“SourcifyChina” Factory stands out for purchasing Doosan machine tools from China due to its unwavering commitment to quality and cost-effectiveness. With established relationships with top-tier suppliers, they ensure access to authentic, high-performance Doosan equipment at competitive prices, maximizing buyer value and operational efficiency.

Their customer service is dedicated and responsive, ensuring seamless communication and support throughout the purchasing process. With a team of experts familiar with both the Doosan brand and local Chinese market intricacies, they provide insightful advice and swift issue resolution, enhancing buyer confidence and satisfaction.

Purchasing from “SourcifyChina” ensures rigorous quality control and compliance with international standards. They conduct thorough inspections and offer detailed documentation, giving buyers peace of mind regarding the authenticity and reliability of their machine tools. This focus on quality mitigates the risk of faulty or substandard products.

“SourcifyChina” also offers comprehensive logistics solutions, streamlining the complex process of international shipping. Their expertise in customs regulations and shipping procedures guarantees timely and cost-effective delivery of Doosan machine tools, minimizing downtime and optimizing operational timelines for buyers.

In summary, choosing “SourcifyChina” Factory for purchasing Doosan machine tools from China means benefiting from their commitment to quality, exceptional customer support, rigorous quality control, and efficient logistics. This holistic approach ensures buyers receive high-quality products swiftly and reliably, making “SourcifyChina” a trusted partner in industrial machinery procurement.

Doosan Machine Tools offers a wide range of high-precision, reliable machining equipment suitable for diverse applications. These machines are known for their advanced technology, durability, and versatility, catering to industries like automotive, aerospace, and manufacturing.

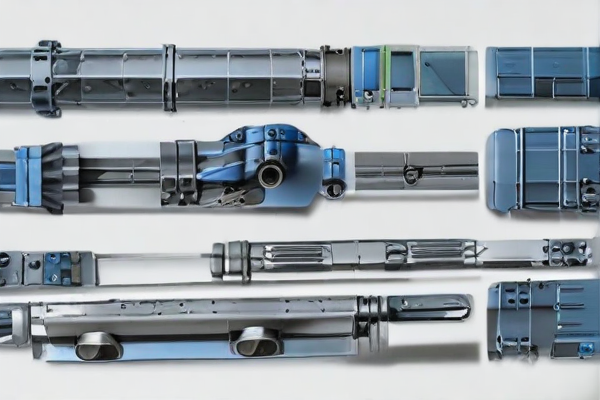

– CNC Turning Centers: High-performance machines designed for precision turning operations. They come in horizontal and vertical configurations and offer features like multi-tasking capabilities.

– Machining Centers: Available in various configurations such as horizontal, vertical, and 5-axis. Ideal for complex milling, drilling, and boring tasks, offering high-speed and high-precision operations.

– Multi-Tasking Machines: These are hybrid machines capable of performing various operations such as milling, turning, and drilling in a single setup, thereby boosting productivity and reducing cycle time.

– Horizontal Boring Mills: Suitable for heavy-duty and large-scale machining tasks. They offer precision and stability for applications that require substantial material removal and accuracy.

– Vertical Turning Lathes (VTL): Designed for large-diameter and heavy parts, these lathes offer rigidity and precision, ideal for industries requiring large-scale turning operations.

– 5-Axis Machines: Provide the ability to machine complex geometries with high precision. These machines reduce the need for multiple setups, resulting in enhanced efficiency.

– Double Column Machining Centers: These are ideal for large part machining and provide high rigidity and precision. Suitable for industries requiring high stability and accuracy in large components.

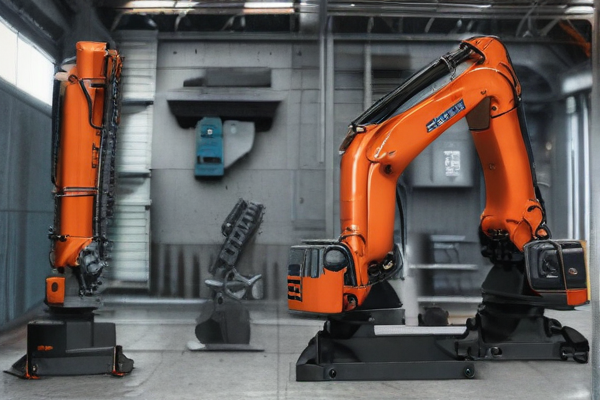

– Automation Solutions: Doosan also offers automation solutions including robotic loading/unloading systems and pallet changers, which enhance productivity and operational efficiency.

– Support and Training: Comprehensive support and training services to ensure optimal machine performance and operations. This includes maintenance services, software updates, and operator training.

These diverse options and features make Doosan Machine Tools a versatile choice for various industrial applications, ensuring enhanced productivity and precision.

Doosan Machine Tools primarily serve industries requiring precision machining and high-performance manufacturing. Their advanced CNC machines are essential for producing complex parts efficiently, ensuring quality and consistency.

– Automotive: Engine components, transmission parts, and brake systems.

– Aerospace: Aircraft parts, turbine blades, and structural components.

– Medical: Surgical instruments, prosthetics, and medical devices.

– Oil and Gas: Drill bits, valves, and pipeline components.

– Defense: Weaponry parts, armored vehicle components, and defense system elements.

– Heavy Equipment: Construction machinery parts, mining equipment components.

– Electronics: Semiconductor equipment parts, connectors.

– Energy: Wind turbine parts, solar panel components, nuclear reactor parts.

– General Manufacturing: Custom parts, prototyping, and mass production.

– Tool and Die: Molds, dies, and press tools.

These applications illustrate the versatility and critical role that Doosan Machine Tools play across various sectors, fostering innovation and precision.

SourcifyChina is a reputable supplier of industrial equipment, including Doosan machine tools. These tools are known for their precision and durability, making them ideal for a range of manufacturing applications. Doosan’s machine tools are crafted from high-grade materials, ensuring longevity and reliable performance under rigorous conditions.

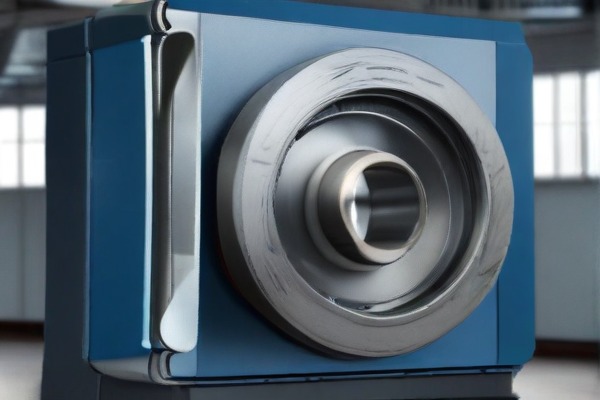

The use of advanced alloys and composite materials in Doosan machine tools contributes to their strength and resistance to wear and tear. This enhances the tools’ ability to handle high-stress tasks, maintaining accuracy and efficiency over long periods.

Moreover, Doosan incorporates cutting-edge technology in their tool construction, such as CNC systems and automation capabilities. This integration not only boosts productivity but also minimizes downtime, providing significant cost savings for businesses.

In summary, SourcifyChina’s provision of Doosan machine tools offers manufacturers robust, high-quality equipment. These tools’ superior materials and technological enhancements ensure they meet the demanding needs of modern manufacturing industries.

SourcifyChina partners with Doosan to offer a variety of machine tools renowned for their high-quality manufacturing standards. The quality control process is rigorous, ensuring that each machine tool meets stringent industry criteria.

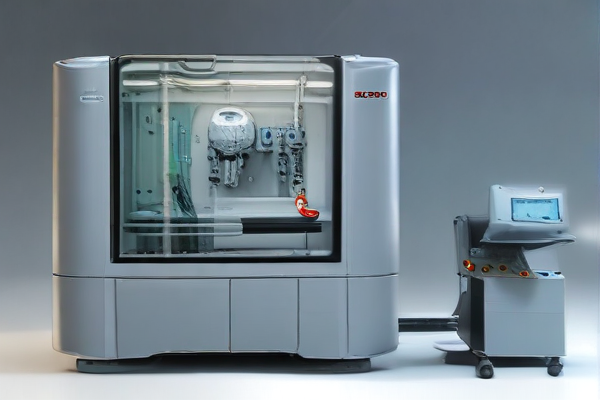

The initial phase of quality control starts with raw material inspection. Each component undergoes meticulous examination to verify its consistency and integrity. This ensures that only top-grade materials enter the manufacturing line.

During the production phase, precision machining is complemented by continuous monitoring. High-tech sensors and real-time data analytics are utilized to detect any deviations from specified dimensions and tolerances, guaranteeing exactness.

Post-production testing is an integral part of the process. Each machine tool undergoes a series of functional tests to validate performance under various operating conditions. This step ensures that the products can withstand the demands of real-world applications.

Final inspection brings everything together. Experienced quality control engineers conduct comprehensive reviews, comparing the finished products against detailed specifications and standards. Any discrepancies are immediately addressed before shipment.

Customer feedback is actively sought and analyzed. This feedback loop allows SourcifyChina and Doosan to continually enhance their quality control protocols, ensuring that customer expectations are not just met but exceeded. By embedding quality control into each stage of the manufacturing process, SourcifyChina and Doosan consistently deliver machine tools that are robust, reliable, and precise.

SourcifyChina excels in providing access to high-quality Doosan machine tools, renowned for their precision and durability. These tools cater to various industries, ensuring optimal performance and reliability in manufacturing processes.

As an official distributor, SourcifyChina ensures that all Doosan machine tools come with comprehensive warranties and support services. Their range includes CNC lathes, machining centers, and boring mills, addressing diverse operational needs.

The company prides itself on offering tailored solutions, assisting clients with selecting the right machine tool configurations. Their expert team provides detailed consultations, ensuring the best fit for any project requirements.

Further enhancing their service, SourcifyChina provides training and maintenance programs to ensure clients can maximize the utility of their Doosan machines. This commitment to post-purchase support highlights their dedication to customer satisfaction.

Combining advanced technology with exceptional service, SourcifyChina stands out in the machine tool industry. Their comprehensive offerings underscore their capacity to meet the evolving needs of modern manufacturing.

Doosan Machine Tools offers innovative, high-quality solutions for various manufacturing needs. Their advanced technology and robust design ensure optimal performance and reliability.

– Precision and Accuracy: Doosan machines are engineered to deliver high precision and consistent accuracy, essential for intricate machining tasks.

– Durability: Built with high-quality materials, these tools are durable and designed to withstand rigorous use over time.

– Efficiency: Doosan’s advanced technology enhances operational efficiency, reducing cycle times and increasing productivity.

– Versatility: Their wide range of machine tools caters to diverse industrial applications, from automotive to aerospace.

– User-Friendly Interface: The intuitive controls and interfaces make these machines easy to operate, minimizing the learning curve.

– Customer Support: Doosan provides excellent customer service and support, ensuring minimal downtime and quick resolution of issues.

– Cost-Effective: Despite their advanced features, Doosan machine tools offer competitive pricing, providing great value for investment.

– Environmental Considerations: Designed with energy efficiency in mind, Doosan machines help reduce environmental impact.

– Innovation: Continuous R&D efforts keep Doosan at the forefront of technological advancements in the machine tool industry.

Doosan Machine Tools is renowned for its precision, innovation, and reliability, making it a preferred choice in the manufacturing industry. Its machines are designed to meet various machining needs with high efficiency and accuracy.

– Advanced Technology: Incorporates the latest CNC (Computer Numerical Control) technology for precision and control.

– Durability: Built with robust materials ensuring long-term use and reduced maintenance costs.

– Versatility: Offers a wide range of models suitable for different machining tasks, from milling to turning.

– Automation: Includes options for automation to enhance productivity and reduce manual intervention.

– User-Friendly Interface: Features intuitive control panels that simplify operation and programming.

– Energy Efficiency: Designed to optimize energy consumption, reducing operational costs.

– Support and Service: Provides comprehensive customer support and service plans to ensure maximum uptime.

– High Performance: Delivers superior cutting speeds and accuracy, improving overall production quality.

– Customization: Allows for customization to meet specific customer requirements and applications.

– Innovation: Continuously integrates new technologies and improvements to stay ahead in the industry.

SourcifyChina specializes in customizing Doosan machine tools to meet the specific needs of various industries. Their expertise in engineering ensures precision and optimized performance tailored to specific project requirements.

They provide comprehensive solutions, from design to final production, ensuring that each custom machine tool delivers efficient and reliable performance. Their services cater to a wide range of industries, including automotive, aerospace, and heavy machinery.

By leveraging advanced technology and skilled craftsmanship, SourcifyChina is capable of producing Doosan machine tools that maximize output while maintaining stringent quality controls. They continually innovate to keep up with the evolving demands of modern manufacturing.

Their customized solutions enhance productivity, reduce downtime, and optimize overall operational efficiency. SourcifyChina’s collaborative approach ensures that customer needs and expectations are met, fostering long-term partnerships built on trust and success.

In addition to creating bespoke machine tools, they also offer ongoing support and maintenance, ensuring that the equipment remains in optimal condition throughout its lifecycle. This commitment extends to providing training and resources to help clients achieve the best possible results from their investments.

SourcifyChina’s dedication to quality and customer satisfaction sets them apart in the industry. They continuously strive to exceed expectations, delivering high-performance Doosan machine tools that drive innovation and growth. Through their customized solutions, SourcifyChina plays a pivotal role in advancing manufacturing technologies and contributing to industrial success.

SourcifyChina, in collaboration with Doosan Machine Tools, has emerged as a significant player in the manufacturing and machinery industry. Specializing in the provision and distribution of high-precision and reliable machine tools, the company caters to a diverse range of industrial sectors, including automotive, aerospace, and energy. Doosan Machine Tools, known for its cutting-edge technology and robust machinery, enhances SourcifyChina’s offerings with a broad spectrum of products such as CNC lathes, machining centers, and multitasking machines. This partnership enables SourcifyChina to deliver superior solutions that optimize production efficiency and ensure high quality. By leveraging Doosan’s innovative engineering and SourcifyChina’s expertise in sourcing and supply chain management, the company not only meets the rigorous demands of modern manufacturing but also supports its clients in achieving operational excellence and competitiveness in the global market. This synergy underscores the commitment of both entities to advancing industrial capabilities and fostering growth through technological innovation and strategic cooperation.

Doosan Machine Tools are pivotal in the aerospace sector, where precision and reliability are paramount. The high-performance machining centers and multi-axis turning centers offered by Doosan are instrumental in manufacturing complex aerospace components such as turbine blades, engine casings, and structural parts. These machines ensure the tight tolerances and superior surface finishes required for aerospace applications, where even minor deviations can significantly impact performance and safety. The integration of advanced features like high-speed spindles, automated tool changers, and real-time monitoring systems allows for enhanced productivity and consistency, meeting the rigorous demands of aerospace manufacturing.

In the defense and marine industries, Doosan Machine Tools provide robust and versatile solutions for producing critical components. For defense applications, these machines are used to manufacture parts for vehicles, weaponry, and communication systems, where durability and precision are crucial. In the marine sector, Doosan’s machine tools are employed to create components for ships and submarines, such as propellers, shafts, and engine parts, which must withstand harsh marine environments. The ability of Doosan’s equipment to handle large, heavy workpieces with exceptional accuracy and repeatability ensures that both defense and marine manufacturers can maintain the highest standards of quality and reliability in their production processes.

Doosan Machine Tools has established a formidable presence in the automotive industry with its advanced machining solutions that cater to the complexity and precision required in automotive manufacturing. Automotive parts, ranging from engine components to transmission systems, demand high levels of accuracy and repeatability. Doosan’s CNC machines are engineered to meet these demands, offering high-speed performance and exceptional rigidity. For example, their horizontal machining centers (HMCs) and vertical turning centers (VTCs) are pivotal in producing high-precision gears, crankshafts, and brake components. The integration of automated solutions and cutting-edge software further enhances productivity and reduces cycle times, enabling manufacturers to keep up with the fast-paced nature of automotive production.

In the realm of electronics, Doosan Machine Tools excels by providing specialized equipment designed for the intricacies and delicate nature of electronic components. Printed circuit boards (PCBs), connectors, and semiconductor components require meticulous handling and pinpoint accuracy. Doosan’s vertical machining centers (VMCs) and turning centers are specifically designed to produce these components with minimal tolerances. The machines offer superior thermal stability and high spindle speeds, which are essential for the fine machining processes in electronics manufacturing. Additionally, Doosan’s advanced automation solutions enhance throughput and reduce human error, ensuring the production of consistently high-quality electronic parts. These capabilities make Doosan Machine Tools a trusted partner in the electronics industry, where precision and reliability are non-negotiable.

Doosan Machine Tools has cemented its reputation as a versatile and robust provider of manufacturing solutions in the construction industry. Offering a wide array of machine tools such as CNC machining centers, lathes, and boring mills, Doosan ensures precision and durability in the production of essential construction components. From the fabrication of structural steel elements to the detailed crafting of specialized components like hydraulic fittings and gear systems, their machinery addresses every need with unparalleled accuracy and speed. The company’s multi-axis machining centers and advanced automation options streamline workflows, reducing labor costs and enhancing productivity. This adaptability and innovation enable construction firms to produce high-quality, custom parts in shorter time frames, ensuring timely project completions and bolstering construction quality standards.

In the energy sector, Doosan Machine Tools plays a pivotal role in the manufacturing of critical components for the oil, gas, renewable, and power generation industries. The company’s precision machinery facilitates the production of complex parts such as turbine blades, compressor wheels, and valve bodies, which require stringent tolerance levels and robust material integrity. By utilizing their advanced multi-tasking lathes and high-performance machining centers, energy companies can achieve optimized production cycles with minimized waste, ensuring efficient and reliable component manufacturing. Moreover, Doosan’s commitment to incorporating the latest technologies, like IoT and AI-driven diagnostics, enhances predictive maintenance and operational efficiency. This not only extends the lifespan of their machinery but also ensures that energy companies maintain uninterrupted production flows, ultimately contributing to global energy sustainability efforts through precise and dependable manufacturing solutions.

Doosan Machine Tools, a leading manufacturer in the industrial equipment sector, provides advanced machining solutions essential for various industries, including automotive, aerospace, and heavy equipment manufacturing. Their comprehensive range of CNC (Computer Numerical Control) machines, such as lathes, milling machines, and multi-axis machining centers, are engineered for high precision and productivity. These tools enable manufacturers to achieve superior quality and efficiency in their production processes, facilitating complex machining tasks with ease. Doosan’s commitment to innovation is evident in their integration of smart technologies, such as IoT (Internet of Things) connectivity and automation, which optimize machine performance and provide real-time data analytics for predictive maintenance and operational efficiency.

In the industrial equipment industry, Doosan Machine Tools’ products play a crucial role in enhancing the capabilities of manufacturing operations. Their robust and versatile machines are designed to handle a wide range of materials and intricate designs, meeting the stringent demands of modern production. By offering solutions that increase accuracy and reduce cycle times, Doosan helps manufacturers minimize downtime and improve overall output. Moreover, their global support network ensures that clients receive timely technical assistance and training, maximizing the value of their investment. As a result, Doosan Machine Tools not only boosts productivity but also supports the advancement of manufacturing technologies, driving growth and innovation across various industrial sectors.

Doosan Machine Tools plays a pivotal role in the medical devices industry by providing advanced manufacturing solutions that ensure high precision, reliability, and efficiency. Their state-of-the-art CNC (Computer Numerical Control) machines are crucial for producing intricate components used in medical devices such as implants, surgical instruments, and diagnostic equipment. The precision and versatility of Doosan’s machining centers and lathes allow for the creation of complex geometries and fine details necessary for these critical medical applications. By leveraging their extensive expertise in automation and intelligent manufacturing, Doosan enables medical device manufacturers to maintain stringent quality standards and meet the regulatory requirements essential for patient safety.

Furthermore, Doosan Machine Tools’ focus on innovation and customization enhances the production capabilities of medical device companies. Their machines are equipped with advanced features like multi-axis machining, high-speed spindles, and superior rigidity, which are essential for working with the diverse materials commonly used in medical devices, such as titanium, stainless steel, and biocompatible polymers. Additionally, Doosan’s support services, including application engineering and training, help medical device manufacturers optimize their production processes, reduce downtime, and improve overall operational efficiency. This commitment to excellence ensures that medical devices produced using Doosan Machine Tools meet the highest standards of performance and reliability, ultimately contributing to better healthcare outcomes.

Doosan Machine Tools is a prominent player in the machining and manufacturing industry, known for its advanced and reliable machinery that caters to a wide range of industrial applications. With a comprehensive portfolio that includes CNC lathes, machining centers, and multi-tasking machines, Doosan provides the precision and versatility needed for high-quality production. The CNC lathes from Doosan, for instance, are engineered to deliver superior accuracy and efficiency, making them ideal for industries such as automotive, aerospace, and medical devices. These machines offer high-speed turning capabilities, robust construction, and user-friendly interfaces, which ensure consistent performance and reduced downtime, thereby enhancing overall productivity.

In addition to lathes, Doosan’s machining centers are designed for complex and high-precision tasks, suitable for both heavy-duty and delicate component manufacturing. Their vertical and horizontal machining centers incorporate cutting-edge technology such as high-speed spindles, advanced control systems, and automation solutions that allow for seamless integration into smart manufacturing environments. This versatility is crucial for various sectors, including the mold and die industry, electronics, and heavy machinery production. Furthermore, Doosan’s multi-tasking machines consolidate multiple operations like milling, turning, and drilling into a single machine, streamlining the production process and reducing cycle times. Overall, the application of Doosan machine tools in machining and manufacturing underlines a commitment to excellence, innovation, and customer satisfaction, making them a valuable asset in achieving high efficiency and precision in today’s competitive industrial landscape.

Sure, here is a concise list of FAQs with answers related to manufacturing “Doosan machine tools quality work from SourcifyChina factory”.

1. What types of Doosan machine tools can SourcifyChina manufacture?

SourcifyChina specializes in producing various types of Doosan machine tools, including CNC lathes, machining centers, multi-tasking machines, and more. They ensure high precision and quality in every unit.

2. How does SourcifyChina ensure the quality of Doosan machine tools?

SourcifyChina employs rigorous quality control (QC) standards, including ISO certification, frequent inspections, and precise calibration processes. They also use advanced technology and experienced technicians to maintain the highest quality.

3. Can SourcifyChina customize Doosan machine tools?

Yes, SourcifyChina offers customization services to suit specific operational needs. This includes modifications in design, functionality, and additional features based on client requirements.

4. What is the lead time for manufacturing Doosan machine tools at SourcifyChina?

The lead time depends on the complexity and quantity of the order. Typically, it ranges from a few weeks to a few months. Specific timelines can be provided upon request.

5. Are there warranty and after-sales services available for Doosan machine tools from SourcifyChina?

Yes, SourcifyChina provides warranty coverage and comprehensive after-sales services, including maintenance, repairs, and technical support to ensure long-term functionality and performance.

6. How does SourcifyChina handle international shipping and logistics?

SourcifyChina has a robust logistics network that facilitates international shipping. They handle all necessary documentation, customs procedures, and use reliable shipping partners to ensure timely delivery.

7. Are there opportunities for factory visits and quality inspections?

Absolutely, SourcifyChina welcomes clients for factory visits and encourages pre-shipment inspections to verify quality and specifications before delivery.

8. How competitive are SourcifyChina’s pricing structures?

SourcifyChina offers competitive pricing without compromising quality. They provide detailed quotations based on specific client needs, ensuring cost-effectiveness and value for money.

When considering Doosan machine tools manufacturing from a Sourcify China factory, keep the following tips in mind:

1. Quality Assurance:

– Reputation: Verify the factory’s reputation for producing high-quality Doosan machine tools. Look for reviews and testimonials from other buyers.

– Certifications: Ensure the factory holds relevant certifications, such as ISO 9001, indicating adherence to international quality standards.

2. Supplier Verification:

– Audits: Conduct factory audits to confirm their capabilities and quality control processes.

– Sample Testing: Request samples to evaluate the build quality and performance of the machine tools.

3. Communication:

– Clear Specifications: Provide detailed specifications and requirements to avoid misunderstandings.

– Regular Updates: Maintain regular communication to stay updated on production progress and address issues promptly.

4. Cost Management:

– Transparent Pricing: Ensure the pricing structure is transparent, including costs for materials, manufacturing, and shipping.

– Negotiate Terms: Negotiate payment terms and conditions to protect your interests, such as milestone-based payments.

5. Logistics and Shipping:

– Shipping Methods: Choose reliable shipping methods to ensure timely and safe delivery.

– Customs and Duties: Be aware of customs regulations and import duties in your country to avoid unexpected costs.

6. After-Sales Support:

– Warranty and Service: Confirm warranty terms and availability of after-sales support, including maintenance and repair services.

– Spare Parts: Ensure easy access to spare parts for future repairs or replacements.

7. Cultural Considerations:

– Cultural Awareness: Understand cultural differences to foster better communication and relationships with the factory management.

By following these tips, you can enhance your experience and success when sourcing Doosan machine tools from a Sourcify China factory.

Sure, here’s a list of frequently asked questions (FAQ) and their answers for sourcing Doosan Machine Tools from the SourcifyChina factory:

Q: What types of Doosan Machine Tools are available from SourcifyChina?

A: SourcifyChina offers a wide range of Doosan Machine Tools, including CNC machining centers, lathes, turning centers, and multi-tasking machines. For specific models, you can directly contact SourcifyChina’s sales team.

Q: How can I ensure the quality of Doosan Machine Tools sourced from SourcifyChina?

A: SourcifyChina is known for its rigorous quality control measures. They provide detailed inspection reports and certifications. Additionally, factory visits and third-party audits can be arranged for further assurance.

Q: What is the lead time for purchasing Doosan Machine Tools from SourcifyChina?

A: The lead time can vary depending on the specific model and order quantity. Generally, it ranges from 4 to 12 weeks. Spare parts and accessories may have shorter lead times.

Q: Are there any customization options available?

A: Yes, SourcifyChina offers customization based on your specific needs. You can discuss your requirements with their technical team to tailor the machine tools to your operational requirements.

Q: What payment methods are accepted?

A: SourcifyChina accepts multiple payment methods, including Wire Transfer (TT), Letter of Credit (LC), and sometimes even PayPal for smaller amounts. Detailed payment terms should be confirmed with their sales department.

Q: What about after-sales service and support?

A: SourcifyChina provides comprehensive after-sales service, including installation support, training, and regular maintenance. They have a responsive customer service team to handle any issues that arise.

Q: How can I get a quote for my Doosan Machine Tool needs?

A: You can easily get a quote by filling out the inquiry form on SourcifyChina’s website or by directly contacting their sales team via email or phone. Be sure to provide detailed specifications for an accurate quote.

Q: Is there a minimum order quantity (MOQ) when sourcing from SourcifyChina?

A: The MOQ can vary depending on the specific machine tool and customization requirements. Generally, there is more flexibility with higher quantities, but it’s best to discuss this directly with their sales team.

Sourcing Doosan machine tools from a factory like SourcifyChina involves a few crucial steps to ensure you get quality products at competitive prices. Here are some tips:

1. Research and Identify Needs: Define your specific requirements for Doosan machine tools, such as model, size, and features.

2. Find Reputable Suppliers: Use platforms like Alibaba, Global Sources, and Made-in-China to find suppliers. Look for those with strong ratings and reviews, and preferably those who have been verified or certified.

3. Verify Legitimacy: Ensure SourcifyChina is a legitimate factory by checking their business licenses, certifications, and customer feedback. You can use third-party verification services if needed.

4. Request Quotations: Contact multiple suppliers to request detailed quotations. Compare their pricing, specifications, and terms of trade.

5. Evaluate Quality: Ask for samples or visit the factory if possible. This helps in assessing the quality of the machine tools and the process standards of the factory.

6. Negotiate Terms: Discuss payment terms, lead times, and shipping details. Ensure there’s a clear agreement on terms to avoid any misunderstandings later.

7. Consider Logistics: Plan the logistics for shipping and customs clearance. This may involve partnering with a freight forwarder who can handle imports efficiently.

8. Trial Order: Place a small initial order to test the waters. Monitor quality and delivery times before committing to a larger purchase.

9. Build Relationships: Establish a good working relationship with your supplier. Clear communication and strong partnerships can often lead to better deals and priority service in the future.

10. Legal Agreements: Have a legally binding contract in place that outlines all terms and conditions, including penalties for non-compliance and quality issues.

By following these steps, you can effectively source Doosan machine tools from SourcifyChina factory, ensuring quality and cost-effectiveness.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.