Technology and Applications of electrical discharge machine

Electrical Discharge Machining (EDM) is a non-traditional machining process that utilizes electrical discharges or sparks to remove material from a workpiece. This technique is particularly effective for hard materials and complex shapes that are difficult to machine with conventional methods.

Technology of EDM:

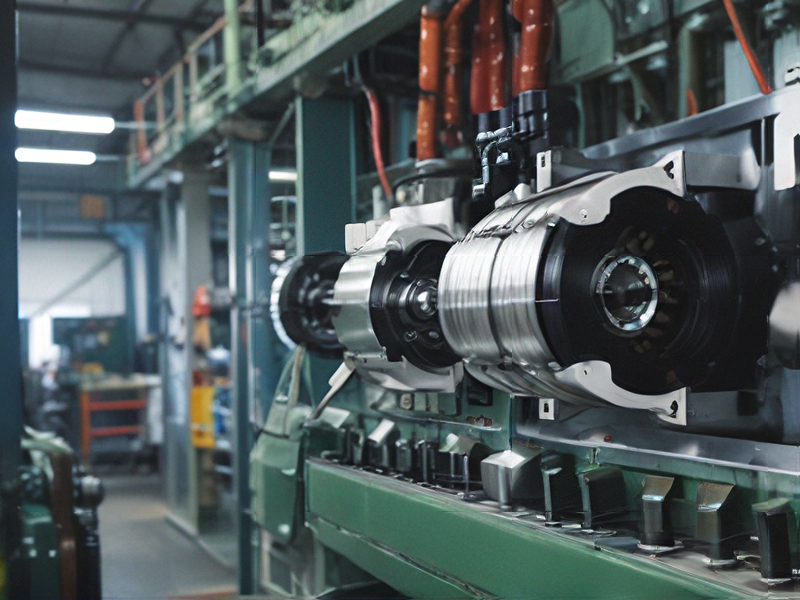

EDM operates on the principle of spark erosion. It involves the creation of a series of controlled electrical discharges between an electrode and the workpiece immersed in a dielectric fluid, which cools the process and flushes away debris. The electrode can be made from materials like copper or graphite. Two primary types of EDM are:

1. Wire EDM: A thin wire acts as the electrode, fed continuously to cut through the material. It is ideal for precise and intricate shapes.

2. Sinker EDM: A shaped electrode is used to create cavities or contours in the workpiece.

Applications of EDM:

EDM is widely used across various industries due to its ability to produce intricate designs with high precision. Key applications include:

– Tool and Die Making: Creating complex shapes and molds for manufacturing processes.

– Aerospace Industry: Machining components with tight tolerances and complex geometries.

– Medical Devices: Producing precise instruments and implants.

– Automotive Industry: Manufacturing specialized parts that require intricate details.

The advantages of EDM include minimal mechanical stress on the workpiece, high precision, and the ability to machine hard materials. However, it requires a detailed understanding of the process parameters to optimize efficiency and surface finish.

In conclusion, EDM is a crucial technology in modern manufacturing, enabling the production of precision components across diverse sectors.

Quality Testing Methods for electrical discharge machine and how to control quality

Quality testing for Electrical Discharge Machines (EDM) is essential for ensuring precision and reliability in manufacturing. Here are key testing methods and quality control measures:

Testing Methods:

1. Dimensional Accuracy Check:

Utilize precision measurement tools like CMM (Coordinate Measuring Machine) to measure the machined parts’ dimensions against the technical specifications.

2. Surface Finish Inspection:

Employ surface roughness testers (e.g., Mitutoyo) to assess the finish of the workpiece. Optimal surface quality is crucial for features like tolerances and part functionality.

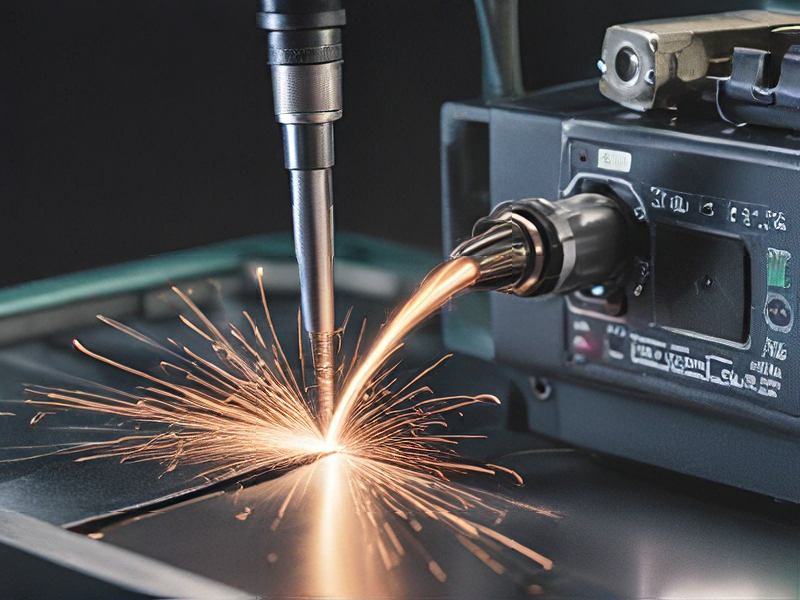

3. Spark Test:

Conduct spark tests to evaluate the machine’s discharge circuit performance. This involves analyzing spark characteristics, which can indicate wear or improper settings.

4. Thermal Testing:

Monitor the temperature of the machine components during operation. Excessive heat can indicate inefficiencies or potential overloads.

5. Tool Wear Assessment:

Observe and measure electrode wear to predict tool life and adjust operations to minimize costs and maintain quality.

Quality Control Measures:

1. Standard Operating Procedures (SOPs):

Develop and adhere to detailed SOPs for machining processes to ensure consistent operation.

2. Regular Calibration:

Implement a calibration schedule for all measuring instruments and machines to guarantee accuracy.

3. In-Process Monitoring:

Utilize real-time monitoring systems that collect data on machining parameters (e.g., current, voltage) to detect anomalies immediately.

4. Statistical Process Control (SPC):

Apply SPC techniques to analyze data trends and variations, which helps in identifying potential quality issues early.

5. Training and Competency Development:

Ensure operators are well-trained in both machine operation and quality standards. Consistent training minimizes human error and enhances output quality.

By integrating these quality testing methods and control measures, EDM operations can achieve high precision, improve part quality, and reduce rework, leading to overall enhanced manufacturing efficiency.

Tips for Procurement and Considerations when Purchasing from electrical discharge machine

When procuring an electrical discharge machine (EDM), consider the following tips to ensure a successful purchase:

1. Define Requirements: Clearly outline your project needs, including part sizes, materials, precision levels, and tolerance requirements. This will help you select a machine that meets your operational demands.

2. Technology Type: Decide between sinker (traditional) EDM and wire EDM based on your application. Sinker EDM is suitable for complex cavities, while wire EDM excels in cutting intricate profiles.

3. Budget Constraints: Establish a clear budget, considering not only the initial purchase price but also operation, maintenance, and potential downtime costs.

4. Supplier Reputation: Research manufacturers and suppliers. Look for established companies with positive reviews, robust customer service, and a history of reliable machine performance.

5. Machinery Specifications: Evaluate key specifications such as power output, electrode size compatibility, machining speed, and precision. Ensure the machine can handle your specific materials (e.g., hardened steel, titanium).

6. Maintenance and Support: Inquire about warranty, availability of spare parts, and technical support. A reliable support network can minimize downtime and extend machine longevity.

7. Training and Documentation: Ensure that the supplier provides comprehensive training and clear operational manuals. Proper training can enhance efficiency and reduce the risk of operator errors.

8. Operational Efficiency: Assess the machine’s efficiency features, like automation, user interface, and software compatibility. Automated functions can significantly speed up processes and improve output quality.

9. Demo and Trial: Whenever possible, request a live demonstration or a trial period to evaluate the machine’s performance in your specific environment.

By considering these factors, you can make an informed decision that enhances your shop’s capabilities and productivity.

FAQs on Sourcing and Manufacturing from electrical discharge machine in China

FAQs on Sourcing and Manufacturing with Electrical Discharge Machines (EDM) in China

1. What are Electrical Discharge Machines (EDM)?

EDM is a manufacturing process that uses electrical discharges (sparks) to remove material from a workpiece, allowing for precise machining of complex shapes and hard materials.

2. Why source EDM parts from China?

China offers competitive pricing, a wide range of manufacturing capabilities, and access to advanced technologies. Many manufacturers in China specialize in EDM, ensuring high-quality production.

3. How to find reliable EDM manufacturers in China?

Start by researching reputable websites, trade shows, and industry forums. Verify manufacturers’ credentials, request samples, and check customer reviews. Consider platforms like Alibaba or Made-in-China for supplier listings.

4. What should I consider when evaluating EDM suppliers?

Assess their technical capabilities, equipment used, production capacity, quality control processes, and communication skills. Request detailed quotations and timelines.

5. What are the typical lead times for EDM manufacturing in China?

Lead times can vary based on complexity and order volume, typically ranging from 2 to 8 weeks for prototypes and around 6 to 12 weeks for higher volume production.

6. How can I ensure quality control when sourcing EDM parts?

Implement a quality management system and conduct regular inspections. You may also consider hiring third-party inspection services to verify product quality before shipment.

7. What are the shipping considerations?

Plan for customs duties, import regulations, and shipping methods. Research logistics companies experienced in international shipping to ensure timely delivery.

8. What are payment and contract considerations?

Negotiate clear payment terms and ensure contracts outline quality standards, timelines, and recourse for defects to protect your investment.

For more detailed inquiries, consider consulting industry experts or sourcing agents familiar with EDM manufacturing in China.