“SourcifyChina” Factory stands out due to its commitment to quality and precision in crafting injection mould parts. Our state-of-the-art facilities ensure meticulous production standards, guaranteeing each part meets strict specifications and performance benchmarks.

We offer competitive pricing without compromising on quality. By leveraging advanced manufacturing technologies and efficient processes, “SourcifyChina” Factory delivers superior value, making it an economical yet reliable choice for buyers.

Our dedicated team of experts provides exceptional customer service. From initial consultation to final delivery, we ensure clear communication, timely updates, and comprehensive support, fostering a seamless purchasing experience for our clients.

“SourcifyChina” Factory emphasizes sustainable practices. By prioritizing eco-friendly materials and energy-efficient operations, we contribute to environmental preservation, aligning with global trends towards more responsible manufacturing practices.

Commitment to innovation drives our continuous improvement. By adapting to the latest industry developments and incorporating cutting-edge technologies, “SourcifyChina” Factory consistently delivers forward-thinking solutions, addressing the evolving needs of our clients in the dynamic marketplace.

Choose “SourcifyChina” Factory for a holistic, reliable, and forward-thinking partner in your pursuit of high-quality injection mould parts from China. Our dedication to excellence, sustainability, and customer satisfaction sets us apart, ensuring your investment fosters growth and success.

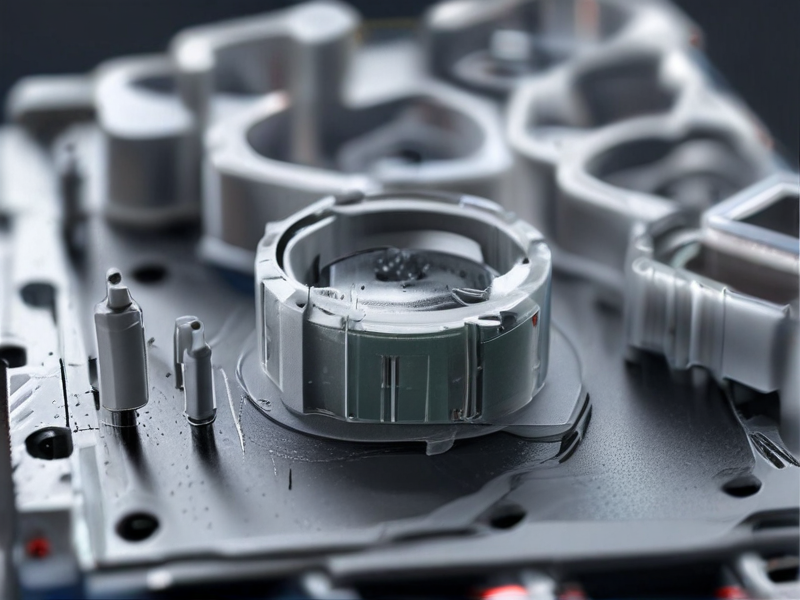

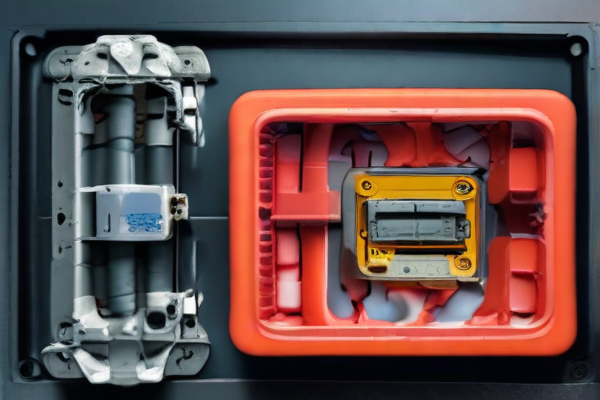

Injection mold parts come in various types, such as standard mold bases, custom cavities, and inserts. Options include different materials, surface finishes, and precision levels to meet specific requirements.

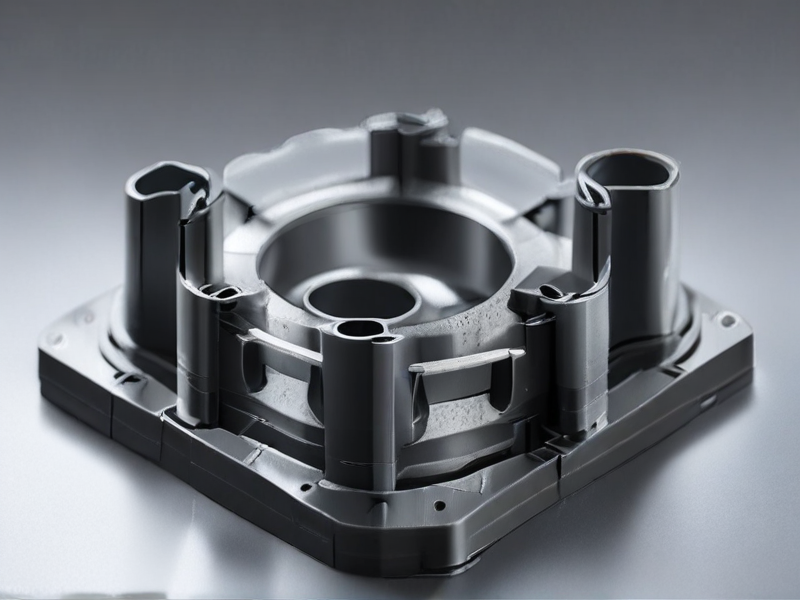

– Standard Mold Bases: Pre-machined bases that serve as the foundation for mold assemblies.

– Custom Cavities: Designed specifically to create the desired part shape and features.

– Inserts: Interchangeable pieces that can be replaced or modified without changing the whole mold.

– Cooling Systems: Channels and inserts designed for efficient temperature control to minimize cycle times.

– Ejector Systems: Mechanisms to eject the finished parts from the mold without damage.

– Runners and Gates: Pathways for molten material to flow into the mold cavities.

– Lifters and Slides: Components that create undercuts and complex geometries in the molded parts.

– Aligning and Locking Mechanisms: Ensure precise alignment and secure locking of mold halves during operation.

– Materials: Options range from hardened steel for durability to aluminum for cost efficiency.

– Surface Finishes: Vary from polished finishes for cosmetic parts to textured surfaces for better grip.

– Precision Levels: Standard tolerances or high-precision machining based on the application requirements.

– Insert Molding: Inserting pre-assembled components into the mold before injecting plastic.

– Overmolding: Multiple layers of materials molded over one another for enhanced properties.

– Hot Runner Systems: Ensure consistent temperature and efficient flow of molten material.

– Collapsible Cores: For producing complex internal geometries and shapes.

– Sprue Bushings: Connect the injection molding machine to the mold’s runner system.

– Hardened Pins: For precise detailing and longer mold life.

– Venting: Techniques to allow gas and air to escape during the injection process, reducing defects.

– Parting Line Locks: Secure the mold parts and ensure proper alignment during the injection cycle.

Each option offers specific benefits and is selected based on the complexity, volume, and desired characteristics of the final product.

Injection mould parts are critical components in manufacturing processes, facilitating the mass production of complex and precise plastic products efficiently. They are widely used across various industries due to their versatility and reliability.

– Automotive Industry: Used for making dashboards, bumpers, and other internal components.

– Consumer Electronics: Essential for crafting casings and housings for devices like smartphones, laptops, and cameras.

– Medical Devices: Create precise components for devices such as syringes, inhalers, and pill containers.

– Packaging: Used in the creation of plastic packaging materials for food, beverages, and other goods.

– Toy Manufacturing: Essential for producing detailed and durable plastic toys.

– Household Appliances: Utilized in the formation of parts for items like vacuum cleaners, mixers, and refrigerators.

– Aerospace Industry: Manufacture lightweight yet durable components used in airplane interiors and other aerospace applications.

– Industrial Equipment: Create robust parts and tools required in various heavy machinery and equipment.

– Construction Materials: Essential for producing items such as plumbing components, fixtures, and fittings.

– Furniture: Used in the production of plastic parts for furniture, including chairs, tables, and storage units.

– Sporting Goods: Create various parts for equipment such as helmets, protective gear, and accessories.

– Agricultural Tools: Utilized for making durable parts for various farming equipment and machinery.

– Telecommunications: Manufacture components for network devices and infrastructure.

– Beauty and Personal Care: Essential for making packaging and parts for products such as hairdryers, shavers, and cosmetic containers.

The adaptability of injection mould parts makes them indispensable in modern manufacturing, ensuring efficiency, cost-effectiveness, and consistency in mass production.

SourcifyChina specializes in providing top-quality injection mould parts, utilizing robust and precise materials. They primarily use high-grade steel, renowned for its durability and resistance to wear and tear. This ensures long-lasting moulds capable of handling high-volume production runs seamlessly.

Stainless steel and hardened tool steel are commonly used for their corrosion resistance and strength. These materials are subjected to stringent quality control measures, ensuring each mould part meets the highest standards. This focus on material excellence translates into reliable and efficient performance in various manufacturing applications.

In addition to steel, SourcifyChina also incorporates engineering plastics where appropriate. These materials offer flexibility, reduced weight, and cost-effectiveness for less demanding applications. The combination of both metallic and non-metallic materials enables SourcifyChina to cater to diverse industry needs, ensuring adaptability and innovation in their product offerings.

SourcifyChina’s commitment to quality materials not only enhances the longevity of its injection mould parts but also guarantees superior performance. This dedication to selecting the best materials reflects their commitment to customer satisfaction and operational excellence across all projects.

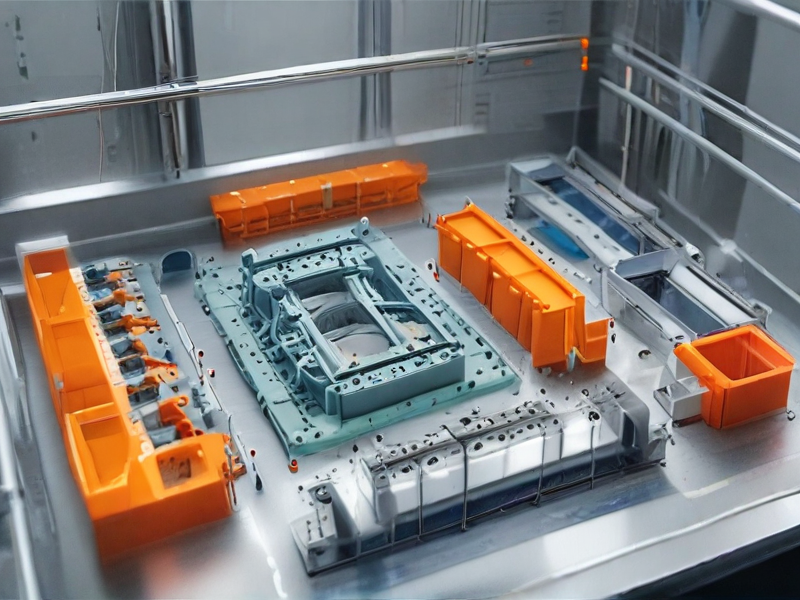

SourcifyChina ensures top-notch quality control for its injection mold parts through rigorous material selection. By sourcing high-grade materials, the company guarantees the durability and reliability of its products. The selection process involves stringent testing and verification to meet international standards.

Precision engineering is a cornerstone at SourcifyChina. Utilizing advanced CAD/CAM software, the company designs intricate mold parts with high accuracy. This commitment to precision minimizes production errors and enhances the overall functionality of the molds. Regular calibration of equipment ensures consistent performance and accurate outputs.

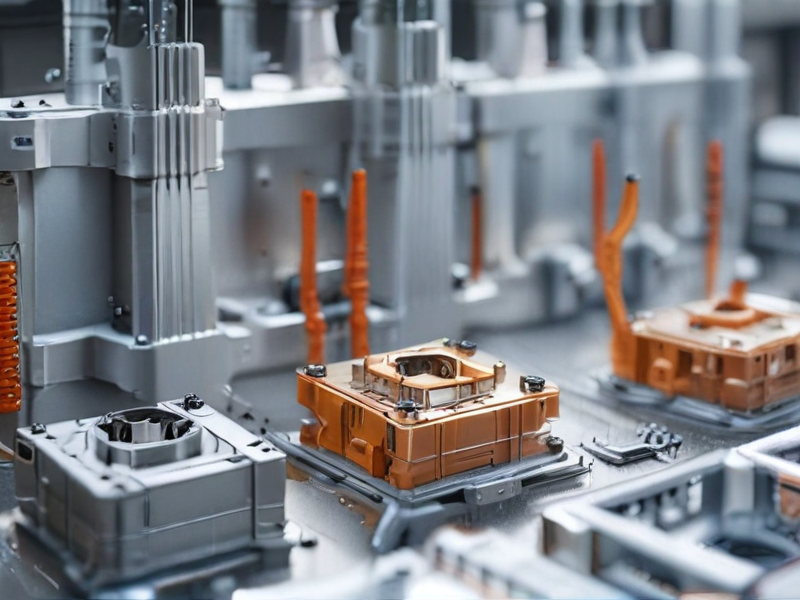

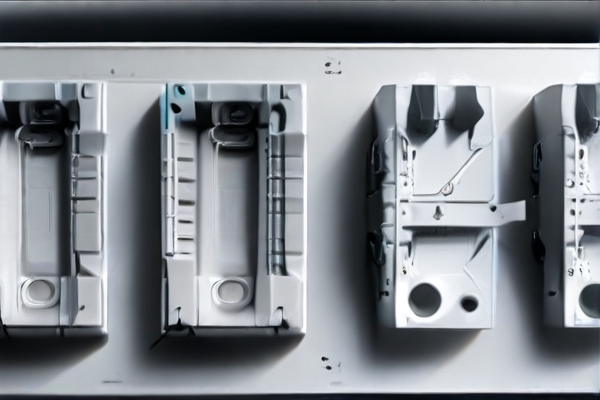

The manufacturing process incorporates state-of-the-art machinery and automation. CNC machines and robotic arms are used to produce components with minimal human error. Automated systems are programmed to maintain consistent quality across batches, ensuring uniformity in each manufactured part. Continuous monitoring helps in maintaining optimal operational efficiency.

Quality control measures are strictly enforced at every stage. Initial inspections verify raw material integrity. During production, in-process inspections check dimensional accuracy and surface finish. Post-production, comprehensive testing and compliance checks are conducted. This multi-tiered approach ensures that each part meets the specified tolerances and quality benchmarks.

Final inspection before shipping involves thorough scrutiny. Each part is examined for defects, and tolerances are verified once again. Only parts that pass these rigorous checks are approved for dispatch. This meticulous attention to detail reinforces SourcifyChina’s commitment to quality and customer satisfaction. By integrating advanced technology and comprehensive quality control methods, SourcifyChina consistently delivers reliable and high-performing injection mold parts.

SourcifyChina specializes in high-precision injection mould parts, offering exceptional quality and durability. Their advanced engineering techniques ensure that each part meets stringent industry standards.

The company utilizes state-of-the-art machinery for production, ensuring consistent and accurate results. This includes the use of CNC machines and EDM technology to achieve intricate design specifications.

SourcifyChina employs a team of highly skilled professionals who are experienced in various aspects of injection moulding. Their expertise ranges from initial design to final quality inspection, ensuring each part is flawless.

A comprehensive quality control process is in place, employing rigorous testing protocols. This ensures that all products are defect-free and meet customer requirements precisely.

Customization options are available to meet diverse client needs. SourcifyChina collaborates closely with clients to deliver tailor-made solutions that align perfectly with project specifications.

Their production capacity is capable of handling both small and large-scale orders efficiently. This makes them a reliable partner for businesses of all sizes, ensuring timely delivery.

Environmental responsibility is a key focus for SourcifyChina. They employ eco-friendly materials and adhere to sustainable manufacturing practices, reducing their carbon footprint.

Customer support at SourcifyChina is unparalleled, providing full assistance from the initial consultation to post-delivery services. This ensures that all client concerns are addressed promptly.

Competitive pricing combined with high-quality output makes SourcifyChina an attractive option. They offer cost-effective solutions without compromising on the quality of their injection mould parts.

SourcifyChina injection mould parts are trusted by a diverse range of industries including automotive, electronics, and medical devices. Their capability to deliver on complex requirements sets them apart in the competitive marketplace. With an unwavering commitment to excellence, SourcifyChina continues to be a leader in the injection moulding sector. Their relentless focus on quality, precision, and customer satisfaction makes them an ideal choice for businesses seeking reliable injection mould parts.

Injection moulding offers significant advantages for the production of parts, making it a preferred manufacturing method for numerous industries due to its efficiency and cost-effectiveness.

– High Precision: Injection moulding produces extremely precise and consistent parts, essential for industries needing tight tolerances.

– Cost Efficiency: Especially beneficial for high-volume production, reducing the unit cost significantly over time.

– Material Versatility: Compatible with a wide range of materials, including various types of plastics, metals, and composites.

– Complex Geometry: Allows for the creation of complex and intricate shapes that may be challenging with other manufacturing processes.

– Reduced Waste: Excess material can be recycled and reused in subsequent batches, promoting sustainability.

– High Production Speed: Once the initial moulds are created, manufacturing cycles are rapid, speeding up overall production timelines.

– Durability and Strength: Parts produced are robust and durable, meeting stringent quality and performance standards.

– Surface Finish: Provides excellent surface finishes, minimizing the need for additional post-processing.

– Automated Process: Highly automated, minimizing human error and labor costs while maintaining consistent quality.

– Scalability: Easily scales from prototyping to full-scale production, making it ideal for projects of varying sizes.

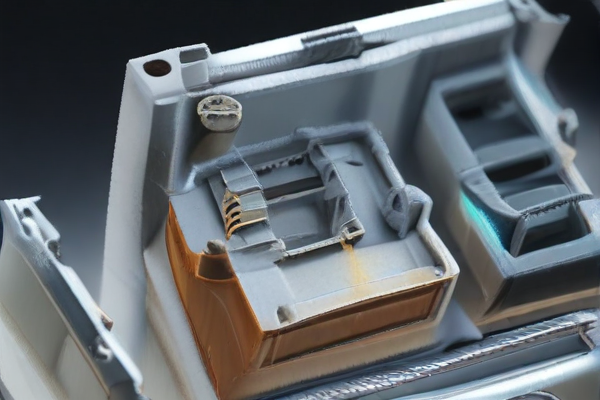

Injection mould parts are integral to the manufacturing process, ensuring precision and efficiency in producing replicated components. These parts come with various features tailored to specific production needs, ensuring high-quality outputs.

– Material: Typically made from durable metals such as steel or aluminum to withstand high pressure and temperature.

– Precision: Designed with exact tolerances to ensure consistency in the produced parts.

– Surface Finish: Options for different finishes to meet aesthetic and functional requirements.

– Cavity Design: Includes multiple cavities to enhance productivity by producing several parts in one cycle.

– Cooling Systems: Incorporate water channels or conformal cooling to regulate mould temperature and reduce cycle time.

– Ejection Mechanisms: Various ejection methods such as ejector pins, sleeves, or blades to remove the finished part without damage.

– Venting: Properly designed vents to allow gas escape and prevent defects like burn marks or voids.

– Wear Resistance: Hardening treatments or coatings to extend the mould’s lifespan.

– Draft Angles: Ensured for easy removal of the part from the mould.

– Customization: Tailored features to accommodate diverse product designs and specifications.

– Integration Points: Compatibility with automation systems for streamlined operations.

– Maintenance Access: Designed for easy maintenance and cleaning to prolong mould life.

These features contribute to the efficiency, quality, and longevity of injection moulding processes, making them indispensable in modern manufacturing.

SourcifyChina specializes in producing high-quality custom injection mold parts tailored to meet specific client requirements. Leveraging advanced technology and precision engineering, their products cater to a wide range of industries.

Their meticulous design process ensures that each piece matches the client’s exact specifications, allowing for optimal performance and durability. SourcifyChina prides itself on delivering consistent, reliable results for every project.

The company’s state-of-the-art manufacturing facilities enable rapid prototyping and efficient production, ensuring timely delivery without compromising quality. Their skilled team is adept at managing complex projects with intricate designs and tight tolerances.

SourcifyChina’s commitment to excellence extends beyond production. They offer comprehensive after-sales support, ensuring that clients receive full lifecycle service for their custom parts. This holistic approach to customer satisfaction has cemented their reputation as a trusted partner in the injection molding industry.

Each project is executed with precision and care, focusing on innovation and customer needs. SourcifyChina’s injection mold parts not only meet but often exceed industry standards, showcasing their dedication to quality and excellence.

In conclusion, SourcifyChina’s blend of advanced technology, skilled workforce, and strong customer support infrastructure makes them a go-to source for custom injection mold parts. Their relentless pursuit of quality and precision guarantees products that align perfectly with client goals, contributing to the success of diverse projects across various sectors.

SourcifyChina is a prominent player in the field of injection mould parts, distinguishing itself through its commitment to quality, precision, and innovation. Specializing in the manufacturing of high-precision mould components, the company caters to a global clientele spanning various industries, including automotive, consumer electronics, medical devices, and packaging. SourcifyChina leverages state-of-the-art technology and a rigorous quality control process to ensure that each part meets stringent international standards. With a team of highly skilled engineers and technicians, the company excels in producing both standard and custom mould parts that address diverse industrial needs. Their comprehensive service offerings, ranging from design consultation to after-sales support, ensure that clients receive end-to-end solutions tailored to their specific requirements. Emphasizing both cost-efficiency and reliable delivery schedules, SourcifyChina has solidified its reputation as a trusted partner for businesses seeking dependable, high-quality injection mould parts in an increasingly competitive market.

Injection molded parts play a crucial role in aerospace, defense, and marine applications due to their ability to produce complex, high-precision components with consistency, durability, and efficiency. In the aerospace sector, for instance, these parts are essential in the manufacturing of lightweight aircraft components where weight reduction without compromising strength is critical for fuel efficiency and performance. Injection molded parts are utilized to create intricate cockpit controls, housings, and air ducts that require high dimensional accuracy and excellent surface finish. Their ability to be produced in large volumes ensures that they meet the industry’s stringent safety and compliance standards while reducing manufacturing time and cost.

In defense and marine applications, the importance of injection molded parts cannot be overstated. Defense equipment such as communication devices, surveillance systems, and weaponry often relies on these parts for creating robust and precise housings and enclosures that protect sensitive electronics from harsh environmental conditions and mechanical stresses. Similarly, in the marine industry, injection molded parts are pivotal for manufacturing corrosion-resistant components used in harsh, saline environments. These parts are found in navigation systems, underwater propulsion devices, and waterproof housings, where durability and reliability are paramount. The versatility of injection molding materials, from high-performance plastics to composite materials, ensures that these parts can withstand extreme conditions while maintaining structural integrity and functional performance.

Injection molded parts play a pivotal role in the automotive industry due to their versatility, durability, and cost-effectiveness. In modern vehicles, a variety of plastic components like dashboards, bumpers, interior trims, and fuel system components are manufactured through injection molding. This process allows for the mass production of complex shapes with high precision, leading to consistent quality and reduced material waste. The use of high-performance plastics in these parts not only helps in reducing vehicle weight, which consequently improves fuel efficiency and lowers emissions, but also provides excellent resistance to wear and harsh environmental conditions. As automotive technology advances, the demand for lightweight, durable, and cost-efficient components will continue to drive the use of injection molded parts in the industry.

In the electronics sector, injection molded parts are equally critical, especially with the proliferation of consumer electronics and IoT devices. Housings for smartphones, laptops, remote controls, and various other gadgets are often created using injection molding due to its capability to produce components with intricate detailing and tight tolerances. The process is well-suited for integrating features like clips, hinges, and slots directly into the mold design, which simplifies assembly and reduces production costs. Additionally, advanced materials used in injection molding, such as conductive plastics and flame-retardant compounds, enhance the safety, performance, and reliability of electronic devices. As electronics continue to evolve towards more compact and sophisticated designs, the precision and adaptability of injection molding will remain indispensable.

Injection molded parts have revolutionized the construction industry by enabling the mass production of durable, customized components with high precision and efficiency. These parts are commonly used in the production of fixtures, fittings, and structural elements, such as wall panels, insulation components, and even modular buildings. The ability to produce complex geometries with tight tolerances ensures that each piece fits perfectly, reducing on-site adjustments and accelerating the construction process. Moreover, the use of advanced polymers and composite materials in injection molding can enhance the strength, durability, and thermal performance of construction components, leading to more energy-efficient buildings with lower long-term maintenance costs.

In the energy sector, injection molded parts play a critical role in the manufacturing of components for renewable energy systems, such as solar panels, wind turbines, and battery housings. For instance, the precise molding capabilities allow for the production of intricate parts that are essential for the assembly and efficient operation of photovoltaic cells. Similarly, in wind turbines, high-strength, lightweight molded components are used in the manufacturing of turbine blades and internal structures, optimizing performance and durability under varying environmental conditions. Energy storage solutions also benefit from injection molding, as it enables the creation of robust, heat-resistant battery casings that ensure safety and reliability. By enhancing the efficiency, durability, and cost-effectiveness of key components, injection molding supports the advancement and adoption of sustainable energy technologies.

The industrial equipment industry extensively leverages injection mould parts due to their ability to produce complex, precise components at high volumes. Injection moulding, a manufacturing process where molten material is injected into a mould, is particularly suitable for creating intricate parts that meet stringent specifications. It’s a cost-effective method for mass-producing items with consistent quality, making it ideal for components like gears, housings, and connectors in various types of machinery. This precision is crucial for maintaining the operational efficiency and longevity of industrial equipment, where even minor deviations can lead to significant malfunctions. Furthermore, the versatility of injection moulding supports the use of various materials, including plastics, metals, and composites, tailored to the specific needs of the machinery.

Additionally, the capability of injection mould parts to be produced rapidly aids in reducing lead times significantly, which is a critical factor in the industrial equipment industry where downtime can lead to substantial financial losses. The design flexibility inherent in injection moulding also allows for the integration of complex features and functional enhancements into a single moulded part, reducing the need for assembly and thereby lowering manufacturing costs. Optimized for high durability and performance, these parts contribute to the overall reliability and efficiency of industrial machinery. With advancements in injection moulding technology, including improved materials and automated processes, the reliance on precision injection mould parts is likely to grow, further enhancing the capabilities of the industrial equipment sector.

Injection moulding is a pivotal manufacturing process in the medical device industry, renowned for its precision, efficiency, and ability to produce complex components at scale. Medical devices often require intricate parts that must adhere to stringent regulatory standards and possess impeccable detail to ensure proper functionality and patient safety. Injection moulding facilitates the production of a wide range of medical components, such as syringe bodies, needle hubs, and various types of connectors and couplings used in fluid and medication delivery systems. The ability to use medical-grade polymers, which are resistant to sterilization processes and compatible with body tissues and fluids, makes injection moulding particularly suitable for medical applications.

The application of injection mould parts in medical devices is also instrumental in advancing innovations in minimally invasive surgical instruments and implantable devices. This process allows for the creation of intricate, micro-sized components that are essential for the development of advanced medical technologies such as catheter systems, endoscopic devices, and drug delivery mechanisms. Precision in mould design and the capability for mass production without compromising quality ensures consistency across batches, which is critical for regulatory compliance and patient safety. Moreover, using injection moulding for medical parts enables manufacturers to meet the growing demands for cost-effective and reliable medical devices, further enhancing healthcare accessibility and outcomes.

Injection molding is a fundamental process in the manufacturing industry, vital for producing a vast array of plastic parts with high precision and efficiency. This technique involves injecting molten plastic material into a mold cavity, which then cools and solidifies into the desired shape. Injection mold parts are essential in a myriad of applications, from household goods and automotive components to electronics and healthcare devices. The versatility of this process lies in its ability to create complex shapes with fine details, ensuring consistent quality and dimensional accuracy across large production volumes. The efficiency of injection molding not only reduces material waste but also enables rapid production cycles, making it an indispensable method for high-volume manufacturing environments.

Machining plays a crucial role in the production and maintenance of injection mold parts. Precision machining techniques, such as CNC milling and EDM (Electrical Discharge Machining), are employed to create the highly detailed and intricate mold cavities and cores needed for injection molding. These molds must withstand high pressures and temperatures, necessitating the use of durable materials like tool steel and aluminum, which are precisely machined to ensure longevity and performance. Additionally, machining is vital for refurbishing and repairing molds, which can wear down over time due to the repetitive stress of the injection process. By combining advanced machining processes with robust design principles, manufacturers can produce sophisticated molds that reliably produce high-quality injection molded parts, thereby meeting the rigorous demands of modern manufacturing industries.

Sure, here are some Frequently Asked Questions (FAQ) with answers about manufacturing injection mould parts quality work from SourcifyChina factory:

Q1: What is the typical lead time for manufacturing injection mould parts?

A1: The typical lead time for manufacturing injection mould parts at SourcifyChina is generally between 4 to 8 weeks, depending on the complexity and size of the project. We also accommodate urgent orders with special arrangements if necessary.

Q2: How does SourcifyChina ensure the quality of injection mould parts?

A2: SourcifyChina follows stringent quality control protocols which include multiple inspection stages such as raw material inspection, in-process inspection, and final product testing. We use advanced measurement technologies and adhere to international quality standards like ISO 9001.

Q3: What materials can be used for injection mould parts at SourcifyChina?

A3: We can work with a wide range of materials including but not limited to ABS, Polypropylene, Polyethylene, Nylon, Polycarbonate, and more. We also provide material selection consultation based on specific project requirements.

Q4: Does SourcifyChina offer design support for injection mould parts?

A4: Yes, we offer comprehensive design support. Our experienced engineering team can assist in optimizing your designs for manufacturability, performance, and cost-efficiency. We can work with your existing designs or help you develop new ones from scratch.

Q5: How can I request a quote for my project?

A5: To request a quote, simply provide us with the detailed specifications, including material requirements, quantity, and any critical dimensions or tolerances. You can submit this information through our website or contact us directly via email.

Q6: What payment options are available?

A6: We offer multiple payment options including bank transfer (T/T), PayPal, and credit card. We also provide flexible payment terms based on client relationships and project scope.

Q7: Can SourcifyChina handle large volume orders?

A7: Yes, we are capable of handling large volume orders efficiently. Our state-of-the-art manufacturing facilities are equipped with high-capacity production lines to meet high-demand projects.

Q8: What is the process for quality complaints or returns?

A8: If you encounter any quality issues, you can contact our customer service team immediately. We have a structured process for handling complaints and returns, ensuring prompt resolution and customer satisfaction.

When considering injection mould parts manufacturing from SourcifyChina factory, here are several key tips to ensure a successful partnership and high-quality products:

1. Material Selection: Communicate clearly about the specific materials you need for your parts. SourcifyChina offers a range of plastic and metal options, so ensure the material matches your product’s requirements.

2. Design for Manufacturability (DFM): Before finalizing the design, engage with the factory to conduct a DFM analysis. This will help identify potential issues and enable smooth production processes.

3. Prototype and Testing: Request prototypes before mass production. This step is crucial for verifying the design and functionality, helping to catch defects early.

4. Quality Control: Ensure stringent quality control measures are in place. SourcifyChina provides options for on-site inspections and third-party quality audits to maintain high standards.

5. Lead Times and Scheduling: Clearly understand the lead times for mould production and part manufacturing. Factor in shipping times and possible delays to manage your supply chain efficiently.

6. Cost Transparency: Discuss all costs upfront, including mould creation, per-unit production, and shipping. SourcifyChina is known for cost-effective solutions, but clear communication will avoid surprises.

7. Communication: Maintain regular and clear communication throughout the process. Use detailed technical drawings and specs, and consider video calls to discuss complex issues.

8. Sustainability: Inquire about environmentally friendly practices and sustainable materials if this is important for your project. SourcifyChina offers options catered to greener manufacturing.

9. After-Sales Support: Ensure there is strong after-sales support for handling any issues that may arise post-production. SourcifyChina is reputed for responsive customer service, which can be a significant asset.

10. Legal Framework: Understand and establish clear contracts, including IP protection, delivery schedules, and quality standards to safeguard your interests.

By following these tips, you can optimize your manufacturing experience with SourcifyChina factory, ensuring high-quality injection mould parts that meet your specifications.

Sure! Below are Frequently Asked Questions (FAQ) for sourcing injection mould parts from SourcifyChina factory:

Q: What is SourcifyChina?

A: SourcifyChina is a reputable manufacturing and sourcing company based in China that specializes in producing high-quality injection mould parts and other manufacturing solutions.

Q: Why should I choose SourcifyChina for my injection mould parts?

A: SourcifyChina offers competitive pricing, high-quality production, fast turnaround times, and detailed quality control processes to ensure top-notch products.

Q: What materials can SourcifyChina work with for injection mould parts?

A: SourcifyChina works with a wide range of materials including ABS, PP, PC, PS, PVC, Nylon, and more, catering to various industry needs.

Q: How do I start a project with SourcifyChina?

A: You can start by submitting an inquiry through their website, providing detailed specifications and requirements for your injection mould parts. They will follow up with a quotation and further instructions.

Q: How long does it take to get a quote?

A: Typically, it takes 1-3 business days to receive a detailed quote after submitting your project specifications.

Q: What is the lead time for production?

A: Lead times vary depending on the complexity of the project, but generally, it ranges from 2 to 6 weeks.

Q: Can SourcifyChina handle custom designs?

A: Yes, SourcifyChina specializes in custom designs and offers design assistance to ensure your parts meet all specifications.

Q: What quality control measures are in place?

A: SourcifyChina has stringent quality control processes including inspections at various stages of production, material verification, and final product testing.

Q: Are prototypes available before mass production?

A: Yes, prototypes can be produced to verify the design and functionality before commencing mass production.

Q: How do I ensure my designs are protected?

A: SourcifyChina ensures confidentiality and protection of your intellectual property through non-disclosure agreements (NDAs) and secure handling of design files.

Q: What shipping options are available?

A: SourcifyChina offers various shipping options including air, sea, and express courier services to match your delivery requirements.

Q: What payment methods are accepted?

Sourcing injection mould parts from SourcifyChina factory can streamline your supply chain and reduce costs. Below are key tips to ensure a smooth and efficient process:

1. Research and Vetting:

– Background Check: Investigate the factory’s reputation, years of operation, and customer feedback.

– Certifications: Verify industry certifications (e.g., ISO 9001) to ensure quality standards.

2. Clear Communication:

– Detailed Specifications: Provide comprehensive blueprints and technical drawings of the parts needed.

– Language Barriers: Use clear, concise language or hire a translator to mitigate misunderstandings.

3. Quotation and Cost Analysis:

– Request Quotes: Obtain multiple quotes to compare pricing and services.

– Hidden Costs: Clarify any additional costs such as tooling, mold maintenance, shipping, or tariffs.

4. Quality Assurance:

– Sample Approval: Request prototype samples to verify quality before full production.

– Inspection Plan: Establish a rigorous inspection regime, including pre-shipment inspections.

5. Contracts and Agreements:

– Detailed Contracts: Ensure contracts cover all aspects, from pricing and delivery schedules to IP protection and dispute resolution.

– Payment Terms: Negotiate fair payment terms, potentially using a Letter of Credit to reduce risk.

6. Logistics and Shipping:

– Lead Times: Confirm realistic lead times for production and shipping.

– Reliable Shipping: Partner with reputable logistics providers and consider insurance for high-value shipments.

7. Ongoing Relationship:

– Regular Audits: Conduct periodic factory audits to ensure ongoing compliance with standards.

– Feedback Loop: Maintain an open line of communication for continuous improvement and issue resolution.

By adhering to these tips, you can effectively source high-quality injection mould parts from SourcifyChina factory, ensuring timely delivery and cost efficiency.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.