Choosing SourcifyChina Factory for purchasing galvanizing processes from China ensures high-quality products, reliable service, and competitive pricing. Their advanced technology guarantees superior corrosion resistance and durability, meeting international standards.

SourcifyChina’s experienced team provides personalized solutions tailored to your needs, ensuring efficient communication and seamless project execution. Their comprehensive quality control ensures consistency and reliability.

Additionally, SourcifyChina’s strategic location in China offers logistical advantages, reducing shipping costs and delivery times. This makes them an ideal partner for businesses seeking efficient and cost-effective galvanizing solutions.

In conclusion, partnering with SourcifyChina Factory means accessing top-notch galvanizing services, expert support, and a strong commitment to customer satisfaction, all contributing to your business’s success.

Galvanizing is a process used to coat steel or iron with zinc to prevent rusting. There are several methods, each with unique advantages and applications. Here are the main types of galvanizing processes:

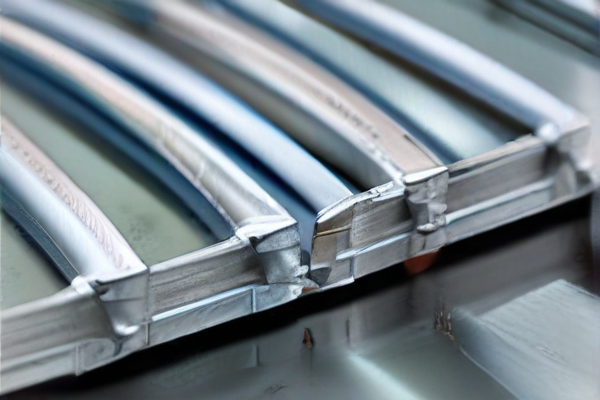

– Hot-dip galvanizing: Immersion of steel in molten zinc, providing a thick, durable coating.

– Electro-galvanizing: Using an electrical current to apply a thinner zinc layer, ideal for precision applications.

– Sherardizing: Heating steel in a closed container with zinc powder, creating a uniform, corrosion-resistant layer.

– Galvannealing: Combining hot-dip galvanizing with annealing to produce a harder, more paintable surface.

– Mechanical plating: Tumbling steel parts with zinc powder and glass beads, forming a zinc coating without heat.

Each method varies in coating thickness, adhesion, and application suitability, catering to different industrial needs.

The galvanizing process involves coating steel or iron with a layer of zinc to prevent rusting and corrosion, extending the material’s lifespan and durability.

– Construction: Structural beams, roofing, and metal frameworks.

– Automotive: Car bodies, chassis, and components.

– Agriculture: Fencing, gates, and farming equipment.

– Utilities: Power transmission towers and poles.

– Marine: Ship hulls and offshore platforms.

– Infrastructure: Bridges, guardrails, and street furniture.

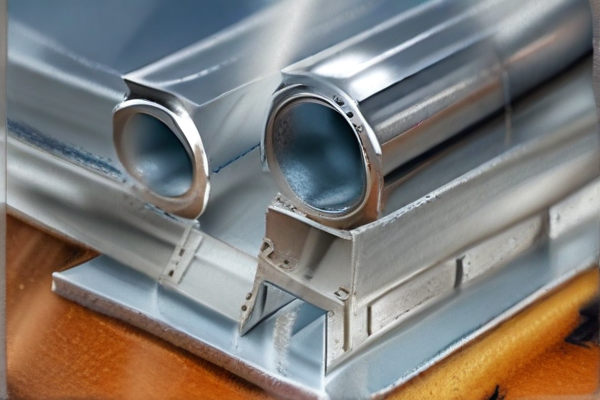

– HVAC: Ductwork and components.

– Consumer Goods: Appliances and outdoor furniture.

– Energy: Wind turbines and solar panel frames.

– Telecommunications: Antenna towers and equipment shelters.

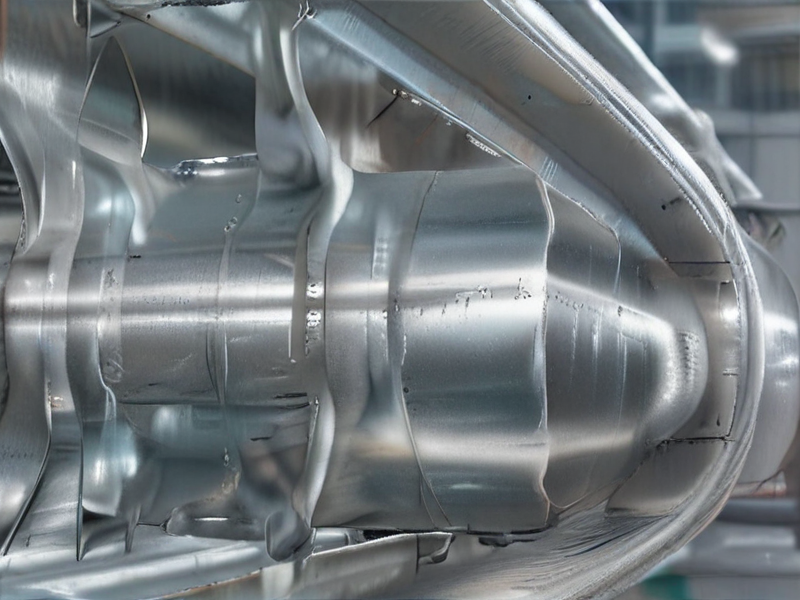

SourcifyChina employs advanced galvanizing processes to enhance the durability of metal products. The company utilizes both hot-dip and electro-galvanizing techniques. In the hot-dip method, metal is submerged in molten zinc, forming a robust protective layer. This process ensures superior corrosion resistance, making it ideal for outdoor applications.

Electro-galvanizing involves applying zinc through an electrolytic solution, creating a thinner, smoother coating. This method is preferred for items requiring a fine finish and is suitable for indoor use. Both techniques extend the lifespan of metal products, providing a cost-effective solution for preventing rust and degradation.

SourcifyChina’s galvanizing processes adhere to stringent quality standards, ensuring consistent coating thickness and adherence. They also incorporate eco-friendly practices, reducing waste and emissions during production. This commitment to sustainability not only benefits the environment but also enhances the long-term performance of their galvanized products.

Additionally, SourcifyChina offers customized galvanizing services to meet specific client requirements. They provide tailored solutions for various industries, ensuring that each product receives the appropriate level of protection. This flexibility and attention to detail have made SourcifyChina a trusted partner in the global market.

Their expertise in galvanizing, coupled with state-of-the-art technology, allows SourcifyChina to deliver high-quality, reliable products. By continuously innovating and improving their processes, they maintain a competitive edge and ensure customer satisfaction. Overall, SourcifyChina’s galvanizing techniques significantly improve the durability and longevity of metal products, offering an effective solution against corrosion.

SourcifyChina’s galvanizing process emphasizes rigorous quality control at each manufacturing stage. Initially, raw materials are inspected to ensure they meet specified standards. Only materials that pass stringent tests proceed further.

During the cleaning phase, materials undergo degreasing, pickling, and fluxing. Each step is meticulously monitored to guarantee contaminants are eliminated, ensuring optimal zinc adhesion during galvanization.

The galvanizing phase involves immersing materials in molten zinc. Temperature and immersion time are precisely controlled to achieve uniform coating thickness. Regular sample testing ensures consistency and adherence to industry standards.

Finally, post-galvanizing inspection includes visual checks and thickness measurements. This comprehensive quality control ensures durable, corrosion-resistant products, meeting SourcifyChina’s high standards and customer expectations.

SourcifyChina offers a comprehensive galvanizing process, providing high-quality corrosion protection for steel products. Their advanced facilities ensure consistent coating thickness and adherence, meeting international standards for durability and longevity.

The company utilizes hot-dip galvanizing, an efficient method that involves immersing steel in molten zinc. This creates a robust, zinc-iron alloy layer, enhancing resistance against rust and environmental wear.

SourcifyChina’s expertise includes managing intricate shapes and sizes, ensuring uniform coating across complex geometries. Their process is versatile, suitable for various industries, from construction to automotive.

A stringent quality control system underpins their operations. Regular inspections and testing guarantee that each batch meets stringent specifications, ensuring reliability and performance.

Additionally, SourcifyChina prioritizes environmental sustainability. Their galvanizing process incorporates eco-friendly practices, minimizing waste and energy consumption, and adhering to regulatory compliance.

Customer service excellence is a cornerstone of their operations. SourcifyChina provides comprehensive support, from initial consultation to final delivery, ensuring a seamless experience.

In conclusion, SourcifyChina’s galvanizing capabilities stand out for their technological prowess, quality assurance, and customer-centric approach. Their commitment to excellence makes them a trusted partner in the industry.

The galvanizing process, which involves coating steel or iron with a layer of zinc, provides significant benefits for corrosion resistance and longevity of metal products.

– Corrosion Resistance: The zinc coating protects the underlying metal from corrosion, extending its lifespan significantly.

– Durability: Galvanized steel is highly durable and can withstand harsh environmental conditions without deteriorating.

– Low Maintenance: The protective zinc layer reduces the need for frequent maintenance and repairs.

– Cost-Effective: While the initial cost may be higher, the extended life and reduced maintenance costs make galvanizing economically beneficial in the long run.

– Quick Application: The galvanizing process is relatively fast and can be applied to complex shapes and sizes.

– Environmental Benefits: Zinc is recyclable, and galvanized products have a long lifecycle, reducing the environmental impact.

– Aesthetic Appeal: Galvanized metal has a uniform, attractive appearance and can be used in visible structures.

– Adhesion: Paint and other coatings adhere well to galvanized surfaces, allowing for further customization if needed.

– Comprehensive Protection: Galvanizing provides both barrier and cathodic protection, ensuring the metal is safeguarded even if the coating is damaged.

Overall, galvanizing is a robust and versatile method for enhancing the performance and longevity of metal structures and components.

Galvanizing is a process used to apply a protective zinc coating to steel or iron, preventing rust and corrosion. It is widely used in various industries for its durability and cost-effectiveness.

Key features of the galvanizing process:

– Hot-Dip Galvanizing: Steel is dipped in molten zinc, providing a thick, durable coating.

– Electrogalvanizing: Uses an electrical current to apply a thinner zinc layer, ideal for fine details.

– Corrosion Resistance: Zinc coating acts as a barrier against moisture and oxygen.

– Self-Healing: Zinc can repair minor scratches and damages due to its sacrificial nature.

– Longevity: Extends the lifespan of steel structures significantly.

– Adhesion: Zinc coating bonds well with the steel, preventing flaking or peeling.

– Cost-Effective: Lowers maintenance and repair costs over time.

– Aesthetic Appeal: Provides a shiny, uniform finish.

– Environmentally Friendly: Zinc is a recyclable material, reducing environmental impact.

SourcifyChina specializes in the galvanizing process, ensuring high-quality protection for metal products against corrosion. Their advanced techniques guarantee durability and longevity for various custom products.

The company offers tailored galvanizing solutions to meet specific project requirements. They cater to diverse industries, providing customized services that align with each client’s unique needs.

With a focus on precision and efficiency, SourcifyChina’s galvanizing process enhances the structural integrity of metal components. Their expertise ensures that every project, regardless of size, receives meticulous attention to detail.

Clients benefit from SourcifyChina’s commitment to excellence, receiving products that are not only robust but also aesthetically pleasing. Their state-of-the-art facilities enable them to handle complex projects with ease.

In addition to galvanizing, SourcifyChina offers comprehensive support, including design consultation and project management. Their holistic approach ensures seamless execution from concept to completion, delivering superior results.

SourcifyChina’s galvanizing process is integral to the success of various infrastructure, construction, and industrial projects. Their dedication to quality and innovation sets them apart as a trusted partner in the field.

By leveraging advanced technologies and industry best practices, SourcifyChina delivers reliable, cost-effective solutions. Their commitment to sustainability and environmental standards further enhances their reputation in the market.

Ultimately, SourcifyChina’s galvanizing services provide unparalleled protection and performance for custom products and projects, ensuring they withstand the test of time. Their unwavering dedication to customer satisfaction makes them a preferred choice for galvanizing needs.

SourcifyChina is a prominent player in the galvanizing industry, known for its advanced and reliable galvanizing processes. The company specializes in providing high-quality galvanizing services, ensuring the durability and corrosion resistance of steel products used in various industrial applications. With a strong emphasis on technological innovation, SourcifyChina employs state-of-the-art equipment and rigorous quality control measures to meet international standards. Their processes include hot-dip galvanizing and other customized coating solutions tailored to client specifications. This commitment to excellence has positioned SourcifyChina as a trusted partner for industries ranging from construction to manufacturing, offering not only superior product protection but also extending the lifespan of critical infrastructure components. Through their expertise and dedication to customer satisfaction, SourcifyChina continues to set benchmarks in the galvanizing sector, reflecting their role as a leader in sustainable and efficient metal treatment solutions.

The galvanizing process, primarily involving the application of a protective zinc coating to steel or iron, is crucial in the aerospace, defense, and marine industries due to its ability to enhance corrosion resistance and extend the lifespan of metal components. In aerospace applications, galvanized coatings protect critical components such as landing gear, structural parts, and fasteners from the corrosive effects of high-altitude environments and varying weather conditions. This ensures reliability and safety in aircraft operations, reducing maintenance costs and preventing premature failure. Additionally, the lightweight nature of zinc coatings makes them ideal for use in aircraft, where weight considerations are paramount.

In the defense and marine sectors, the galvanizing process plays a pivotal role in safeguarding equipment exposed to harsh environments. Naval vessels, offshore platforms, and military vehicles are frequently subjected to corrosive elements like saltwater, humidity, and extreme temperatures. Galvanized steel is extensively used in constructing ship hulls, decks, and various on-board equipment, offering long-term protection against rust and structural degradation. Similarly, in defense applications, galvanizing ensures the durability and performance of vehicles, weaponry, and infrastructure in challenging conditions. The ability to maintain the integrity of materials under such stress is critical for operational readiness and longevity, making galvanizing an indispensable process in these fields.

The galvanizing process, which involves coating iron or steel with a layer of zinc to prevent corrosion, has significant applications in the automotive industry. Vehicles are constantly exposed to harsh environmental conditions, including moisture, salt, and varying temperatures, which can lead to rust and degradation of metal components. By galvanizing critical parts like the chassis, body panels, and undercarriages, manufacturers enhance the durability and longevity of vehicles. This protective zinc layer acts as a barrier, preventing corrosive substances from reaching the underlying metal. Additionally, galvanizing offers cost-effective protection and is preferred over other methods due to its ability to provide uniform coverage and long-term performance, which is crucial for maintaining vehicle safety and structural integrity over time.

In the electronics industry, the galvanizing process is employed to protect various metal components used in electronic devices and infrastructure. Many electronic systems rely on metal connectors, casings, and fasteners that need to resist corrosion to maintain reliable performance. Galvanized metals are used in circuit boards, battery terminals, and other electronic enclosures to ensure conductivity and prevent failure due to rust. Moreover, the process is vital for outdoor electronics, such as telecommunications equipment and solar panel mounts, which are exposed to the elements and require robust corrosion resistance. By employing galvanizing, the electronics industry can enhance the lifespan and functionality of products, reducing maintenance costs and improving overall reliability.

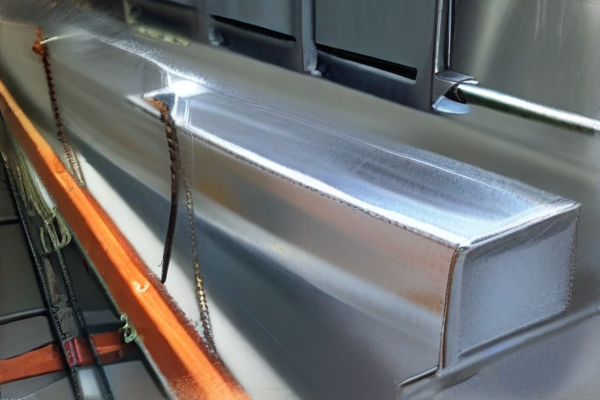

Galvanizing, a process where steel or iron is coated with a thin layer of zinc, is a paramount technique in the construction industry to enhance the durability, lifespan, and corrosion resistance of materials. This protective zinc layer acts as a barrier, preventing rust and the impacts of weathering, making it particularly essential for outdoor structures like bridges, buildings, and roads. In construction, galvanized steel is extensively used for structural beams, roofing, and facades. The long-lasting protection it offers reduces the need for frequent maintenance and replacements, translating into significant cost savings over time. Moreover, the aesthetic appeal of galvanized steel, with its sleek, silver finish, is an added benefit that architects and engineers often leverage in modern design.

In the energy sector, the galvanizing process holds critical importance for ensuring the reliability and efficiency of infrastructure. Energy facilities, such as power plants, wind turbines, and solar panel structures, are subject to harsh environmental conditions, including moisture, salt, and extreme temperatures. Galvanized steel’s robust corrosion resistance ensures that these facilities remain operational and safe over extended periods. For instance, transmission towers and substations, which are crucial for electricity distribution, are often galvanized to prevent downtime due to structural failures. Furthermore, in renewable energy applications, such as offshore wind farms, where exposure to harsh marine environments is inevitable, galvanizing provides the necessary protection to withstand saline conditions. Thus, through enhancing durability and reducing maintenance, the galvanizing process substantially contributes to the sustainability and resilience of energy infrastructure.

The galvanizing process, involving the application of a protective zinc coating to steel or iron, plays a crucial role in the industrial equipment industry. This process is primarily used to enhance the durability and longevity of equipment exposed to harsh environments, such as construction machinery, agricultural tools, and transportation infrastructure. By preventing rust and corrosion, galvanizing significantly extends the service life of these products, reducing maintenance costs and downtime. The hot-dip galvanizing method, where components are submerged in molten zinc, creates a robust metallurgical bond that provides superior protection compared to other coating techniques. This is particularly beneficial for industrial equipment frequently exposed to moisture, chemicals, and mechanical wear.

In addition to durability, galvanizing also offers economic advantages for the industrial equipment industry. The process is cost-effective, providing a lower initial cost compared to alternative protective coatings and minimizing the need for expensive, frequent replacements. The ease of inspecting galvanized coatings ensures that quality control can be maintained with minimal effort, further contributing to cost savings. Additionally, the recyclability of zinc aligns with sustainable manufacturing practices, supporting the industry’s move towards more environmentally friendly solutions. Overall, the galvanizing process is integral to ensuring that industrial equipment remains reliable, cost-efficient, and sustainable, meeting the rigorous demands of various industrial applications.

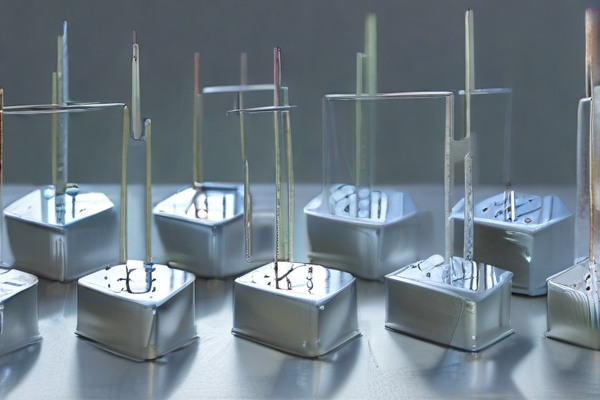

The galvanizing process, a method traditionally employed to coat steel or iron with a layer of zinc, has found innovative applications in the medical devices sector. This process enhances the corrosion resistance of medical instruments, ensuring longevity and reliability in harsh sterilization environments. Medical devices, such as surgical tools and hospital beds, are frequently exposed to corrosive substances, including bodily fluids and sterilizing agents. The zinc coating provided by galvanizing acts as a protective barrier, preventing rust and degradation. This not only extends the life span of the equipment but also maintains its functionality and safety, which are critical in medical settings.

Moreover, the galvanizing process contributes to the biocompatibility of certain medical devices. Zinc, a trace element essential to human health, is naturally biocompatible, reducing the risk of adverse reactions when medical devices come into contact with tissues and bodily fluids. This is particularly important for implants and other devices that remain inside the body for extended periods. Additionally, the antimicrobial properties of zinc help minimize the risk of infections, a crucial factor in the success of medical procedures. The application of galvanizing in medical devices, therefore, not only ensures durability and reliability but also enhances patient safety and outcomes by leveraging the protective and biocompatible qualities of zinc.

The galvanizing process, particularly hot-dip galvanizing, is a vital technique in machining and manufacturing for protecting steel and iron components from corrosion. This process involves immersing the metal parts in a bath of molten zinc, creating a robust, long-lasting coating that shields the underlying material from environmental factors. In machining, galvanized materials are often used for parts that require superior resistance to rust and wear, such as fasteners, pipes, and structural beams. The zinc coating not only enhances durability but also provides a self-healing mechanism where small scratches are resealed by zinc’s sacrificial nature, extending the life of machined components.

In manufacturing, galvanizing is essential for producing high-quality, corrosion-resistant products used in various industries, including construction, automotive, and infrastructure. For instance, galvanized steel is extensively employed in the production of car bodies, bridges, and outdoor structures, where exposure to moisture and chemicals is prevalent. The galvanizing process ensures that these products maintain their structural integrity and aesthetic appeal over long periods. Additionally, galvanizing is environmentally friendly, as zinc is a recyclable material, aligning with sustainable manufacturing practices. Overall, the galvanizing process significantly contributes to the reliability and longevity of machined and manufactured goods, making it an indispensable technique in modern industrial applications.

FAQ for Galvanizing Process Quality Work from SourcifyChina Factory

Q1: What is the galvanizing process?

A1: Galvanizing is a process of coating iron or steel with zinc to protect against rusting. The most common method is hot-dip galvanizing, where steel parts are submerged in molten zinc.

Q2: What are the benefits of using SourcifyChina’s galvanizing services?

A2: SourcifyChina provides high-quality galvanizing that enhances corrosion resistance, extends the lifespan of products, and ensures uniform coating. Our state-of-the-art facilities and stringent quality control measures guarantee superior results.

Q3: What standards do you follow for galvanizing?

A3: We adhere to international standards such as ASTM A123, ISO 1461, and BS EN 1461, ensuring our galvanizing processes meet or exceed industry requirements for thickness, uniformity, and durability.

Q4: How does SourcifyChina ensure the quality of the galvanizing process?

A4: Our quality assurance includes multiple inspection stages, such as visual inspections, thickness measurements using magnetic gauges, and adhesion tests. We also employ skilled technicians and regularly calibrate our equipment.

Q5: Can SourcifyChina handle large or custom-sized parts?

A5: Yes, we have the capacity to galvanize a wide range of sizes, from small components to large structural parts. Our facilities are equipped to handle custom requirements efficiently.

Q6: What is the typical lead time for galvanizing services?

A6: Lead times vary depending on order size and complexity, but we strive to complete most projects within 1-2 weeks. Expedited services are available upon request.

Q7: Does SourcifyChina offer after-sales support?

A7: Absolutely. We provide comprehensive after-sales support, including technical assistance and guidance on maintenance to ensure the longevity of the galvanized coating.

Q8: How can I get a quote for galvanizing services?

A8: You can request a quote by contacting us via our website or email. Provide details about the project, including dimensions, quantity, and any specific requirements, and our team will respond promptly.

Q9: Are there any environmental considerations in your galvanizing process?

A9: Yes, we are committed to environmentally responsible practices. Our processes minimize waste and emissions, and we follow strict regulations to ensure our operations are eco-friendly.

Q10: What industries does SourcifyChina serve with its galvanizing services?

A10: We serve a diverse range of industries, including construction, automotive, agriculture, and telecommunications, providing tailored galvanizing solutions to meet specific industry needs.

The galvanizing process is crucial for protecting steel and iron from rust and corrosion. SourcifyChina factory provides several tips for efficient and high-quality galvanizing in manufacturing:

1. Surface Preparation:

– Cleaning: Ensure thorough cleaning of the steel surface by removing dirt, oil, and scale. This is typically achieved through degreasing, pickling (acid cleaning), and rinsing.

– Inspection: Post-cleaning, inspect the surface to ensure all contaminants are removed. A clean surface ensures proper zinc adhesion.

2. Fluxing:

– Apply a flux solution to prevent oxidation before the steel is immersed in molten zinc. This step is essential for promoting the wetting of the steel by the zinc.

3. Galvanizing:

– Zinc Bath: Immerse the prepared steel into a bath of molten zinc (temperature around 450°C). The immersion time depends on the steel’s thickness.

– Control Parameters: Monitor temperature and immersion duration closely to ensure a uniform coating.

4. Post-Treatment:

– Cooling: Quench the galvanized steel in a passivation solution to cool it down quickly and to provide an additional layer of corrosion resistance.

– Inspection: Check for coating uniformity, thickness, and adherence. Use tools like coating thickness gauges to measure the zinc layer.

5. Quality Control:

– Regularly test the zinc coating for thickness, adherence, and overall quality. Employ both visual inspections and mechanical tests.

– Adhere to industry standards, such as ASTM A123, for ensuring the quality and longevity of the galvanized products.

6. Environmental Considerations:

– Properly manage waste materials, including acidic solutions and zinc dross, to minimize environmental impact.

– Implement recycling practices for by-products whenever possible.

By following these steps, SourcifyChina ensures high-quality galvanizing that enhances durability and performance of steel products.

What is the galvanizing process offered by SourcifyChina Factory?

The galvanizing process at SourcifyChina involves coating steel or iron with a protective layer of zinc to prevent rusting. The primary methods include hot-dip galvanizing and electro-galvanizing.

What materials can be galvanized at SourcifyChina?

SourcifyChina can galvanize various materials, including steel, iron, and other ferrous metals. They handle products like pipes, beams, and metal sheets.

What are the benefits of using SourcifyChina for galvanizing?

SourcifyChina provides high-quality galvanizing with excellent corrosion resistance, durability, and longevity. Their advanced techniques ensure a uniform coating and adherence to international standards.

What are the typical lead times for the galvanizing process?

Lead times vary depending on the order size and specific requirements. Typically, SourcifyChina completes the galvanizing process within 1-2 weeks after order confirmation.

How does SourcifyChina ensure quality control?

SourcifyChina employs rigorous quality control measures, including thorough inspections, standardized procedures, and advanced testing equipment to ensure each product meets quality standards.

What industries does SourcifyChina serve with their galvanizing services?

SourcifyChina serves a wide range of industries, including construction, automotive, infrastructure, and manufacturing, providing customized galvanizing solutions to meet industry-specific needs.

Can SourcifyChina handle large-volume orders?

Yes, SourcifyChina is equipped to handle both small and large-volume orders, ensuring timely delivery and consistent quality across all batches.

What are the environmental considerations of the galvanizing process at SourcifyChina?

SourcifyChina is committed to environmentally friendly practices, utilizing efficient processes to minimize waste and emissions, and adhering to environmental regulations.

How can I get a quote for the galvanizing process from SourcifyChina?

You can get a quote by contacting SourcifyChina directly through their website or customer service. Provide details about your project, including material type, dimensions, and quantity.

Does SourcifyChina offer any additional services related to galvanizing?

Yes, SourcifyChina offers additional services such as metal fabrication, cutting, and finishing to complement their galvanizing process, providing a comprehensive solution for your needs.

Sourcing the galvanizing process from SourcifyChina factory involves several steps to ensure quality, cost-effectiveness, and reliability. Here are key tips to guide you:

1. Define Your Requirements:

– Clearly specify the type of galvanizing process you need (e.g., hot-dip, electro-galvanizing).

– Provide detailed product specifications, including material type, thickness, and dimensions.

2. Research and Select Suppliers:

– Use SourcifyChina’s platform to identify potential suppliers.

– Check supplier profiles for experience, certifications (e.g., ISO 9001), and customer reviews.

3. Request for Quotation (RFQ):

– Send RFQs to multiple suppliers to compare prices, capabilities, and lead times.

– Include all necessary details in your RFQ to receive accurate quotes.

4. Evaluate Quotes and Capabilities:

– Compare quotes not just on price but also on quality, production capacity, and compliance with standards.

– Ask for samples or visit the factory if possible to verify capabilities.

5. Quality Assurance:

– Ensure the supplier has robust quality control processes.

– Request detailed information on their galvanizing process, including inspection and testing procedures.

6. Negotiate Terms:

– Discuss and finalize terms of payment, delivery schedules, and warranties.

– Make sure all agreements are documented in a formal contract.

7. Monitor Production:

– Regularly communicate with the supplier to monitor production progress.

– Consider third-party inspection services to ensure compliance with your specifications before shipment.

8. Logistics and Shipping:

– Plan for efficient logistics and shipping, considering factors like customs clearance and delivery times.

– Ensure proper packaging to protect galvanized products during transit.

9. Post-Delivery Follow-Up:

– Inspect the received goods thoroughly.

– Provide feedback to the supplier for continuous improvement.

By following these steps, you can effectively source the galvanizing process from SourcifyChina factory, ensuring high-quality and reliable service.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.