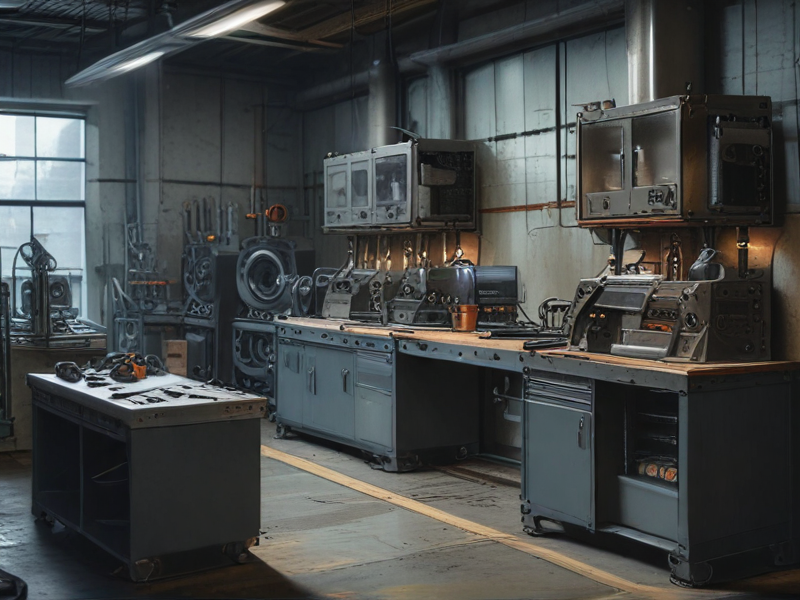

## Reliable EDM Machine Parts from SourcifyChina Factory: High-Quality Manufacturing Solutions

Discover the top-rated EDM machine parts from SourcifyChina Factory, known for its reliability and precision engineering. Get high-quality manufacturing solutions tailored to your needs, ensuring durability and optimal performance for your machinery.

Choosing “SourcifyChina” Factory for purchasing EDM machine parts ensures top-quality products. Their strict quality control and certification processes guarantee reliable and precise parts, essential for efficient EDM operations.

“SourcifyChina” offers competitive pricing without compromising on quality. Their strong relationships with suppliers and streamlined processes help keep costs low, benefiting buyers.

The factory provides comprehensive customer support, including pre-sales consultation and after-sales service. Their expert team assists buyers throughout the purchasing process, ensuring a smooth and satisfactory experience.

In summary, “SourcifyChina” Factory stands out for its quality assurance, competitive pricing, and excellent customer service, making it a reliable choice for EDM machine parts from China.

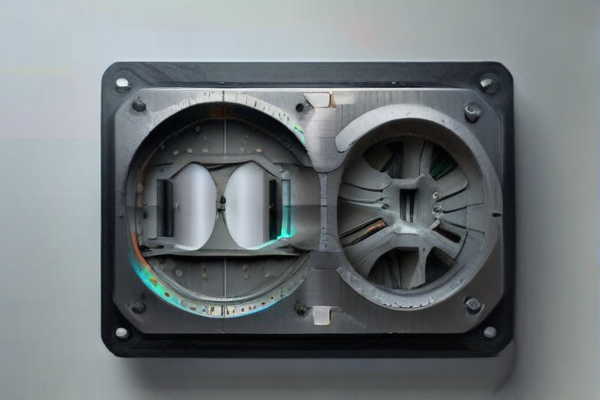

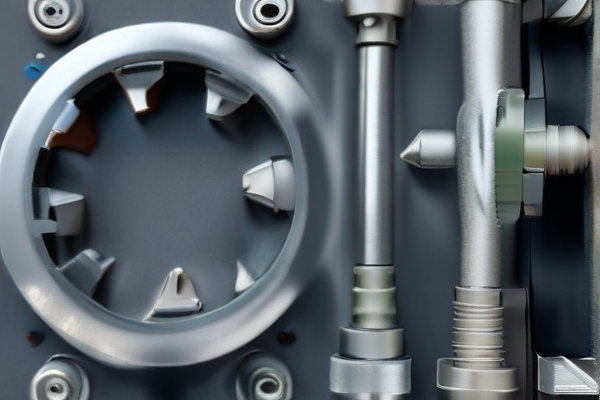

EDM (Electrical Discharge Machining) machine parts are essential for precision manufacturing. These parts include electrodes, filters, wires, power supplies, and dielectric fluids, each critical for the efficient operation of EDM machines.

Types and options for EDM machine parts include:

– Electrodes: Graphite, copper, and tungsten.

– Filters: Paper and wire mesh filters for dielectric fluids.

– Wires: Brass, coated, and composite wires.

– Power Supplies: High-frequency, low-frequency, and adaptive control power supplies.

– Dielectric Fluids: Hydrocarbon-based and deionized water.

– Guides and Nozzles: Diamond and carbide guides, various nozzle sizes.

– Workpiece Clamping Systems: Magnetic, hydraulic, and mechanical clamps.

– Flushing Systems: High-pressure and low-pressure options.

– Automation Components: Robotic arms, part loaders, and unloaders.

– Cooling Systems: Air-cooled and liquid-cooled systems.

Selecting the right combination of these parts ensures optimal performance, precision, and longevity of EDM machines, catering to various industrial applications.

EDM (Electrical Discharge Machining) machine parts are crucial in precision manufacturing, offering high accuracy and intricate detailing for hard metals and conductive materials. Their applications span various industries, enhancing production efficiency and product quality.

– Automotive Industry: Precision parts for engines, transmission systems, and molds.

– Aerospace Industry: Complex components for turbines, fuel systems, and structural parts.

– Medical Devices: Crafting surgical instruments, implants, and micro-electromechanical systems (MEMS).

– Electronics: Manufacturing connectors, semiconductors, and circuit components.

– Tool and Die Making: Producing high-precision dies, molds, and stamping tools.

– Watchmaking: Creating intricate parts for timepieces.

– Defense Industry: Precision components for firearms, missiles, and communication devices.

– Energy Sector: Parts for turbines, generators, and nuclear reactor components.

– Jewelry Making: Crafting detailed and delicate pieces.

– Prototyping and R&D: Producing high-precision prototypes for various applications.

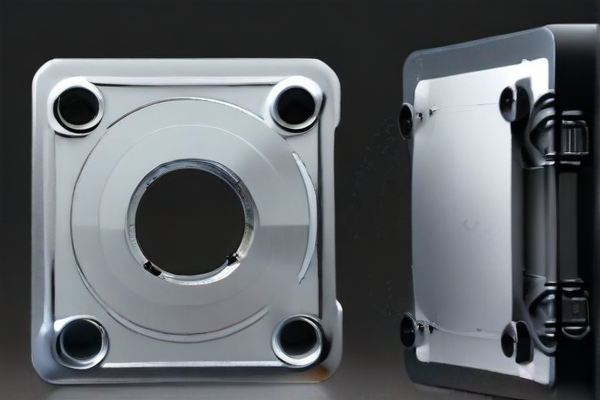

SourcifyChina’s EDM machine parts are crafted from high-grade, durable materials. The primary material used is tool steel, known for its exceptional strength and wear resistance, ensuring longevity and performance under high-stress conditions.

Tool steel’s composition includes alloys such as tungsten, molybdenum, and chromium, which enhance hardness and heat resistance. These properties make it ideal for precision parts in EDM (Electrical Discharge Machining) processes, where accuracy and durability are paramount.

In addition to tool steel, SourcifyChina also utilizes carbide materials. Carbide offers superior hardness and is used for components that require extreme precision and wear resistance, maintaining their integrity under high temperatures.

Quality control is rigorous, with materials undergoing thorough testing to meet industry standards. This ensures that every part produced by SourcifyChina meets the high demands of EDM applications, providing reliability and efficiency in industrial operations.

SourcifyChina’s commitment to quality and material excellence positions it as a trusted supplier in the EDM parts market. By leveraging advanced materials and stringent testing protocols, they deliver parts that enhance the performance and longevity of EDM machinery.

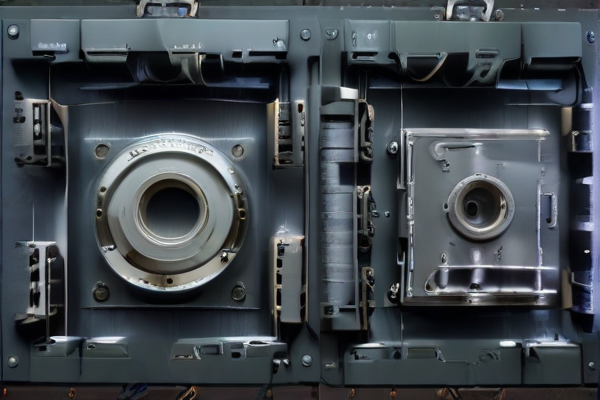

SourcifyChina employs a rigorous quality control process in the manufacturing of EDM machine parts. The process begins with the careful selection of raw materials, ensuring they meet industry standards and specifications.

Precision machining is executed using advanced equipment, maintaining tight tolerances and consistent quality. Each part undergoes thorough inspections at various stages of production to detect and correct any defects early.

State-of-the-art testing methods, including dimensional analysis and surface finish assessments, are applied to validate the integrity and performance of the components. Automated and manual inspections complement each other to achieve comprehensive quality assurance.

The final inspection stage involves a meticulous review of all parts to verify they meet the highest standards before shipment. Documentation and traceability are maintained throughout the process, ensuring transparency and accountability.

SourcifyChina’s commitment to continuous improvement ensures that their quality control processes evolve with technological advancements, maintaining their reputation for reliability and excellence in EDM machine parts manufacturing.

SourcifyChina specializes in the supply of high-quality EDM (Electrical Discharge Machining) machine parts, ensuring precision and durability. These components are essential for achieving accurate and smooth finishes in various manufacturing processes.

Their product range includes electrodes, guides, nozzles, and filters, catering to a wide array of EDM machines. SourcifyChina ensures compatibility with leading EDM brands, enhancing machine performance and lifespan.

Each part is meticulously crafted using advanced materials and manufacturing techniques. This attention to detail results in parts that withstand rigorous use, maintaining their integrity and functionality over extended periods.

SourcifyChina also emphasizes customization, offering tailored solutions to meet specific client requirements. This flexibility allows for optimization of EDM operations, increasing efficiency and productivity.

In addition to quality and customization, SourcifyChina provides excellent customer service. Their team of experts offers technical support and guidance, ensuring clients receive the right parts for their needs.

Overall, SourcifyChina’s EDM machine parts combine superior craftsmanship, versatility, and reliable support, making them a preferred choice for manufacturers seeking excellence in their EDM processes.

Electric Discharge Machining (EDM) machine parts offer numerous advantages, particularly in terms of precision, efficiency, and versatility in manufacturing complex components.

– High Precision: EDM allows for extremely accurate machining, making it ideal for producing intricate and detailed parts.

– Complex Shapes: Capable of creating complex geometries that are difficult or impossible to achieve with traditional machining methods.

– Hard Materials: Can machine very hard materials, such as titanium, carbide, and hardened steel, without compromising the tool’s integrity.

– Minimal Mechanical Stress: As there is no direct contact between the tool and the workpiece, there is minimal mechanical stress, reducing the risk of damage or deformation.

– Fine Surface Finish: Produces a superior surface finish, reducing the need for further machining or polishing.

– Reduced Tool Wear: Non-contact nature of the process leads to less tool wear, increasing the lifespan of the tools.

– Automation Compatibility: Easily integrated with CNC systems, allowing for automation and increased production efficiency.

– Low Heat Affected Zone: Minimal heat generated during the process reduces thermal distortion of the workpiece.

These benefits make EDM a preferred choice for manufacturing high-precision parts in industries like aerospace, medical, and automotive.

Electrical Discharge Machining (EDM) machine parts offer precision and versatility for complex machining tasks. These parts are critical for creating intricate and high-precision components in various industries.

– High Precision: EDM machine parts provide exceptional accuracy, often reaching tolerances within microns.

– Complex Geometries: Capable of producing complex shapes and fine details that traditional machining cannot achieve.

– Material Versatility: Can work with hard and conductive materials like hardened steel, tungsten carbide, and titanium.

– Minimal Mechanical Stress: As a non-contact machining process, it minimizes mechanical stresses on the workpiece.

– Surface Finish: Produces superior surface finishes with minimal need for secondary processes.

– Automated Operations: Advanced EDM machines support automation, enhancing productivity and reducing human error.

– Tool Wear: Reduced tool wear compared to traditional machining, leading to cost savings.

– Temperature Control: Effective in managing thermal effects, preventing warping and deformation.

– Precision Holes: Ideal for drilling small, precise holes, often used in aerospace and medical devices.

– No Burr Formation: Leaves clean edges with no burrs, reducing the need for additional finishing steps.

Overall, EDM machine parts are integral to modern manufacturing, enabling the production of highly detailed and precise components across various industries.

SourcifyChina specializes in custom EDM machine parts, offering precision-engineered components tailored to diverse industry needs. They provide high-quality, reliable products that enhance the performance and lifespan of EDM machines.

Their range includes custom electrodes, fixtures, and wear parts, all manufactured to exact specifications. SourcifyChina uses advanced technology and stringent quality control to ensure each part meets rigorous standards.

They cater to various sectors, including automotive, aerospace, and electronics, ensuring versatile solutions for complex machining tasks. Their products are designed to improve efficiency and reduce downtime in manufacturing processes.

SourcifyChina also undertakes bespoke projects, collaborating closely with clients to deliver innovative and effective EDM solutions. This customer-centric approach ensures tailored support for unique project requirements.

Their commitment to quality and customer satisfaction positions SourcifyChina as a trusted partner in the EDM industry. Their expertise and dedication ensure the successful completion of projects, providing optimal value and performance.

SourcifyChina is a specialized company that provides high-quality EDM (Electrical Discharge Machining) machine parts, serving a diverse range of industries that require precision engineering solutions. Renowned for its reliability and technological expertise, SourcifyChina offers an extensive inventory of parts designed to enhance the performance and longevity of EDM machines. The company focuses on delivering exceptional value through stringent quality control processes, ensuring that every component meets rigorous industry standards. By leveraging advanced manufacturing techniques and maintaining a strong commitment to customer satisfaction, SourcifyChina has established itself as a trusted partner for businesses seeking durable and efficient EDM machine parts. Additionally, their dedicated support team offers technical assistance and guidance, helping clients optimize their machining operations and achieve superior results. With a reputation for excellence and a commitment to continuous innovation, SourcifyChina is at the forefront of the EDM parts industry, providing solutions that drive productivity and precision.

Electrical Discharge Machining (EDM) is a critical manufacturing process in the aerospace, defense, and marine industries due to its precision and ability to work with hard materials. In aerospace applications, EDM is employed to produce intricate components such as turbine blades, fuel system parts, and landing gear components. These parts often require high precision and the ability to maintain structural integrity under extreme conditions, which EDM’s non-contact nature facilitates by minimizing mechanical stresses. The process is particularly valuable for working with superalloys and composites commonly used in aerospace engineering, ensuring the reliability and safety of aircraft.

In the defense sector, EDM is crucial for manufacturing complex and high-tolerance components such as missile guidance systems, armor plating, and weaponry. The process’s accuracy and consistency ensure that these critical components meet stringent defense standards. In marine applications, EDM is used to produce parts for submarines, ships, and offshore platforms. This includes components like propeller blades, engine parts, and various custom fixtures that require corrosion-resistant materials. The precision and versatility of EDM help maintain the performance and longevity of marine vessels, particularly in harsh oceanic environments where durability is essential. Overall, EDM’s ability to machine hard materials with high precision makes it indispensable across these demanding industries.

Electrical Discharge Machining (EDM) is a crucial technology in the automotive industry, primarily for producing intricate parts with high precision. EDM machine parts are essential for creating components such as fuel injectors, transmission parts, and turbochargers. These parts require tight tolerances and complex geometries that are challenging to achieve with traditional machining methods. The non-contact nature of EDM minimizes mechanical stress on delicate materials, ensuring the durability and reliability of the automotive parts. Additionally, EDM is vital in producing molds and dies used in manufacturing automotive body panels and other critical components, enhancing the overall quality and performance of vehicles.

In the electronics industry, EDM machine parts play a significant role in fabricating intricate and precise components necessary for modern electronic devices. EDM is instrumental in the production of microelectronic components, including connectors, lead frames, and semiconductor components. The ability of EDM to work with hard and brittle materials like tungsten and silicon makes it indispensable for manufacturing parts that are essential for electronic devices. Furthermore, EDM enables the production of detailed and complex shapes required in printed circuit boards (PCBs) and micro-electromechanical systems (MEMS), ensuring high accuracy and repeatability. The precision and efficiency of EDM significantly contribute to the advancement and miniaturization of electronic technologies.

Electrical discharge machining (EDM) plays a crucial role in the construction industry by enabling the precise creation of complex and high-tolerance parts that are essential for modern construction machinery and equipment. EDM machine parts are used to fabricate custom components for heavy-duty machines such as cranes, excavators, and bulldozers. These components, which include intricate gears, cutting tools, and hydraulic parts, demand high precision and durability to withstand the harsh conditions of construction sites. EDM’s ability to cut hard materials without inducing thermal stress or deformation ensures that these parts maintain their integrity and performance over extended periods, contributing to the reliability and efficiency of construction operations.

In the energy sector, EDM machine parts are indispensable for the manufacturing and maintenance of critical components in power generation and distribution systems. The precision and accuracy of EDM are particularly beneficial in producing turbine blades, fuel injector nozzles, and intricate cooling channels for gas and steam turbines used in power plants. These components require extremely tight tolerances and smooth surface finishes to operate efficiently and safely under high-pressure and high-temperature conditions. Additionally, EDM is used to produce parts for renewable energy systems, such as molds for solar panel production and components for wind turbine gearboxes. The technology’s capability to work with hard and exotic materials ensures that energy systems are robust, reliable, and capable of meeting the demands of modern energy production.

Electrical Discharge Machining (EDM) parts play a pivotal role in the industrial equipment sector, offering unparalleled precision and efficiency in manufacturing complex components. EDM machines utilize electric discharges to erode material from a workpiece, enabling the creation of intricate shapes and fine details that traditional machining methods cannot achieve. This capability is especially critical in industries like aerospace, automotive, and medical device manufacturing, where the demand for precision-engineered parts is paramount. EDM machining is employed to fabricate components such as turbine blades, fuel injection nozzles, and prosthetic devices, which require extreme accuracy and high-quality finishes. This method’s ability to process hard materials like titanium and carbide without compromising structural integrity makes it indispensable for producing high-stress parts that must meet stringent performance standards.

Moreover, the use of EDM machine parts in the industrial equipment industry significantly enhances production efficiency and operational flexibility. By utilizing EDM technology, manufacturers can reduce tooling costs and setup times because the process does not require custom tooling for each new part design. This allows for rapid prototyping and quick adaptations to design changes, which is crucial in dynamic industrial environments. Additionally, EDM machining minimizes thermal damage to the material, preserving the mechanical properties of high-performance alloys. Consequently, companies can maintain tighter tolerances and deliver higher quality products, ultimately driving innovation and competitiveness in the marketplace. The strategic application of EDM machine parts thus not only boosts manufacturing capabilities but also helps industries meet the evolving demands for more sophisticated and reliable equipment.

Electrical discharge machining (EDM) machine parts play a crucial role in the manufacturing of medical devices, where precision and reliability are paramount. EDM technology allows for the creation of complex, high-tolerance components that are often required in medical devices such as implants, surgical instruments, and diagnostic equipment. The process involves using electrical discharges to shape hard metals and conductive materials into intricate geometries that are difficult or impossible to achieve with traditional machining methods. This capability is particularly beneficial in producing parts with tight tolerances and fine finishes, ensuring that medical devices meet strict regulatory standards and perform reliably in critical applications.

Furthermore, EDM machine parts enable the production of customized medical devices tailored to individual patient needs. For example, in orthopedic surgery, patient-specific implants can be created to match the unique anatomy of a patient, enhancing the fit and effectiveness of the implant. The precision of EDM allows for the fabrication of micro-scale features and complex internal geometries that are essential in minimally invasive surgical tools and advanced diagnostic devices. This level of customization and precision contributes to better patient outcomes, faster recovery times, and overall improvements in the quality of healthcare. The versatility and accuracy of EDM machining make it an indispensable tool in the medical device manufacturing industry.

Electrical Discharge Machining (EDM) is a crucial technology in the realm of machining and manufacturing, particularly for producing intricate and high-precision parts. EDM machines utilize electrical discharges or sparks to erode material from a workpiece, allowing for the creation of complex geometries that are difficult or impossible to achieve with traditional machining methods. This process is especially valuable for machining hard materials like tool steel, titanium, and superalloys, which are commonly used in aerospace, medical, and automotive industries. The capability of EDM to produce parts with tight tolerances and excellent surface finishes makes it indispensable for applications requiring high precision, such as mold and die making, fine hole drilling, and the creation of intricate shapes in hardened materials.

In manufacturing, EDM machine parts play a vital role in enhancing productivity and quality. These parts include critical components such as electrodes, wire guides, power supplies, and dielectric fluid systems. The precision and reliability of these components directly impact the efficiency and accuracy of the EDM process. For instance, high-quality electrodes ensure consistent spark erosion, leading to uniform material removal and superior surface integrity. Similarly, advanced wire guides and power supplies enhance cutting speed and accuracy in wire EDM operations. The integration of EDM in manufacturing processes not only improves the ability to produce complex parts but also reduces the need for secondary finishing operations, thereby streamlining production workflows and reducing overall costs.

1. What materials are used for EDM machine parts at SourcifyChina?

We use high-quality materials such as tungsten carbide, copper, brass, and graphite, tailored to meet specific customer requirements and ensure optimal performance.

2. How does SourcifyChina ensure the quality of EDM machine parts?

We implement strict quality control measures, including ISO 9001:2015 certification, in-process inspections, and final quality checks using advanced measuring instruments.

3. What is the typical lead time for EDM machine parts production?

The lead time varies based on the complexity and quantity of the order. Generally, it ranges from 2 to 6 weeks after order confirmation.

4. Can SourcifyChina handle custom designs for EDM machine parts?

Yes, we specialize in custom designs. Our engineering team works closely with clients to develop parts that meet precise specifications and performance criteria.

5. What are the tolerances SourcifyChina can achieve for EDM parts?

We can achieve tight tolerances up to ±0.005mm, ensuring high precision and performance in critical applications.

6. Does SourcifyChina offer prototyping services for EDM parts?

Yes, we provide prototyping services to help clients validate designs before full-scale production, ensuring the parts meet all functional and quality standards.

7. What types of EDM machines are compatible with your parts?

Our parts are compatible with a wide range of EDM machines, including wire EDM, sinker EDM, and hole drilling EDM.

8. How does SourcifyChina handle shipping and logistics?

We offer comprehensive shipping solutions, including international shipping. Our logistics team ensures safe and timely delivery of parts worldwide.

9. What industries does SourcifyChina serve with EDM machine parts?

We serve diverse industries such as aerospace, automotive, medical, electronics, and mold making, providing tailored solutions for each sector’s unique needs.

10. How can I get a quote for EDM machine parts from SourcifyChina?

You can request a quote by contacting our sales team via email or through our website. Provide detailed specifications and quantities for an accurate quote.

When considering EDM (Electrical Discharge Machining) machine parts manufacturing from SourcifyChina factory, here are some key tips to ensure a successful partnership:

1. Understand EDM Technology: EDM is a precision machining method ideal for complex shapes and hard materials. Ensure you comprehend the process and its capabilities to effectively communicate your needs.

2. Assess Capabilities: Verify that SourcifyChina has experience and expertise in producing the specific EDM parts you need. Check for certifications, past projects, and client testimonials.

3. Material Quality: EDM is often used on hard metals and exotic materials. Confirm that the factory sources high-quality, suitable materials to meet your specifications and standards.

4. Precision and Tolerances: Precision is critical in EDM. Ensure the factory can meet the required tolerances and surface finishes for your parts. Request samples or case studies to verify their precision capabilities.

5. Advanced Equipment: Inquire about the EDM machinery and technology used by SourcifyChina. Modern, well-maintained equipment ensures higher efficiency and accuracy.

6. Cost and Lead Time: Discuss pricing structures and lead times upfront. SourcifyChina should provide transparent pricing and realistic timelines based on your order volume and complexity.

7. Quality Control: Quality assurance processes are essential. Ensure that SourcifyChina has robust inspection and testing procedures, such as in-process inspections and final product checks.

8. Communication: Clear, consistent communication is vital for overseas manufacturing. Ensure that SourcifyChina offers reliable points of contact and regular updates on production status.

9. Intellectual Property Protection: Protect your designs and IP. Ensure that SourcifyChina has appropriate measures in place to safeguard your proprietary information.

10. Logistics and Shipping: Discuss logistics and shipping arrangements to ensure smooth delivery. Understand customs procedures, shipping costs, and timelines for international shipping.

By focusing on these aspects, you can effectively collaborate with SourcifyChina to manufacture high-quality EDM machine parts.

1. What types of EDM machine parts does SourcifyChina offer?

SourcifyChina provides a wide range of EDM machine parts, including wire EDM consumables, electrodes, filters, and various replacement parts for different EDM machine brands.

2. How can I place an order for EDM machine parts from SourcifyChina?

You can place an order by visiting the SourcifyChina website, contacting their sales team via email or phone, or through their online ordering system. Ensure you have detailed specifications and quantities ready.

3. What is the typical lead time for orders?

The lead time varies depending on the part’s availability and order size. Standard parts are usually shipped within 1-2 weeks, while custom or bulk orders may take longer.

4. Does SourcifyChina provide custom parts manufacturing?

Yes, SourcifyChina offers custom manufacturing services for EDM machine parts based on your specific requirements. You need to provide detailed technical drawings or samples.

5. What quality control measures are in place?

SourcifyChina follows stringent quality control protocols, including material inspection, precision testing, and final product inspection to ensure high-quality parts.

6. Are there minimum order quantities (MOQs) for purchases?

MOQ policies depend on the specific part and order size. It is best to consult with the sales team for details on MOQs for your desired parts.

7. What payment methods does SourcifyChina accept?

SourcifyChina accepts various payment methods, including wire transfers, PayPal, and major credit cards. Payment terms can be discussed during the order process.

8. Can SourcifyChina ship internationally?

Yes, SourcifyChina ships internationally. They work with various logistics partners to ensure timely and cost-effective delivery to your location.

9. How can I track my order?

Once your order is shipped, SourcifyChina provides a tracking number and details via email. You can track the shipment through their logistics partner’s website.

10. What should I do if I receive damaged or incorrect parts?

In case of any issues with your order, contact SourcifyChina’s customer service immediately. They will guide you through the return or replacement process.

Sourcing EDM machine parts from SourcifyChina factory requires a strategic approach to ensure quality and reliability. Here are some tips:

1. Define Requirements: Clearly specify the parts you need, including material, dimensions, tolerances, and any other technical specifications. This will help the supplier understand your needs accurately.

2. Research Suppliers: Look into SourcifyChina’s reputation and track record. Check for certifications, customer reviews, and industry experience to ensure they can meet your standards.

3. Request Quotes: Contact SourcifyChina with detailed RFQs (Request for Quotes). Provide all necessary specifications and request a breakdown of costs, including shipping, taxes, and any potential extra fees.

4. Sample Testing: Before placing a large order, request samples to evaluate the quality of the parts. Test these samples under actual working conditions to ensure they meet your performance requirements.

5. Negotiate Terms: Discuss payment terms, lead times, and minimum order quantities. Establish clear agreements on delivery schedules and penalties for delays or defects.

6. Quality Assurance: Verify SourcifyChina’s quality control processes. Ask for documentation on their QA procedures, and consider arranging third-party inspections.

7. Communication: Maintain open and clear communication with SourcifyChina. Use detailed and unambiguous language to avoid misunderstandings. Regular follow-ups can ensure the process stays on track.

8. Legal and Compliance: Ensure that all transactions comply with both local and international trade laws. Have a clear contract outlining all terms and conditions, including intellectual property protections if necessary.

9. Shipping and Logistics: Plan the logistics for shipping the parts from China to your location. Consider using a reputable logistics provider to handle customs clearance and delivery efficiently.

10. Build a Relationship: Developing a strong relationship with SourcifyChina can lead to better terms, priority service, and potentially lower costs over time.

By following these steps, you can effectively source high-quality EDM machine parts from SourcifyChina, minimizing risks and ensuring smooth procurement.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)