1. Exceptional Quality Control

SourcifyChina Factory implements strict quality control measures, ensuring that each laser cleaning machine surpasses industry standards. This reliability translates into consistent performance and long-term durability.

2. Competitive Pricing

By leveraging local resources and manufacturing efficiencies, SourcifyChina delivers top-grade products at competitive prices. Buyers get excellent value without compromising on quality.

3. Advanced Technology

Our factory is equipped with cutting-edge technology, enabling the production of advanced laser cleaning systems. Customers benefit from enhanced features and improved efficiency.

4. Certified and Compliant

SourcifyChina complies with international certifications and regulations, ensuring each product is safe and environmentally friendly. Buyers can trust in the legal and ethical manufacturing standards.

5. Customized Solutions

We offer tailored laser cleaning systems to meet specific customer requirements. This customization ensures the optimal solution for diverse applications, increasing productivity and satisfaction.

6. Experienced Team

Our team comprises seasoned professionals with extensive expertise in laser technology. Their knowledge guarantees high-quality production and superior technical support for buyers.

7. Reliable After-Sales Service

SourcifyChina provides comprehensive after-sales service, including maintenance and troubleshooting. This ongoing support ensures that customers’ investments continue to perform exceptionally over time.

8. Positive Customer Feedback

Positive reviews and testimonials from satisfied global clients attest to SourcifyChina’s commitment to excellence. Buyers can be confident in making a trusted and proven choice.

9. Efficient Logistics

We have streamlined logistics to ensure timely delivery. Our efficient supply chain management guarantees that buyers receive their orders promptly, regardless of their location.

10. Sustainable Practices

SourcifyChina adopts sustainable manufacturing practices, reducing environmental impact. This commitment to sustainability aligns with global buyer preferences for eco-friendly solutions.

In summary, choosing SourcifyChina Factory for purchasing laser cleaning machines from China means benefiting from outstanding quality, advanced technology, competitive pricing, and excellent customer service. Buyers can trust in our reliable and tailored solutions, making us the ideal partner for their needs.

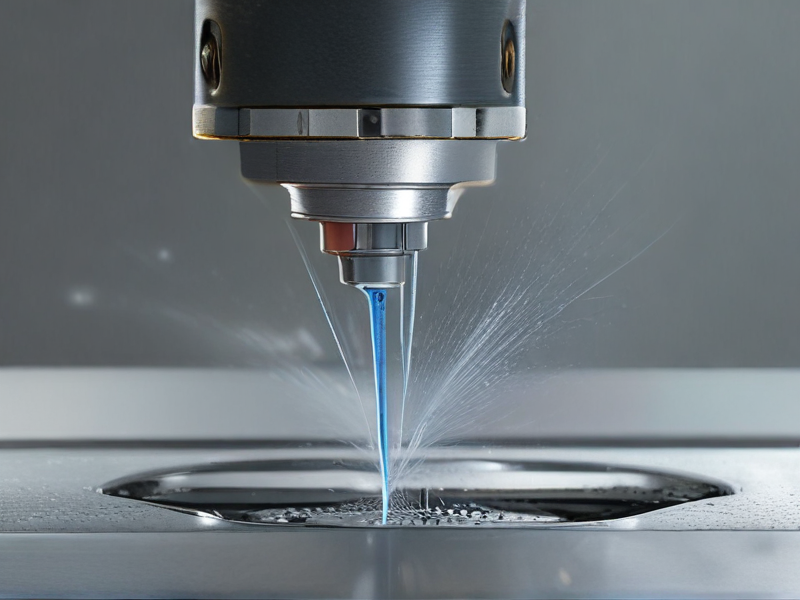

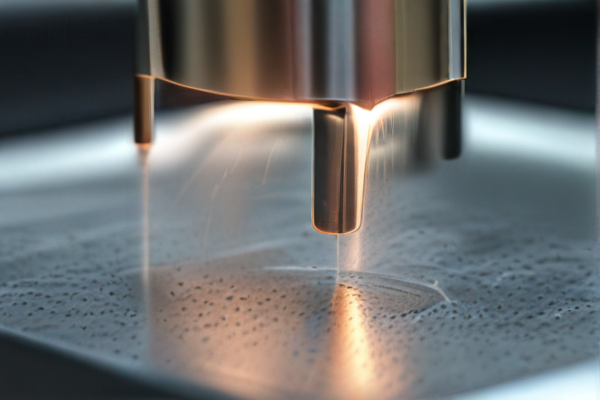

Laser cleaning metal is a modern, non-abrasive method for removing contaminants like rust, paint, or oxides. It uses laser pulses to ablate surface impurities without damaging the base material.

Types and options for laser cleaning metal include:

– Pulsed Fiber Lasers: Efficient for removing thin layers of rust and paint.

– Continuous Wave Lasers: Suitable for larger areas and thicker contaminants.

– Handheld Laser Cleaners: Portable and flexible for various applications.

– Automated Laser Systems: Ideal for high-volume, consistent cleaning tasks.

– Low Power Lasers (up to 100W): Best for light cleaning and delicate surfaces.

– High Power Lasers (100W and above): Effective for heavy-duty cleaning and industrial applications.

– Portable Units: Easy to transport and use in different locations.

– Stationary Systems: Designed for fixed installations, often integrated into production lines.

– Surface Pre-treatment: Prepares metal surfaces for coating or bonding processes.

– Rust and Oxide Removal: Efficiently removes rust and oxide layers without damaging the metal.

– Paint and Coating Stripping: Removes old paint and coatings, preparing surfaces for new applications.

– Precision Cleaning: Ideal for intricate parts and components requiring detailed cleaning.

– Environmentally Friendly: No chemical use, reducing environmental impact.

– Minimal Waste Generation: Produces minimal residue, usually in the form of dust particles.

These options cater to different needs, from delicate, detailed work to heavy industrial cleaning, making laser cleaning a versatile and efficient solution for metal maintenance and preparation.

Laser cleaning metal is an advanced technique for removing contaminants like rust, paint, and oxides. This precise, non-contact process offers numerous applications across various industries, enhancing efficiency and reducing damage to the substrate.

– Automotive industry: Cleans engine parts, gearbox components, and molds, enhancing performance and lifespan.

– Aerospace sector: Removes oxidation from aircraft components, ensuring safety and compliance with strict regulations.

– Manufacturing: Prepares surfaces for welding, bonding, and coating, improving adhesion and quality of the finish.

– Restoration projects: Cleans historical artifacts, statues, and heritage sites without damaging the underlying material.

– Electronics: Degreases and cleans circuit boards and other delicate components without the risk of physical damage.

– Medical field: Sterilizes and cleans medical implants and surgical tools, ensuring they meet health standards.

– Nuclear facilities: Decontaminates equipment surfaces exposed to radioactive substances safely and effectively.

– Marine industry: Removes biofouling from ship hulls, improving fuel efficiency and preventing corrosion.

– Precision engineering: Cleans precision parts where conventional methods may be too abrasive.

– Maintenance and repair: Periodically cleans industrial machinery to ensure optimal operation and prolong equipment life.

Laser cleaning technology is especially valued for its ability to precisely target contaminants, minimal material loss, and environmentally friendly process compared to chemical methods. The increasing adoption of laser cleaning exemplifies a trend towards more efficient and sustainable industrial practices.

“SourcifyChina laser cleaning metal” uses advanced laser technology to clean metal surfaces effectively. This innovative method focuses on removing contaminants, rust, and coatings without damaging the base material.

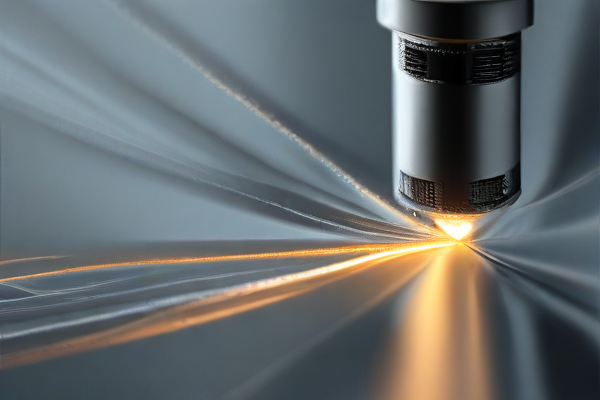

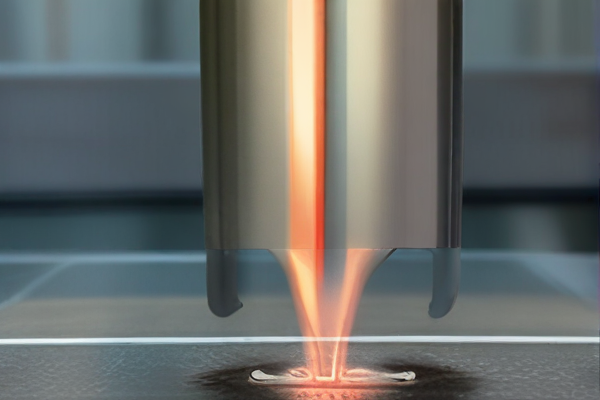

The core of this process lies in laser beams that deliver precise energy bursts. These bursts vaporize the unwanted layer, ensuring the metal remains intact and undamaged. This precision makes it ideal for delicate and valuable metals.

Durability and longevity are significantly improved through this method, as it avoids the chemical and abrasive techniques that could weaken the metal. It also proves effective in making subsequent treatments more reliable.

Environmental safety is a key advantage of laser cleaning. It eliminates the use of harmful chemicals, thereby reducing pollution and ensuring safer working conditions. This method aligns with modern sustainability goals.

In conclusion, laser cleaning for metal by SourcifyChina exemplifies cutting-edge technology in industrial maintenance. It provides high precision, environmental friendliness, and enhanced durability, making it a superior choice over traditional methods.

SourcifyChina employs a rigorous quality control process for their laser cleaning metal services. Beginning with raw material inspection, they ensure that only high-quality inputs are used. Advanced monitoring tools scrutinize every material to meet stringent standards.

The production phase is meticulously controlled with state-of-the-art laser equipment. Each machine undergoes regular calibration to maintain optimal performance. Operators are highly trained to handle these precision tools, making sure the process runs smoothly and efficiently.

Random sampling and real-time analytics are crucial to the process. These practices help identify any deviations from quality standards early, allowing for immediate corrective actions. This minimizes errors and maximizes consistency.

Upon completion, each cleaned metal piece undergoes a final inspection. Sophisticated measurement and testing tools ensure the cleaned surfaces meet the required specifications. This guarantees that the end product is not only clean but also structurally sound.

Customer satisfaction is paramount for SourcifyChina. Feedback loops are integrated into the quality control process. Post-delivery surveys and performance metrics are analyzed to continuously improve and meet customer expectations, ensuring a product that is both reliable and superior in quality.

SourcifyChina’s laser cleaning metal capabilities set a benchmark in precision and efficiency. High-powered lasers seamlessly remove rust, paint, and contaminants, preserving the integrity of the metal surface. This non-contact method ensures minimal environmental impact.

Advanced technology in SourcifyChina’s lasers offers unmatched control, adjusting power and speed for diverse metal types and contamination levels. This adaptability suits industries from automotive to aerospace, ensuring consistent quality.

Safety and user-friendliness are central to SourcifyChina’s laser cleaning systems. Built-in safety features, intuitive controls, and comprehensive training support operational excellence while minimizing risks during maintenance activities.

The cost-effectiveness of SourcifyChina’s solutions is notable. By reducing downtime and consumable costs, industries gain a sustainable, long-term cleaning solution. Enhanced productivity and decreased operational costs amplify the overall value.

Renowned for innovation, SourcifyChina continues to refine its laser cleaning technology. They integrate cutting-edge advancements, ensuring their equipment remains at the forefront of industrial cleaning solutions, meeting evolving market demands.

With global outreach, SourcifyChina stands as a trusted partner for businesses seeking reliable laser cleaning solutions. Their comprehensive service and robust product offerings underscore their commitment to quality and customer satisfaction.

Laser cleaning metal offers an efficient, eco-friendly, and precise method for removing contaminants, rust, and coatings. This advanced technology ensures superior surface preparation without causing damage.

Key Benefits of Laser Cleaning Metal:

– Non-Abrasive: Laser cleaning is a non-contact process, eliminating the risk of surface damage typically associated with traditional abrasive methods.

– Precision: The laser can be finely controlled, targeting specific areas that need cleaning, thus preserving the integrity of the substrate.

– Environmental Friendly: No need for chemical solvents or hazardous materials, significantly reducing environmental pollution.

– Cost-Effective: Reduces labor, waste disposal, and material costs over time, making it a more economical solution.

– Minimal Waste: Creates minimal waste as it vaporizes contaminants, which are then collected using a vacuum system.

– Versatility: Effective on a wide range of metals including steel, aluminum, and titanium, making it suitable for various industries.

– Improved Safety: Reduces the exposure of workers to dangerous chemicals and physical hazards associated with traditional cleaning methods.

– Low Maintenance: Laser systems require minimal maintenance and have a longer operational life compared to mechanical or chemical cleaning equipment.

– Speed and Efficiency: Capable of cleaning large surfaces quickly and efficiently, improving overall productivity.

– Enhanced Quality: Produces a cleaner, smoother surface that can improve adhesion for subsequent coatings and treatments.

– Reduced Downtime: Faster setup and processing times lead to reduced downtime in industrial operations.

Using laser technology for cleaning metal surfaces brings multifaceted advantages, driving operational efficiency, safety, and environmental sustainability across various industries.

Laser cleaning of metal offers a non-abrasive, precise, and environmentally friendly method for removing contaminants, rust, and coatings from metallic surfaces.

– Non-Abrasive: Unlike traditional methods, laser cleaning does not wear down or damage the substrate material.

– Precision: Offers high precision, enabling selective cleaning of intricate designs and hard-to-reach areas without affecting the surrounding material.

– Efficiency: Capable of removing contaminants quickly and uniformly, drastically reducing the time required compared to mechanical or chemical cleaning methods.

– Environmentally Friendly: Eliminates the need for hazardous chemicals and produces minimal waste, making it a safer and greener alternative.

– Low Maintenance: Requires minimal occasional calibration and cleaning, leading to lower operational costs over time.

– Versatility: Applicable to various metals and surface types, be it aluminum, steel, or alloy, and effective on rust, paint, oil, and other residues.

– Automation Compatibility: Easily integrated into automated systems and robotics for streamlined industrial processes.

– Surface Preparation: Provides an excellent pre-treatment for welding, painting, or adhesive bonding by creating a clean, oxide-free surface.

– Safety: Reduces the risk of operator exposure to toxic substances commonly associated with chemical cleaning.

These features collectively make laser cleaning a superior alternative for maintenance, restoration, and manufacturing applications where precision, speed, and environmental impact are of significant concern.

SourcifyChina specializes in laser cleaning metal, offering innovative solutions for custom products and projects. Using advanced laser technology, they ensure precise, efficient, and environmentally friendly cleaning processes.

Their laser cleaning systems remove rust, paint, and contaminants without damaging the underlying material. This extends the lifecycle of metal parts, making it ideal for industries like automotive, aviation, and manufacturing.

SourcifyChina tailor their services to meet specific client needs, whether it’s for high-volume production or intricate, one-off projects. Their expertise allows for flexibility and adaptability in various applications.

Not only does SourcifyChina focus on quality and efficiency, but they also prioritize customer satisfaction. They work closely with clients, offering continuous support and consultation from project inception to completion. This ensures all requirements are met with precision.

Additionally, their commitment to sustainability is evident in their eco-friendly cleaning methods. By eliminating chemical and abrasive cleaning techniques, they contribute to a greener environment while maintaining high standards of cleanliness.

Overall, SourcifyChina’s laser cleaning solutions are a game-changer for metal maintenance and preparation. They combine advanced technology, expert knowledge, and customer-centric services to deliver unparalleled results in custom products and projects.

SourcifyChina Laser Cleaning Metal stands at the forefront of the industrial cleaning sector, offering cutting-edge laser cleaning solutions tailored for metal surfaces. This innovative company harnesses the power of advanced laser technology to effectively and efficiently remove rust, paint, oxides, and other contaminants from metal substrates. By employing high-precision, non-contact laser cleaning systems, SourcifyChina ensures that the integrity of the metal is preserved, offering an environmentally friendly alternative to traditional abrasive methods. Their state-of-the-art equipment, designed with precision and durability in mind, delivers unparalleled cleaning speed and quality. As a trusted partner for manufacturing and industrial clients globally, SourcifyChina is committed to enhancing operational efficiency, lowering maintenance costs, and extending the lifespan of metal components through its robust laser cleaning solutions. The company’s steadfast dedication to innovation, quality control, and customer satisfaction solidifies its reputation as a leader in the industrial cleaning market.

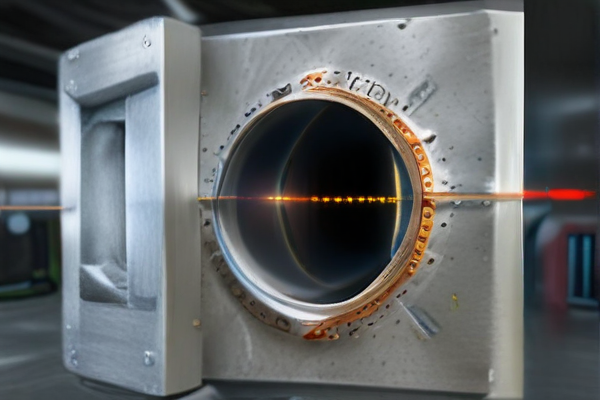

Laser cleaning technology has revolutionized maintenance and manufacturing in the aerospace, defense, and marine industries by providing a precise and non-abrasive method for removing contaminants from metal surfaces. In the aerospace sector, laser cleaning is employed to prepare metal surfaces for welding, painting, or bonding. This technique is highly advantageous for delicate aircraft components, where traditional methods might cause surface damage or compromise the integrity of the material. The precision of laser cleaning ensures that only unwanted substances, such as corrosion, oxidation, or paint, are removed without altering the underlying metal. Its application reduces preparation time, enhances the quality of surface treatments, and extends the longevity of critical components.

In the defense and marine industries, laser cleaning is equally transformative. Military and naval equipment, often exposed to harsh environmental conditions, are prone to corrosion and contamination. Laser cleaning provides an efficient and environmentally friendly method for maintaining such equipment, ensuring optimal performance and longevity. For instance, laser cleaning can effectively de-rust and decontaminate metal surfaces on battleships, submarines, and other marine vessels without producing hazardous waste or secondary pollutants. In defense manufacturing, it facilitates the preparation of metal parts for coating and assembly, thereby improving durability and reliability. The non-contact nature of laser cleaning also minimizes the risk of damage to sensitive components, making it an indispensable tool in these high-stakes applications.

Laser cleaning metal has found significant applications in both the automotive and electronics industries due to its precision, efficiency, and environmental benefits. In the automotive sector, laser cleaning is highly effective for removing rust, paint, and other contaminants from metal surfaces, preparing components for welding, bonding, or coating processes. This not only enhances the quality and durability of automotive parts but also reduces the need for chemical cleaners and abrasives, lowering production costs and minimizing environmental impact. High-precision laser cleaning ensures that intricate components, such as engine parts and transmission systems, maintain their integrity and performance, leading to safer and more reliable vehicles.

In the electronics industry, laser cleaning metal is utilized primarily for the preparation and maintenance of delicate components. As electronic devices continue to shrink in size and increase in complexity, maintaining clean and precise surfaces becomes crucial for ensuring optimal functionality and longevity. Laser cleaning is particularly useful for removing oxides and other contaminants from circuit boards, connectors, and semiconductor surfaces without causing thermal damage or leaving residues. This non-contact and precise method supports the high standards of purity and reliability required in electronics manufacturing, especially in the production of advanced devices like smartphones, computers, and medical electronics. Additionally, the ability to automate laser cleaning processes aligns with the industry’s push towards greater efficiency and scalability in production lines.

Laser cleaning metal has emerged as a revolutionary technology in the construction industry, providing an efficient, environmentally friendly alternative to traditional cleaning methods. The precision of laser cleaning makes it particularly advantageous for restoring metal structures, removing rust, contaminants, and paint without damaging the underlying material. This non-abrasive technique employs high-energy laser pulses to vaporize surface impurities, ensuring minimal waste and eliminating the need for harmful chemicals. Moreover, its ability to target specific areas with pinpoint accuracy makes it ideal for delicate restoration projects and preparation of metal surfaces for welding or coating, ultimately enhancing the durability and aesthetics of construction components.

In the energy sector, laser cleaning’s application significantly improves the maintenance and performance of critical infrastructure. For instance, in power generation facilities, laser cleaning is used to maintain turbine blades, heat exchangers, and pipelines. The precision cleaning ensures these components remain free of corrosion and deposits, optimizing efficiency and reducing the risk of unplanned outages. In the renewable energy industry, particularly in solar energy production, laser cleaning is employed to maintain the purity of solar panels, ensuring maximum light absorption and energy output. In both conventional and renewable energy fields, the adoption of laser cleaning reduces downtime, extends equipment lifespan, and minimizes the environmental impact, thereby supporting a more sustainable and efficient energy system.

The application of laser cleaning technology in the industrial equipment sector has revolutionized maintenance and fabrication processes. Laser cleaning metal involves using high-intensity laser beams to remove contaminants, oxides, or coatings from metal surfaces without damaging the substrate. This method is highly effective across various industries, from automotive to aerospace, due to its precision, reliability, and eco-friendliness. Unlike traditional methods such as sandblasting or chemical cleaning, laser cleaning does not generate secondary waste or require abrasive media, making it a more sustainable option. The ability to precisely control the laser parameters allows for the cleaning of intricate components and surfaces, thus extending the life and performance of industrial equipment.

In addition to its environmental benefits, laser cleaning offers substantial economic advantages. The non-contact nature of this technology minimizes mechanical stress and wear on the equipment being cleaned, reducing downtime and maintenance costs. Moreover, the automation potential of laser cleaning systems means they can be integrated into production lines, enhancing operational efficiency. Customizable for various applications, from surface preparation before welding to removing rust or paint layers, laser cleaning ensures consistent and repeatable results. This high precision and efficiency can significantly improve the quality and durability of industrial components, ultimately boosting overall productivity and cost savings across the industry.

Laser cleaning of metal surfaces is a burgeoning technology with significant applications in the medical device industry. This method employs high-intensity laser beams to remove contaminants, oxide layers, and other impurities from metal surfaces without causing significant material loss or damage. Medical devices, often composed of metals such as stainless steel, titanium, and cobalt-chrome alloys, require extraordinary levels of cleanliness and precision. Laser cleaning offers a non-contact, eco-friendly solution that can achieve these stringent standards. The technique is particularly advantageous for preparing surfaces before processes like welding, coating, or assembly, ensuring superior adhesion and longevity of the coatings applied. Furthermore, by eliminating the need for abrasive materials and chemical solvents, laser cleaning mitigates contamination risks, thus enhancing the overall biocompatibility of the devices.

Moreover, the precision and control afforded by laser cleaning are critical in the context of intricate medical devices that feature complex geometries or delicate components. Conventional cleaning methods might struggle to achieve uniformity or could potentially damage or alter fine features. In contrast, laser cleaning can be finely tuned to target specific contaminants at a microscopic level, ensuring a homogenous surface preparation without compromising the integrity of the device. The technology also features real-time monitoring and automation capabilities, which enhance its efficacy and consistency, crucial for the high-volume production typical in the medical industry. By improving the quality and safety of medical devices, laser cleaning not only ensures compliance with rigorous regulatory standards but also augments patient outcomes and trust in medical technologies.

Laser cleaning of metal is a highly advanced technique in machining and manufacturing, leveraging focused laser beams to remove contaminants, rust, oxide layers, and other unwanted materials from metal surfaces. This method is favored for its precision, speed, and environmental friendliness compared to traditional mechanical or chemical methods. By using high-intensity laser pulses, contaminants are vaporized or ejected from the surface, leaving behind a clean and unaltered base material. The precision of laser cleaning ensures that even intricate and delicate components can be cleaned without any physical abrasion or damage to the metal, making it ideal for components with tight tolerances and critical surface finish requirements.

In manufacturing, laser cleaning is particularly advantageous in preparation for processes like welding, painting, or coating, where surface cleanliness is paramount for adhesion and quality. The technology is also employed in the restoration of heritage metal objects and in industries such as aerospace, automotive, and electronics, where maintaining the integrity and performance of metal surfaces is crucial. Additionally, laser cleaning systems are programmable and can be automated, integrating seamlessly into production lines for enhanced efficiency and consistency. This level of automation reduces the dependency on manual labor, thereby increasing throughput while maintaining high safety standards, as operators are not exposed to hazardous chemicals or mechanical wear. Overall, laser cleaning stands out as a transformative technology that boosts productivity, enhances surface quality, and supports sustainable manufacturing practices.

FAQ for Laser Cleaning Metal Quality Work from SourcifyChina Factory

Q1: What is laser cleaning for metals?

A1: Laser cleaning is a non-contact process that uses laser technology to remove contaminants, oxides, and other impurities from metal surfaces. It is precise, environmentally friendly, and does not damage the substrate.

Q2: What types of metals can be cleaned with laser technology?

A2: Laser cleaning can be applied to various metals including steel, aluminum, copper, brass, and more. It is suitable for both ferrous and non-ferrous metals.

Q3: How does laser cleaning compare to traditional cleaning methods?

A3: Unlike abrasive or chemical cleaning methods, laser cleaning is non-destructive and does not produce secondary waste. It is safer for operators and the environment, offering consistent and high-quality results.

Q4: What are the applications of laser cleaning in the manufacturing industry?

A4: Laser cleaning is used for rust and oxide removal, paint stripping, mold cleaning, surface preparation before welding or coating, and more. It is widely used in automotive, aerospace, and heavy machinery industries.

Q5: What are the advantages of sourcing laser cleaning services from SourcifyChina?

A5: SourcifyChina offers advanced laser cleaning technology with high precision, cost-effective solutions, and a commitment to quality. Our factory ensures thorough cleaning, improved surface quality, and enhanced product lifespan.

Q6: Is laser cleaning suitable for all sizes and shapes of metal parts?

A6: Yes, laser cleaning can be adapted to various sizes and shapes, from small components to large structures. It is versatile and can be customized to meet specific cleaning requirements.

Q7: What are the safety measures in place during the laser cleaning process?

A7: SourcifyChina follows stringent safety protocols including protective eyewear for operators, proper ventilation systems, and controlled laser parameters to ensure safe and efficient operation.

Q8: How can I get a quote for laser cleaning services from SourcifyChina?

A8: To get a quote, you can contact us via our website or email with details about your project, including metal type, size, and specific cleaning needs. Our team will provide a tailored quote based on your requirements.

Laser cleaning has become an essential process in metal manufacturing, and SourcifyChina factory offers advanced solutions for this technology. Here are some key tips for effectively using laser cleaning in your operations:

1. Understand Material Properties: Different metals react differently to laser cleaning. Ensure you understand the specific properties of the metal you are working with, such as reflectivity and thermal conductivity.

2. Choose the Right Laser System: SourcifyChina offers various laser systems tailored for different applications. Select a laser with the appropriate wavelength, power, and pulse duration for your specific needs.

3. Optimize Parameters: Fine-tuning parameters like laser power, pulse frequency, and scanning speed can significantly impact the cleaning efficiency and quality. Start with the manufacturer’s recommended settings and adjust as necessary.

4. Safety First: Laser cleaning involves high-intensity light that can be harmful. Always wear appropriate protective gear like laser safety goggles and ensure that the operation area is well-ventilated to avoid fume inhalation.

5. Surface Preparation: Ensure the surface is free from loose contaminants that could be vaporized and create unwanted residues. Pre-clean the area if necessary to achieve the best results.

6. Use Automated Systems for Consistency: Automated laser cleaning systems provide consistent results and reduce the risk of human error. SourcifyChina offers customizable automated solutions to enhance productivity.

7. Maintenance and Calibration: Regularly maintain and calibrate your laser cleaning equipment to ensure long-term performance. SourcifyChina provides comprehensive maintenance support to keep your systems running smoothly.

8. Training: Proper training for operators is crucial. SourcifyChina offers detailed training programs to help your team efficiently and safely handle laser cleaning systems.

9. Environmental Considerations: Laser cleaning is eco-friendly as it minimizes the need for chemical cleaners. However, ensure that any by-products generated during the process are properly filtered and disposed of.

By leveraging these tips and utilizing SourcifyChina’s cutting-edge laser cleaning technology, you can significantly enhance the quality and efficiency of your metal manufacturing process.

Certainly! Here are some FAQs for sourcing laser cleaning metal services from SourcifyChina Factory:

What is laser cleaning?

Laser cleaning is a non-contact process that utilizes laser beams to remove contaminants, rust, or coatings from metal surfaces with high precision and without damaging the underlying material.

What types of metals can be cleaned using laser technology?

Laser cleaning is highly versatile and can be used on a wide range of metals including steel, aluminum, copper, and various alloys.

Is laser cleaning environmentally friendly?

Yes, laser cleaning is environmentally friendly as it does not require the use of chemicals or abrasive materials. It produces minimal waste, usually in the form of small particles that can be easily collected and disposed of.

What are the benefits of using laser cleaning over traditional methods?

Laser cleaning offers several advantages:

– Non-abrasive and non-damaging

– Highly precise and controllable

– No need for chemicals or solvents

– Minimal waste and easy cleanup

– Fast and efficient

How long does the laser cleaning process take?

The duration of the laser cleaning process depends on the size and condition of the metal object. Generally, the process is much quicker than traditional cleaning methods.

Does SourcifyChina provide customized laser cleaning solutions?

Yes, SourcifyChina offers customized laser cleaning services tailored to meet specific requirements of different industries and applications.

What is the cost of sourcing laser cleaning services from SourcifyChina?

The cost varies depending on factors such as the size of the project, type of metal, level of contamination, and specific customization needs. It’s best to request a detailed quote from SourcifyChina.

Does SourcifyChina provide a quality assurance for their laser cleaning services?

Yes, SourcifyChina follows strict quality control measures to ensure high standards in their laser cleaning services.

How can I source laser cleaning metal services from SourcifyChina?

You can get in touch with SourcifyChina through their website, email, or customer service hotline to discuss your requirements and obtain a quote.

Sourcing laser cleaning metal equipment from SourcifyChina factory can be a straightforward process if approached methodically. Here are some key tips to ensure success:

1. Research and Identification: Start by conducting thorough research on different suppliers. SourcifyChina Factory is reputed, but it’s crucial to compare their offerings with other providers to understand market standards. Look for reviews, testimonials, and industry certifications that establish credibility.

2. Clear Specifications: Clearly outline your requirements. Specify the type and dimensions of the metals you plan to clean, the desired cleaning efficiency, and any other critical parameters. This helps the factory provide relevant information and accurate quotations.

3. Direct Communication: Establish a direct line of communication with SourcifyChina’s sales team. Use email, phone, or platforms like WeChat to discuss your needs in detail. Direct communication minimizes misinterpretations and speeds up the sourcing process.

4. Request Samples: Before placing a large order, request product samples. This allows you to verify the quality of the laser cleaning equipment and ensure it meets your standards.

5. Factory Visit: If feasible, arrange for an in-person visit to the factory. This offers a firsthand look at their production capabilities, quality control processes, and overall operational standards.

6. Negotiation and Contract: Discuss terms including price, delivery schedules, minimum order quantities, and payment conditions. Ensure all agreements are documented in a contract to protect both parties and clarify expectations.

7. Quality Assurance: Confirm the factory’s quality assurance practices. Ask for details on their testing procedures and certification status, ensuring compliance with international standards.

8. Logistics and Shipping: Work out shipping logistics early on. SourcifyChina should provide clear timelines for production and delivery, along with shipping options that suit your budget and urgency.

By following these structured steps, you can effectively source laser cleaning metal equipment from SourcifyChina Factory, ensuring high-quality products and reliable service.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.