SourcifyChina excels in providing top-notch end milling machines, ensuring high-quality production standards. Their rigorous quality control processes guarantee reliable and durable machines that meet global standards, which is essential for any serious buyer.

Choosing SourcifyChina streamlines the purchasing process, offering expert guidance from start to finish. They handle everything from factory audits to shipping logistics, reducing the buyer’s workload and minimizing risks associated with international transactions.

Competitive pricing is another advantage of SourcifyChina. By leveraging strong relationships with manufacturers and understanding market dynamics, they can offer fair and cost-effective prices without compromising on quality.

SourcifyChina values customer satisfaction, providing exceptional after-sales support. Their dedicated team is readily available to address any issues, ensuring smooth operations and maintaining the integrity of the buyer’s investment.

Ultimately, SourcifyChina stands out as a reliable partner for purchasing end milling machines from China. Their commitment to quality, streamlined processes, competitive pricing, and excellent customer support make them an optimal choice for savvy buyers.

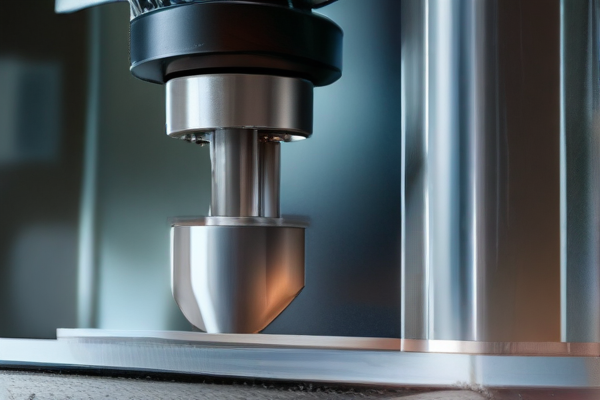

End milling machines are versatile tools used in manufacturing to cut and shape materials. They come in various types tailored for specific tasks, enhancing precision and efficiency in machining operations.

– Horizontal End Milling Machines: Ideal for heavy-duty milling, with a horizontally oriented spindle.

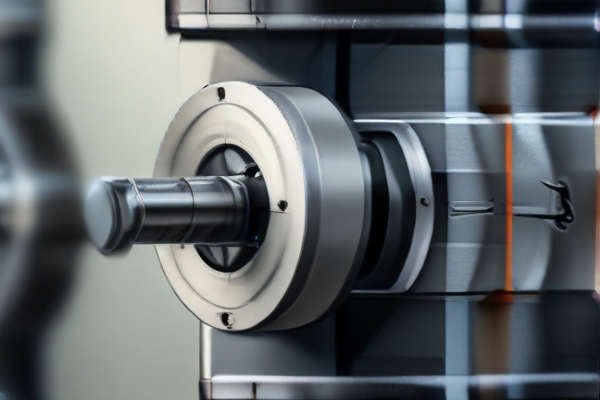

– Vertical End Milling Machines: Commonly used for lighter, versatile tasks; feature a vertically oriented spindle.

– Universal End Milling Machines: Combine features of both horizontal and vertical types, suitable for complex tasks.

– CNC End Milling Machines: Offer automated, highly precise operations with programmable controls.

– Turret Milling Machines: Equipped with a turret to move in various directions, ideal for versatile tasks.

– Ram-Type Milling Machines: Feature a movable housing tower, offering flexibility in positioning.

– Gantry Milling Machines: Suitable for large-scale or heavy materials, with a bridge-like structure.

– Bed-Type Milling Machines: Offer a fixed spindle and a table movement for sturdy and stable milling.

Options and Features:

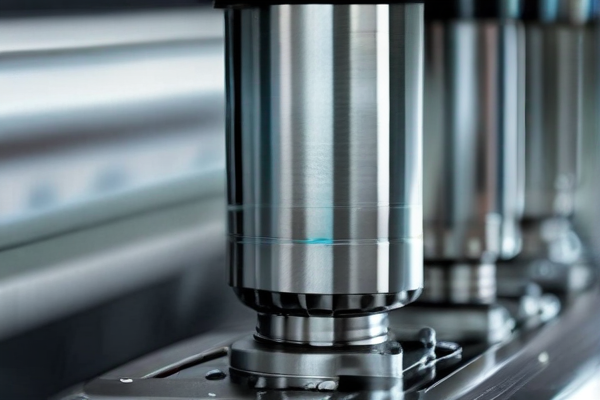

– Spindle Speed Control: Adjustable speeds for different materials and precision requirements.

– Tool Changers: Automatic tool changers to enhance productivity and reduce downtime.

– Coolant Systems: Integral coolant systems to manage heat and prolong tool life.

– Precision Scales: Digital readouts and precision scales for accurate measurements.

– Workholding Solutions: Various clamps, vises, and fixtures to secure workpieces.

– Axis Travel: Various X, Y, and Z axis travel distances to accommodate different sizes of material.

– Software Compatibility: CNC models often compatible with a variety of CAD/CAM software for complex designs.

– Dust Collection: Integrated dust collection systems to maintain a clean working environment.

– Automation: Options for full automation with robotic arms and advanced control systems.

End milling machines enhance production capabilities with their wide range of types and numerous options, making them indispensable in modern machining environments.

End milling machines are essential tools in manufacturing, used for creating complex shapes, slots, and holes. They are integral in producing parts with high precision and smooth finishes in various industries.

Applications of End Milling Machines:

– Automotive Industry: Manufacturing gears, engine parts, and various components.

– Aerospace Industry: Producing aircraft parts, turbine blades, and structural components.

– Medical Devices: Crafting surgical instruments and prosthetic parts.

– Tool and Die Making: Creating molds, dies, and custom tools.

– Electronics: Fabricating parts for electronic devices and enclosures.

– Metalworking: Cutting, finishing, and deburring metal parts.

– Plastic Processing: Shaping and refining plastic components.

– Woodworking: Producing intricate designs and joineries.

– Jewelry Making: Crafting detailed and delicate jewelry pieces.

– Consumer Goods Manufacturing: Creating precision parts for appliances and gadgets.

– Defense Industry: Manufacturing components for weapons and military equipment.

– Telecommunication: Producing parts for communication devices and infrastructure.

– Renewable Energy: Fabricating components for wind turbines and solar panels.

– Robotics: Producing parts for automated systems and robots.

– Prototyping: Developing prototype models for new products.

– Custom Manufacturing: Tailoring parts for specific, non-standard applications.

– Education and Research: Used in labs for developing new materials and technologies.

– Sports Equipment: Crafting components for high-performance sporting gear.

– Furniture Making: Creating detailed and precision wood joints and components.

– Art and Sculpture: Producing intricate designs and artistic pieces.

End milling machines offer versatility across various fields, enhancing production efficiency and enabling the creation of detailed, high-precision parts.

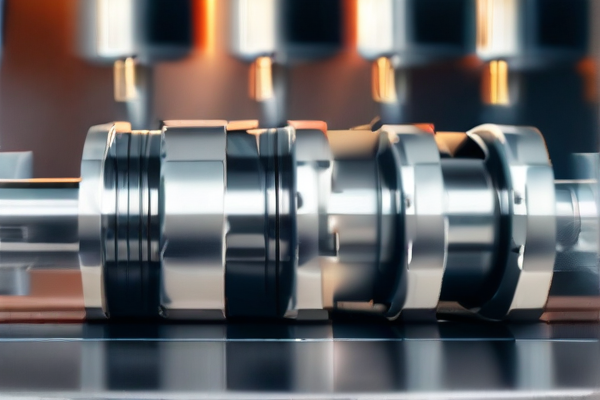

SourcifyChina’s end milling machines boast exceptional quality materials designed for precision and durability. The primary construction material is high-grade cast iron, known for its excellent vibration damping and stability during machining processes.

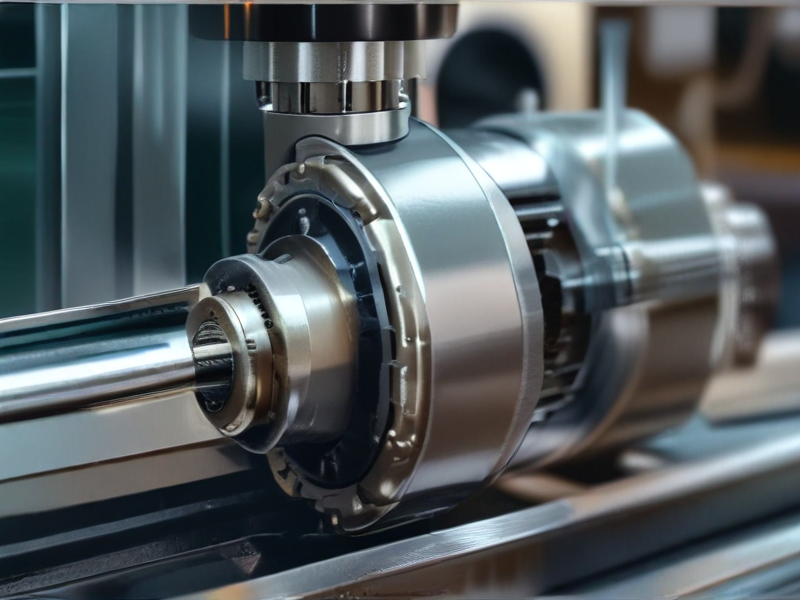

The machine’s spindles are crafted from hardened steel, providing necessary rigidity and surface toughness. This choice ensures longevity while maintaining tight tolerances even under heavy loads. High-speed bearings support the spindles, contributing to reduced friction and wear.

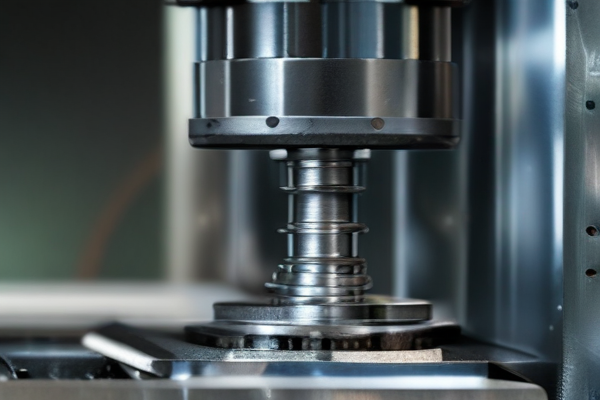

The cutting tools used are typically carbide-tipped, delivering superior cutting performance and a longer lifespan compared to conventional steel tools. This material choice supports high-speed operations and ensures fine, accurate finishes.

Additionally, the guideways are often hardened and ground, enhancing smoothness and reducing long-term wear. These meticulous material selections contribute to consistent performance, making SourcifyChina’s end milling machines reliable and efficient for various industrial applications.

Furthermore, the incorporation of high-quality electronic components, such as servo motors and control systems, enhances precision and operability. These elements ensure that the machines meet the sophisticated demands of modern manufacturing.

In summary, the comprehensive use of high-grade materials in the construction of SourcifyChina’s end milling machines results in robust, reliable, and precision-oriented equipment, capable of meeting the rigorous standards of today’s manufacturing environments.

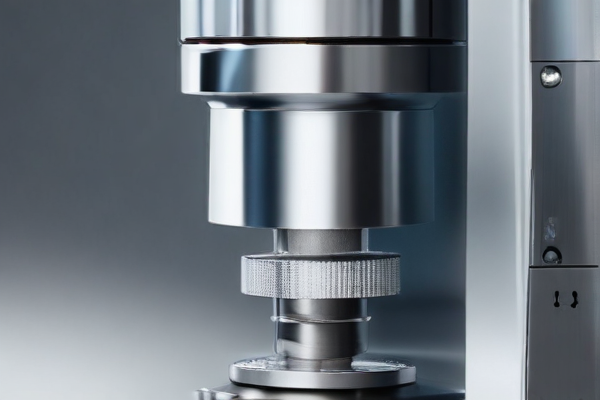

SourcifyChina’s end milling machines undergo a meticulous quality control process, ensuring superior product performance. It begins with the careful selection of premium raw materials, sourced from trusted suppliers to guarantee durability.

Precision machining is utilized during the manufacturing stages. CNC technology ensures that each machine component meets stringent dimensional accuracy standards. Rigorous inspections at each step prevent errors and maintain consistency.

To verify functionality, each end milling machine undergoes extensive testing, including load and performance trials. Engineers use stress tests to simulate real-world conditions, ensuring reliability and efficiency in various applications.

Final assembly is completed by skilled technicians who adhere to strict protocols. Every unit is subjected to a comprehensive quality check to eliminate defects, ensuring each machine meets international certifications.

SourcifyChina’s dedication to quality control doesn’t end at the factory door. They implement feedback loops with customers to continuously improve and maintain high standards. This commitment fosters trust and satisfaction among their global clientele.

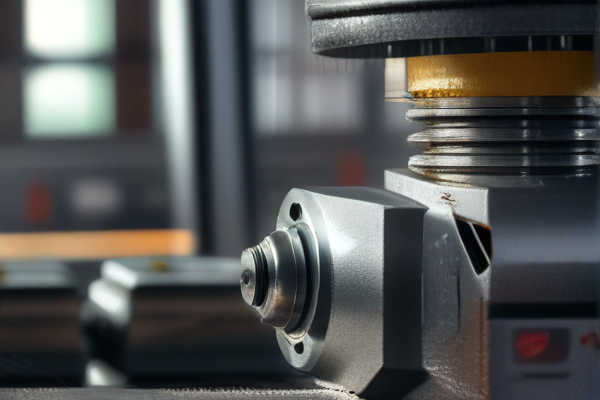

SourcifyChina end milling machines are renowned for their precision and efficiency. They are equipped with advanced CNC technology, allowing for accurate cutting and shaping of complex geometries.

These machines boast robust construction, ensuring durability and stability even during heavy-duty operations. Their high-speed spindles significantly reduce production time, enhancing overall productivity.

SourcifyChina end milling machines offer versatile tooling options, accommodating various materials such as metals, plastics, and composites. This versatility makes them suitable for a wide range of industrial applications.

The user-friendly interface and smart control systems facilitate easy operation and quick setup, minimizing downtime and maximizing efficiency. They also incorporate advanced cooling systems to extend tool life.

Additionally, these machines are designed with safety features, ensuring operator protection and reducing the risk of accidents. This commitment to safety further underscores their reliability in demanding production environments.

End milling machines from SourcifyChina also include features like automatic tool changers and real-time monitoring. This ensures continuous operation and optimizes machining processes for higher throughput.

In essence, SourcifyChina end milling machines blend cutting-edge technology with robust performance, making them an invaluable asset in precision engineering tasks. They promise consistent results, enhancing both quality and output.

End Milling Machine Benefits

End milling machines offer precise shaping and cutting capabilities, significantly enhancing manufacturing efficiency and versatility. These machines are indispensable in numerous industries.

– Precision and Accuracy: End milling machines enable highly accurate and detailed cuts, ensuring consistency and uniformity in manufacturing processes.

– Versatility: Suitable for a wide range of materials, including metals, plastics, and wood, making them applicable across various industrial sectors.

– Efficiency: High-speed operations reduce production time, allowing for increased output and quicker project completion.

– Cost-Effectiveness: By minimizing material waste and reducing manual labor, end milling machines lower production costs.

– Complex Designs: Capable of intricate and complex geometries, making them ideal for advanced manufacturing needs such as aerospace and automotive parts.

– Automation: Many models come with CNC capabilities, which enhance automation, reduce human error, and enable repeatability.

– Durability: Modern end milling machines are built to withstand rigorous industrial environments, providing long-term reliability.

– Enhanced Surface Finish: Achieves smooth and refined surface finishes, often eliminating the need for additional finishing processes.

– Safety: Equipped with advanced safety features to protect operators, ensuring a safer working environment.

– Customization: Allows for custom tooling setups to meet specific project requirements, enhancing overall productivity and flexibility.

By leveraging these benefits, industries can achieve higher quality products, faster turnaround times, and more efficient operations, ultimately driving competitive advantage.

End milling machines are versatile tools widely used in manufacturing for creating complex shapes and precision components. They offer advanced features for efficient and accurate material removal.

– Spindle Speed & Power: Adjustable spindle speeds and high power capabilities to handle various materials.

– Cutting Tool Compatibility: Supports a multitude of cutting tools for different operations.

– Table Size & Movement: Large, precisely controlled tables for accommodating and manipulating workpieces of various sizes.

– Axis Control: Typically offer 3 to 5 axes of movement for complex geometries.

– CNC Integration: Many end milling machines are CNC-controlled for enhanced precision, repeatability, and ease of automation.

– Coolant Systems: Integrated coolant systems to prolong tool life and improve cutting efficiency.

– Digital Readout (DRO): Accurate digital readout systems for precise measurements and positioning.

– Safety Features: Includes guards, emergency stop buttons, and automatic shutoff to ensure user safety.

– Tool Changers: Automatic tool changers for increased efficiency in operations requiring multiple tools.

– Stability & Rigidity: Robust construction to minimize vibrations and enhance machining accuracy.

– User-Friendly Interface: Intuitive controls and interfaces for easier setup and operation.

These features collectively contribute to the versatility and effectiveness of end milling machines in various machining operations.

SourcifyChina specializes in providing top-notch end milling machines tailored to meet specific customer needs. Their product lineup is designed to optimize precision machining and enhance productivity across various industries. Custom solutions are at the core of their offerings, ensuring each machine is suited for unique manufacturing requirements.

The company offers a wide range of end milling machines, from standard models to bespoke designs, catering to diverse industrial applications. Their expert team collaborates closely with clients to understand their exact needs, designing machines that maximize efficiency and accuracy.

Projects at SourcifyChina are handled with utmost professionalism, ensuring timely delivery. From initial consultation to the final product, every step is meticulously planned and executed. Their commitment to quality and customer satisfaction is evident through their continuous innovations and superior service.

Clients can rely on SourcifyChina for a seamless experience, from prototype development to full-scale production. Advanced technology and skilled craftsmanship combine to produce machines that are both durable and high-performing.

In conclusion, SourcifyChina excels at providing customized end milling machines that meet and exceed market demands. Their focus on quality, innovation, and customer satisfaction makes them a trusted partner in the manufacturing sector. Whether it’s a standard machine or a custom project, they deliver excellence every time.

SourcifyChina End Milling Machines has positioned itself as a crucial player in the manufacturing industry, particularly in the field of precision machining tools. Based in China, this innovative company has built a solid reputation for delivering high-quality end milling machines that cater to a diverse range of industrial applications. The company’s commitment to superior craftsmanship, advanced technology, and stringent quality control measures ensures that their products meet international standards. SourcifyChina takes pride in its cutting-edge R&D department, which continually drives innovation to enhance performance, efficiency, and durability of its milling machines. Offering a comprehensive array of products, SourcifyChina serves a global clientele spanning various sectors, including aerospace, automotive, and electronics. Their customer-centric approach, competitive pricing, and robust after-sales support have fostered long-term relationships and significant trust within the industry. As they continue to expand their footprint, SourcifyChina remains dedicated to advancing the engineering capabilities of end milling machines, helping businesses achieve precision and efficiency in their manufacturing processes.

End milling machines are indispensable tools in the aerospace, defense, and marine sectors, given their precision and versatility in fabricating complex components. In the aerospace industry, these machines are pivotal in manufacturing high-strength, lightweight parts required for aircraft structure and engine components. They excel in machining materials such as titanium, nickel alloys, and composite materials, which are often used due to their high strength-to-weight ratios and thermal stability. The capability of end milling machines to execute intricate cutting paths ensures that components such as turbine blades, fuselage panels, and landing gear parts are produced to strict tolerances and superior surface finishes, ultimately contributing to the safety and efficiency of modern aircraft.

In the defense sector, end milling machines are used to produce components for a variety of critical systems, including armored vehicles, weaponry, and communication equipment. Precision and reliability are paramount, as these components often operate in harsh environments and under extreme stresses. The machines are leveraged to cut materials that offer ballistic resistance, such as hardened steels and advanced composites. In marine applications, end milling machines play a crucial role in building and maintaining naval vessels and underwater systems. They are used to fabricate parts ranging from propeller shafts to pressure hull sections for submarines. The ability to work with corrosion-resistant materials like stainless steel and aluminum alloys ensures the longevity and reliability of marine components in saltwater environments. Overall, end milling machines enhance the production of complex, high-performance parts essential for the aerospace, defense, and marine industries.

End milling machines play an essential role in both the automotive and electronics industries due to their precision, efficiency, and versatility. In the automotive sector, these machines are integral for fabricating various components, including engine parts, transmission systems, and brake disc rotors. The precise nature of end milling allows for the creation of complex geometries and tight tolerances required in high-performance automotive parts. By enabling the mass production of these critical components with consistent accuracy, end milling machines contribute significantly to reducing manufacturing costs and increasing production velocity. Additionally, advanced materials like aluminum and titanium used in modern automobiles are often machined using end milling processes, which ensure both material integrity and optimal performance in the final product.

In the electronics industry, end milling machines are invaluable in the production of intricate components found in consumer electronics, telecommunications devices, and printed circuit boards (PCBs). The ability to perform fine detailed work makes these machines well-suited for creating complex patterns and structures on PCBs, which are essential for dense electronic packaging and miniaturization. Precision end milling is used to carve out exact slots, pockets, and holes needed for component placement and integration. The machines’ capability to handle various substrate materials, such as FR4 fiberglass, ceramics, or soft metals, ensures their application across a spectrum of electronic devices. This flexibility, coupled with high-speed operations, minimizes production time while maintaining high-quality standards, thus playing a pivotal role in the advancement of modern electronics manufacturing.

End milling machines play an indispensable role in the construction industry, significantly enhancing efficiency and precision in various tasks. These machines are paramount for creating intricate designs and ensuring that materials are cut with an unparalleled level of accuracy. In building components such as beams, columns, and joints, end milling machines allow for precise cuts and intricate detailing, ensuring structural integrity and aesthetic coherence in modern architectural designs. Furthermore, the machines can process a wide array of materials, including metals, composites, and polymers, making them versatile tools in the construction toolkit. They enable rapid prototyping and production, which is crucial in meeting the tight schedules often associated with construction projects.

In the energy sector, especially in the manufacturing of components for renewable energy systems such as wind turbines, solar panels, and hydroelectric equipment, end milling machines are equally vital. These machines are employed to manufacture and refine components with high precision, ensuring that they meet the stringent tolerances required for optimal performance. For instance, wind turbine blades and solar panel mounts require milling machines to achieve exact shapes and sizes, reducing aerodynamic drag and maximizing efficiency. Additionally, the reliability and robustness of energy sector components are critical; end milling machines help in achieving the durability required to withstand harsh environmental conditions. By leveraging advanced milling techniques, the energy sector can produce more efficient, durable, and cost-effective components, thus driving innovation and sustainability in energy production.

These two sectors rely heavily on the capabilities of end milling machines to enhance both performance and productivity, underlining the machines’ broad applicability and invaluable contribution to modern industry.

End milling machines play a pivotal role in the industrial equipment industry, serving as essential tools in various manufacturing processes. These machines, equipped with rotating cutting tools, are adept at removing material from a workpiece, allowing for the creation of complex shapes, contours, and cavities. Industries ranging from automotive to aerospace and electronics utilize end milling machines to enhance precision and efficiency in their production lines. For instance, in the automotive sector, these machines are instrumental in producing engine components, transmission parts, and intricate metal pieces that demand high accuracy. Similarly, in aerospace, end milling machines contribute to fabricating turbine blades and other critical aircraft components, ensuring they meet stringent safety and performance standards.

Moreover, the versatility and adaptability of end milling machines make them invaluable across various sectors. Their capability to work with a multitude of materials—including metals, plastics, and composites—expands their application range. Engineers leverage these machines to achieve tight tolerances, superior surface finishes, and intricate geometries, which are often required in advanced manufacturing processes. Additionally, the integration of computer numerical control (CNC) technology with end milling machines has further revolutionized the industry, allowing for automated, programmable, and repeatable operations. This synergy not only enhances productivity by reducing manual intervention but also improves consistency and quality of the final products. As industries continue to push the boundaries of innovation and precision, the end milling machine remains a staple in modern manufacturing, driving advancements and meeting the ever-evolving demands of quality and complexity.

End milling machines play a pivotal role in the manufacture of medical devices, where precision, reliability, and miniaturization are paramount. These machines are utilized in the fabrication of intricate components for medical instruments such as orthopedic implants, surgical tools, and prosthetics. With the ability to execute complex cuts and fine details, end milling machines ensure that the components meet stringent tolerances and surface finish requirements. Their computer numerical control (CNC) capabilities enable the production of highly consistent and precise parts, essential for maintaining the high-quality standards demanded by the medical industry. These machines can handle a variety of materials, including metals, plastics, and composites, which are commonly used in medical device manufacturing.

Moreover, end milling machines contribute significantly to rapid prototyping and the iterative design process, allowing for quick modifications and improvements in medical device designs. This capability is critical in the development phase, where clinicians and engineers frequently collaborate to refine devices that better meet patient needs and clinical outcomes. By leveraging advanced end milling technology, manufacturers can accelerate the time-to-market for innovative medical solutions while ensuring the devices are safe and effective. Additionally, the high degree of automation and precision offered by these machines minimizes human error, ensures reproducibility, and enhances the overall efficiency and cost-effectiveness of the production process. In an industry where precision can have life-saving implications, the application of end milling machines in medical device manufacturing underscores their indispensable value.

End milling machines are versatile tools in the realm of machining and manufacturing, employed for a range of applications including cutting, shaping, slotting, and contouring materials. Unlike traditional milling devices, end milling machines utilize rotating cutting tools known as end mills, which have cutting teeth on both their cylindrical and end surfaces. This design enables them to perform complex operations that require high precision and fine detail, such as creating intricate cavities and slots or producing smooth finishes on various workpiece materials like metals, plastics, and composites. One of the significant advantages of end milling machines is their ability to handle both vertical and horizontal milling tasks, offering flexibility in terms of machining angles and directions. This adaptability makes them indispensable assets in industries that prioritize customization and detailed work, such as aerospace, automotive, mold-making, and electronics.

In manufacturing applications, end milling machines contribute substantially to enhancing productivity and quality. They are essential for producing components with high dimensional accuracy and surface finish, which are critical in sectors like aerospace and medical device manufacturing, where precision is paramount. Modern advancements in end milling technology have introduced features like multi-axis capabilities and CNC (Computer Numerical Control) systems, which allow for more complex geometries to be machined with consistent repeatability and minimal human intervention. Additionally, the integration of smart technologies and automation has reduced setup times and improved operational efficiency, ultimately leading to cost reductions and faster production cycles. The ability to utilize a variety of end mills, each designed for specific types of cuts and materials, further amplifies the versatility and effectiveness of end milling machines in high-precision manufacturing environments.

1. What sets the end milling machines from SourcifyChina factory apart in terms of quality?

SourcifyChina factory is known for its stringent quality control measures, advanced manufacturing technologies, and use of premium materials. These factors ensure that the end milling machines produced are durable, precise, and reliable.

2. Are the end milling machines from SourcifyChina factory compliant with international standards?

Yes, the end milling machines from SourcifyChina factory are designed and manufactured in compliance with international standards such as ISO and CE certifications, ensuring high quality and safety.

3. What materials are used in the manufacturing of SourcifyChina’s end milling machines?

The end milling machines from SourcifyChina are primarily constructed from high-grade steel and other durable alloys. The cutting tools often incorporate tungsten carbide to maintain sharpness and efficiency.

4. Does SourcifyChina factory offer customization options for their end milling machines?

Yes, SourcifyChina factory provides customization options to cater to specific client requirements. Customers can specify parameters such as machine size, power, and additional features to match their operational needs.

5. How does SourcifyChina factory ensure the precision and accuracy of their end milling machines?

Precision and accuracy are ensured through advanced CNC technology, regular calibration, and rigorous testing protocols. Each machine undergoes detailed inspections and quality checks before shipment.

6. What is the typical lead time for manufacturing and delivery of these machines?

The lead time for manufacturing and delivery of end milling machines from SourcifyChina factory typically ranges from 4 to 8 weeks, depending on the complexity and customization requirements of the order.

7. What kind of after-sales support does SourcifyChina factory offer?

SourcifyChina factory provides comprehensive after-sales support including installation guidance, operator training, routine maintenance services, and a robust warranty program. Technical assistance is also available 24/7.

8. Are spare parts readily available for the end milling machines from SourcifyChina factory?

Yes, SourcifyChina factory maintains a wide inventory of spare parts to ensure quick replacements and minimal downtime. Customers can easily order parts directly from the factory or authorized dealers.

9. Can I visit the SourcifyChina factory to inspect the production facilities and meet with the engineering team?

Absolutely. SourcifyChina factory welcomes clients to visit their production facilities. It’s an excellent opportunity to observe the manufacturing process, discuss specific requirements, and ensure confidence in your purchase.

10.

When considering end milling machines from SourcifyChina factory, here are some crucial tips to ensure a successful purchase:

1. Quality Assurance: Verify the quality certifications and standards adhered to by SourcifyChina’s factory. Look for ISO 9001 certification, which indicates standardized and reliable manufacturing processes.

2. Customization Options: Inquire if there are customization options available to tailor the end milling machines to your specific requirements. This can include spindle speed, milling head types, and automation levels.

3. Material Compatibility: Confirm the types of materials the end milling machines can handle efficiently, such as metals, plastics, and composites. This ensures the machine’s suitability for your intended applications.

4. Technological Integration: Ensure the milling machines incorporate advanced technologies such as CNC (Computer Numerical Control) for enhanced precision, automation, and ease of operation.

5. Spare Parts and Maintenance: Ascertain the availability of spare parts and the ease of maintenance. A reliable supply of spare parts and comprehensive after-sales support is crucial for long-term operation.

6. Factory Visit: If possible, arrange a visit to SourcifyChina’s factory. This allows you to assess their production capabilities, quality control systems, and overall working environment firsthand.

7. Customer Feedback: Check reviews and feedback from other customers who have purchased similar machines from SourcifyChina. This provides insights into the machine’s performance and reliability.

8. Delivery and Logistics: Discuss delivery timelines, shipping costs, and logistics. Ensure the factory has experience in handling international shipping and customs regulations.

9. Training and Support: Verify if SourcifyChina offers training for operating the end milling machines, as well as ongoing technical support.

10. Cost and ROI: Evaluate the cost relative to the features and benefits offered. Consider the return on investment (ROI) over the machine’s expected lifespan.

Adhering to these tips will help you make an informed decision when purchasing end milling machines from SourcifyChina.

Sure! Here are some frequently asked questions (FAQ) with answers for sourcing end milling machines from SourcifyChina factory:

Q: What types of end milling machines does SourcifyChina factory offer?

A: SourcifyChina provides a wide range of end milling machines including vertical, horizontal, CNC, and manual models to suit various industrial needs.

Q: How do I place an order with SourcifyChina factory?

A: You can place an order by contacting SourcifyChina via their official website, email, or customer service hotline. Provide your specifications and quantity requirements for a detailed quote.

Q: What are the payment options available?

A: SourcifyChina accepts multiple payment options such as bank transfers, credit cards, and PayPal. They may also offer flexible payment terms for bulk orders or long-term partnerships.

Q: Can I request a sample machine before making a bulk order?

A: Yes, SourcifyChina often allows customers to purchase a sample machine for evaluation purposes. Contact their sales team for more details on sample policies.

Q: How long does it take to receive my order?

A: Delivery times vary based on the quantity ordered and your location. Typically, it takes between 4 to 8 weeks for production and shipping. Expedited shipping options may be available at an additional cost.

Q: Does SourcifyChina provide after-sales service and support?

A: Yes, SourcifyChina offers comprehensive after-sales service, including technical support, spare parts availability, and maintenance services. They have a dedicated customer service team to assist you.

Q: Are the end milling machines customizable?

A: SourcifyChina can customize machines to meet your specific requirements, including modifications in size, capacity, and additional features. Make sure to discuss customization options during the initial consultation.

Q: What quality assurance practices are in place?

A: SourcifyChina adheres to strict quality control procedures including rigorous testing and inspection processes to ensure high standards of product quality and reliability.

Q: How can I ensure the machines comply with international standards?

A: SourcifyChina’s machines are manufactured in compliance with international standards and certifications such as ISO and CE. Request certification details during your inquiry.

Q: Do you offer training for machine operation?

A: Yes, SourcifyChina provides training for proper operation and maintenance of their end milling machines. Training materials and on-site training sessions can be arranged if needed.

Sourcing end milling machines from SourcifyChina factory can be streamlined by following these tips:

1. Research & Verify:

– Check Background: Investigate SourcifyChina factory’s reputation through reviews and ratings.

– Certifications: Ensure they have relevant ISO certifications and quality control measures.

2. Detailed Inquiry:

– Specific Requirements: Clearly define the specifications of end milling machines you need.

– Customization: Inquire about customization options if you have specific requirements.

3. Request Samples:

– Sample Order: Place a sample order to assess machine quality and performance.

4. Factory Visit:

– In-person Inspection: If possible, visit the factory to inspect their production process and machinery.

– Virtual Tour: If travel is not feasible, request a virtual tour.

5. Evaluate Costs:

– Detailed Quotation: Get a comprehensive quote that includes machine cost, shipping, and any other additional fees.

– Compare Prices: Compare the quotation with other suppliers to ensure competitiveness.

6. Negotiation:

– Bulk Discounts: Negotiate for bulk order discounts or favorable payment terms.

– After-Sales Service: Discuss after-sales support and warranty terms.

7. Sample Testing:

– Performance Testing: Run thorough testing on received samples for performance, durability, and operational ease.

8. Quality Assurance:

– Third-party Inspection: Consider hiring a third-party inspection service for unbiased quality assurance.

9. Logistics:

– Shipping Arrangements: Confirm shipping logistics, including packaging, delivery times, and insurance options.

– Customs Clearance: Ensure compliance with import/export regulations in your destination country.

10. Legal Agreements:

– Contract: Draft a detailed contract specifying terms, conditions, and penalties for non-compliance.

– IP Protection: If design specifics are proprietary, ensure there are strong IP protections in place.

By diligently following these steps, you can efficiently source high-quality end milling machines from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.