“Reliable Cost Calculation with SourcifyChina’s Factory Injection Mold Calculator: Your Essential Tool for Budget-Friendly Manufacturing”

Discover accurate and trustworthy cost estimates for your injection molding needs with SourcifyChina’s state-of-the-art calculator, designed to streamline manufacturing processes and ensure budget-friendly factory quotes. Perfect for businesses seeking precision and reliability in cost planning.

Choosing “SourcifyChina” Factory for purchasing an injection mold cost calculator from China ensures high-quality production standards. Their team of experts boasts extensive experience in mold manufacturing, using state-of-the-art technology.

Additionally, SourcifyChina offers competitive pricing without compromising quality. They focus on delivering cost-effective solutions tailored to your specific needs, ensuring optimal value for your investment.

Their customer support is exceptional, guiding you through every step of the purchasing process. This ensures clear communication, timely updates, and addressing any concerns or questions you might have.

SourcifyChina also emphasizes stringent quality control measures, adhering to international standards. This guarantees that every injection mold cost calculator you purchase meets rigorous performance and durability benchmarks.

Furthermore, they provide comprehensive after-sales service, ensuring long-term satisfaction. Whether it’s maintenance advice or troubleshooting assistance, their dedicated support team is always ready to help.

In conclusion, choosing SourcifyChina Factory for your injection mold cost calculator needs guarantees top-notch quality, cost-efficiency, and unparalleled customer support, making it the ideal choice for discerning buyers.

Injection mold cost calculators help manufacturers estimate production costs. These tools consider factors like material type, mold complexity, and production volume, guiding budget planning and making informed decisions.

Types and Options:

– Online Calculators: User-friendly web-based tools.

– Software Solutions: Comprehensive desktop applications.

– Mobile Apps: Convenient, on-the-go cost estimation.

– Custom Calculators: Tailored to specific industry needs.

– Built-in ERP Modules: Integrated into enterprise resource planning systems.

Key Features:

– Material Cost Estimation: Calculate costs based on selected materials.

– Labor Cost Estimation: Factor in labor hours and rates.

– Mold Complexity Analysis: Evaluate design intricacy and impact on expense.

– Production Volume: Adjust costs based on batch sizes.

– Lead Time Calculation: Estimate time needed from start to finish.

– Waste Management: Account for material waste during production.

– Energy Consumption: Include energy costs for machinery usage.

– Customization Options: Modify parameters to fit specific project requirements.

– Reporting and Analytics: Generate detailed cost reports for analysis.

– Cost Comparisons: Compare different materials or production methods.

– Multi-Currency Support: Useful for global manufacturers.

– API Integration: Connect with other business tools and databases.

– User-Friendly Interface: Intuitive design for ease of use.

– Regular Updates: Stay updated with the latest cost parameters and market conditions.

– Real-Time Data: Instant access to updated cost information.

These calculators empower manufacturers to optimize budgets, enhance project planning, and make cost-effective decisions.

An injection mold cost calculator is an essential tool for manufacturers, designers, and engineers to estimate the expenses involved in creating injection molds. It helps in budgeting, feasibility analysis, and decision-making.

Applications for injection mold cost calculator:

– Budget Planning: Predicts overall project costs and aids in financial planning.

– Feasibility Studies: Determines if the injection molding process is economically viable for a specific project.

– Quote Generation: Provides accurate cost estimates for client proposals and pricing strategies.

– Resource Management: Assists in allocating resources efficiently by predicting labor, material, and time requirements.

– Cost Optimization: Identifies areas where costs can be reduced without compromising quality.

– Project Scheduling: Helps in planning timelines by estimating production and setup times.

– Comparative Analysis: Enables comparison between different design and material choices based on cost implications.

– Inventory Control: Aids in determining the amount of raw materials needed, reducing waste and excess stock.

– Supplier Negotiations: Strengthens purchasing power by providing detailed cost breakdowns for negotiations.

– Risk Management: Identifies potential cost overruns and helps mitigate financial risks.

– Custom Configurations: Allows for adjustments based on specific project needs, enhancing customization.

– Market Competitiveness: Assists in pricing products competitively by understanding production costs.

– Sustainability Goals: Analyzes cost benefits of using sustainable materials and methods.

– Return on Investment (ROI) Analysis: Projects potential profitability and justifies the investment in new molds.

– Performance Benchmarking: Measures efficiency and cost-effectiveness against industry standards.

This tool is versatile and integral to the successful execution of injection molding projects across various industries.

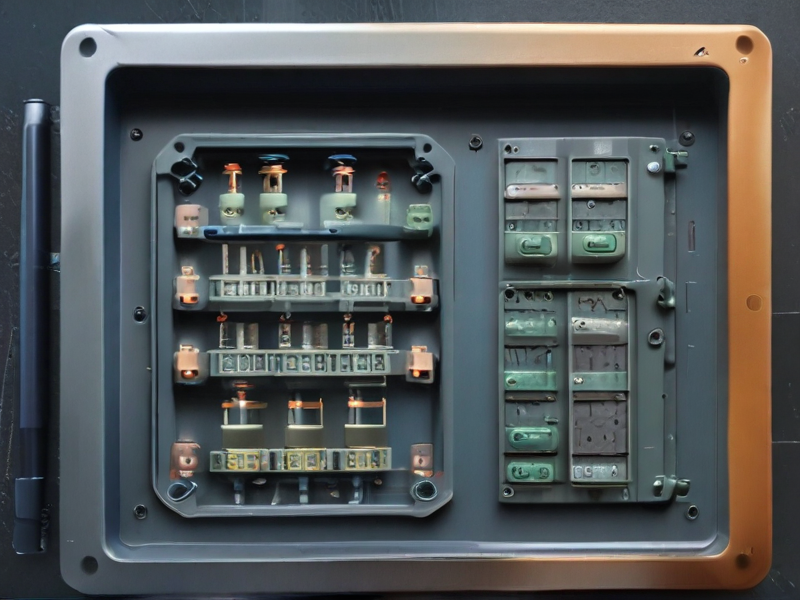

The “SourcifyChina Injection Mold Cost Calculator” is a sophisticated tool designed to estimate the costs associated with plastic injection mold manufacturing in China. It takes into account various parameters such as mold size, material type, and production volume to provide accurate cost predictions. This enables businesses to budget effectively and make informed decisions about their manufacturing processes.

One significant feature of the calculator is its inclusion of different material options. It allows users to choose from an array of materials like polypropylene, polyethylene, ABS, and more. Each material has distinct characteristics, affecting the mold’s cost and the final product’s quality. Consequently, users can balance cost and performance to match their specific needs.

Additionally, the calculator incorporates the complexity and precision required for the mold. Complex designs with intricate details often require more advanced materials and higher precision, leading to increased costs. Simplified designs, on the other hand, can reduce costs substantially. Thus, users have a clear understanding of how their design choices impact overall costs.

The labor cost factor, a vital component in mold-making, is also considered in the cost calculator. China’s competitive labor market provides an advantageous cost structure. This factor is integrated into the estimates, along with machine depreciation costs and overheads, giving a comprehensive financial picture.

In summary, SourcifyChina’s Injection Mold Cost Calculator is an invaluable resource for manufacturers. It offers a detailed breakdown of costs influenced by material choice, design complexity, and labor requirements. This tool empowers users to make data-driven decisions, ensuring the alignment of manufacturing projects with budget constraints and quality expectations. As a result, businesses can achieve efficient production planning and competitive pricing strategies.

SourcifyChina’s injection mold cost calculator provides a streamlined and accurate method for estimating costs. By inputting specific parameters, users receive detailed and transparent pricing, ensuring no hidden fees.

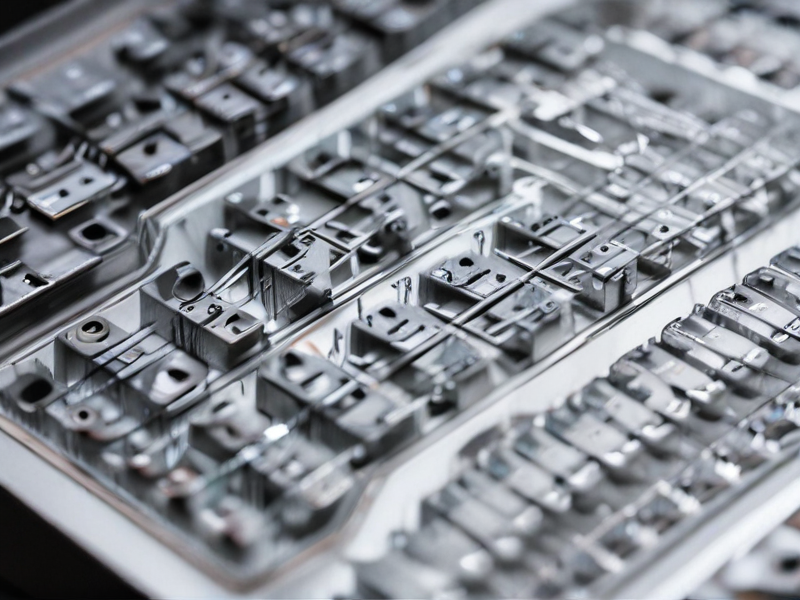

Quality control in manufacturing is stringent. Initial material selection undergoes rigorous scrutiny to ensure compliance with industry standards. This step is crucial for maintaining the integrity of the final product.

During production, real-time monitoring systems identify any deviations from the set specifications. Any anomalies detected are immediately addressed, ensuring consistent quality throughout the manufacturing process.

Post-production quality checks are equally comprehensive. Finished molds undergo detailed inspections using advanced measurement tools to verify adherence to design specifications. Only molds meeting all criteria proceed to delivery.

By integrating these quality control measures, SourcifyChina ensures that their cost calculator not only provides accurate estimates but also reflects their commitment to high manufacturing standards. This dual focus on cost-efficiency and quality assurance makes for a reliable tool in injection mold production planning.

The SourcifyChina injection mold cost calculator offers precise cost estimations for injection molding projects, helping businesses efficiently budget their manufacturing expenses. It considers multiple parameters, including material types, mold sizes, and production volumes, to provide accurate quotations.

This tool is exceptionally user-friendly, designed to simplify the often complex cost calculation processes. By inputting specific project details, users receive instant, tailored cost insights, enabling quicker decision-making and project planning.

One of its standout features is its comprehensive database, containing various material costs and machine rates. This ensures the calculator’s reliability and relevance in an ever-changing market, keeping its estimates up-to-date and practical.

Additionally, SourcifyChina’s tool assists in optimizing the design phase by identifying cost-effective materials and processes. This helps businesses avoid unnecessary expenditures and improve overall efficiency, ultimately contributing to higher profitability and product quality.

Customer support and regular updates further enhance the calculator’s value. Continued enhancements ensure that it remains compatible with the latest industry standards and technological advancements, offering users the best possible experience.

In conclusion, the SourcifyChina injection mold cost calculator is an indispensable resource for manufacturers. It streamlines the cost estimation process, supports effective planning, and promotes cost-efficient manufacturing, making it an essential tool in the competitive landscape of injection molding.

Injection mold cost calculators are valuable tools for manufacturers, enabling precise cost estimation and resource allocation for molding projects. These tools offer several benefits:

– Accuracy: Provides detailed and accurate cost breakdowns.

– Time-saving: Reduces time spent on manual calculations.

– Efficiency: Helps in identifying cost-saving opportunities.

– Budgeting: Aids in setting realistic budgets and forecasts.

– Resource management: Assists in optimal utilization of resources.

– Competitive advantage: Grants an edge by facilitating competitive pricing.

– Scenario analysis: Allows for testing different scenarios and materials.

– Decision making: Supports better decision-making through detailed insights.

– Cost monitoring: Enables ongoing project cost tracking.

– Easy comparisons: Simplifies comparing costs for multiple projects.

An injection mold cost calculator is a versatile tool designed to estimate the expenses associated with producing molded parts. It streamlines budgeting and planning for manufacturing projects.

– Material Costs: Analyzes expenses based on different types of raw materials.

– Mold Complexity: Considers design intricacies, which affect mold manufacturing time and cost.

– Production Volume: Estimates cost per part according to batch size, optimizing economies of scale.

– Labor Costs: Accounts for the time and workforce needed for mold creation and part production.

– Machine Costs: Includes operational costs tied to utilizing various types of molding machines.

– Cycle Time: Calculates the duration each molding cycle takes, impacting overall production costs.

– Overhead Costs: Factors in ancillary costs such as facility, maintenance, and utilities.

– Geography-Based Costs: Adjusts for regional variations in material and labor expenses.

– Tooling Durability: Projects costs over the tool’s lifecycle, including potential maintenance.

– Setup Costs: Covers initial setup expenses for mold installation and calibration.

– Quality Control: Estimates costs linked to inspection, testing, and ensuring part conformity.

– Customization Options: Allows for adjustments in parameters to see immediate changes in cost projections.

– Eco-Friendly Options: Incorporates cost implications of using sustainable materials and processes.

– Detailed Reports: Provides comprehensive breakdowns and summaries of all cost factors.

– User-Friendly Interface: Designed to be intuitive, often incorporating drag-and-drop functionalities and easy-to-read dashboards for quick analysis.

Using an injection mold cost calculator ensures transparent budgeting, helps identify cost-saving opportunities, and optimizes overall financial planning in the manufacturing process.

SourcifyChina’s Injection Mold Cost Calculator is an essential tool for businesses seeking to streamline the creation of custom products and projects. This calculator enables companies to estimate the costs associated with injection molding accurately, ensuring optimal budgeting and financial planning.

Businesses benefit from SourcifyChina’s user-friendly interface, which allows quick input of design specifications, material preferences, and production volumes. This convenience accelerates the decision-making process, fostering efficiency in product development timelines.

SourcifyChina’s calculator also accommodates various customization options, catering to different industry needs. By offering precise cost projections, it aids in pinpointing the most cost-effective solutions for intricate designs and complex projects.

The transparency provided by this tool mitigates financial risks and enhances trust between manufacturers and clients. Accurate cost estimations ensure that there are no hidden expenses, fostering a smoother transaction from design to production.

Ultimately, the SourcifyChina Injection Mold Cost Calculator empowers businesses to bring their innovative ideas to life more effectively. With comprehensive cost insights, companies can allocate resources wisely, ensuring the successful completion of custom projects tailored to their market demands.

SourcifyChina is a pioneering company specializing in providing precise and user-friendly injection mold cost calculators designed to optimize and streamline the cost estimation process for businesses in the manufacturing sector. Catering primarily to businesses looking to manufacture high-quality plastic products, SourcifyChina leverages its deep industry expertise and innovative technology to offer cost-effective and reliable solutions. By incorporating various critical parameters such as mold complexity, material type, production volume, and production techniques, their cost calculators ensure accurate and tailored costing insights. This not only aids businesses in budgeting and financial planning but also fosters transparency in supplier negotiations. The company’s dedication to enhancing efficiency and cost predictability has made it a trusted partner for enterprises aiming to navigate the intricate and often costly landscape of mold manufacturing in China. SourcifyChina’s commitment to quality and precision significantly empowers businesses to make informed decisions, ultimately driving competitive advantage and growth in the dynamic manufacturing domain.

The Aerospace, Defense, and Marine sectors place a high premium on precision and reliability, driving the need for advanced manufacturing technologies. An injection mold cost calculator is an invaluable tool in these industries, as it enables manufacturers to estimate the costs associated with creating specialized components. In Aerospace, this means accurately projecting the expenses linked to producing lightweight, high-strength parts critical for aircraft performance. For Defense, the calculator ensures that the budgets for manufacturing weaponry, communication devices, and protective gear are meticulously planned and adhered to. Marine applications similarly benefit, with precise estimates for molds required to manufacture durable underwater equipment and corrosion-resistant ship components. The tool’s ability to assess costs based on materials, complexity, and production volume translates into more efficient resource allocation and adherence to stringent regulatory requirements.

By integrating an injection mold cost calculator into their workflow, firms in these high-stakes industries can significantly enhance their operational efficiency. This is particularly vital given the long development cycles and stringent oversight typical in these domains. The calculators support decision-making by providing immediate cost breakdowns, allowing engineers and project managers to explore different design iterations and materials without committing to expensive trial-and-error processes. In Aerospace and Marine, where weight and durability are paramount, the tool helps to optimize material choices and reduce waste. For Defense, where security and precision are crucial, understanding cost implications early on mitigates risks and ensures mission-critical components are produced within budget. Overall, the injection mold cost calculator fosters a more streamlined, cost-effective approach to producing high-quality, reliable parts in these demanding fields.

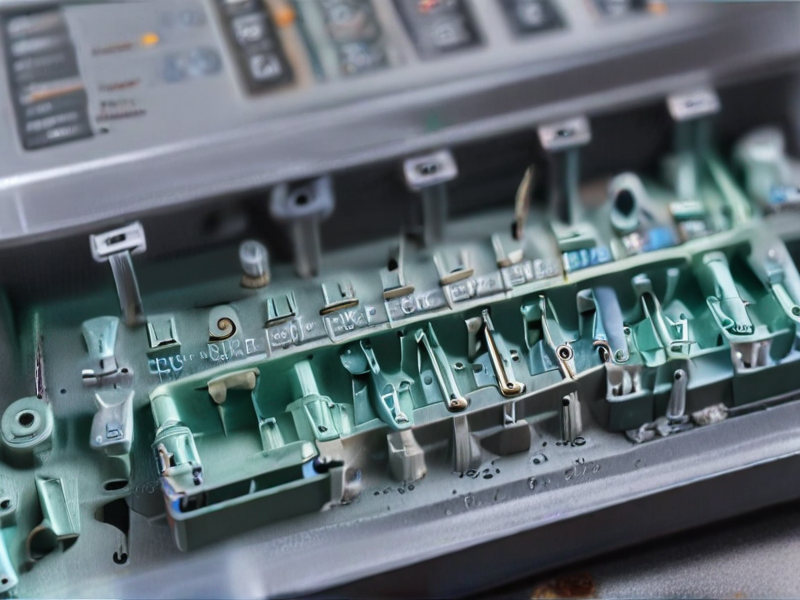

In the automotive sector, an injection mold cost calculator is an indispensable tool that enhances efficiency and precision in the manufacturing process. Automotive components often require intricate designs and robust materials to meet safety and performance standards. By utilizing an injection mold cost calculator, manufacturers can accurately estimate the costs associated with mold creation, material choices, and production volumes. This allows for better financial planning and resource allocation, ensuring that development costs stay within budget while maintaining high-quality standards. Furthermore, by predicting potential expenses early in the design phase, automotive engineers can make informed decisions to optimize part design, reduce manufacturing time, and minimize waste.

In the electronics industry, where rapid innovation and fast time-to-market are critical, an injection mold cost calculator plays a pivotal role in maintaining both cost-effectiveness and product integrity. Electronic components often require precise and miniaturized molds to accommodate complex circuits and high-performance materials. The cost calculator assists in evaluating different design scenarios and material options, allowing manufacturers to compare and select the most economical and efficient routes to market. It also aids in identifying potential cost overruns and logistical challenges before the production begins. This proactive approach leads to more streamlined manufacturing processes, quicker prototyping cycles, and ultimately, a faster product launch, giving companies a competitive edge in the fast-paced electronics marketplace.

The construction industry increasingly relies on precision and efficiency, which can be significantly enhanced by utilizing an injection mold cost calculator. This tool provides accurate cost estimates for producing molds used in creating construction components, such as plastic fixtures, fittings, and panels. By compiling data on material costs, labor, and manufacturing overhead, the calculator helps construction project managers to make informed decisions, streamline budgeting, and minimize wasteful expenditure. For instance, when integrating prefabricated plastic parts into large-scale builds, knowing the precise costs involved enables better resource allocation, timely project execution, and adherence to financial plans. Furthermore, the increased predictability in expenses facilitates smoother negotiations with suppliers and subcontractors, ultimately contributing to the overall efficiency and success of construction projects.

In the energy sector, particularly in renewable energy systems like solar panels and wind turbines, the application of an injection mold cost calculator proves invaluable. Energy companies often require customized plastic components for housings, connectors, and blades—a demand that necessitates precise budgeting and cost management. By using the injection mold cost calculator, energy firms can estimate the financial implications of producing these components, ensuring cost-effective manufacturing processes. Additionally, the tool helps in comparing different material options and production methods to achieve optimal performance and durability while adhering to budget constraints. In a time where sustainable practices and economic viability are paramount, the injection mold cost calculator aids in advancing innovative and efficient energy solutions, supporting the industry’s goal to provide reliable and affordable energy while minimizing environmental impact.

The industrial equipment industry benefits significantly from the utilization of an injection mold cost calculator, particularly in the production planning and budgeting stages. This tool enables manufacturers to estimate the expenses involved in creating molds with a high degree of precision. By inputting variables such as material costs, design complexity, and production volume, companies can obtain detailed cost projections that inform their financial strategies. This serves as a crucial advantage in a marketplace where competitive pricing and cost-efficiency are paramount. Moreover, the ability to foresee expenses helps in identifying potential financial risks early in the development process, allowing for proactive decision-making and resource allocation.

Additionally, the injection mold cost calculator streamlines communication and collaboration between various stakeholders involved in the production process. Engineers, financial planners, and project managers can access a unified set of data, which facilitates a more synchronized approach to project execution. It simplifies the quoting process for clients and ensures that suppliers and manufacturers are aligned in terms of cost expectations. This transparency minimizes the risk of unexpected cost overruns and ensures that projects remain within budget and on schedule. The results are faster turnaround times, improved customer satisfaction, and a more agile manufacturing process that can swiftly respond to market demands and changes.

Injection mold cost calculators have emerged as a transformative tool in the medical devices industry, significantly enhancing the efficiency and cost-effectiveness of manufacturing processes. These calculators use complex algorithms to estimate the costs associated with creating molds for various medical devices, such as syringes, IV components, and intricate surgical instruments. By providing instant cost estimations, these tools enable manufacturers to make well-informed decisions about material selection, design modifications, and production volumes. This not only reduces the time spent on back-and-forth consultations but also minimizes the risk of costly errors and delays in the production schedule. As a result, medical device companies can allocate their resources more strategically, ensuring that high-quality, regulatory-compliant products reach the market faster and at a more competitive price point.

Moreover, injection mold cost calculators contribute to the broader goals of innovation and sustainability within the medical field. With precise cost projections, manufacturers are more likely to experiment with advanced materials and pioneering designs that can enhance the functionality and durability of medical devices. For instance, the ability to accurately predict the cost implications of using biodegradable or biocompatible materials encourages their adoption, thereby supporting environmentally friendly manufacturing practices. Furthermore, these calculators often feature comprehensive reporting capabilities, allowing companies to conduct detailed cost-benefit analyses and risk assessments. This data-driven approach facilitates continuous improvement and innovation, ensuring that medical devices not only meet but exceed regulatory and safety standards, ultimately improving patient outcomes and advancing the field of medical technology.

In the realm of machining and manufacturing, the “injection mold cost calculator” emerges as a pivotal tool, significantly enhancing both efficiency and precision in production planning. Injection molding, a predominant manufacturing process for producing parts by injecting material into a mold, requires meticulous cost estimation to ensure economic viability and competitiveness. The injection mold cost calculator streamlines this process by enabling manufacturers to swiftly estimate the costs associated with mold creation, material consumption, labor, and production time. By offering real-time cost analysis, this tool facilitates informed decision-making, allowing for adjustments to design or production parameters to achieve optimal balance between cost and quality. Additionally, it aids in identifying cost-saving opportunities and forecasting budget requirements, ultimately contributing to more strategic financial planning and resource allocation in machining and manufacturing operations.

Moreover, the practical application of an injection mold cost calculator extends beyond mere cost estimation. It plays a crucial role in enhancing communication and coordination across various departments, including design, engineering, and finance. By providing a standardized and transparent cost assessment, it helps in aligning the expectations among all stakeholders, ensuring that projects can progress smoothly from conception to production. Additionally, this tool aids in the early detection of potential cost overruns and production bottlenecks, enabling proactive problem-solving. The injection mold cost calculator thus not only optimizes economic outcomes but also boosts overall operational efficiency, supporting the manufacturing industry’s drive towards innovation and competitiveness in the global market.

What factors influence the cost of an injection mold?

Several factors affect the cost of an injection mold, including mold complexity, material choice, part size, number of cavities, and production volume. Higher complexity and larger molds generally lead to increased costs.

How accurate is the injection mold cost calculator?

The injection mold cost calculator provided by SourcifyChina offers a reasonably accurate estimate based on standard parameters and industry rates. However, for a precise quote, a detailed discussion with our experts is recommended.

What is the turnaround time for an injection mold from SourcifyChina factory?

Turnaround time typically ranges from 4 to 8 weeks, depending on the complexity of the mold and current workload. For a more accurate timeline, please contact our sales team.

Can SourcifyChina ensure high-quality mold manufacturing?

Yes, SourcifyChina employs stringent quality control processes. Our team of experienced engineers and quality assurance professionals work diligently to meet the highest standards of manufacturing quality.

What materials can SourcifyChina use for injection molds?

SourcifyChina can work with a variety of materials including steel, aluminum, and other specialized alloys. The choice of material depends on the production requirements and lifespan of the mold.

Is there a warranty for molds produced by SourcifyChina?

Yes, SourcifyChina provides a standard warranty on all molds. The specifics of the warranty depend on the mold complexity and usage conditions. Please consult our sales team for detailed terms.

How do I get a customized quote for my injection mold project?

You can get a customized quote by providing detailed specifications and requirements to our team through our website contact form or direct email. Our experts will then generate a tailored quote for you.

Does SourcifyChina offer post-production support and maintenance?

Yes, SourcifyChina offers comprehensive post-production support, including maintenance services to ensure the longevity and optimal performance of your molds.

What is the process for modifying an existing mold?

When considering manufacturing with SourcifyChina and looking to utilize their injection mold cost calculator, here are some essential tips to ensure you get accurate and comprehensive cost analysis:

1. Design Details: Provide clear and detailed CAD (Computer-Aided Design) files. Accurate designs help in evaluating the complexity of the mold and needed materials, leading to a precise cost calculation.

2. Material Selection: Specify the type of plastic resin you intend to use. Some materials are more expensive than others and can impact mold and production costs. SourcifyChina typically offers a range of standard materials.

3. Mold Complexity: Understand that complex designs with intricate details, undercuts, or thin walls can significantly increase mold costs. Simplify the design if possible to cut costs.

4. Production Volume: Higher production volumes often justify the cost of more durable, long-lasting molds. Indicate your production requirements to get an accurate cost-benefit analysis.

5. Mold Life Expectancy: Determine the number of cycles (shots) the mold is expected to perform. Different molds have varying lifespans, and higher durability materials and manufacturing might raise upfront costs but lower long-term expenses.

6. Tooling Requirements: Specify any specific tooling requirements, such as multi-cavity molds or special surface finishes like texturing or polishing. These factors directly influence the mold cost.

7. Lead Time: Clearly communicate your timeline. Rushed productions can incur additional costs due to expedited shipping and prioritized manufacturing.

8. Post-Processing: Consider any post-molding requirements such as assembly, painting, or additional treatments. These should be factored into the overall cost calculated.

9. Currency and Tariffs: Factor currency exchange rates and potential tariffs or import duties into the total cost. Utilize SourcifyChina’s expertise to navigate international trade nuances.

10. Compare Quotes: Use the cost calculator to compare quotes from different suppliers. SourcifyChina can help negotiate competitive prices based on calculated costs.

By adhering to these tips while using SourcifyChina’s injection mold cost calculator, you’ll ensure a thorough and realistic understanding of your manufacturing expenses.

What is the injection mold cost calculator offered by SourcifyChina factory?

The injection mold cost calculator from SourcifyChina factory is an online tool designed to estimate the costs associated with producing injection molds. It takes into account various factors such as material costs, mold complexity, manufacturing time, and other relevant parameters to give a comprehensive cost estimate.

How accurate is the injection mold cost calculator?

While the calculator provides a close estimate, the actual costs may vary due to specific project complexities, design changes, and variable material costs. It is always recommended to use the calculator for initial budgeting and then get a detailed quote from SourcifyChina for exact pricing.

What information do I need to use the cost calculator?

You will typically need to provide details such as the part dimensions, material type, number of cavities, surface finish requirements, mold life expectancy, and any special features. The more precise the information, the more accurate the estimate you will receive.

Can I use the cost calculator for any type of injection mold?

Yes, the calculator is versatile and designed to handle various types of injection molds, including those for automotive parts, consumer electronics, medical devices, and more.

Is there any cost to use the injection mold cost calculator?

No, the injection mold cost calculator is generally available for free on SourcifyChina’s website. However, you may need to sign up or provide an email address to access the tool.

How can I ensure the lowest possible cost for my injection mold?

To minimize costs, provide clear, detailed specifications and consider simplifying the part design if possible. Using standard materials and avoiding unnecessary features can also reduce costs. SourcifyChina experts can provide advice on cost-saving measures.

What if my estimated cost exceeds my budget?

If the estimated cost is higher than your budget, you can consult with SourcifyChina’s team. They can suggest design modifications, alternative materials, or other adjustments to help reduce costs without compromising on quality.

Can I get direct support while using the calculator?

Yes, SourcifyChina offers customer support to assist you with any questions or issues you may encounter while using the injection mold cost calculator. You can reach out through their official contact channels for quick assistance.

To source an injection mold cost calculator from a SourcifyChina factory, follow these streamlined steps:

1. Visit SourcifyChina Platform:

– Go to SourcifyChina’s official website or app to explore their offerings and resources.

2. Search for Injection Mold Cost Calculator:

– Use specific keywords like “injection mold cost calculator” or “mold cost estimation tools” in the search bar.

3. Filter Results:

– Narrow down results by selecting filters like ‘factory’, ‘price range’, ‘ratings’, or ‘delivery time’.

4. Review Factory Profiles:

– Check profiles, reviews, and ratings of prospective factories.

– Assess details like past projects, expertise in mold making, and customer feedback.

5. Direct Inquiry:

– Contact selected factories directly through SourcifyChina’s messaging system.

– Request information on their available cost calculators and any customization options.

6. Request Quotes:

– Ask for a quote or a demo to understand the accuracy and functionality of their calculators.

– Compare quotes and features offered by different factories.

7. Evaluate Tools:

– Assess each cost calculator for user-friendliness, accuracy, and comprehensiveness.

– Check if they allow inputs like material type, mold complexity, production volume, etc.

8. Confirm and Place Order:

– Once satisfied, confirm terms, ensure after-sales support, and place your order through SourcifyChina.

– Negotiate payment terms and shipping details if necessary.

9. Check Compliance:

– Ensure the tool complies with international standards or specific needs of your project.

By leveraging the SourcifyChina platform and performing diligent evaluations, you can efficiently source a reliable injection mold cost calculator tailored to your needs.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.