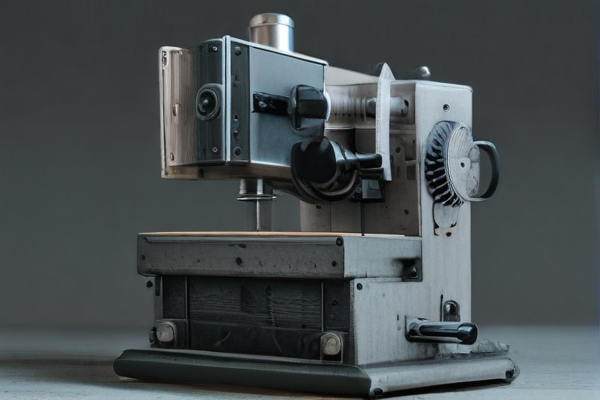

The SourcifyChina DIY milling machine offers precision and versatility, allowing hobbyists and professionals to create intricate designs and prototypes. Its robust build ensures durability and reliable performance in various milling tasks.

Equipped with advanced control software, this machine supports diverse materials, including wood, plastic, and metal. Users can achieve high accuracy and repeatability in their projects, enhancing productivity and creativity.

The machine features a user-friendly interface, making it accessible for beginners while still offering advanced settings for experienced users. Its compact design fits well in small workshops or home garages, maximizing space efficiency.

Additionally, the DIY aspect allows for customization and upgrades, enabling users to tailor the machine to their specific needs. This flexibility ensures that the SourcifyChina DIY milling machine remains a valuable tool as projects evolve and new challenges arise.

Overall, the SourcifyChina DIY milling machine is a cost-effective solution for those seeking high-quality milling capabilities. Its blend of precision, versatility, and ease of use makes it a standout choice in the DIY market.

DIY milling machines provide hobbyists and small business owners with the versatility to create custom parts efficiently and cost-effectively. These machines empower users with hands-on control over their projects.

Benefits:

– Cost-Effective: Building your own milling machine can be considerably cheaper than purchasing a commercial one.

– Customization: Tailor the machine to fit specific needs and projects, allowing for greater versatility.

– Skill Development: Enhances technical skills and knowledge in machining, engineering, and design principles.

– Maintenance Knowledge: Understanding the machine’s components makes troubleshooting and maintenance easier.

– Upgradability: Modify and upgrade parts over time to improve performance without shelling out large sums.

– Learning Opportunity: Provides a deep learning experience in the mechanics and electronics of manufacturing systems.

– Project Flexibility: Allows for quick adjustments and design changes, ensuring a dynamic workflow.

– Accessibility: Lowers the barrier to entry for enthusiasts and small businesses in need of precise machining capabilities.

– Material Variety: Capable of working on diverse materials such as metal, wood, and plastic.

– Sense of Achievement: Building and effectively using a DIY milling machine can be incredibly rewarding and fulfilling.

In summary, a DIY milling machine offers unmatched customization, cost savings, and educational opportunities, making it an attractive option for hobbyists and small businesses alike.

A DIY milling machine offers the flexibility to fabricate various parts and prototypes while saving costs. It can be customized and upgraded to meet specific user needs.

– Customization: Easily adjustable components to suit specific projects.

– Cost-Effective: Significantly cheaper than commercially available milling machines.

– Versatility: Suitable for multiple materials including wood, plastic, and metals.

– Compact Size: Can be built to fit limited workspaces.

– Learning Experience: Provides hands-on knowledge about machining and engineering.

– Upgradeability: Components can be upgraded or replaced as needed.

– Software Integration: Compatible with various CAD/CAM software for precision control.

– Accessibility: Built using readily available materials and parts.

– Maintenance: Easy to repair and maintain with user-friendly design.

– Precision: Capable of high-precision milling tasks with proper calibration.

In sum, a DIY milling machine is a practical solution for those seeking a cost-effective, customizable, and educational tool for various milling applications.

SourcifyChina specializes in DIY milling machines, offering custom products tailored to individual project needs. These machines are perfect for hobbyists and professionals looking to create precise components.

With SourcifyChina’s milling machines, users can craft intricate designs, ensuring high-quality output. Their customizable options allow for modifications, enhancing the versatility of each unit.

Projects utilizing these machines range from small-scale models to complex engineering parts. The ability to customize ensures each machine can adapt to specific requirements, making them invaluable in various fields.

For those seeking reliable and efficient milling solutions, SourcifyChina provides robust equipment designed to meet diverse project demands, ensuring satisfaction and precision in every endeavor.

SourcifyChina is a prominent company in the DIY milling machine industry, specializing in providing high-quality, customizable milling solutions for hobbyists and small-scale manufacturers. Known for their innovative approach, SourcifyChina offers a range of products that cater to different levels of technical expertise and project requirements. Their milling machines are designed with precision and durability in mind, incorporating advanced features that ensure ease of use and consistent performance. By leveraging their extensive experience and strong manufacturing capabilities in China, SourcifyChina delivers cost-effective solutions without compromising on quality. The company also emphasizes customer support, offering detailed guides, technical assistance, and a vibrant community forum where users can share their projects and troubleshoot issues. This commitment to customer satisfaction and product excellence has established SourcifyChina as a trusted name in the DIY milling machine market, appealing to both beginners and seasoned machinists alike.

The aerospace, defense, and marine industries often require highly specialized, precise, and durable components that can withstand extreme conditions. In these fields, DIY milling machines have become valuable tools for rapid prototyping and customized manufacturing. In aerospace, for instance, engineers can utilize DIY milling machines to create intricate parts for aircraft engines, control systems, or aerodynamic surfaces. With the ability to swiftly produce one-off or limited run components, these machines enable quick iteration and testing, leading to faster development cycles and more innovative solutions. Similarly, in the defense sector, DIY milling machines facilitate the fabrication of complex components for surveillance systems, tactical gear, and weaponry, offering the flexibility to adapt designs on the fly in response to changing tactical needs or emerging technologies.

In the marine industry, DIY milling machines are instrumental in crafting customized parts for yachts, submarines, and naval vessels. Given the harsh marine environments, the ability to rapidly produce and replace components with specific materials like corrosion-resistant alloys or composites is crucial. DIY milling machines enable shipbuilders and marine engineers to fabricate precise parts onsite, reducing downtime and dependency on external suppliers. This capability is especially important for remote locations or naval operations where immediate repairs or modifications are essential for maintaining operational readiness. Overall, DIY milling machines provide these high-stakes industries with the ability to quickly adapt, innovate, and maintain functionality through precise, customized manufacturing solutions.

A DIY milling machine offers considerable benefits to the automotive industry by enabling enthusiasts and small-scale manufacturers to produce custom components with high precision and at a lower cost. Automotive parts such as custom brackets, engine components, and suspension components can be crafted with a DIY milling machine, ensuring that they meet specific design requirements and performance standards. This capability is particularly valuable for vintage vehicle restorers and racers who often need parts that are no longer in production. With precise machining, the DIY approach can also pave the way for on-demand prototyping, allowing rapid testing and iteration of new automotive designs, thus accelerating innovation and customization within the industry.

In the electronics domain, a DIY milling machine can revolutionize the creation of custom PCB (Printed Circuit Board) designs and enclosures. Hobbyists and small startups can produce intricate circuit layouts and housing that adheres to their unique requirements without the need for outsourcing to professional workshops, which can often be expensive and time-consuming. This autonomous control over the production process enables quicker iterations and experimentation, fostering an environment ripe for innovation. Furthermore, a DIY milling machine can be used to fabricate entirely new electronic devices, enclosures, and various components, ultimately enhancing the capability to create custom solutions tailored to specific projects and reducing the barrier to entry for aspiring electronics inventors and entrepreneurs. By bringing high-precision tooling into the realm of DIY, enthusiasts and professionals alike can push the boundaries of what is possible in electronics manufacturing.

A DIY milling machine offers immense potential in the construction industry, where precision and customization are paramount. Homebuilt or small-scale CNC milling machines enable hobbyists and professional builders alike to craft high-quality components on-site, reducing lead times and costs associated with outsourcing. These machines can produce everything from custom brackets and fixtures to more complex architectural elements, ensuring that unique designs and specific measurements are faithfully executed. Besides enhancing productivity and efficiency, DIY milling machines bolster innovation in bespoke construction projects, allowing builders to experiment with avant-garde designs and materials without a significant financial burden.

In the realm of energy applications, DIY milling machines contribute significantly by enabling the fabrication of intricate parts for renewable energy systems such as wind turbines and solar panels. For instance, custom gears, housings, and mounts crucial for the efficient operation of small-scale wind turbines can be fabricated with precision at a fraction of the cost of commercially produced components. This level of customization is vital for optimizing the performance of renewable energy systems tailored to specific environments. Additionally, these machines allow for rapid prototyping and iterative development of novel energy solutions, fostering a culture of innovation and sustainability. By empowering individuals and small enterprises to design and manufacture precise components, DIY milling machines play a crucial role in advancing localized and cost-effective renewable energy initiatives.

The Industrial Equipment industry has witnessed transformative changes with the advent of DIY milling machines, which offer unprecedented flexibility and cost efficiency for both small-scale manufacturers and large industrial entities. These machines, often built and customized by the users themselves, allow for precise milling operations tailored to specific project needs. As opposed to traditional, pre-configured milling machines, DIY versions provide an affordable entry point for startups and hobbyists, offering the ability to produce complex components with remarkable precision. This self-built machinery grants users control over the machine’s specs and features, enabling customization to fit unique project requirements, which is particularly advantageous for producing bespoke parts or conducting R&D activities. This versatility broadens the scope for innovation within the industry, facilitating rapid prototyping and small-batch productions without incurring hefty costs.

Furthermore, the implementation of DIY milling machines in industrial settings promotes a culture of ingenuity and technical skill development among employees. By engaging in the assembly and customization process, workers gain a deeper understanding of the operational intricacies and maintenance requirements of milling equipment. This knowledge transfer can lead to improved operational efficiencies and reduced downtime since in-house personnel can swiftly address technical issues without waiting for external specialists. Additionally, the trend towards DIY solutions aligns with the larger movement towards sustainability and resource optimization in manufacturing, as companies can repurpose and upgrade existing machinery components rather than purchasing entirely new units. Altogether, DIY milling machines are revolutionizing the Industrial Equipment industry by enhancing accessibility, fostering innovation, and driving both economic and operational benefits.

The advent of DIY milling machines has revolutionized the medical devices sector by enabling the production of highly customized and precise equipment. Traditional manufacturing methods often result in prolonged production times and increased costs, posing significant challenges for both manufacturers and healthcare providers. DIY milling machines, which can be assembled and operated at a fraction of the cost of industrial-scale milling machines, address these issues by offering an affordable and efficient alternative. These machines are particularly valuable for creating prototypes and small batches of personalized medical devices, such as custom implants, surgical tools, and dental prosthetics. Their ability to mill intricate designs with high accuracy ensures that the resulting devices meet stringent medical standards and patient-specific needs.

Moreover, the use of DIY milling machines fosters innovation and rapid iteration in medical device design. Researchers and developers can quickly prototype and test new concepts, significantly speeding up the development cycle for advanced medical technologies. This flexibility is crucial for advancing personalized medicine, where the ability to quickly produce and modify devices based on individual patient data can lead to better outcomes and improved patient care. Additionally, DIY milling machines can be vital in low-resource settings or remote locations, offering a means to locally produce essential medical devices without relying on complex supply chains. As open-source software and community-shared designs become more prevalent, the accessibility of DIY milling technology will likely continue to expand, further democratizing the field of medical device manufacturing and facilitating widespread innovation.

DIY milling machines have become a significant tool in both machining and manufacturing applications due to their versatility and cost-effectiveness. These machines allow hobbyists and small-scale manufacturers to perform various machining operations such as cutting, drilling, and shaping materials like metal, wood, and plastic. By using computer numerical control (CNC) technology, DIY milling machines offer precision and repeatability, which are critical in producing complex parts and prototypes. The accessibility of DIY kits and the availability of online resources have empowered individuals to build and customize their milling machines, catering to specific project needs without the high investment required for industrial-grade equipment.

In manufacturing, DIY milling machines contribute to rapid prototyping and small-batch production, enabling manufacturers to quickly iterate and refine designs. This agility is particularly beneficial for startups and small businesses that need to bring products to market swiftly without substantial capital expenditure. Moreover, DIY milling machines can be used for educational purposes, providing hands-on experience with CNC technology and machining processes. This practical learning approach helps in developing skills that are essential for modern manufacturing careers. Overall, the application of DIY milling machines in machining and manufacturing highlights their role in democratizing production capabilities and fostering innovation in various industries.

Sure, here are some frequently asked questions (FAQs) for manufacturing a DIY milling machine with quality work from SourcifyChina factory:

Q1: What are the key features of the DIY milling machine from SourcifyChina?

A1: The DIY milling machine from SourcifyChina boasts a sturdy build, precise control, high-quality spindles, and customizable options to suit various project requirements. It’s equipped with state-of-the-art CNC technology ensuring accuracy and reliability.

Q2: What materials can the milling machine process?

A2: Our milling machine can handle a wide range of materials, including metals (such as aluminum and steel), plastics, wood, and composites, making it versatile for numerous DIY projects.

Q3: How is the machine shipped and what is the lead time?

A3: The machine is securely packaged and shipped worldwide. The lead time typically ranges from 4 to 6 weeks, depending on the customizations and current production schedule at SourcifyChina factory.

Q4: Is technical support available after purchase?

A4: Yes, SourcifyChina offers comprehensive technical support and customer service to assist with installation, troubleshooting, and any operational queries you may have after purchasing the milling machine.

Q5: How difficult is it to assemble the DIY milling machine?

A5: The assembly process is straightforward, with detailed instructions provided. Basic knowledge of mechanical assembly and CNC operations is recommended, but SourcifyChina also offers remote assistance if needed.

Q6: Can I customize the milling machine according to my specific requirements?

A6: Absolutely! SourcifyChina allows for various customizations including size, spindle power, and control systems to better fit your unique project needs.

Q7: What safety features does the milling machine include?

A7: The milling machine is equipped with multiple safety features including emergency stop buttons, overload protection, and safety shields to ensure safe operations.

Q8: What is the warranty period for the machine?

A8: SourcifyChina provides a 1-year warranty on the milling machine, covering any manufacturing defects. Extended warranties and maintenance plans are also available.

Q9: Are there financing options available for purchasing the milling machine?

A9: Yes, financing options are available to accommodate different budget needs. Contact SourcifyChina’s sales team for more details on financing plans.

Q10: Where can I find user reviews or testimonials about the DIY milling machine?

If you’re planning to manufacture a DIY milling machine and considering sourcing components or services from a factory like SourcifyChina, here are some essential tips to ensure a smooth process:

1. Research and Specification:

– Clearly define your project’s requirements.

– Create detailed specifications for each part, including materials, dimensions, and tolerances.

2. Supplier Verification:

– Verify the factory’s credentials, experience, and reputation.

– Request samples or visit the factory if possible to assess quality and adherence to standards.

3. Prototype Development:

– Start with a prototype to test design and functionality.

– Use the prototype to identify any potential issues and refine your specifications accordingly.

4. Quality Assurance:

– Establish clear quality assurance processes.

– Insist on regular quality checks and obtain reports.

– Consider using third-party inspection services if necessary.

5. Cost Management:

– Get quotes from multiple suppliers to compare prices and negotiate effectively.

– Be aware of all costs, including shipping, duties, and taxes, to avoid surprises.

6. Communication:

– Maintain regular and clear communication with the factory.

– Use project management tools to keep track of progress and timelines.

7. Logistics and Shipping:

– Plan your logistics comprehensively, including shipping methods and timelines.

– Prepare for potential delays and have contingency plans in place.

8. Legal and Compliance:

– Ensure all purchases and agreements comply with local and international regulations.

– Protect your intellectual property with patents or NDAs where applicable.

By following these tips, you’ll boost the efficiency, quality, and reliability of your DIY milling machine manufacturing project when working with SourcifyChina or any other supplier.

Sure, here are some frequently asked questions (FAQ) about sourcing a DIY milling machine from SourcifyChina factory with concise answers:

1. What is SourcifyChina factory?

SourcifyChina is a manufacturing and sourcing service provider that connects global buyers with Chinese factories, offering a range of products including DIY milling machines.

2. How can I trust the quality of the milling machines from SourcifyChina?

SourcifyChina performs rigorous quality checks and audits on their partnered factories. They also provide product samples and detailed quality inspection reports before you commit to a bulk order.

3. What is the minimum order quantity (MOQ) for DIY milling machines?

The MOQ varies depending on the specific factory and model, but typically it ranges from 10 to 50 units.

4. Can I get a sample before placing a bulk order?

Yes, you can request a sample. This allows you to evaluate the quality and performance of the milling machine before committing to a larger order.

5. How long does it take to receive an order?

Lead times can vary based on order size, customization requirements, and shipping methods, but it typically takes 30-45 days for production and shipping.

6. Is customization available for DIY milling machines?

Yes, many factories in the SourcifyChina network offer customization options such as branding, specifications, and additional features.

7. What payment methods are accepted?

SourcifyChina usually accepts multiple payment methods including bank transfers, PayPal, and credit cards. Specific terms should be confirmed directly with them.

8. Are there warranties or post-purchase support available?

Most manufacturers provide warranties ranging from 6 months to 1 year. SourcifyChina can facilitate communication between the buyer and the factory for any post-purchase support needed.

9. How can I start the sourcing process with SourcifyChina?

You can start by visiting their website, filling out a quote request form, or contacting their customer service directly to discuss your requirements.

10. What are the shipping options available?

SourcifyChina offers multiple shipping options including sea freight, air freight, and express courier services. Choose the one that best suits your timeline and budget.

Sourcing a DIY milling machine from a SourcifyChina factory can be efficient with these steps:

1. Research and Identify Suppliers: Use SourcifyChina’s platform to identify reputable suppliers. Check their experience, customer reviews, and product portfolio to ensure they meet your specifications.

2. Clear Specifications: Define and document your exact requirements, including materials, dimensions, and performance specifications. This helps in matching with the right supplier and avoiding misunderstandings.

3. Request for Quotes (RFQ): Contact multiple suppliers, providing them with detailed specifications and asking for quotes. Compare prices, delivery times, and payment terms.

4. Samples and Prototypes: Request samples or prototypes to assess the quality of work before making a bulk order. This helps in verifying that the supplier can meet your product standards.

5. Quality Assurance: Ensure the supplier has a robust quality management system. Request documentation of quality checks and certifications to guarantee the product meets your standards.

6. Communicate Clearly: Maintain clear and consistent communication with the supplier. Use detailed emails and establish a point of contact to streamline the process.

7. Factory Visit: If feasible, plan a visit to the factory. This provides firsthand insight into their manufacturing capabilities and quality control processes.

8. Negotiate Terms: Discuss and negotiate terms regarding pricing, delivery times, payment terms, and warranties to ensure a favorable deal.

9. Legal Considerations: Draft a clear contract outlining all agreed terms, including intellectual property rights, confidentiality clauses, and dispute resolution mechanisms.

10. Logistics and Shipping: Plan logistics early. Choose reliable shipping methods and understand the import regulations of your country to avoid delays.

By following these tips, you can efficiently source a quality DIY milling machine from a SourcifyChina factory, ensuring a smooth and successful procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.