SourcifyChina offers unparalleled access to high-quality stainless steel fabrication services. Their factories are equipped with advanced technology, ensuring precision and consistency in every product, which meets international standards.

Buyers can rely on SourcifyChina for competitive pricing without compromising on quality. Their bulk purchasing power and streamlined processes translate to cost savings for customers.

SourcifyChina boasts an experienced team adept at handling custom orders. Whether it’s intricate designs or specific material requirements, they cater to diverse needs efficiently and effectively.

With rigorous quality control measures, SourcifyChina ensures that every batch of stainless steel meets stringent quality criteria. This commitment to excellence minimizes defects and enhances customer satisfaction.

Timely delivery is another hallmark of SourcifyChina. Their strategic location and robust logistics network guarantee that your orders arrive on schedule, supporting smooth business operations.

Customer service at SourcifyChina is exceptional, offering dedicated support throughout the purchasing process. From initial inquiry to post-purchase follow-up, they prioritize clear communication and client satisfaction.

Sustainability is also a focus, with SourcifyChina implementing eco-friendly manufacturing practices. Their commitment to reducing environmental impact aligns with global green initiatives.

Choosing SourcifyChina means partnering with a reliable, cost-effective, and environmentally conscious supplier that prioritizes quality, timeliness, and exceptional customer service.

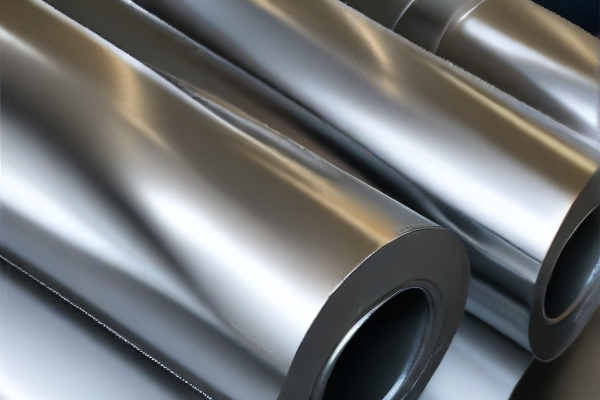

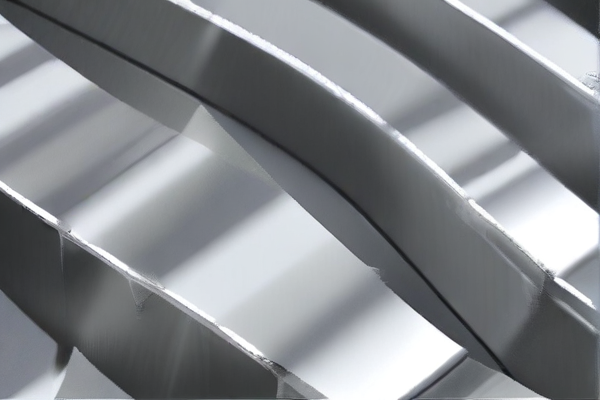

Fabricating stainless steel involves various methods tailored to specific applications. These techniques ensure durability, corrosion resistance, and aesthetic appeal. Below are some popular types and options:

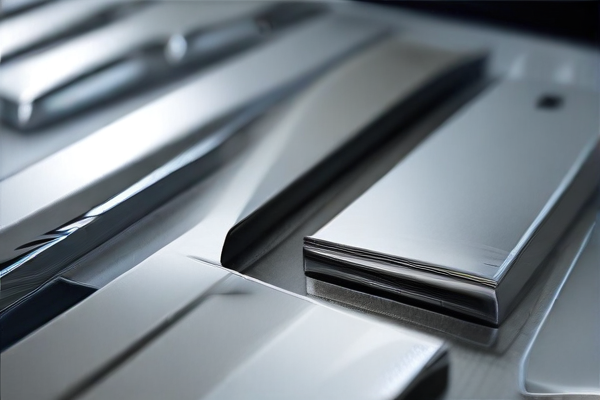

– Cutting: Laser, plasma, and waterjet cutting providing precision and minimal heat distortion.

– Welding: TIG, MIG, and spot welding for strong, clean joints.

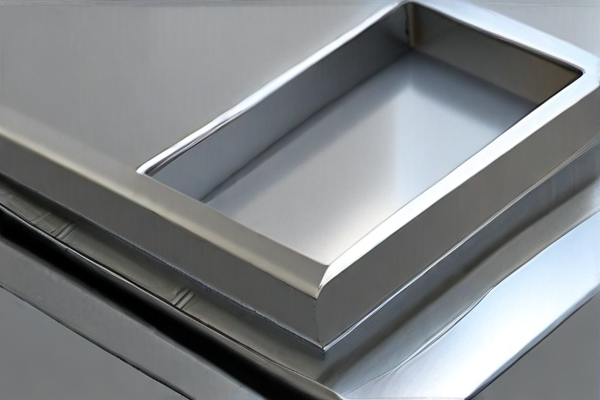

– Forming: Press braking, rolling, and stamping for desired shapes and angles.

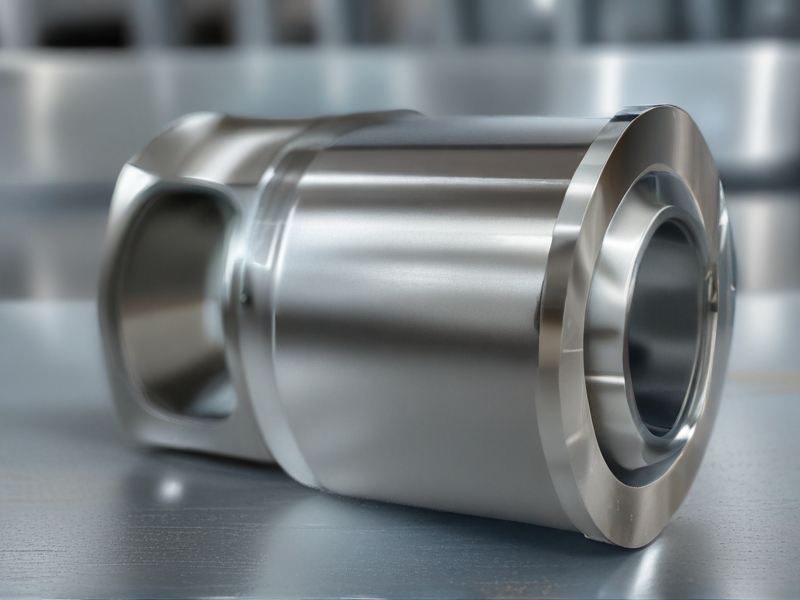

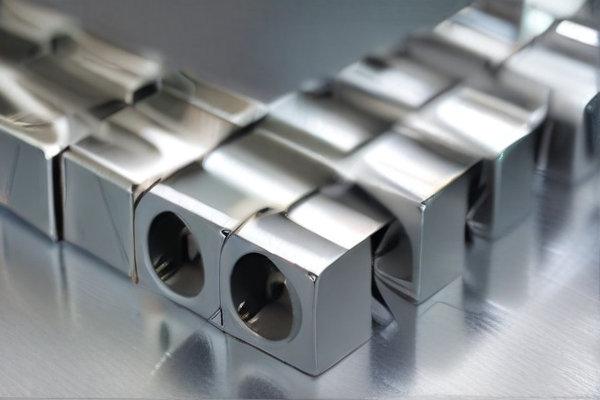

– Machining: CNC machining and milling for detailed and complex parts.

– Finishing: Polishing, brushing, and coating for enhanced appearance and protection.

Each method serves unique purposes depending on the project requirements, ensuring high-quality stainless steel fabrication.

Fabricate stainless steel has numerous applications due to its durability, resistance to corrosion, and aesthetic appeal. It is widely used in a variety of industries for various purposes.

– Construction: Bridges, buildings, and monuments.

– Medical: Surgical instruments, implants, and medical devices.

– Automotive: Exhaust systems, trims, and structural components.

– Aerospace: Aircraft parts and structural components.

– Food Processing: Storage tanks, piping, and kitchen equipment.

– Chemical Industry: Reactors, heat exchangers, and storage vessels.

– Energy: Nuclear reactors, wind turbines, and solar panel frames.

– Marine: Shipbuilding, offshore platforms, and submarines.

– Consumer Goods: Appliances, cookware, and cutlery.

– Petrochemical: Pipelines, Valves, and pumps.

– Pharmaceutical: Production equipment, cleanrooms, and lab tools.

– Architecture: Handrails, sculptures, and facades.

– Water Treatment: Filtration systems, storage tanks, and desalination plants.

– Electronics: Enclosures, connectors, and mounting hardware.

– HVAC: Ductwork, heat exchangers, and ventilation systems.

– Textiles: Machinery, dyes, and processing equipment.

– Mining: Conveyor systems, chutes, and material handling equipment.

– Agriculture: Silos, irrigation systems, and machinery components.

– Defense: Military vehicles, weapons systems, and protective barriers.

– Renewables: Wave and tidal energy machinery, and biofuel processing units.

SourcifyChina specializes in fabricating high-quality stainless steel products. Their stainless steel is known for its durability, corrosion resistance, and aesthetic appeal. This makes it an ideal choice for a range of applications, from kitchenware to industrial machinery.

The stainless steel used by SourcifyChina is sourced from reputable suppliers, ensuring consistency and reliability. Their rigorous quality control processes guarantee that each piece meets stringent industry standards. This meticulous attention to detail sets them apart from competitors.

Advanced technologies, such as laser cutting and CNC machining, are employed to shape and finish the stainless steel. These techniques allow for precision crafting, enhancing both functionality and design. This results in products that are not only robust but also visually pleasing.

Sustainability is a key focus for SourcifyChina, and they take measures to minimize waste throughout their fabrication processes. By recycling materials and optimizing resource use, they contribute to environmental conservation. Customers can trust that their purchases have a lower ecological footprint.

Customer satisfaction is central to SourcifyChina’s mission, leading them to provide personalized solutions for unique requirements. From bespoke designs to bulk orders, they offer flexibility to meet diverse needs. This customer-centric approach fosters long-term partnerships and repeat business.

Their commitment to excellence extends beyond production. SourcifyChina provides robust after-sales support, including maintenance advice and troubleshooting assistance. This comprehensive service ensures that clients get the most out of their stainless steel products.

In summary, SourcifyChina’s expertise in stainless steel fabrication ensures that clients receive superior products tailored to their specifications. Combining high-grade materials, advanced technology, and a focus on sustainability, they stand out in the competitive market. Their customer-oriented approach and comprehensive support further solidify their reputation as a reliable partner in stainless steel manufacturing.

SourcifyChina employs state-of-the-art technology to guarantee the highest quality stainless steel fabrication. The process starts with the thorough inspection of raw materials to ensure they meet stringent quality standards.

In the next stage, advanced machinery and skilled technicians precisely cut, form, and weld the stainless steel components. Consistent monitoring at every step helps prevent defects and ensures premium quality output.

A dedicated quality control team conducts meticulous checks throughout the manufacturing process. They utilize various measurement tools and techniques to assess dimensional accuracy and structural integrity.

Before final delivery, the products undergo rigorous testing for hardness, corrosion resistance, and durability. This comprehensive quality control process assures clients of exceptional and reliable stainless steel products.

Ultimately, SourcifyChina’s commitment to quality control in stainless steel fabrication ensures robust, high-performing, and long-lasting products that meet and exceed customer expectations. This dedication to perfection reinforces their reputation as a trusted industry leader.

SourcifyChina specializes in fabricating high-quality stainless steel products, leveraging cutting-edge technology and advanced machinery. Their capabilities extend from designing complex structures to producing intricate components with precision and consistency.

State-of-the-art manufacturing facilities at SourcifyChina ensure superior quality control at every stage of production. The company offers custom fabrication solutions tailored to meet the specific needs of diverse industries, from automotive to construction.

Expert engineers and technicians at SourcifyChina work collaboratively to innovate and improve processes. This commitment to excellence results in durable, corrosion-resistant stainless steel products that meet or exceed international standards.

SourcifyChina’s streamlined supply chain processes and robust logistics support enable timely delivery of fabricated stainless steel goods. Their efficient project management ensures minimal downtime, maximizing client satisfaction.

Moreover, SourcifyChina provides comprehensive after-sales support, including maintenance and repair services. Their customer-centric approach means clients receive end-to-end solutions, enhancing overall project efficiency and longevity of the products.

With extensive experience and a reputation for reliability, SourcifyChina continues to lead in the stainless steel fabrication industry. Their dedication to quality, innovation, and customer service sets them apart as a preferred partner for stainless steel needs.

Fabricating stainless steel offers numerous advantages, making it a preferred material in various industries due to its durability, aesthetic appeal, and resistance to corrosion.

– Corrosion Resistance: Stainless steel’s ability to resist rust and corrosion makes it ideal for applications exposed to moisture and harsh environments.

– Durability: Its robust nature ensures longevity, reducing the need for frequent replacements and maintenance.

– Aesthetic Appeal: Stainless steel provides a sleek, modern look that is pleasing to the eye for architectural and design purposes.

– Hygienic Properties: Easy to clean and sanitize, making it suitable for medical, food processing, and pharmaceutical industries.

– Heat and Fire Resistance: Can withstand high temperatures, making it a safe choice for various industrial applications.

– Recyclability: Stainless steel is 100% recyclable, contributing to environmental sustainability.

– Strength-to-Weight Ratio: Offers substantial strength without being overly heavy, which is beneficial for construction and automotive industries.

– Versatility: Can be molded, welded, and machined into countless shapes and forms, providing flexibility in design.

– Cost-Effective: Although the initial cost might be higher, its long life and low maintenance costs make it an economical choice over time.

– Compatibility with Other Materials: Can be used alongside other materials without causing adverse reactions, ensuring integrity in mixed-material applications.

Stainless steel fabrication offers a range of features that make it a popular choice in many industries due to its durability, corrosion resistance, and aesthetic appeal. Here’s an in-depth look at its key features:

– Durability: Stainless steel is exceptionally strong, which makes it capable of withstanding high pressure and temperature environments.

– Corrosion Resistance: One of the main advantages of stainless steel is its high resistance to rust and corrosion, thanks to its chromium content.

– Aesthetic Appeal: It has a sleek, modern look which is suitable for both functional and decorative applications.

– Low Maintenance: The material is easy to clean, making it ideal for applications where hygiene is crucial, such as in kitchens and hospitals.

– Versatility: Stainless steel can be fabricated into various shapes and sizes, making it suitable for a wide range of industries from construction to automotive.

– Environmental Sustainability: It is 100% recyclable, contributing to sustainable practices.

– Heat Resistance: Can withstand extreme temperatures, making it ideal for heat exchangers or furnaces.

– Non-Reactive Surface: Suitable for applications involving chemicals or food processing, as it doesn’t react with most substances.

– High Strength-to-Weight Ratio: Despite its robustness, it is relatively light, making it easier to handle and transport.

In summary, the features of fabricated stainless steel make it an incredibly useful and versatile material, suitable for a variety of demanding applications across many industries.

SourcifyChina excels in fabricating high-quality stainless steel custom products and projects. Utilizing advanced technologies and skilled craftsmanship, they ensure precision and durability in every piece. Their comprehensive services cater to diverse industries, offering tailored solutions that meet exact specifications.

The company’s strength lies in its broad spectrum of capabilities, from small fittings to large structural components. By maintaining strict quality control measures and adhering to international standards, SourcifyChina guarantees superior products that perform reliably under demanding conditions.

With a team of experienced engineers and designers, SourcifyChina delivers innovative solutions. They partner closely with clients to understand their needs, ensuring that every custom project is executed flawlessly and meets all requirements.

Timely delivery and customer satisfaction are paramount. Committed to excellence, SourcifyChina stays ahead of market trends, continuously improving their processes and adopting new technologies to provide the best stainless steel fabrications.

Their portfolio showcases a variety of successful projects, reflecting their versatility and dedication to quality. Whether for industrial, commercial, or residential applications, SourcifyChina’s custom stainless steel products stand out for their resilience and aesthetic appeal.

In conclusion, SourcifyChina is a reliable partner for stainless steel custom products and projects. Their unwavering commitment to quality, innovation, and customer satisfaction makes them a preferred choice for clients around the globe. By consistently delivering exceptional results, they ensure that every project is a testament to their expertise and dedication.

SourcifyChina Fabricate Stainless Steel stands as a leader in the stainless steel manufacturing sector, renowned for its exceptional quality and innovation. Headquartered in one of China’s bustling industrial hubs, SourcifyChina integrates state-of-the-art technology with skilled craftsmanship to produce a wide range of stainless steel products, including custom fabrication services. Their extensive product catalog serves various industries such as construction, automotive, healthcare, and food processing, ensuring that each item meets rigorous international standards. With a strong commitment to sustainability, SourcifyChina employs eco-friendly processes and materials, emphasizing long-term durability and minimal environmental impact. Their dedicated team of engineers and designers work collaboratively with clients to deliver tailored solutions, from initial concept to final production. This client-centric approach has cemented SourcifyChina’s reputation for reliability and excellence, making it the go-to partner for businesses seeking high-quality stainless steel solutions.

Stainless steel’s fabrication holds significant value in the aerospace, defense, and marine sectors due to its enduring properties such as corrosion resistance, high strength-to-weight ratio, and longevity. In aerospace, critical components like fuselage sections, landing gear parts, and engine components utilize fabricated stainless steel. The material’s resistance to extreme temperatures and wear ensures reliability and safety in the challenging conditions of aviation, from high-altitude flights to the immense stress during take-offs and landings. Its adaptability allows for precise shaping and welding, meeting the rigorous standards required for modern aircraft.

In the defense sector, stainless steel is indispensable for manufacturing armored vehicles, submarines, and personal protective equipment. Its ability to withstand harsh environments and impacts makes it ideal for producing durable and resilient military gear and infrastructure. The marine industry similarly benefits from stainless steel’s anti-corrosive properties, essential for shipbuilding, underwater pipelines, and offshore drilling platforms. The metal’s resistance to saltwater corrosion significantly enhances the lifespan and maintenance frequency of marine vessels and structures. The synergy of these properties fosters innovation and reliability across these high-stakes industries, reinforcing the critical role of stainless steel fabrication in advancing technology and safety.

Stainless steel fabrication plays a pivotal role in the automotive industry, enhancing the performance, safety, and durability of vehicles. Fabricated stainless steel is used extensively due to its impressive strength, corrosion resistance, and ability to withstand extreme temperatures. Components such as exhaust systems, fuel tanks, and chassis parts are commonly made from this robust material. The non-corrosive properties of stainless steel ensure longevity and reduce maintenance requirements, crucial for parts exposed to harsh environmental conditions. Moreover, the aesthetic appeal of stainless steel contributes to the sleek, modern design of automotive exteriors and interiors, making it a material of choice for both functional and decorative applications.

In the electronics sector, stainless steel fabrication is equally indispensable, especially for components that demand high precision and durability. Consumer electronics such as smartphones, laptops, and kitchen appliances often incorporate stainless steel due to its reliability and superior finish. Its non-reactive nature makes it ideal for sensitive electronic environments, preventing contamination and ensuring product longevity. Stainless steel is also widely used in manufacturing enclosures and casings for industrial electronic equipment, offering excellent protection against electromagnetic interference and physical impact. Its ability to be precisely fabricated into complex shapes and fine details supports the intricate design needs of modern electronics, ensuring performance and durability over the product’s lifespan.

Fabricating stainless steel plays a pivotal role in the construction industry due to its unmatched durability, resistance to corrosion, and aesthetic appeal. Stainless steel is extensively used in the fabrication of structural components such as beams, columns, and reinforcements, ensuring that buildings can withstand severe environmental conditions without degrading. Additionally, its strength-to-weight ratio is advantageous for creating lighter structures that require less material without sacrificing integrity, thereby reducing overall costs and resource consumption. Architects and designers often rely on stainless steel for facades and interior features, appreciating its versatile and contemporary finish. As metropolitan areas grow and the demand for innovative, resilient infrastructure increases, the fabrication of stainless steel will continue to be a cornerstone of modern construction.

In the realm of energy, the fabrication of stainless steel is crucial for creating efficient and lasting solutions in both traditional and renewable energy sectors. Stainless steel’s resistance to high temperatures and harsh environmental conditions makes it ideal for fabricating components used in oil and gas exploration, such as storage tanks, pipelines, and offshore platforms. This material ensures longevity and reliability in infrastructure that is subjected to extreme demands. In renewable energy applications, stainless steel is essential for constructing wind turbines, solar panel frames, and hydroelectric systems, where durability and weather resistance are critical. Moreover, its recyclability aligns with the sustainability goals of the renewable energy sector, making it an environmentally friendly choice. Overall, the adaptability and robust properties of fabricated stainless steel significantly bolster performance and safety in energy production and infrastructure.

The industrial equipment industry relies heavily on the fabrication of stainless steel due to its exceptional properties, including corrosion resistance, durability, and ease of maintenance. The process of fabricating stainless steel involves cutting, bending, forming, and welding to create robust components and machinery that stand up to the challenging environments typical in industries such as food processing, pharmaceuticals, petrochemical, and power generation. Stainless steel components are preferred in these sectors because they do not react easily with most substances, making them ideal for applications that require stringent hygiene standards, such as in food and beverage production facilities where contamination must be minimized. The ability to withstand high temperatures and pressures also makes stainless steel an essential material for constructing reactors, pipelines, and storage tanks used in chemical processing plants.

Advancements in stainless steel fabrication technologies, such as laser cutting and CNC machining, have further expanded its application by enabling the production of highly precise and complex industrial equipment. These innovations allow manufacturers to create custom stainless steel parts that meet the specific requirements of complex machinery, leading to improved performance and longevity. The adaptability of stainless steel fabrication means that it can be tailored to construct everything from massive structural frames to minute precision instruments, facilitating diverse industrial applications. Additionally, the recyclability of stainless steel promotes sustainability within the industrial equipment industry, aligning with the growing emphasis on environmentally responsible manufacturing practices. As a result, the continual evolution of fabrication techniques ensures that stainless steel remains a cornerstone material for cutting-edge industrial equipment and infrastructure.

Fabricating stainless steel plays a crucial role in the development and manufacturing of medical devices, given the material’s unique properties that align well with medical requirements. Stainless steel is renowned for its corrosion resistance, strength, and biocompatibility, making it an ideal choice for various medical tools and implants. The fabrication process, which includes cutting, shaping, forming, and welding, ensures that stainless steel can meet the stringent standards necessary for medical applications. For instance, surgical instruments such as scalpels, forceps, and surgical scissors are fabricated from stainless steel to maintain sharpness, hygiene, and durability. The non-porous surface of stainless steel also minimizes the risk of harboring bacteria, which is critical in the sterile environments of operating rooms and clinics.

Furthermore, stainless steel is extensively used in the production of orthopedic implants, such as joint replacements and bone screws, as well as cardiovascular devices like stents and heart valves. The mechanical properties of stainless steel provide the necessary support and longevity required for implants to function effectively within the human body. Advanced fabrication techniques, such as precision machining and laser cutting, allow for the detailed and intricate designs necessary for these devices. Additionally, the use of medical-grade stainless steel ensures that devices meet regulatory standards and perform reliably within biological systems, reducing the risk of adverse reactions. Overall, the application of fabricating stainless steel in medical devices exemplifies a perfect synergy between material science and medical engineering, contributing significantly to advancements in healthcare and patient outcomes.

Machining and manufacturing applications involving the fabrication of stainless steel are critical in various industries due to the material’s exceptional properties, such as corrosion resistance, durability, and aesthetic appeal. In the realm of machining, stainless steel poses unique challenges due to its tendency to work-harden and its poor thermal conductivity. Precision equipment and tools made from specialized materials, like carbide or ceramic, are often required to cut, drill, and shape stainless steel components effectively. Techniques such as CNC (Computer Numerical Control) machining play a pivotal role in producing intricate and high-precision parts. These parts are used in industries ranging from aerospace to medical devices, where the reliability and performance of stainless steel are paramount.

In the broader manufacturing context, stainless steel fabrication encompasses a variety of processes, including welding, bending, forming, and finishing. Welding stainless steel requires a thorough understanding of the material’s properties to prevent issues like carbide precipitation, which can lead to corrosion. Advanced welding techniques, such as TIG (Tungsten Inert Gas) and laser welding, are frequently employed to maintain the integrity and appearance of the final product. Forming and bending stainless steel sheets or tubes necessitates careful control of the material’s grain structure to avoid cracking. Post-fabrication, various surface treatments like passivation and electropolishing are applied to enhance corrosion resistance and achieve the desired finish. This meticulous attention to detail in every stage of fabrication ensures that stainless steel components meet the stringent requirements of sectors like food processing, construction, and automotive manufacturing.

Sure, here is an FAQ section for fabricating stainless steel quality work from SourcifyChina factory:

1. What types of stainless steel does SourcifyChina factory work with?

SourcifyChina factory works with various types of stainless steel, including 304, 316, 201, and duplex stainless steels to meet different project requirements.

2. What are the production capabilities of SourcifyChina factory?

SourcifyChina factory offers a range of production capabilities including cutting, welding, bending, and finishing with high precision to ensure top-quality stainless steel products.

3. Can SourcifyChina factory handle custom stainless steel fabrication projects?

Yes, SourcifyChina factory specializes in custom stainless steel fabrication to meet specific client requirements. They provide tailored solutions for unique design and functional needs.

4. What quality control measures are in place at SourcifyChina factory?

The factory employs stringent quality control measures, including material certification, inspection of welds, dimensional verification, and surface finishing tests to ensure superior quality.

5. How does SourcifyChina ensure timely delivery of orders?

SourcifyChina factory utilizes efficient production scheduling and logistics planning to ensure timely delivery of orders, keeping clients updated on progress throughout the fabrication process.

6. Are there minimum order quantities for stainless steel fabrication?

Minimum order quantities may vary depending on the complexity and scope of the project. It’s best to contact SourcifyChina factory directly for specific details regarding your order.

7. What industries does SourcifyChina serve with their stainless steel fabrication?

SourcifyChina serves a wide range of industries including automotive, construction, food and beverage, medical, and marine industries, providing high-quality stainless steel solutions.

8. Do they provide design assistance for stainless steel projects?

Yes, SourcifyChina factory offers design assistance and consultation services to help clients achieve optimal results for their stainless steel fabrication projects.

9. What are the payment terms for orders placed with SourcifyChina?

Payment terms can vary based on order size and specific client agreements. Typically, a deposit is required with the balance paid upon completion and inspection.

10. How can I get a quote for my stainless steel fabrication project?

Fabricating stainless steel in collaboration with SourcifyChina factory can be highly efficient and cost-effective with the right approach. Here are some essential tips to ensure a successful manufacturing process:

1. Detailed Design Plans: Ensure you have comprehensive CAD drawings and specifications. Precision is crucial for stainless steel parts to meet your exact requirements.

2. Material Selection: Choose the appropriate grade of stainless steel, such as 304 or 316, based on factors like corrosion resistance, strength, and intended use.

3. Quality Standards: Communicate your quality standards clearly. Use ISO-certified processes, and request material certifications to guarantee consistency and reliability.

4. Prototyping: Begin with a prototype to verify design and functional aspects before moving to mass production, minimizing costly mistakes.

5. Cost Estimates: Get detailed quotes that include material, labor, tooling, and shipping costs. Always plan for potential additional expenses like customs duties.

6. Sample Validation: Before mass production, request samples to ensure the factory can meet your specifications and quality expectations.

7. Lead Time: Plan for lead times, including manufacturing and shipping, by staying in close contact with the factory. Ensure any delays are communicated immediately.

8. Communication: Maintain regular communication to resolve issues promptly. Use a project management tool or dedicated point of contact for seamless collaboration.

9. Factory Visits: If possible, visit the factory to understand their capabilities, processes, and quality control measures firsthand.

10. SourcifyChina Expertise: Leverage SourcifyChina’s expertise in sourcing and manufacturing to navigate challenges, from supplier vetting to logistics management.

By following these tips, you can optimize your stainless steel fabrication process with SourcifyChina, ensuring high-quality output and a smooth production experience.

Sure! Here are some FAQ with answers for sourcing “fabricate stainless steel from SourcifyChina factory”:

Q1: What types of stainless steel products can SourcifyChina fabricate?

A1: SourcifyChina specializes in fabricating a wide range of stainless steel products including sheets, plates, tubes, rods, and custom machined parts tailored to specific requirements.

Q2: What grades of stainless steel are available?

A2: SourcifyChina offers various grades of stainless steel such as 304, 316, 430, and more, catering to different applications that require specific properties and standards.

Q3: Can I get a custom design for my stainless steel product?

A3: Yes, SourcifyChina provides custom stainless steel fabrication services. You can share your design specifications, and they will develop a tailored solution to meet your needs.

Q4: What is the lead time for a typical order?

A4: The lead time varies depending on the complexity and volume of the order. Typically, it ranges from 15-45 days. Confirming with SourcifyChina for specific timelines based on your order is recommended.

Q5: Do you provide samples before full-scale production?

A5: Yes, SourcifyChina can provide samples for your approval before moving ahead with mass production to ensure quality and design specifications are met.

Q6: What quality control measures are in place?

A6: SourcifyChina implements stringent quality control measures including material inspections, in-process quality checks, and final product evaluations to ensure all products meet international quality standards.

Q7: What are the payment terms and options?

A7: Payment terms usually involve a deposit followed by the balance upon completion or shipment. Accepted payment options include T/T (Telegraphic Transfer), L/C (Letter of Credit), and other agreed methods.

Q8: Can SourcifyChina handle large volume orders?

A8: Yes, SourcifyChina is well-equipped to handle both small and large volume orders, ensuring timely delivery and consistent quality across all quantities.

Q9: How can I request a quote?

A9: You can request a quote by contacting SourcifyChina through their official website or email, providing details about your project, including specifications, quantities, and any other relevant information.

Q10: Is international shipping available?

Sourcing stainless steel fabrication from SourcifyChina factory can be a streamlined process if you follow these tips:

1. Define Your Requirements: Clearly outline the specifications of the stainless steel product you need. Include dimensions, grades, surface finishes, tolerance levels, and quantity.

2. Research SourcifyChina: Visit their website, review their services, capabilities, and past projects to ensure they align with your needs. Check for certifications and quality assurances.

3. Request a Quote: Contact SourcifyChina directly through their official communication channels. Provide all necessary details about your project for an accurate quote.

4. Verify Quality Standards: Ask for information about their quality control processes. Request samples if possible to inspect the material and craftsmanship.

5. Inquire About Lead Times: Get a clear understanding of their production and delivery timelines to ensure they can meet your deadlines.

6. Assess Communication: Evaluate their responsiveness and clarity in communication. Effective communication is crucial for managing your project efficiently.

7. Negotiate Terms: Discuss payment terms, minimum order quantities, and shipping options. Ensure all terms are clear and agreed upon to avoid any misunderstandings.

8. Check References: Ask for references or case studies from past clients to gauge reliability and performance.

9. Review Contract*:* Carefully read the contract, ensuring it covers all aspects of production, quality, timelines, and dispute resolution.

10. Monitor Production: Stay in regular contact during the production phase for updates and to address any issues promptly.

By following these steps, you’ll enhance the likelihood of a successful collaboration with SourcifyChina for your stainless steel fabrication needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.

How can I help you? :)