Technology and Applications of injection molding machining

Injection molding is a widely used manufacturing process for creating plastic parts. It involves injecting molten plastic material into a mold cavity, allowing it to cool and solidify before being ejected as a finished product.

Here’s a breakdown:

Technology:

* Injection Machine: A specialized machine heats and pressurizes the plastic, injecting it into the mold.

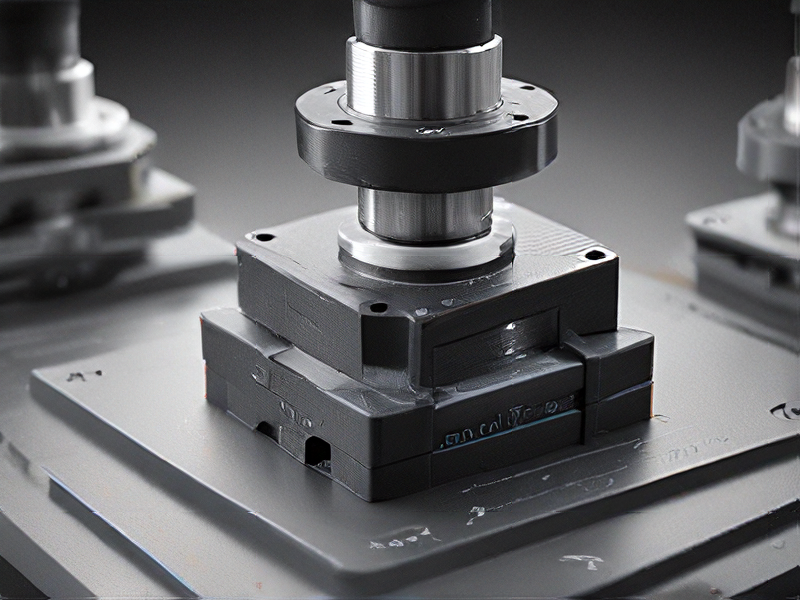

* Mold: A metal tool with cavities shaped to the desired part.

* Material: Thermoplastic or thermoset plastics are used, supplied in pellet form.

Applications:

Injection molding is versatile and used for a vast range of products:

* Consumer Goods: Toys, electronics housings, bottles, packaging.

* Automotive: Interior and exterior components, engine parts.

* Medical: Surgical instruments, drug delivery devices, implants.

* Industrial: Gears, housings, connectors.

Advantages:

* High Production Rates: Efficient for mass production.

* Complex Shapes: Can create intricate designs.

* Cost-Effective: Economical for large-scale runs.

* Material Variety: Suitable for diverse plastics.

Limitations:

* Mold Cost: Initial mold creation can be expensive.

* Limited Material Thickness: Thicker parts can be challenging.

* Short Cycle Times: Not ideal for small batch production.

Quality Testing Methods for injection molding machining and how to control quality

Injection molding machining quality control involves various methods to ensure parts meet specifications.

Inspection Methods:

* Visual Inspection: Examining parts for surface defects like sink marks, weld lines, and scratches.

* Dimensional Inspection: Using calipers, micrometers, and CMMs to check dimensions against blueprints.

* Functional Testing: Assessing part functionality through simulations or real-world applications.

* Material Testing: Analyzing material properties like tensile strength, impact resistance, and heat deflection temperature.

Control Measures:

* Process Control: Monitoring and adjusting molding parameters like temperature, pressure, and injection speed to maintain consistency.

* Mold Design & Maintenance: Ensuring proper mold design and regular maintenance to prevent defects.

* Material Selection: Choosing appropriate materials based on part requirements and application.

* Statistical Process Control (SPC): Using statistical tools to track process performance and identify trends.

By implementing these methods and controls, manufacturers can minimize defects, improve product quality, and ensure customer satisfaction.

Tips for Procurement and Considerations when Purchasing from injection molding machining

When procuring parts from injection molding machining, consider these tips:

Design:

* Optimize for Moldability: Ensure your design is suitable for injection molding, considering factors like wall thickness, draft angles, and undercuts.

* Material Selection: Choose the right material based on your application’s needs (durability, flexibility, heat resistance, etc.).

Tooling:

* Tool Type: Understand the different types of molds (single-cavity, multi-cavity, etc.) and their implications for cost and production volume.

* Tooling Cost: Factor in the cost of creating the mold as part of your overall budget.

Supplier Selection:

* Experience and Expertise: Choose a supplier with experience in your industry and material expertise.

* Capacity and Lead Times: Ensure the supplier has the capacity to meet your production needs and delivery timelines.

* Quality Control: Inquire about their quality control processes and certifications.

Other Considerations:

* Prototyping: Request prototypes to verify design and functionality before committing to large-scale production.

* Minimum Order Quantities (MOQs): Be aware of MOQs and plan accordingly.

* Pricing and Payment Terms: Negotiate competitive pricing and favorable payment terms.

FAQs on Sourcing and Manufacturing from injection molding machining in China

## FAQs on Sourcing & Manufacturing from Injection Molding Machining in China

Q: Why China for injection molding?

A: China boasts extensive manufacturing capabilities, experienced engineers and a robust ecosystem of suppliers. It offers competitive pricing due to lower labor and material costs.

Q: How do I find reliable manufacturers?

A: Utilize online platforms like Alibaba, GlobalSources, and industry-specific directories. Attend trade shows and leverage industry connections. Get recommendations from other businesses.

Q: What are key factors to consider when selecting a manufacturer?

A: Experience in your industry, production capacity, quality control measures, certifications (ISO 9001, etc.), communication skills, and pricing transparency are crucial. Request samples and references.

Q: What are common challenges?

A: Language barriers can complicate communication. Ensuring quality control and adherence to deadlines requires meticulous planning and monitoring.

Q: How can I mitigate risks?

A: Conduct thorough due diligence on potential manufacturers. Use a reputable third-party inspection agency. Establish clear contracts outlining specifications, payment terms, and quality standards.

Q: What are the main costs involved?

A: Mold tooling costs, material costs, labor costs, shipping costs, and potential inspection fees are key factors. Obtain detailed quotes from multiple manufacturers.