Technology and Applications of fabricate sheet metal

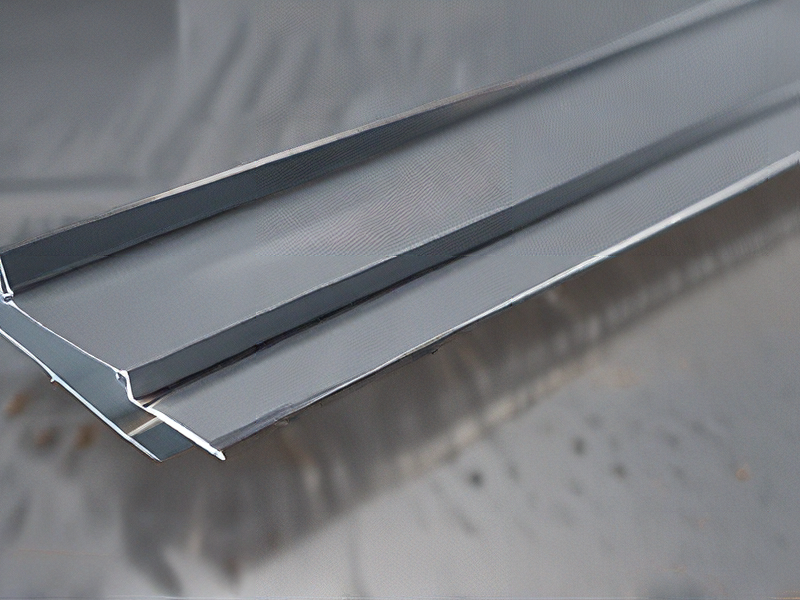

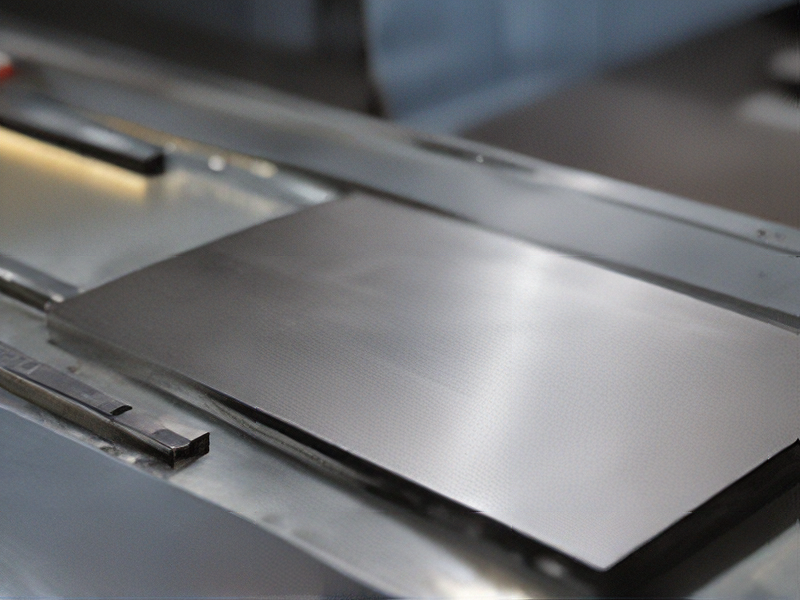

Technology and Applications of Fabricating Sheet Metal

Technology:

1. Cutting:

– Laser Cutting: Uses a high-powered laser to cut precise shapes.

– Waterjet Cutting: Employs high-pressure water mixed with abrasives for cutting.

– Plasma Cutting: Utilizes an accelerated jet of hot plasma to cut conductive materials.

2. Forming:

– Bending: Involves using a press brake to create bends and angles.

– Rolling: Rolls flat sheets into cylindrical shapes.

– Stamping: Employs a die to shape the sheet metal through a press.

3. Joining:

– Welding: Fuses pieces together using heat (TIG, MIG, and spot welding).

– Riveting: Uses rivets to fasten sheets together.

– Adhesive Bonding: Glues sheets with industrial adhesives.

4. Finishing:

– Painting/Coating: Adds protective and aesthetic layers.

– Anodizing: Enhances corrosion resistance and surface hardness.

Applications:

1. Automotive Industry:

– Manufacturing car bodies, frames, and various components.

2. Aerospace:

– Producing aircraft skins, wings, and structural parts.

3. Construction:

– Creating roofing, structural frameworks, and facades.

4. Consumer Goods:

– Making appliances, electronics housings, and furniture.

5. Industrial Equipment:

– Fabricating enclosures, tanks, and machinery components.

Sheet metal fabrication is crucial in modern manufacturing, enabling the production of durable, precise, and versatile components for various industries. Its evolution continues to push the boundaries of what can be achieved in metalworking.

Quality Testing Methods for fabricate sheet metal and how to control quality

Quality testing for fabricated sheet metal involves several methods to ensure the products meet specified standards. Here’s an overview of common methods and control measures:

Testing Methods

1. Visual Inspection:

– Purpose: Detect surface defects like scratches, dents, and irregularities.

– Procedure: Examine the metal surface under adequate lighting conditions.

2. Dimensional Inspection:

– Purpose: Ensure the metal parts meet the specified dimensions.

– Procedure: Use calipers, micrometers, and coordinate measuring machines (CMM) to check dimensions.

3. Thickness Testing:

– Purpose: Verify the sheet metal thickness.

– Procedure: Employ ultrasonic thickness gauges or micrometers.

4. Tensile Testing:

– Purpose: Assess the metal’s strength and ductility.

– Procedure: Pull a sample until it breaks and measure the stress and strain.

5. Hardness Testing:

– Purpose: Measure resistance to indentation.

– Procedure: Use Rockwell, Brinell, or Vickers hardness testers.

6. Non-Destructive Testing (NDT):

– Purpose: Identify internal flaws without damaging the metal.

– Procedure: Techniques include X-ray, ultrasonic testing, and dye penetrant inspection.

7. Corrosion Testing:

– Purpose: Evaluate resistance to corrosion.

– Procedure: Salt spray testing or exposure to corrosive environments.

Quality Control Measures

1. Standard Operating Procedures (SOPs):

– Develop and follow detailed SOPs for fabrication processes.

2. Training:

– Regularly train employees on quality standards and inspection techniques.

3. Calibration:

– Ensure all testing and measuring equipment are regularly calibrated.

4. Documentation:

– Maintain detailed records of inspections, tests, and any deviations.

5. Statistical Process Control (SPC):

– Use SPC charts to monitor and control the fabrication process.

6. Internal Audits:

– Conduct regular audits to ensure compliance with quality standards.

7. Corrective Actions:

– Implement corrective measures promptly when defects are detected.

By combining these testing methods and quality control measures, manufacturers can effectively ensure the quality of fabricated sheet metal products.

Tips for Procurement and Considerations when Purchasing from fabricate sheet metal

When procuring and purchasing fabricated sheet metal, consider these essential tips to ensure quality, cost-effectiveness, and timely delivery:

1. Material Selection:

– Quality: Choose the appropriate type of metal (aluminum, steel, stainless steel) based on your project’s requirements. Ensure the metal meets industry standards.

– Thickness: Select the correct gauge for durability and functionality.

2. Supplier Evaluation:

– Reputation: Opt for suppliers with a proven track record. Check reviews, certifications, and client testimonials.

– Capabilities: Ensure the supplier can handle your specific needs, from cutting and bending to finishing processes like powder coating or anodizing.

3. Cost Considerations:

– Quotes: Obtain multiple quotes to compare pricing. Be wary of significantly lower prices, which might indicate compromised quality.

– Hidden Costs: Account for additional costs such as transportation, packaging, and potential custom duties.

4. Quality Control:

– Standards Compliance: Ensure the supplier adheres to relevant standards (ISO, ASTM).

– Inspection: Request quality control reports and consider third-party inspections to verify the quality of the fabricated parts.

5. Lead Times and Delivery:

– Turnaround Time: Confirm the supplier’s lead time and ensure it aligns with your project schedule.

– Logistics: Discuss delivery options and ensure reliable shipping methods to avoid delays.

6. Customization and Design Support:

– Capabilities: Check if the supplier offers customization options to meet your specific design requirements.

– Technical Support: Opt for suppliers that provide design assistance and technical support to optimize your product design.

7. Sustainability:

– Environmental Practices: Consider suppliers with sustainable practices and certifications. This can improve your company’s eco-friendly credentials.

8. Contracts and Agreements:

– Terms: Clearly define payment terms, delivery schedules, and penalties for non-compliance in your contract.

– Warranty: Ensure the supplier offers warranties on their products to safeguard against defects.

By meticulously evaluating these factors, you can ensure a successful procurement process for fabricated sheet metal that meets your quality, cost, and timeline requirements.

FAQs on Sourcing and Manufacturing from fabricate sheet metal in China

FAQs on Sourcing and Manufacturing Fabricated Sheet Metal in China

1. Why source fabricated sheet metal from China?

China offers competitive pricing, a wide range of materials, advanced manufacturing technologies, and high production capacities, making it an attractive option for sourcing fabricated sheet metal.

2. What types of sheet metal fabrication services are available in China?

Chinese manufacturers provide various services including laser cutting, stamping, bending, welding, and surface treatments such as powder coating and anodizing.

3. How do I find reliable sheet metal manufacturers in China?

You can find manufacturers through online directories (like Alibaba and Made-in-China), trade shows, and referrals. It’s important to verify their credentials, certifications, and previous work.

4. What quality standards should I expect?

Ensure manufacturers comply with international standards such as ISO 9001 for quality management and ISO 14001 for environmental management. Request quality inspection reports and prototypes.

5. What are the typical lead times for production?

Lead times can vary but generally range from 2 to 6 weeks, depending on the complexity of the project and the manufacturer’s capacity.

6. How can I ensure effective communication?

Clear and detailed communication is crucial. Use bilingual project managers, provide precise technical drawings, and clarify all specifications and expectations upfront.

7. What are the costs involved?

Costs include the price of the materials, fabrication, shipping, and any additional treatments. Get multiple quotes to compare prices and services.

8. How do I handle shipping and logistics?

Work with experienced freight forwarders who can manage customs clearance, shipping, and delivery. Incoterms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) are commonly used.

9. What payment terms are standard?

Common payment terms include a 30% deposit with the balance paid before shipment. Letters of Credit (LC) and Trade Assurance (on platforms like Alibaba) are also used to secure transactions.

10. How can I protect my intellectual property (IP)?

Sign Non-Disclosure Agreements (NDAs) and work with manufacturers that respect IP rights. Registering your IP in China can also provide legal protection.

By addressing these FAQs, you can navigate the complexities of sourcing and manufacturing fabricated sheet metal in China more effectively.