Reliable Source for Quality Stainless Steel Fabrication: SourcifyChina Factory Ensures Excellence

SourcifyChina factory stands as a reliable source for quality stainless steel fabrication, offering unmatched excellence and durability. With a focus on precision and innovation, SourcifyChina delivers top-tier steel solutions meeting various industrial needs.

“SourcifyChina” Factory stands out for purchasing fabricated stainless steel from China due to its uncompromising quality control. Each product meets international standards, ensuring long-lasting durability and superior performance.

Additionally, the factory offers competitive pricing without compromising quality, making it a cost-effective solution for buyers seeking value for their investments.

Efficient logistics and timely delivery also set “SourcifyChina” Factory apart. Buyers can rely on streamlined processes that minimize delays, ensuring that projects stay on schedule.

Moreover, the factory’s customer service is exceptional. Dedicated representatives assist buyers throughout the entire purchasing process, addressing concerns and providing updates promptly.

“SourcifyChina” Factory also takes pride in its innovative manufacturing techniques and advanced technology, continually improving to meet evolving market demands.

Lastly, the factory is committed to sustainability, using eco-friendly methods and materials. This dedication to the environment makes it an ethical choice for conscientious buyers.

Choose “SourcifyChina” Factory for your fabricated stainless steel needs, where quality, affordability, efficiency, and sustainability come together to offer an unmatched purchasing experience.

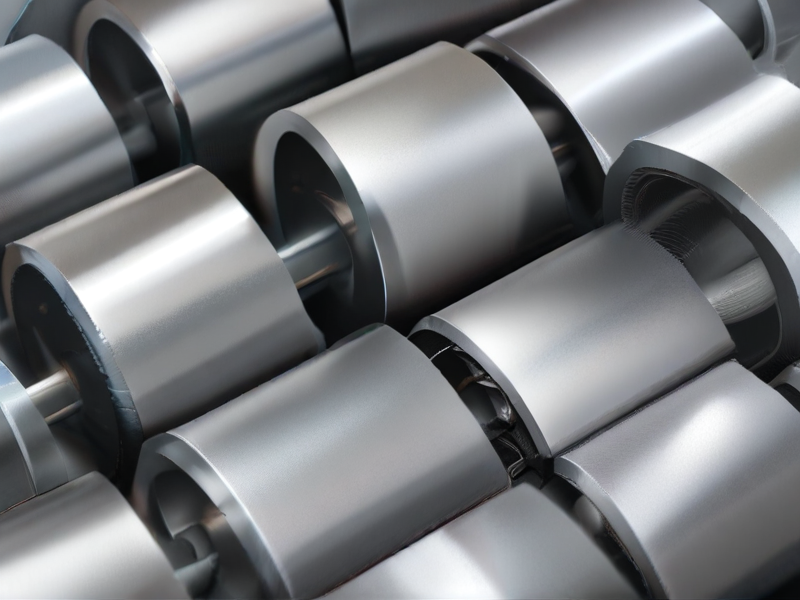

Fabricated stainless steel encompasses various types and options tailored to diverse applications, showcasing its durability, resistance to corrosion, and aesthetic appeal. Popular types include austenitic, ferritic, martensitic, and duplex stainless steels.

– Austenitic Stainless Steel:

– High corrosion resistance

– Non-magnetic

– Easy to weld and form

– Common grades: 304, 316

– Ferritic Stainless Steel:

– Moderate corrosion resistance

– Magnetic

– Higher thermal conductivity

– Common grades: 430, 409

– Martensitic Stainless Steel:

– High strength and hardness

– Corrosion-resistant to a lesser extent

– Magnetic and heat-treatable

– Common grades: 410, 420

– Duplex Stainless Steel:

– Combination of austenitic and ferritic properties

– High strength and corrosion resistance

– Superior stress corrosion cracking resistance

– Common grades: 2205, 2507

– Fabrication Processes:

– Welding: Essential for joining components; methods like TIG, MIG, and resistance welding are common.

– Cutting: Laser, plasma, and waterjet cutting offer precision and efficiency.

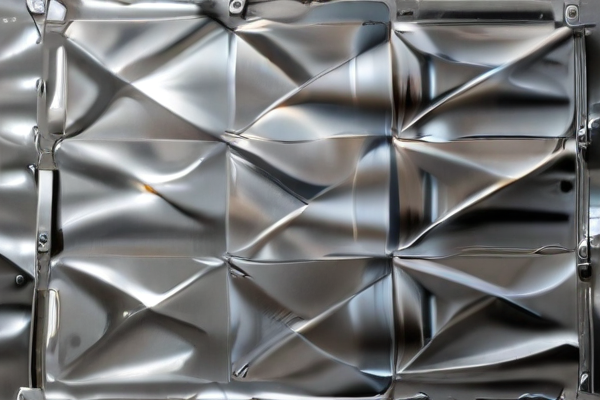

– Forming: Includes techniques like bending and shaping to achieve desired geometries.

– Machining: CNC and conventional methods for detailed work.

– Surface Finishing: Polishing and passivation to enhance appearance and performance.

Choosing the appropriate type and fabrication method involves considering the specific requirements of the application, such as environmental conditions, mechanical stresses, and aesthetic factors. Each type of stainless steel serves different purposes, balancing cost, and performance to meet diverse industrial needs.

Fabricated stainless steel is extensively used due to its corrosion resistance, durability, and aesthetic appeal in various industries. Its adaptability and robustness make it invaluable across numerous applications.

– Construction: Structural components, handrails, and architectural facades.

– Automotive: Exhaust systems, trim, and structural parts.

– Medical: Surgical instruments, implants, and medical equipment.

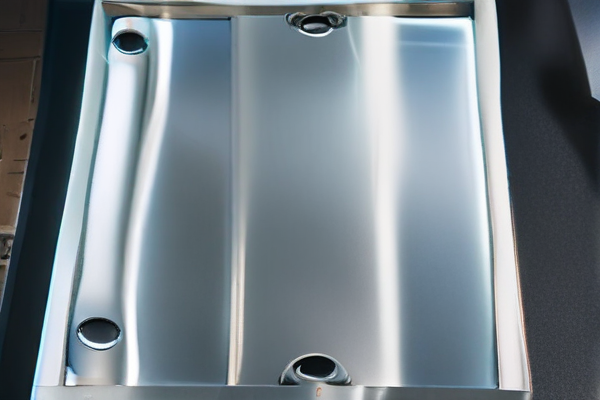

– Food Processing: Kitchen equipment, industrial ovens, and storage tanks.

– Aerospace: Aircraft components, fasteners, and engine parts.

– Marine: Boat fittings, hulls, and storage tanks.

– Energy: Oil and gas pipelines, heat exchangers, and nuclear reactors.

– Chemical Processing: Reactors, pressure vessels, and storage tanks.

– Consumer Goods: Home appliances, cutlery, and jewelry.

– Water Treatment: Pipes, storage vessels, and filtration systems.

– Pharmaceuticals: Hygienic processing equipment, storage vessels, and mixing tanks.

– Defense: Armor plating, weaponry, and vehicle components.

This extensive use in diverse settings showcases the versatility and high-performance characteristics of fabricated stainless steel.

SourcifyChina fabricates high-quality stainless steel, a versatile material known for its durability, resistance to corrosion, and appealing aesthetic. Used across various industries, it excels in both performance and appearance.

The stainless steel from SourcifyChina features a blend of iron, chromium, and other metals, providing exceptional strength and resistance to rust. This composition assures longevity in diverse environments, from industrial settings to household applications.

Manufactured with precision, SourcifyChina’s stainless steel undergoes rigorous quality control. This ensures each product meets stringent standards, delivering reliability and consistency to customers worldwide.

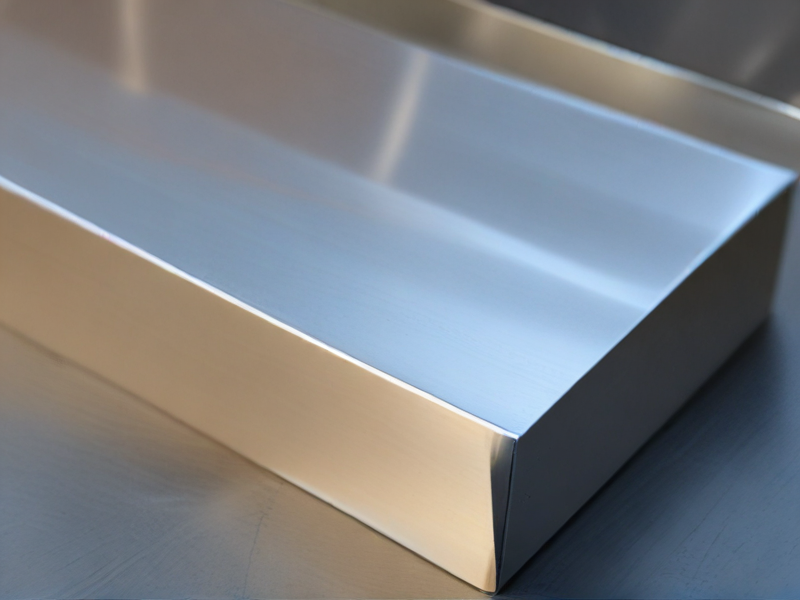

Beyond its functional attributes, the polished finish of SourcifyChina’s stainless steel enhances its visual appeal, making it a preferred choice in design-focused projects. The sleek, modern look elevates any application, from kitchen appliances to architectural structures.

Incorporating eco-friendly practices, SourcifyChina focuses on sustainable production methods. They prioritize reducing environmental impact, making their stainless steel both a high-performance and responsible choice for various uses.

In summary, SourcifyChina’s fabricated stainless steel stands out for its comprehensive advantages. Its blend of durability, aesthetic appeal, and eco-friendliness makes it a top choice in many sectors. This material, crafted with meticulous attention to quality and sustainability, ensures customer satisfaction and contributes positively to the environment.

SourcifyChina ensures high-quality stainless steel fabrication through rigorous quality control measures. Each phase in the manufacturing process is meticulously monitored to maintain stringent standards. From raw material inspection to final product evaluation, comprehensive checks are in place.

The initial stage involves sourcing top-grade stainless steel, verified by material certification and chemical composition analysis. This initial scrutiny guarantees that only premium materials proceed to the next steps. Advanced machinery and skilled technicians execute precise cutting, bending, and welding processes. Regular maintenance of equipment and continuous training ensure peak performance and accuracy.

Each fabricated piece undergoes multiple quality assessments, including dimensional checks, visual inspection, and surface finish evaluation. Non-destructive testing methods like ultrasonic and X-ray inspections are employed to detect any internal flaws. The final inspection phase ensures that all specifications and customer requirements are met before delivery. Consistent communication with clients provides feedback and continuous improvement, creating a cycle of excellence.

Ultimately, SourcifyChina’s dedication to quality control results in superior stainless steel products that exceed industry standards, ensuring reliability, durability, and customer satisfaction. This robust process establishes a foundation for trust and long-term partnerships with clients worldwide.

SourcifyChina is a leading supplier of fabricated stainless steel products, known for its high-quality manufacturing standards. Their state-of-the-art facilities ensure precision and durability.

They specialize in a diverse range of stainless steel products, from kitchenware to industrial components. This versatility makes them a preferred choice for various sectors, including food processing, pharmaceuticals, and construction.

The company’s advanced fabrication techniques include cutting, welding, and polishing. Their skilled workforce and cutting-edge technology ensure that each product meets stringent quality parameters.

SourcifyChina places a strong emphasis on sustainability. They adhere to eco-friendly practices in their production processes, ensuring minimal environmental impact.

Customer satisfaction is a top priority. They offer custom solutions tailored to specific needs and provide comprehensive after-sale support, ensuring long-lasting partnerships with their clients.

With competitive pricing and efficient delivery, SourcifyChina stands out in the global market as a reliable partner for all stainless steel fabrication needs. Their commitment to excellence continues to drive their growth and reputation.

Benefits of Fabricated Stainless Steel

Fabricated stainless steel offers numerous advantages, making it a popular choice for various applications. Its durability, corrosion resistance, and aesthetic appeal are unparalleled.

– Durability: Stainless steel is known for its high strength, making it resistant to wear and tear over time.

– Corrosion Resistance: One of its standout features is its ability to resist rust and corrosion, even in harsh environments.

– Aesthetic Appeal: With its sleek and modern look, stainless steel enhances the visual appeal of any project.

– Hygiene: Its smooth, non-porous surface is easy to clean, making it ideal for food processing and medical equipment.

– Sustainability: Stainless steel is 100% recyclable, contributing to environmental conservation efforts.

– Temperature Resistance: It can withstand extreme temperatures, both hot and cold, making it versatile for various industrial applications.

– Low Maintenance: Requires minimal upkeep, translating to cost savings over its lifespan.

– Strength-to-Weight Ratio: Provides high strength without adding significant weight, beneficial for construction and automotive industries.

– Customization: Easily fabricated into various shapes and sizes, meeting specific needs of different projects.

– Longevity: Offers a long service life, reducing the need for frequent replacements.

By choosing fabricated stainless steel, industries benefit from a material that combines functionality, longevity, and environmental responsibility.

Stainless steel is a versatile and durable material often used in various industries due to its exceptional features such as corrosion resistance, aesthetic appeal, and strength.

– Corrosion Resistance: It exhibits remarkable resistance to rust and oxidation, making it ideal for harsh environments.

– Aesthetic Appeal: The shiny, polished finish of stainless steel enhances the visual appeal of products and structures.

– Strength and Durability: High tensile strength and durability make it suitable for heavy-duty applications.

– Hygienic Properties: Non-porous nature prevents the growth of bacteria, making it perfect for medical and food industries.

– Ease of Fabrication: Can be easily welded, machined, and formed into various shapes and sizes.

– Low Maintenance: Requires minimal upkeep, reducing long-term costs.

– Recyclable: Environmentally friendly as it is 100% recyclable.

– Temperature Resistance: Can withstand extreme temperatures, both hot and cold.

– Non-reactive Surface: Does not react with most chemicals, preserving the integrity of stored substances.

– Versatility: Available in various grades and finishes to meet diverse project requirements.

– Fire and Heat Resistance: Maintains structural integrity and fire-resistance properties.

– Cost-Effective: Long-term durability makes it a cost-effective investment despite higher initial costs.

SourcifyChina offers a diverse range of fabricated stainless steel custom products tailored to meet specific client needs. By leveraging advanced manufacturing techniques, they deliver high-quality, durable solutions for various industries.

Their expertise encompasses a vast array of applications, including industrial machinery, kitchen equipment, and architectural elements. Each product is meticulously crafted to ensure functionality and aesthetic appeal.

Projects undertaken by SourcifyChina are managed with precision, from initial design to final delivery. Their commitment to quality is evident in every stage, ensuring client satisfaction and long-lasting performance of custom stainless steel products.

In addition to standard offerings, they provide bespoke solutions to address unique project requirements. SourcifyChina collaborates closely with clients, promising a seamless integration of custom designs into practical applications.

The company’s robust supply chain and efficient production processes enable timely delivery, regardless of the project size or complexity. Attention to detail and adherence to international quality standards underscore SourcifyChina’s commitment to excellence.

Overall, SourcifyChina stands out as a reliable partner for fabricated stainless steel products. Their dedication to innovation and quality drives successful project outcomes, fostering long-term relationships with clients across diverse industries.

SourcifyChina Fabricated Stainless Steel is a leading manufacturer and supplier of high-quality stainless steel products in China, dedicated to serving the global market with precision-engineered solutions. Established with a mission to provide durable and aesthetically appealing stainless steel components, the company offers an extensive range of products, including custom-made structural parts, sanitary fittings, and decorative elements designed to meet diverse industry standards. Leveraging advanced manufacturing technologies and stringent quality control processes, SourcifyChina ensures every piece meets the highest benchmarks for durability, corrosion resistance, and finish quality. Their team of skilled engineers and fabricators works closely with clients to develop tailored solutions that precisely match project specifications, enhancing functionality and longevity. Committed to sustainability and eco-friendly practices, SourcifyChina also strives to minimize environmental impact through efficient resource management and waste reduction initiatives. With a reputation for reliability, innovation, and customer-centric service, SourcifyChina Fabricated Stainless Steel continues to build enduring partnerships worldwide, delivering excellence in stainless steel manufacturing.

Fabricated stainless steel plays a crucial role in the aerospace, defense, and marine industries due to its exceptional properties such as corrosion resistance, high strength-to-weight ratio, and durability under extreme conditions. In aerospace applications, stainless steel is utilized in manufacturing critical components such as turbine blades, heat exchangers, and structural members of aircraft. The material’s ability to withstand high temperatures and resist oxidation ensures the reliability and safety of aerospace vehicles. Additionally, the precision fabrication required for aerospace components benefits from the material’s excellent machinability and formability, enabling the production of complex, high-performance parts essential for modern aviation technology.

In the defense and marine sectors, fabricated stainless steel is equally indispensable. Naval vessels and submarines rely on stainless steel for their hulls, propulsion systems, and submersible components due to its exceptional resistance to seawater corrosion and biofouling. For defense applications, the material’s strength and durability under harsh environmental conditions make it ideal for armored vehicles, weapon systems, and infrastructure. Stainless steel’s non-reactive and non-magnetic properties are also advantageous in the manufacture of sensitive electronic and communication equipment used in defense. The ability to fabricate stainless steel into precise, robust components ensures that these critical applications meet stringent performance and safety standards, safeguarding both personnel and technological assets.

Fabricated stainless steel plays a crucial role in the automotive industry due to its exceptional strength, rust resistance, and aesthetic appeal. Key components such as exhaust systems, trim, and structural elements often utilize this material to ensure long-lasting durability and optimal performance. Stainless steel exhaust systems, for example, are valued for their ability to resist corrosion and withstand high temperatures, thereby extending the vehicle’s life and improving air quality by reducing emissions. Moreover, the sleek, polished finish of stainless steel trim elements enhances the overall visual appeal of vehicles, contributing to both functionality and style. The material’s ability to endure extreme conditions makes it an indispensable component in automotive design and manufacturing.

In the electronics sector, fabricated stainless steel is equally indispensable, especially for its utility in housing and protective enclosures for sensitive components. Its non-magnetic properties make it ideal for providing electromagnetic interference (EMI) shielding in devices like smartphones, computers, and medical equipment. Additionally, stainless steel is frequently employed in the construction of industrial and consumer appliance components, from the casing of high-end refrigerators to the internal workings of sophisticated electronic gadgets. Its excellent resistance to heat, corrosion, and mechanical stress ensures that these devices maintain their integrity and performance over time. The adaptability of stainless steel to various fabrication processes, including cutting, bending, and welding, allows for precise component design, making it a versatile choice for the ever-evolving field of electronics.

Fabricated stainless steel plays a pivotal role in the construction industry due to its remarkable properties, including durability, resistance to corrosion, and aesthetic appeal. It is widely used in the construction of high-rise buildings, bridges, and architectural facades where structural integrity and longevity are paramount. Stainless steel’s resistance to corrosion ensures that structures maintain their strength and appearance over long periods, even in harsh environments. Moreover, its sleek and modern look contributes to the aesthetic value of contemporary architecture, enabling innovative and eye-catching designs. Additionally, the material’s high strength-to-weight ratio allows for the creation of lighter yet robust structures, which can lead to cost savings in terms of materials and foundational requirements.

In the realm of energy applications, fabricated stainless steel is indispensable, especially in sectors such as oil and gas, renewable energy, and nuclear power. Its resistance to extreme temperatures and pressures, as well as corrosive environments, makes it an ideal material for constructing pipelines, storage tanks, and processing equipment. For instance, in the oil and gas industry, stainless steel is used to manufacture equipment that must withstand the highly corrosive nature of crude oil and natural gas. In renewable energy systems, such as solar and wind power, stainless steel components are essential for their resilience against environmental stressors. Furthermore, in the nuclear sector, stainless steel is crucial for the construction of reactors, containment vessels, and other critical components due to its ability to maintain structural integrity under high radiation and thermal stress. Overall, the versatility and durability of fabricated stainless steel make it a cornerstone in advancing both traditional and emerging energy technologies.

Fabricated stainless steel plays a crucial role in the industrial equipment sector, known for its unparalleled corrosion resistance, durability, and strength-to-weight ratio. These properties make it an ideal material for manufacturing a wide range of industrial machinery used in harsh environments, such as chemical processing plants, petrochemical industries, and food and beverage production facilities. The non-reactive nature of stainless steel ensures that it does not contaminate or alter the chemicals or food products it comes into contact with, thereby maintaining high levels of purity and safety. Additionally, its resistance to corrosion significantly reduces maintenance costs and extends the operational life of industrial equipment, ensuring better long-term investment returns for companies.

Moreover, fabricated stainless steel enables customization and precision engineering, essential for creating tailored solutions that meet specific industrial requirements. For instance, stainless steel can be easily welded, cut, and machined to produce bespoke components and assemblies, ensuring seamless integration into existing systems. The versatility offered by stainless steel fabrication allows manufacturers to design and produce intricate parts that perform reliably under extreme temperatures and pressures, common in industrial operations. The hygienic properties of stainless steel also make it indispensable in industries where cleanliness and sterility are paramount. Hence, the adoption of fabricated stainless steel in the industrial equipment industry not only enhances performance and safety but also contributes significantly to longevity and sustainability.

Fabricated stainless steel holds a crucial role in the medical device industry, primarily due to its biocompatibility, corrosion resistance, and mechanical strength. These properties make stainless steel an ideal material for various medical applications, ranging from surgical instruments to implants and diagnostic equipment. For instance, stainless steel surgical instruments such as scalpels, forceps, and scissors are valued for their ability to withstand repeated sterilization processes without degrading. This ensures they meet the stringent hygiene standards required in medical settings. Additionally, stainless steel implants, including bone plates, screws, and joint replacements, benefit from the metal’s strength and durability, providing long-lasting solutions for patients with minimal risk of adverse reactions.

Moreover, fabricated stainless steel finds extensive use in clinical diagnostic equipment like MRI machines and hospital beds. The non-reactive nature of stainless steel makes it safe for use in environments where precision and cleanliness are paramount. Its application extends beyond just traditional tools to cutting-edge medical technologies. For example, in the realm of minimally invasive surgery, stainless steel is employed in the construction of intricate guidewires, stents, and endoscopic devices. The material’s malleability allows for delicate yet robust designs that enhance the precision and efficacy of such medical procedures. Overall, stainless steel’s versatility, coupled with its high performance in demanding clinical environments, makes it an indispensable material in the fabrication of advanced medical devices.

Fabricated stainless steel plays a critical role in machining processes due to its remarkable properties, such as high strength, corrosion resistance, and durability. When undergoing machining operations, like milling, turning, and drilling, stainless steel retains its structural integrity and surface finish, making it a preferred material in precision engineering. Its machinability allows for the creation of intricate components and parts needed in various high-performance applications, such as aerospace, automotive, and medical industries. Advanced machining techniques, including Computer Numerical Control (CNC) machining, enable the production of complex and precise parts from stainless steel, ensuring consistency and high quality. Special tooling and techniques may be required to manage its hardness and toughness, but the benefits of using stainless steel far outweigh these challenges.

In manufacturing, fabricated stainless steel is indispensable due to its versatility and resistance to harsh environments. It is extensively used in the construction of industrial equipment, kitchen appliances, and infrastructure components. The ability to fabricate stainless steel through processes such as welding, bending, and cutting allows manufacturers to produce custom-tailored solutions that meet specific industry needs. For instance, stainless steel is the backbone of food processing equipment due to its sanitary properties and ease of cleaning. Its implementation in manufacturing also extends to sectors like chemical processing and pharmaceuticals, where material integrity under high-stress conditions and resistance to chemical reactions are paramount. The combination of functionality and aesthetics also makes stainless steel a popular material choice in architectural designs, providing sleek and modern structures that are both durable and visually appealing.

Sure, here is a concise FAQ list for manufactured fabricated stainless steel quality work from SourcifyChina factory:

Q: What materials does SourcifyChina use for stainless steel fabrication?

A: SourcifyChina primarily uses high-grade stainless steel materials such as 304, 316, and 316L to ensure durability, corrosion resistance, and superior quality.

Q: What industries do SourcifyChina’s fabricated stainless steel products cater to?

A: SourcifyChina’s products cater to various industries including automotive, aerospace, food processing, pharmaceuticals, and construction, among others.

Q: What fabrication processes are employed for stainless steel work?

A: SourcifyChina employs a variety of fabrication processes including cutting, bending, welding, grinding, and polishing to produce precise and high-quality stainless steel components.

Q: Can SourcifyChina handle custom stainless steel fabrication projects?

A: Yes, SourcifyChina specializes in custom stainless steel fabrication projects, tailored to meet specific client requirements and specifications.

Q: What quality control measures are in place at SourcifyChina’s factory?

A: SourcifyChina implements rigorous quality control measures such as material inspections, dimensional checks, welding inspections, and final product testing to ensure that all products meet international standards.

Q: What is the typical production lead time for stainless steel fabrication at SourcifyChina?

A: Production lead times generally vary depending on the complexity and scale of the project but typically range from 4 to 8 weeks.

Q: Does SourcifyChina provide design assistance for fabrication projects?

A: Yes, SourcifyChina offers design assistance and engineering support to help clients optimize their designs for manufacturability and cost-efficiency.

Q: Are there any minimum order requirements for stainless steel fabrication?

A: SourcifyChina is flexible with order quantities and can accommodate both low-volume prototypes and high-volume production runs.

Q: How can I get a quote for my stainless steel fabrication project?

A: To get a quote, you can contact SourcifyChina through their website, providing detailed project specifications and drawings for an accurate and prompt response.

Q: What are the shipping options for international orders?

A: SourcifyChina offers various shipping options, including sea freight, air freight, and express courier services to ensure timely delivery across the globe.

When considering fabricated stainless steel manufacturing from SourcifyChina factory, keep these key tips in mind to ensure quality and efficiency:

1. Verify Expertise: Ensure the factory specializes in stainless steel fabrication. Check their portfolio, past projects, and client testimonials.

2. Material Quality: Confirm the grade and source of stainless steel used. High-grade materials (e.g., 304, 316) offer better longevity and resistance to corrosion.

3. Advanced Machinery: SourcifyChina factory should utilize modern CNC machines, laser cutters, and welding equipment to achieve precision and consistency in fabrication.

4. Customization Capabilities: Assess their ability to handle customized designs, sizes, and finishes. This is vital for specific project requirements.

5. Quality Control: Ensure stringent quality control processes are in place, including material inspection, dimensional checks, and functional testing.

6. Certifications: Look for ISO 9001 or similar certifications, indicating adherence to international manufacturing standards.

7. Prototyping Services: Opt for a factory that offers prototyping to refine designs before mass production, minimizing errors and costs.

8. Lead Times and Scalability: Check their lead times and capacity to scale production as your demands grow. Reliable timelines are crucial for project planning.

9. Communication: Effective communication is key. Ensure the factory has English-speaking staff and clear communication channels to address queries and updates promptly.

10. Cost Considerations: While competitive pricing is important, avoid sacrificing quality for lower costs. Balance cost with quality and service reliability.

11. Post-Production Support: Inquire about post-production services like assembly, packaging, and logistics support for seamless delivery.

By focusing on these aspects, you can maximize the benefits of fabricated stainless steel manufacturing from SourcifyChina factory, ensuring high-quality results and a smooth manufacturing process.

Q: What types of fabricated stainless steel products can SourcifyChina factory provide?

A: SourcifyChina factory specializes in a wide range of fabricated stainless steel products, including but not limited to custom metal parts, steel enclosures, industrial equipment, and architectural components.

Q: What grades of stainless steel does SourcifyChina factory use?

A: The factory primarily works with common grades like 304, 316, and 430 stainless steel, but other specialized grades can also be sourced based on customer requirements.

Q: Can SourcifyChina factory handle custom designs?

A: Yes, SourcifyChina factory has a dedicated team for custom fabrication. Clients can submit their designs or work collaboratively with the factory’s engineers to develop tailored solutions.

Q: What is the typical lead time for orders?

A: Lead times vary based on the complexity and volume of the order. Generally, standard orders can take between 4 to 6 weeks from design approval to delivery.

Q: Are quality control measures in place at SourcifyChina factory?

A: Absolutely. SourcifyChina factory employs strict quality control protocols, including material verification, precision measurements, and final inspections to ensure all products meet specified standards.

Q: Does SourcifyChina factory offer shipping options?

A: Yes, SourcifyChina factory provides various shipping options including air freight, sea freight, and express shipping. They work with clients to choose the most cost-effective and timely method.

Q: How can I request a quote from SourcifyChina factory?

A: You can request a quote by contacting them directly through their website or via email. Provide detailed information about your project, including specifications, quantities, and any special requirements.

Q: Is there a minimum order quantity (MOQ) for fabricated stainless steel products?

A: The MOQ depends on the specific product and project requirements. Typically, the factory is flexible and can accommodate smaller orders but may offer better pricing for larger quantities.

Q: Does SourcifyChina factory provide material certifications?

A: Yes, material certifications and compliance documents can be provided upon request to ensure that the stainless steel used meets industry standards.

Sourcing fabricated stainless steel from SourcifyChina factory can be a streamlined process if managed effectively. Here are some concise tips to help you navigate:

1. Research and Verification: Begin by researching SourcifyChina factory to ensure they have a solid reputation and high-quality standards. Check for certifications and read customer reviews to gauge credibility.

2. Clear Specifications: Provide detailed specifications for your stainless steel requirements. Include grade, dimensions, fabrication processes, and any necessary finishes. Precision in your order minimizes misunderstandings.

3. Request Samples: Before committing to large orders, request samples of the fabricated stainless steel. This ensures the factory’s output matches your expectations in terms of quality and craftsmanship.

4. Quality Assurance: Inquire about the factory’s quality assurance processes. Ask about inspections, testing protocols, and quality control measures in place to maintain high standards.

5. Communication: Establish clear and constant communication channels with the factory. Use email, phone calls, and instant messaging apps to stay updated on your order’s progress and address any issues promptly.

6. Negotiate Terms: Discuss payment terms, lead times, and shipping options upfront. Ensure there is mutual agreement on these terms to avoid delays or unexpected costs.

7. Factory Visit: If possible, arrange a visit to SourcifyChina factory. This offers firsthand insight into their operations, facilities, and working conditions, reinforcing your trust in their capabilities.

8. Legal Contracts: Draft clear contracts that outline all agreed terms, including delivery schedules, payment structures, and quality expectations. Legal protection is crucial for safeguarding your interests.

9. Third-party Inspection: Consider hiring a third-party inspection company to verify product quality before shipment. This step ensures that the consignment meets your specifications and reduces the risk of defects.

10. Maintain Relationships: Building a solid relationship with the factory management can lead to better service, potential discounts, and smoother transactions in future orders.

By following these tips, you can ensure a smooth sourcing process from SourcifyChina factory, securing high-quality fabricated stainless steel for your needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.