Technology and Applications of is al a metal

Gallium (Ga) is a post-transition metal with a unique property: it melts at just 29.76 °C, slightly above room temperature. This makes it useful in various technologies:

* Thermometers: Gallium’s low melting point makes it ideal for thermometers, especially those designed for high-temperature applications.

* Semiconductors: Gallium arsenide (GaAs) is a compound semiconductor used in high-speed electronics, optoelectronics, and solar cells due to its superior electron mobility compared to silicon.

* LEDs: Gallium nitride (GaN) is another compound semiconductor used in blue and green LEDs, contributing to the development of energy-efficient lighting.

* Liquid Metal Alloys: Gallium is often used in liquid metal alloys due to its low melting point and good electrical conductivity. These alloys find applications in flexible electronics, self-healing materials, and thermal management systems.

Despite its unique properties, gallium is relatively rare and can be expensive, limiting its widespread use in some applications.

Quality Testing Methods for is al a metal and how to control quality

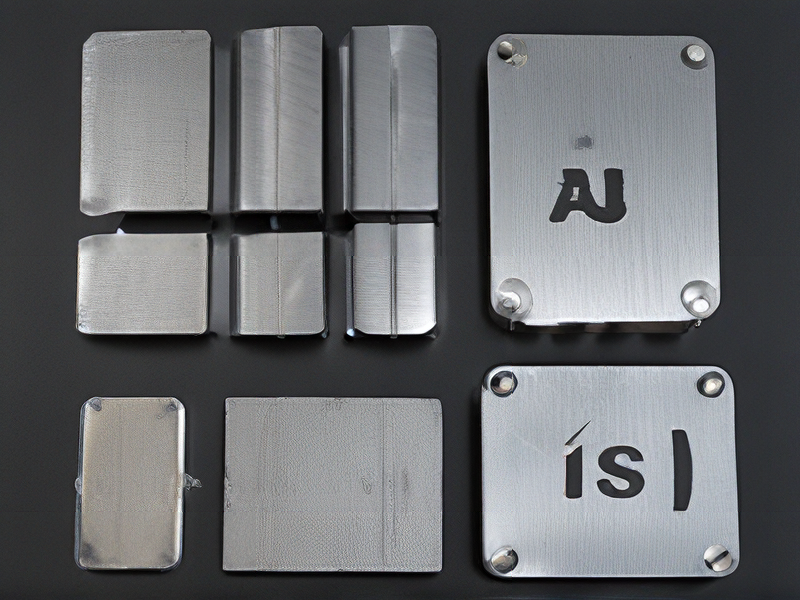

Quality testing for materials like aluminum involves several methods to ensure its properties meet specifications.

1. Chemical Analysis: This determines the composition of aluminum, checking for impurities and alloying elements. Techniques include spectroscopy and X-ray fluorescence.

2. Mechanical Testing: Tests like tensile strength, hardness, and elongation measure the strength, ductility, and resistance to deformation of the aluminum.

3. Physical Testing: This includes density testing, thermal conductivity measurement, and corrosion resistance evaluation.

4. Microstructure Analysis: Observing the aluminum’s internal structure under a microscope reveals grain size, distribution, and potential defects, impacting its strength and performance.

Quality Control Measures:

* Incoming Material Inspection: Verify raw materials meet specifications before processing.

* Process Monitoring: Control parameters like temperature, pressure, and cooling rates during manufacturing.

* In-Process Quality Checks: Conduct tests at various stages of production to ensure quality is maintained.

* Final Product Testing: Rigorous testing of finished products to guarantee they meet predetermined standards.

Continuously monitoring and adjusting these processes ensures consistent quality aluminum production.

Tips for Procurement and Considerations when Purchasing from is al a metal

Purchasing aluminium presents unique considerations compared to other metals. Here are some tips:

Procurement:

* Source Reputable Suppliers: Look for suppliers with experience in aluminium and certifications ensuring quality.

* Specify Alloy and Grade: Aluminium comes in various alloys, each with unique properties. Clearly define the required alloy and grade for your application.

* Request Samples: Always request samples to verify the metal’s quality, colour, and finish before placing a large order.

* Negotiate Pricing: Aluminium prices fluctuate. Negotiate with suppliers to secure the best possible price, considering quantity and delivery timeframe.

Considerations:

* Corrosion Resistance: Aluminium naturally forms a protective oxide layer, making it highly corrosion resistant.

* Weight: Aluminium is lightweight, making it ideal for applications where reducing weight is crucial.

* Recyclability: Aluminium is highly recyclable, making it an environmentally friendly choice.

* Thermal Conductivity: Aluminium is an excellent conductor of heat, making it suitable for heat sinks and other thermal management applications.

* Machinability: Aluminium is relatively easy to machine, making it versatile for various fabrication processes.

Remember to factor in transportation costs and potential fabrication requirements when making your final decision.

FAQs on Sourcing and Manufacturing from is al a metal in China

## FAQs on Sourcing and Manufacturing Metal from China

1. Q: Is China a good source for metal?

A: China is a major global producer and exporter of various metals, offering competitive pricing and large-scale production capabilities.

2. Q: What types of metals can I source from China?

A: China produces a wide range of metals, including steel, aluminum, copper, zinc, nickel, and rare earth elements.

3. Q: How do I find reliable metal suppliers in China?

A: Utilize online directories, industry trade shows, and recommendations from other businesses. Vet potential suppliers through certifications, customer reviews, and factory visits.

4. Q: What are the key factors to consider when manufacturing metal in China?

A:

* Quality standards: Ensure suppliers meet your required quality specifications.

* Production capacity: Verify the supplier can handle your order volume.

* Lead times: Understand the production and delivery timelines.

* Logistics and shipping: Plan for efficient transportation and customs clearance.

* Cost: Compare pricing from different suppliers while considering factors like material costs, labor, and shipping.

5. Q: What are the potential challenges of sourcing and manufacturing metal from China?

A: Language barriers, cultural differences, intellectual property protection, and quality control can pose challenges. Building strong relationships with reliable partners and conducting thorough due diligence is crucial.