Technology and Applications of ferrous metal and non ferrous metal

Ferrous Metals

Technology:

Ferrous metals primarily consist of iron and its alloys, including steel and cast iron. The technologies involved in processing ferrous metals include:

1. Smelting: Extracting iron from its ore using high temperatures.

2. Alloying: Combining iron with other elements (e.g., carbon, manganese) to improve properties.

3. Heat Treatment: Processes like annealing, quenching, and tempering to alter mechanical properties.

4. Forging and Rolling: Shaping metals under high pressure.

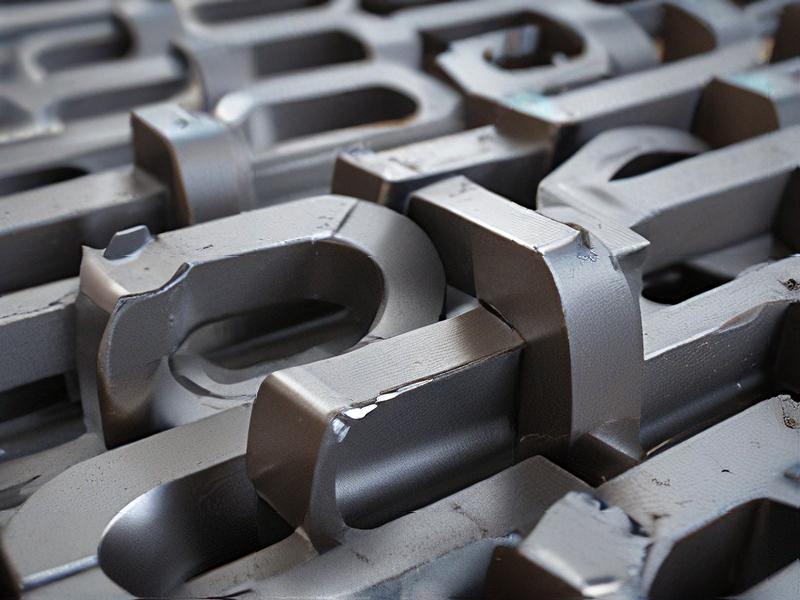

5. Casting: Pouring molten metal into molds to create shapes.

Applications:

1. Construction: Structural steel for buildings, bridges, and infrastructure.

2. Automotive: Steel for car bodies, engines, and suspension systems.

3. Manufacturing: Machine tools, pipes, and industrial machinery.

4. Railways: Tracks, locomotives, and train carriages.

5. Home Appliances: Refrigerators, washing machines, and other durable goods.

Non-Ferrous Metals

Technology:

Non-ferrous metals do not contain iron and are more resistant to corrosion. Technologies for non-ferrous metals include:

1. Electrolysis: Extracting metals like aluminum and copper.

2. Casting and Molding: Similar to ferrous but tailored for metals like aluminum and zinc.

3. Extrusion and Drawing: Shaping metals by pushing or pulling through dies.

4. Powder Metallurgy: Creating components from powdered metal.

5. Plating and Coating: Applying a non-ferrous metal layer on surfaces for protection or aesthetics.

Applications:

1. Electrical: Copper and aluminum in wiring, motors, and electronics.

2. Aerospace: Aluminum and titanium in aircraft structures and components.

3. Packaging: Aluminum cans and foil.

4. Jewelry: Gold, silver, and platinum.

5. Construction: Copper pipes, aluminum roofing, and cladding.

In summary, ferrous metals are predominantly used in applications requiring strength and durability, while non-ferrous metals are chosen for their lightweight, resistance to corrosion, and electrical conductivity.

Quality Testing Methods for ferrous metal and non ferrous metal and how to control quality

Quality Testing Methods

For Ferrous Metals:

1. Magnetic Particle Inspection (MPI): Detects surface and near-surface defects by using magnetic fields and iron particles.

2. Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws.

3. X-Ray Inspection: Visualizes internal structures and defects using X-rays.

4. Tensile Testing: Measures strength and ductility by stretching a sample until it breaks.

5. Hardness Testing: Determines resistance to deformation using methods like Rockwell, Brinell, and Vickers.

For Non-Ferrous Metals:

1. Eddy Current Testing: Uses electromagnetic induction to detect surface and near-surface defects.

2. Dye Penetrant Inspection (DPI): Reveals surface-breaking defects through dye and developer application.

3. Radiographic Testing (RT): Employs X-rays or gamma rays to view internal structures.

4. Spectroscopy: Analyzes the elemental composition to ensure material consistency.

5. Fatigue Testing: Evaluates the material’s behavior under repeated loading.

Quality Control Methods

1. Standards and Specifications: Adhering to industry standards (e.g., ASTM, ISO) ensures consistency and reliability.

2. Process Control: Monitoring manufacturing processes to maintain parameters like temperature, pressure, and speed within specified limits.

3. Statistical Process Control (SPC): Using statistical methods to monitor and control production quality.

4. Regular Inspections: Conducting systematic inspections at various production stages to identify defects early.

5. Training and Certification: Ensuring workers are trained and certified in quality control procedures.

6. Documentation and Traceability: Maintaining records of materials, processes, and inspections to trace and rectify any issues.

7. Supplier Quality Management: Evaluating and selecting suppliers based on their quality performance and adherence to standards.

By integrating these testing and control methods, manufacturers can ensure the quality and reliability of both ferrous and non-ferrous metals.

Tips for Procurement and Considerations when Purchasing from ferrous metal and non ferrous metal

Tips for Procurement

1. Understand Requirements:

– Ferrous Metals: These metals, like steel and iron, are known for their strength and durability. They are typically used in construction and heavy machinery. Ensure you know the specific grade and type needed for your project.

– Non-Ferrous Metals: Metals such as aluminum, copper, and brass are lightweight, corrosion-resistant, and non-magnetic. They are ideal for electrical, piping, and aerospace applications.

2. Supplier Selection:

– Reputation and Reliability: Choose suppliers with a solid track record. Check reviews, industry certifications, and compliance with standards.

– Quality Assurance: Ensure suppliers offer material certification and adhere to quality control processes.

3. Cost Management:

– Bulk Purchasing: Buying in bulk can reduce costs but ensure storage conditions prevent degradation.

– Market Trends: Monitor market prices and trends for cost-effective purchasing.

4. Delivery and Logistics:

– Lead Time: Understand the lead times for both ferrous and non-ferrous metals to ensure timely delivery.

– Transportation: Consider transportation costs and the condition of metals upon arrival.

Considerations When Purchasing

1. Material Properties:

– Ferrous Metals: Consider properties like tensile strength, hardness, and ductility. These metals are prone to rust, so consider protective coatings.

– Non-Ferrous Metals: Focus on corrosion resistance, conductivity, and weight. They are generally more expensive but offer longevity and performance in specific applications.

2. Environmental Factors:

– Corrosion Resistance: Non-ferrous metals are typically more resistant to corrosion. Ferrous metals may require additional treatments or coatings.

– Sustainability: Consider the environmental impact of your metal choices. Recyclability and the carbon footprint of production processes are essential factors.

3. Compliance and Standards:

– Ensure all materials meet industry-specific standards and regulations. This ensures safety and performance, particularly in critical applications like aerospace or construction.

4. Technical Support:

– Seek suppliers who provide technical support and guidance, helping you choose the right materials for your specific needs.

FAQs on Sourcing and Manufacturing from ferrous metal and non ferrous metal in China

FAQs on Sourcing and Manufacturing from Ferrous and Non-Ferrous Metals in China

1. What are ferrous and non-ferrous metals?

– Ferrous metals contain iron and are known for their strength and durability. Examples include steel and cast iron.

– Non-ferrous metals do not contain iron, are generally more resistant to rust and corrosion, and include aluminum, copper, and brass.

2. Why source metals from China?

– Cost-Effective: Competitive pricing due to lower labor and production costs.

– Variety and Availability: Wide range of products and materials readily available.

– Technological Advancements: Access to modern manufacturing processes and technologies.

3. What should I consider when choosing a supplier?

– Quality Standards: Ensure compliance with international quality standards like ISO.

– Reputation: Check reviews and ask for references.

– Capacity: Verify the supplier’s production capacity to meet your needs.

– Communication: Ensure clear and reliable communication.

4. How do I verify the quality of the metals?

– Certifications: Request material certifications and compliance documents.

– Inspections: Conduct pre-shipment inspections and third-party audits.

– Samples: Obtain and test samples before placing large orders.

5. What are the logistics involved in importing metals from China?

– Shipping Methods: Choose between sea, air, or rail freight based on urgency and cost.

– Customs Clearance: Be aware of import duties and customs regulations.

– Lead Times: Consider production and shipping times in your planning.

6. How can I ensure ethical sourcing?

– Supplier Audits: Conduct regular audits to ensure ethical labor practices.

– Sustainability: Choose suppliers with sustainable and environmentally friendly practices.

7. What are the common challenges?

– Quality Control: Maintaining consistent quality can be challenging.

– Intellectual Property: Protect your designs and innovations through patents and agreements.

– Cultural Differences: Understand and respect cultural differences in business practices.

8. Are there any specific regulations to be aware of?

– Import Regulations: Familiarize yourself with the import regulations of your country.

– Environmental Laws: Ensure compliance with environmental regulations in both China and your country.

Sourcing from China can be highly beneficial if managed correctly, ensuring quality, ethical practices, and adherence to regulations.