Choosing SourcifyChina Factory for purchasing heat-treated stainless steel from China offers several advantages. Their extensive experience in the industry ensures high-quality products. The factory employs advanced technology for precise heat treatment, enhancing material properties. Their commitment to rigorous quality control processes guarantees consistent product performance, meeting international standards.

SourcifyChina’s strategic location within China’s industrial hub facilitates efficient logistics, reducing lead times and shipping costs. The factory’s well-established supply chain partnerships ensure timely delivery of raw materials, which translates to faster production cycles and shorter wait times for buyers.

Additionally, SourcifyChina Factory offers competitive pricing without compromising on quality, providing excellent value for buyers. Their flexible production capabilities can accommodate both small and large orders, catering to diverse customer needs. The factory also emphasizes sustainability, using eco-friendly processes and materials.

Customer support at SourcifyChina is top-notch, with a dedicated team available to assist with inquiries and provide after-sales service. They offer customization options to meet specific requirements, ensuring buyers get exactly what they need. This combination of quality, efficiency, and customer-centric services makes SourcifyChina Factory an ideal choice for purchasing heat-treated stainless steel from China.

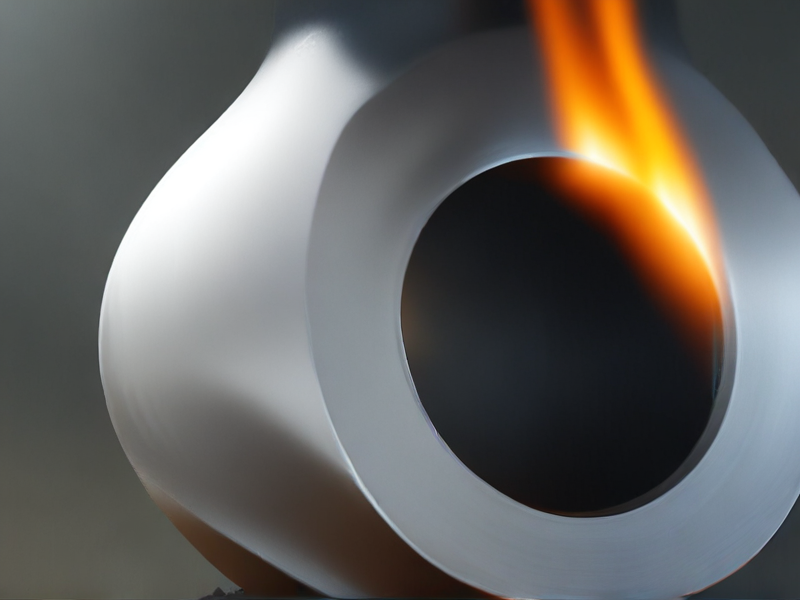

Heat treating stainless steel involves processes like annealing, quenching, and tempering to enhance mechanical properties, corrosion resistance, and stress relief. Each method serves specific purposes depending on the stainless steel grade.

– Annealing:

– Softens steel, improves ductility

– Heats to 1040-1200°C, then slowly cools

– Common for austenitic and ferritic stainless steels

– Quenching:

– Rapid cooling to increase hardness

– Used primarily on martensitic and precipitation-hardened stainless steels

– Often employs water or oil as quenching media

– Tempering:

– Reduces brittleness after quenching

– Involves reheating to 150-370°C, then air cooling

– Balances hardness and toughness

– Solution Treatment:

– Dissolves carbide precipitates

– Heated to 1000-1100°C, then quenched

– Applies to duplex and austenitic stainless steels

– Stress Relieving:

– Reduces residual stresses

– Heats to 370-480°C, then holds for a specific time

– Enhances dimensional stability

– Aging:

– Used for precipitation-hardened stainless steels

– Heated at lower temperatures (450-750°C)

Heat treating stainless steel enhances its mechanical properties, making it suitable for various industrial applications. This process improves hardness, strength, and corrosion resistance, ensuring the material meets specific performance requirements.

Applications for heat-treated stainless steel:

– Aerospace components

– Medical instruments

– Automotive parts

– Food processing equipment

– Oil and gas industry tools

– Chemical processing plants

– Marine hardware

– Heat exchangers

– Construction materials

– Consumer goods (cutlery, appliances)

Heat treating methods:

– Annealing: Reduces hardness, improves ductility.

– Quenching: Increases hardness.

– Tempering: Balances hardness and toughness.

– Solution treating: Enhances corrosion resistance.

Industries rely on tailored heat treatments to optimize stainless steel performance for their unique needs.

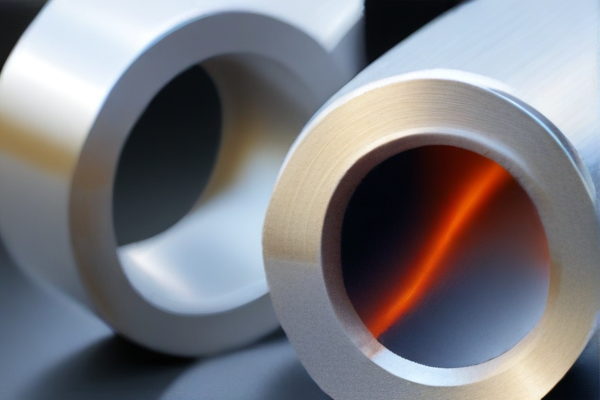

SourcifyChina specializes in providing high-quality heat-treating services for stainless steel. Their process ensures enhanced durability, improved mechanical properties, and excellent resistance to corrosion. By using advanced technologies and skilled professionals, SourcifyChina guarantees top-notch heat treatments.

The company employs various methods, such as annealing, quenching, and tempering, to achieve the desired properties in stainless steel. These techniques involve controlled heating and cooling to alter the metal’s microstructure, tailoring it to suit specific applications. These processes ensure the stability and longevity of the treated materials.

SourcifyChina’s heat-treating services are ideal for a wide array of industries, including automotive, aerospace, and medical devices. Their precision treatment ensures that stainless steel components maintain their integrity even under extreme conditions, contributing to safety and reliability in critical applications.

Furthermore, SourcifyChina places a strong emphasis on quality assurance. They utilize state-of-the-art equipment and adhere to stringent industry standards to meet customer specifications. This commitment to quality not only enhances the material’s performance but also extends its service life, providing significant value to their clientele.

The environmental impact of their processes is also minimized. Utilizing energy-efficient methods and eco-friendly practices, SourcifyChina aims to reduce their carbon footprint. This dedication to sustainability ensures that their heat-treating services are not only effective but also responsible.

In conclusion, SourcifyChina’s expertise in heat treating stainless steel combines advanced technology, skilled personnel, and a commitment to quality and sustainability. Their comprehensive services cater to a variety of industries, ensuring optimal performance and longevity of stainless steel components. Whether for critical aerospace parts or everyday medical devices, SourcifyChina’s heat-treating capabilities stand out as a benchmark of excellence.

SourcifyChina’s heat-treating stainless steel quality control begins with meticulous material selection. High-grade stainless steel is sourced to ensure the best mechanical properties and resistance to corrosion.

Next, the materials undergo stringent chemical composition tests. Advanced spectrometers and analyzers are used to verify that alloys meet industry standards before proceeding to the heat-treating phase.

During heat treatment, precise temperature control is pivotal. Modern furnaces equipped with digital temperature monitors ensure consistent heating and cooling cycles to optimize the material properties of stainless steel.

Post heat-treatment, the stainless steel undergoes rigorous mechanical tests. Hardness, tensile strength, and impact resistance are evaluated to ensure that the final product meets stringent quality standards.

Non-destructive testing methods, like ultrasonic and radiographic inspections, are also employed to identify internal flaws without compromising the integrity of the material.

Final quality checks include visual inspections and surface finishing evaluations. Any defects or inconsistencies are identified and corrected before the product is approved for distribution.

SourcifyChina’s quality control process underscores their commitment to excellence, ensuring that every product meets the highest standards of durability and performance. The comprehensive approach guarantees reliable and high-quality stainless steel products for their global clientele.

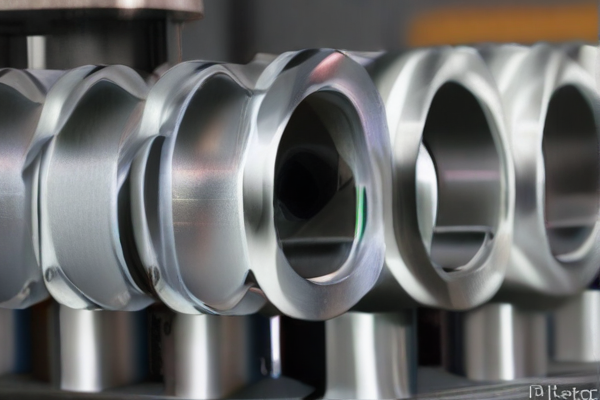

SourcifyChina specializes in heat treating stainless steel, offering state-of-the-art solutions that enhance material performance. Their top-tier facilities ensure precise temperature control and uniform heating, essential for achieving desired mechanical properties.

Through various heat-treating methods like annealing, quenching, and tempering, SourcifyChina optimizes corrosion resistance and tensile strength. Their advanced technologies meet industry standards, catering to diverse applications from automotive to aerospace sectors, ensuring durability and reliability.

Trained technicians at SourcifyChina utilize sophisticated equipment for meticulous heat treatment. Their expertise in handling a wide range of stainless steel grades guarantees consistent quality and improved lifecycle of products.

Focusing on innovation, SourcifyChina continuously invests in research and development to adopt the latest advancements in heat-treating technologies. This commitment to excellence not only enhances their service offerings but also ensures their competitive edge in the market.

In summary, SourcifyChina’s heat-treating capabilities for stainless steel are marked by advanced technology, skilled expertise, and a strong focus on quality and innovation. These attributes make them a preferred partner for industries seeking high-performance stainless steel solutions.

Heat treating stainless steel enhances its mechanical properties, such as hardness, strength, and corrosion resistance, making it suitable for various industrial applications.

– Increased Hardness: Heat treating can significantly increase the hardness of stainless steel, improving its durability.

– Enhanced Strength: The process refines the grain structure, leading to enhanced tensile and fatigue strength.

– Improved Corrosion Resistance: Proper heat treatment can optimize the alloy composition, boosting its resistance to various forms of corrosion.

– Better Wear Resistance: Increased hardness and optimized microstructure contribute to greater wear resistance.

– Improved Machinability: Heat treatment can make stainless steel easier to machine, reducing tool wear and production costs.

– Stress Relief: Annealing and other heat-treating methods can relieve internal stresses, reducing the risk of distortion during machining.

– Homogeneous Microstructure: Heat treatment can ensure a more uniform and consistent microstructure, leading to predictable mechanical properties.

– Enhanced Ductility and Toughness: Proper heat treatment can balance hardness with ductility, improving the material’s overall toughness.

– Surface Hardening Options: Techniques like carburizing or nitriding can harden the surface while maintaining a tough core.

– Extended Service Life: Enhanced mechanical properties contribute to a longer service life for stainless steel components.

In summary, heat treating stainless steel is an essential process to enhance its mechanical properties, making it more suitable for demanding applications by increasing hardness, strength, and corrosion resistance, among other benefits.

Heat treating stainless steel involves heating and cooling processes that enhance its mechanical properties and corrosion resistance. Here are key features of this treatment:

– Annealing: Softens stainless steel, improves ductility, and relieves internal stresses.

– Quenching: Rapid cooling process that increases hardness and strength.

– Tempering: Follows quenching, reduces brittleness while retaining hardness.

– Solution Treatment: Dissolves carbides, making steel more corrosion-resistant.

– Precipitation Hardening: Increases strength by forming small particles within the metal matrix.

– Stress Relieving: Reduces residual stresses from manufacturing processes without significantly altering mechanical properties.

– Normalizing: Refines grain structure, enhances toughness, and prepares steel for further processing.

SourcifyChina specializes in heat-treating stainless steel for custom products and projects, ensuring high-quality and durable results. Their state-of-the-art facilities are equipped with advanced technologies, enabling precise control over the heat-treating process. This ensures that each stainless steel component meets stringent specifications and performance standards.

The company’s tailored solutions cater to various industries, including automotive, aerospace, and medical sectors. By collaborating closely with clients, SourcifyChina customizes each heat-treatment process to fit the unique requirements of projects, enhancing the functionality and lifespan of stainless steel parts.

SourcifyChina’s expert team conducts rigorous testing and quality assurance to guarantee optimal outcomes. From annealing to hardening, every step is meticulously executed, ensuring that the final products exhibit superior mechanical properties and corrosion resistance. These stringent procedures help maintain the integrity and reliability of the components in diverse operating conditions.

Clients benefit from SourcifyChina’s commitment to innovation and excellence. By staying abreast of industry trends and continually upgrading their techniques, the company delivers cutting-edge solutions that drive customer success. Whether it’s a small batch or large-scale production, SourcifyChina ensures that each project is completed on time and within budget.

In summary, SourcifyChina offers exceptional heat-treating services for stainless steel, driven by technological expertise and a dedication to quality. They provide customized solutions across various industries, ensuring robust and reliable products that exceed client expectations.

SourcifyChina has established itself as a prominent player in the niche yet essential field of heat treating stainless steel, demonstrating an impressive blend of innovation, precision, and quality control. Specializing in various heat treatment processes such as annealing, quenching, tempering, and stress relieving, the company caters to a diverse range of industries, including aerospace, automotive, medical, and heavy machinery. Leveraging state-of-the-art technology and robust, standardized procedures, SourcifyChina ensures that stainless steel components exhibit enhanced mechanical properties, corrosion resistance, and durability. Their commitment to excellence is underscored by stringent quality assurance protocols and a team of skilled metallurgists and engineers who continually push the envelope in material science. This dedication not only differentiates SourcifyChina from its competitors but also aligns with global standards, making them a trusted partner for clients seeking reliable and long-lasting stainless steel solutions. Furthermore, their strategic location in China enables them to offer competitive pricing and swift turnaround times, enhancing overall client satisfaction and fostering long-term business relationships.

Heat treating stainless steel is a crucial process in the aerospace, defense, and marine industries, offering enhanced performance characteristics necessary for these demanding applications. In aerospace, stainless steel components are subjected to extreme temperatures and stress, requiring precise heat treatment to enhance their strength, durability, and resistance to fatigue. This process involves controlled heating and cooling cycles, improving the microstructure of the steel to ensure it performs reliably in the high-stakes environment of aircraft and spacecraft. Heat treatment also reduces the risk of stress corrosion cracking, an essential factor in maintaining the structural integrity of aircraft frameworks, turbine engines, and other critical components.

In the defense and marine sectors, the harsh conditions of operation necessitate materials that can withstand severe environments and mechanical stresses. Stainless steel components in naval vessels, submarines, and armored vehicles benefit significantly from heat treatment, which enhances their hardness, wear resistance, and ability to withstand erosion from saltwater and other corrosive elements. For defense applications, heat-treated stainless steel is used in manufacturing weaponry, protective gear, and various other critical systems, ensuring they remain operational under extreme conditions. Overall, heat treating stainless steel is indispensable across these fields, securing the functionality and longevity of vital equipment and structures.

Heat treating stainless steel is pivotal in the automotive industry due to its ability to enhance material properties such as strength, hardness, and corrosion resistance. Automotive components like engine parts, exhaust systems, and fuel injectors are subjected to extreme conditions, requiring materials that can withstand high temperatures and corrosive environments. By employing processes such as annealing, quenching, and tempering, manufacturers can tailor the mechanical properties of stainless steel to meet specific requirements. For instance, annealing can relieve internal stresses and improve ductility, making the steel easier to form and fabricate. Quenching and tempering, on the other hand, can significantly increase the hardness and wear resistance, which is crucial for components exposed to friction and wear.

In the electronics sector, heat treating stainless steel is equally essential, particularly for applications requiring precise and reliable performance under varying thermal conditions. Components like connectors, springs, and fasteners benefit from heat treatment processes that enhance their mechanical properties and longevity. Stainless steel used in electronic devices must often maintain its structural integrity and resist oxidation and corrosion over long periods, even when exposed to high temperatures or harsh environments. Heat treating can optimize the balance between toughness and strength, ensuring that these components perform consistently. Additionally, processes like precipitation hardening can be used to achieve a fine dispersion of secondary phases, which enhances the strength and hardness without compromising the material’s ductility and conductivity, crucial for maintaining electrical performance.

Heat treating stainless steel plays a crucial role in the construction industry, enhancing material properties like strength, hardness, and ductility to meet various structural demands. In infrastructure projects, components such as beams, columns, and support structures benefit significantly from heat treatment processes. These processes, including annealing, hardening, and tempering, refine the microstructure of stainless steel, making it more resistant to mechanical stresses and environmental factors like corrosion and thermal cycles. For example, annealing can recover a stainless steel’s ductility after it has been work-hardened, allowing it to be more easily formed into structural shapes. This adaptability ensures durable, long-lasting construction materials that can withstand the rigors of both time and environmental stressors, thereby contributing to the safety and sustainability of buildings and bridges.

In the energy sector, heat treating stainless steel finds crucial applications in power plants, oil refineries, and renewable energy systems where components are routinely subjected to high temperatures and corrosive environments. By optimizing the heat treating process, engineers can enhance the creep resistance, tensile strength, and corrosion resistance of stainless steel components like turbine blades, heat exchangers, and pipeline systems. For instance, quenching and tempering can produce stainless steel with a balance of toughness and hardness, essential for components that operate under high stress and temperature variations. Additionally, in renewable energy applications such as solar panels and wind turbines, heat treated stainless steel can extend the longevity and efficiency of critical components, thereby improving the overall reliability and performance of renewable energy systems. Thus, heat treating processes bolster the material performance of stainless steel, ensuring that energy infrastructure remains both efficient and resilient.

Heat treating stainless steel is a critical process in the industrial equipment industry, enhancing the material’s mechanical properties and extending its service life in challenging environments. Depending on the specific application, various heat treatment techniques such as annealing, quenching, and tempering are employed to adjust the hardness, strength, and ductility of stainless steel. These treatments align the microstructure of the steel to meet the rigorous demands of industrial processes. For instance, in the manufacturing of pumps, valves, and heavy machinery, heat-treated stainless steel components exhibit improved wear resistance and corrosion resistance, thus ensuring the reliability and efficiency of the equipment.

Moreover, precision in heat treating stainless steel is essential for applications requiring high-tolerance parts, such as in aerospace and medical device manufacturing. In these sectors, components often undergo stringent quality checks, and the heat treatment process can significantly impact their performance. By carefully controlling parameters such as temperature, time, and atmospheric conditions, the desired properties can be consistently achieved, leading to superior product performance. The industrial equipment industry heavily relies on these processes to produce components that not only withstand extreme conditions but also maintain their functional integrity over prolonged periods. Consequently, the correct application of heat treatment techniques adds substantial value to the industrial equipment across various sectors, ensuring safety, durability, and operational efficiency.

Heat treating stainless steel is a crucial process in the manufacturing of medical devices, as it significantly enhances the material’s properties to meet stringent industry standards. This thermal process involves heating the stainless steel to a specific temperature, followed by controlled cooling to alter its microstructure. By doing so, manufacturers can improve the hardness, strength, and corrosion resistance of the metal, which are essential traits for medical instruments that must withstand constant use and sterilization. Stainless steel instruments such as surgical scalpels, forceps, and orthopedic implants benefit from heat treatment, which ensures they remain durable, reliable, and safe for long-term use. Furthermore, the improved crystalline structure achieved through heat treatment can reduce the risk of micro-fractures and mechanical failures in these critical applications.

In addition to mechanical advantages, heat treating stainless steel also enhances its biocompatibility, which is paramount in medical applications. Medical devices must interact with bodily tissues and fluids without provoking adverse reactions. The heat treatment process minimizes impurities and homogenizes the alloying elements, resulting in a smoother, more uniform surface that resists staining and biological contamination. This is particularly important for implants and instruments that need to maintain a high degree of cleanliness and sterility. Moreover, the enhanced corrosion resistance achieved through precise heat treatment protocols ensures that instruments can endure repeated exposure to cleaning agents, autoclaving, and the harsh oxidative environments often found within the human body. Ultimately, heat treating stainless steel is integral to the production of high-quality, safe, and effective medical devices, significantly contributing to patient care and the advancement of medical technology.

Heat treating stainless steel is a crucial process in both the machining and manufacturing industries, serving to enhance the material’s properties for specific applications. During the machining process, stainless steel can become hard and abrasive, causing tool wear and complicating the production of intricate components. By applying heat treatments such as annealing, quenching, and tempering, the metal’s hardness, ductility, and strength can be precisely controlled to achieve more manageable machining characteristics. For instance, annealing stainless steel by heating it to a high temperature and then slowly cooling it reduces hardness, making it easier to cut and shape. This not only extends the lifespan of cutting tools but also enhances the efficiency of the machining process.

In the broader scope of manufacturing, heat treating stainless steel is essential for achieving desired mechanical properties and ensuring long-term performance of the final products. This process can enhance properties such as corrosion resistance, tensile strength, and wear resistance, making the material suitable for high-performance applications in industries like aerospace, automotive, and medical devices. For example, solution treating followed by rapid cooling can help to dissolve and redistribute carbides to prevent intergranular corrosion, which is critical for components exposed to corrosive environments. By tailoring the heat treatment process to the specific requirements of the application, manufacturers can produce stainless steel parts that meet stringent quality standards and perform reliably under demanding conditions.

Q1: What is the process of heat treating stainless steel at SourcifyChina factory?

A1: Heat treating stainless steel at SourcifyChina involves heating the metal to specific temperatures to enhance its properties, followed by controlled cooling. This process enhances strength, durability, and corrosion resistance.

Q2: What types of stainless steel can be heat treated?

A2: SourcifyChina specializes in heat treating a variety of stainless steels, including austenitic, martensitic, and precipitation-hardening grades, tailored to meet specific application requirements.

Q3: What are the benefits of heat treating stainless steel?

A3: Heat treating stainless steel improves mechanical properties such as tensile strength, hardness, and corrosion resistance. It can also refine grain structure and relieve internal stresses, enhancing overall material performance.

Q4: How does SourcifyChina ensure quality in heat treating?

A4: SourcifyChina employs advanced heat treatment technology and strictly controlled processes. Quality is ensured through precise temperature control, cooling rates, and post-treatment testing to meet or exceed international standards.

Q5: Is custom heat treating available?

A5: Yes, SourcifyChina offers custom heat treating services tailored to specific client needs, including different treatment cycles and temperatures to achieve desired material properties.

Q6: What industries benefit from heat-treated stainless steel?

A6: Industries such as aerospace, automotive, medical devices, and food processing benefit significantly from heat-treated stainless steel due to the enhanced physical and chemical properties.

Q7: Can SourcifyChina handle large-volume heat treating orders?

A7: Absolutely. SourcifyChina is equipped with state-of-the-art facilities capable of handling both small and large-volume orders efficiently while maintaining high quality standards.

Q8: What post-heat treating services does SourcifyChina offer?

A8: SourcifyChina offers various post-heat treating services such as machining, polishing, and surface finishing to ensure the treated stainless steel meets detailed specifications.

Q9: How long does the heat treating process take?

A9: The duration varies depending on the type and size of the stainless steel, as well as the specific heat treatment process. SourcifyChina coordinates closely with clients to provide accurate timeframes.

Q10: How can I request a quote for heat treating services?

Heat treating stainless steel is crucial for enhancing its mechanical properties and corrosion resistance. SourcifyChina factory, specializing in this process, offers several key tips for optimal results:

1. Understanding Grades:

– Different stainless steel grades require tailored heat treatment processes. Common grades include austenitic (e.g., 304, 316), martensitic (e.g., 410, 420), and ferritic (e.g., 430).

2. Temperature Control:

– Precise temperature control is vital. Overheating can cause grain growth, while underheating may not achieve the desired properties.

– Typical annealing temperatures range from 1010°C to 1120°C for austenitic steels and 760°C to 830°C for martensitic steels.

3. Quenching Techniques:

– Quenching rates differ based on the stainless steel type. Rapid quenching is essential for martensitic steels to achieve high hardness, typically using air or oil.

– Austenitic steels often use water or air quenching to prevent carbide precipitation.

4. Stress Relieving:

– Post-heat treatment stress relieving at lower temperatures (200°C-400°C) helps reduce residual stresses without significant alteration of mechanical properties.

5. Atmosphere Control:

– Using a controlled atmosphere (e.g., vacuum, inert gas) prevents oxidation and decarburization, maintaining the material’s surface integrity.

6. Cooling Rates:

– Controlled cooling rates are necessary to avoid thermal stress and distortion. For large components, gradual cooling is recommended to minimize thermal gradients.

7. Inspection and Testing:

– Regular inspection and testing, including hardness testing, microstructure analysis, and tensile testing, ensure the desired properties are achieved.

8. Documentation and Traceability:

– Keeping detailed records of the heat treatment process, including temperatures, times, and quenching methods, ensures traceability and repeatability for future production.

SourcifyChina factory emphasizes that these guidelines ensure stainless steel components meet stringent quality standards, improving performance and longevity in their applications.

Sure, here are some frequently asked questions (FAQ) with answers about sourcing heat-treating stainless steel from SourcifyChina Factory:

1. What types of stainless steel can SourcifyChina handle for heat treating?

SourcifyChina Factory is equipped to handle a wide variety of stainless steel grades, including but not limited to 304, 316, 410, and 420. They cater to different heat treatment processes based on the specific grade and application requirements.

2. What heat treatment processes are available for stainless steel at SourcifyChina?

SourcifyChina offers a comprehensive range of heat treatment processes such as annealing, hardening, tempering, stress relieving, and solution treating. Each process is tailored to meet specific material properties and performance needs.

3. How does SourcifyChina ensure quality in heat-treated stainless steel?

Quality assurance at SourcifyChina includes strict adherence to ASTM and ISO standards, advanced quality control equipment, and skilled technicians. The factory utilizes real-time monitoring and detailed inspections to maintain high-quality standards.

4. Can SourcifyChina provide customized heat treatment solutions?

Yes, SourcifyChina offers customized heat treatment solutions to meet specific project requirements. Their team works closely with clients to develop tailored processes, ensuring optimal material performance for particular applications.

5. What is the lead time for heat treating stainless steel at SourcifyChina?

The lead time varies based on the nature and volume of the order, but typically ranges from 2 to 4 weeks. For more accurate timelines, it’s best to consult directly with SourcifyChina’s customer service.

6. How does SourcifyChina’s pricing compare to other providers?

SourcifyChina aims to offer competitive pricing while maintaining high-quality standards. They provide transparent quotations based on material, process complexity, and order volume, often proving more cost-effective due to their advanced techniques and efficient operations.

7. What are the shipping options for international orders?

SourcifyChina provides various shipping options including air freight, sea freight, and express courier services. They work with reliable logistics partners to ensure timely and safe delivery of heat-treated stainless steel products.

8. How can I request a quote from SourcifyChina for heat treating stainless steel?

To request a quote, you can visit SourcifyChina’s website and fill out the quote request form or contact their sales team via email or phone. Providing detailed information about your requirements will help expedite the quotation process.

When sourcing heat treating services for stainless steel from SourcifyChina factory, consider the following tips to ensure a smooth and successful experience:

1. Verify Credentials and Experience:

– Confirm that SourcifyChina specializes in heat treating stainless steel. Check their credentials, certifications, and industry experience.

2. Assess Quality Standards:

– Inquire about their adherence to international quality standards such as ISO 9001 and ASTM. Request samples or case studies to evaluate their work.

3. Communication:

– Establish clear communication channels and specify all technical requirements upfront, including types of stainless steel, desired hardness levels, and other critical parameters.

4. Request a Detailed Quote:

– Obtain a comprehensive quote covering all aspects of the process: material costs, treatment specifics, processing time, and shipping fees.

5. Visit the Facility (if possible):

– If feasible, visit the factory to inspect their heat treating equipment, processes, and quality control measures.

6. Review Terms and Conditions:

– Carefully read the contract terms, including lead times, payment schedules, and warranty conditions.

7. Logistics and Import Regulations:

– Understand the logistics involved in shipping treated materials from China to your location. Familiarize yourself with import regulations and duties.

8. Customer Feedback and References:

– Seek feedback from other clients who have worked with SourcifyChina. References can provide insights into reliability and service quality.

9. Pilot Run:

– Consider a trial run to test the quality and consistency of their heat treating services before committing to a large-scale order.

10. After-Sales Support:

– Ensure SourcifyChina offers robust after-sales support for any potential issues or defects that may arise post-delivery.

By following these tips, you can effectively source reliable and high-quality heat treating services for stainless steel from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.