SourcifyChina Factory stands as a beacon of quality and reliability for buyers sourcing laser cutting CNC machines from China. They offer robust machines that meet international standards, ensuring efficient and precise operations for various industrial applications.

Their team of specialists provides unmatched customer service, guiding buyers through the entire purchasing process. SourcifyChina also offers comprehensive after-sales support, ensuring any issues are promptly addressed, which fosters long-term customer satisfaction and trust.

Cost-effectiveness is another advantage when choosing SourcifyChina. They provide high-quality machines at competitive prices, making advanced laser cutting technology accessible for businesses of all sizes. Bulk purchasing options further enhance savings.

Additionally, the factory’s commitment to continuous innovation ensures buyers access state-of-the-art technology. Regular updates and enhancements to their machinery keep their products at the forefront of industry standards, helping businesses maintain a competitive edge.

In summary, choosing SourcifyChina Factory means investing in quality, reliability, affordability, and cutting-edge technology. Their dedicated customer support and continuous innovation make them a top choice for purchasing laser cutting CNC machines from China. An investment in SourcifyChina is an investment in your business’s future success.

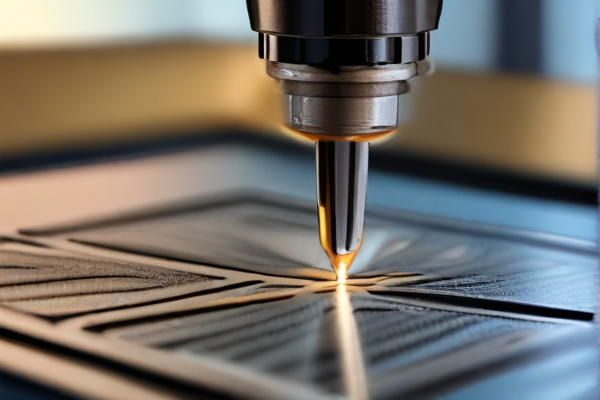

Laser cutting CNC (Computer Numerical Control) is a precise cutting method utilizing focused laser beams to slice materials. Different types include CO2, fiber, and crystal lasers, each suited for various materials and applications.

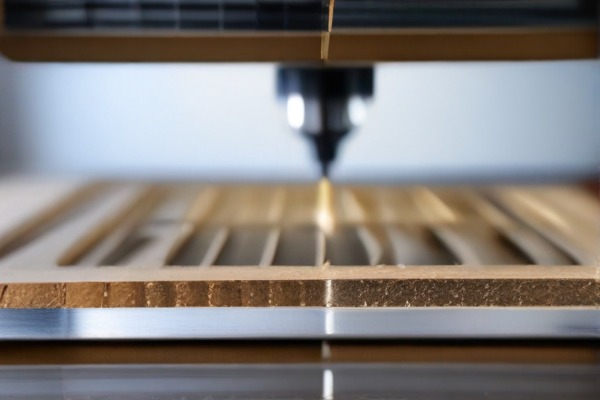

– CO2 Lasers: Ideal for non-metallic materials like wood, plastic, and glass.

– Fiber Lasers: Best for metal cutting, with higher efficiency and precision.

– Crystal Lasers: Suitable for both metals and non-metals but have higher maintenance costs.

Options

for Laser Cutting CNC:

– Power Levels: Choose based on material thickness and cutting speed requirements.

– Bed Sizes: Varying sizes to accommodate different workpiece dimensions.

– Cooling Systems: Water or air cooling options to manage heat during operation.

– Software Compatibility: Ensure the CNC software supports desired design and control features.

– Assisted Gases: Use of oxygen, nitrogen, or air to enhance cutting quality and speed.

– Auto-Focusing: Features for maintaining optimal focus on uneven surfaces.

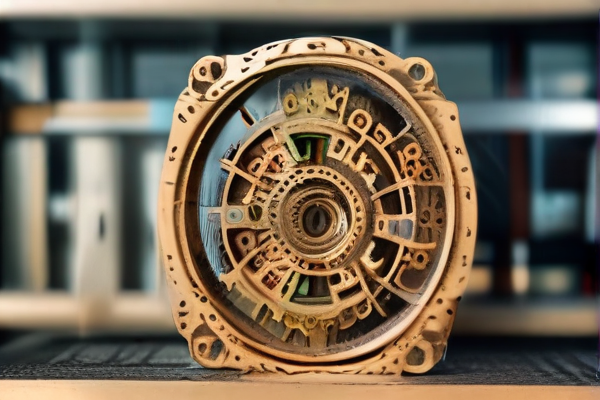

– Rotary Attachments: For cutting cylindrical objects like pipes and tubes.

– Safety Features: Enclosures, fume extractors, and emergency stop functions for safe operation.

– Dual-Head Capability: Allows simultaneous cutting or engraving, enhancing productivity.

– Customizable Settings: Adjust parameters for different materials and design complexities.

Choosing the right laser cutting CNC involves assessing the specific needs of your projects, material types, desired precision, and budget constraints.

Laser cutting CNC machines are versatile tools offering precision and efficiency in various applications. From manufacturing to art, their capabilities enable intricate designs and rapid production times.

– Industrial Manufacturing: Fabrication of parts and components for machinery.

– Automotive: Cutting of metal sheets for car parts.

– Aerospace: Precision cutting for aircraft components.

– Medical Instruments: Crafting intricate parts for devices.

– Electronics: Producing detailed circuit boards.

– Jewelry: Creating intricate designs in metals.

– Signage: Customizing signs with detailed patterns.

– Architecture: Crafting models and structural components.

– Fashion: Cutting fabrics and leather with precision.

– Prototyping: Rapid production of prototype components.

– Furniture: Designing intricate wooden and metal furniture.

– Art and Craft: Producing detailed artwork and decorations.

– Packaging: Creating specialized packaging materials.

– Education: Assisting in teaching manufacturing and design.

– Home Decor: Crafting custom decor items.

These applications highlight the wide-ranging usefulness and efficiency of laser cutting CNC machines across numerous industries.

SourcifyChina laser cutting CNC machines utilize a variety of durable materials to achieve precision in manufacturing tasks. Key materials include stainless steel, aluminum, and mild steel, each offering distinct benefits.

Stainless steel is renowned for its corrosion resistance and smooth finish, ideal for projects requiring high durability and fine detailing. It’s a go-to material for industries that demand quality.

Aluminum, being lightweight yet strong, is perfect for tasks needing excellent strength-to-weight ratios. This metal also offers good thermal and electrical conductivity, broadening its application range.

Mild steel is cost-effective and highly versatile, suitable for a range of industrial applications. It’s easier to cut and shape, making it a practical choice for diverse projects.

Each of these materials plays a vital role in enhancing the effectiveness of SourcifyChina laser cutting CNC machines. Their unique properties ensure that the end products meet stringent quality standards, tailored to various industrial needs.

SourcifyChina ensures top-notch quality control in its laser cutting CNC manufacturing process. The procedure begins with sourcing high-grade raw materials that meet stringent quality standards.

Precision is paramount at SourcifyChina; advanced laser cutting CNC machines are meticulously calibrated before each project. Regular maintenance and checks are performed to ensure optimal performance and accuracy.

Inspection is integral throughout the manufacturing process. Trained quality control inspectors monitor each phase, from initial cutting to the final product, employing sophisticated measurement tools to confirm specifications.

SourcifyChina’s commitment to quality extends to post-production. Each product undergoes rigorous final inspections, including dimensional accuracy and surface finish checks. This comprehensive quality control process ensures that every item produced meets or exceeds customer expectations, delivering consistent, high-quality results every time.

SourcifyChina excels in laser cutting CNC technology, offering precision and accuracy in material processing. Their advanced machinery can handle intricate designs and complex geometries with ease, ensuring high-quality results.

The company uses cutting-edge laser cutting CNC machines that can work with a variety of materials, including metals, plastics, and composites. This versatility makes them suitable for a wide range of industries.

SourcifyChina’s laser cutting services are known for their speed and efficiency. Their streamlined processes reduce turnaround times, helping clients meet tight project deadlines without compromising on quality.

In addition to speed, their laser cutting CNC capabilities also emphasize minimal material wastage. Optimized cutting paths and precision ensure that resources are utilized efficiently, reducing costs for clients.

The company prides itself on strict quality control measures at every stage of the laser cutting process. This attention to detail guarantees that each component meets or exceeds client specifications.

SourcifyChina also offers custom solutions tailored to individual project needs. Their team of experts collaborates closely with clients to ensure that specific requirements are met, providing a personalized touch.

With a commitment to innovation, SourcifyChina continually updates its laser cutting CNC technology. This focus on the latest advancements ensures they remain competitive and capable of handling new challenges.

Furthermore, their customer service is top-notch. They provide comprehensive support from initial consultation through to final delivery, ensuring a seamless experience for their clients.

Overall, SourcifyChina’s laser cutting CNC capabilities combine precision, efficiency, and exceptional customer service. By leveraging state-of-the-art technology and a dedicated team of professionals, they deliver superior results that cater to diverse industrial needs, making them a trusted partner in material processing.

Laser cutting CNC (Computer Numerical Control) technology offers unparalleled precision and efficiency in various industrial applications. It provides numerous advantages that enhance productivity and reduce operational costs.

– Precision: Accurate cutting with minimal material wastage.

– Speed: Faster processing times compared to traditional methods.

– Versatility: Capable of cutting various materials such as metal, wood, and plastic.

– Complexity: Enables intricate designs and complex geometries.

– Automation: Reduces the need for manual intervention, increasing consistency.

– Safety: Minimizes human contact with cutting tools, reducing the risk of accidents.

– Cost-effectiveness: Lowers costs by minimizing material waste and enhancing throughput.

– Quality: Produces clean and precise edges without the need for secondary finishing operations.

– Reproducibility: Ensures consistent results for large batch production.

– Eco-friendly: Generates less waste and often requires no harmful chemicals.

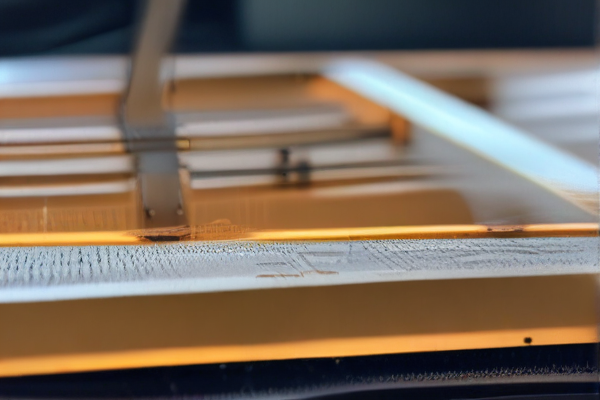

Laser cutting CNC machines offer precise and efficient cutting capabilities for various materials, making them essential in manufacturing and design industries. Here are some key features:

– Precision and Accuracy: Laser cutting CNC machines provide high levels of precision and consistency, allowing for intricate designs and detailed cuts.

– Versatility: They can handle a wide range of materials including metals, plastics, wood, and fabrics.

– Speed and Efficiency: Faster cutting speeds compared to traditional methods, leading to increased productivity.

– Automation: CNC control allows for automated cutting processes, reducing the need for manual intervention.

– Clean Cuts: Produces clean edges with minimal need for post-processing or finishing.

– Reduced Waste: Optimizes material usage with precise cuts, minimizing wastage.

– Complex Geometries: Capable of cutting complex shapes and patterns that would be difficult with other methods.

– Minimal Wear and Tear: Non-contact process reduces tool wear and prolongs machine life.

– Programmability: Easily programmable for different designs, offering flexibility in production.

– Safety: Enclosed systems and safety features protect operators from exposure to laser beams.

– Energy Efficiency: Modern laser cutters are designed to be energy-efficient, reducing operational costs.

– Scalability: Suitable for both small-scale and large-scale production runs.

These features make laser cutting CNC machines a valuable asset in various fields, from automotive to fashion, enhancing both the quality and efficiency of production.

SourcifyChina specializes in laser cutting CNC services, offering precision and quality in custom products and projects. Their advanced technology ensures intricate cuts suitable for various materials, achieving exceptional detail.

Their comprehensive range of services includes custom designs for furniture, signage, and industrial components. Each piece is crafted to meet specific client requirements, ensuring functional and aesthetic value.

Clients benefit from SourcifyChina’s commitment to innovation, with the company continually integrating the latest advancements in laser cutting technology. This guarantees high efficiency and reduced turnaround times for all projects.

Furthermore, SourcifyChina emphasizes quality assurance, employing stringent checks throughout the production process. Every product undergoes detailed inspection to maintain the highest standards.

Customer satisfaction is paramount, with the company providing personalized consultation services. This ensures all client specifications are fully understood and met, from the initial concept to the final product.

SourcifyChina’s dedication to eco-friendly practices is evident in their material selection and waste management. They aim to reduce environmental impact while providing superior quality.

Specializing in small to large-scale projects, SourcifyChina caters to diverse industries. Their versatile and adaptive approach makes them a preferred partner in the manufacturing sector.

In conclusion, SourcifyChina’s laser cutting CNC services exemplify precision, innovation, and quality in custom products and projects. Their client-focused approach, state-of-the-art technology, and environmental consciousness set them apart in the industry.

SourcifyChina is an industry-leading company specializing in laser cutting and CNC (Computer Numerical Control) machining services for a diverse range of materials and applications. Situated in China, the company leverages state-of-the-art technology to provide precision cutting, engraving, and machining solutions that meet the highest international standards. SourcifyChina excels in serving clients across various industries, including automotive, aerospace, consumer electronics, and custom manufacturing. Their highly skilled workforce, combined with rigorous quality control protocols, ensures that every project meets exact specifications and is delivered on time. Furthermore, SourcifyChina is committed to sustainability, employing environmentally friendly processes and materials. By focusing on innovation and customer satisfaction, the company has built a strong reputation as a reliable partner for businesses seeking high-quality, cost-effective CNC and laser cutting solutions.

Laser cutting CNC (Computer Numerical Control) technology has revolutionized the aerospace, defense, and marine industries with its unparalleled precision and efficiency. In aerospace, the technology is utilized for manufacturing complex components from lightweight materials such as titanium, aluminum, and composites, which are critical for reducing the overall weight of aircraft and improving fuel efficiency. The high precision of laser cutting ensures that intricate parts like turbine blades, panels, and structural components meet stringent tolerances and quality standards. This not only enhances the performance and safety of aircraft but also reduces material wastage and production time, translating to significant cost savings.

In the defense sector, laser cutting CNC technology is paramount for producing a wide array of critical components, including armor plating, weaponry parts, and advanced surveillance systems. The capability to accurately cut tough and dense materials like steel and titanium is essential for creating durable and reliable defense equipment. Furthermore, the marine industry benefits from laser cutting CNC technology in the fabrication of ships, submarines, and other marine vessels. The precision cutting of metal sheets and structural components ensures a perfect fit and finish, essential for the seaworthiness and longevity of marine vessels. In both defense and marine applications, the speed and accuracy of laser cutting CNC contribute to shortened production cycles, enhanced design flexibility, and ultimately, superior performance and durability of the final products.

Laser cutting CNC (Computer Numerical Control) technology has revolutionized the automotive industry by providing precise and efficient solutions for manufacturing components. In automotive applications, laser cutting enables the production of complex parts with high accuracy, which is essential for maintaining the quality and safety standards of vehicles. This technology is particularly useful in cutting materials such as steel, aluminum, and various alloys used in car chassis, body panels, and intricate components like gears and brackets. The precision offered by laser cutting CNC minimizes waste and reduces the need for additional finishing processes, leading to cost savings and faster production times. Furthermore, as automotive designs become increasingly intricate with tighter tolerances, the ability of laser cutting CNC to achieve such exact specifications is indispensable, allowing manufacturers to innovate and optimize vehicle performance and aesthetics.

In the electronics industry, laser cutting CNC plays a critical role in the fabrication of small, high-precision components necessary for modern devices. The demand for miniaturized electronics with complex geometries has driven the need for advanced cutting technologies that traditional methods cannot fulfill. Laser cutting CNC excels in this domain by providing clean, burr-free cuts and the ability to work with delicate materials such as silicon wafers, printed circuit boards (PCBs), and thin metallic foils. This precision ensures the integrity of delicate components, which is crucial for the functionality and reliability of electronic devices such as smartphones, laptops, and medical instruments. Additionally, the flexibility and programmability of CNC systems allow for rapid prototyping and modifications, supporting the fast-paced nature of the electronics market. As a result, laser cutting CNC has become an integral tool for producing high-performance components, contributing to innovation and the advancement of electronic technologies.

Construction Application:

In the construction industry, laser cutting CNC (Computer Numerical Control) technology has revolutionized the way materials like steel, aluminum, and other metals are processed and assembled. Precision and efficiency are critical in construction projects, and laser cutting CNC machines offer unparalleled accuracy, reducing material wastage and ensuring components fit perfectly together. This precision extends to intricate designs and customized structural components that are increasingly demanded in modern architectural projects. For example, laser cutting can create intricate façade panels, custom structural brackets, and detailed metal fittings with ease, allowing architects and engineers to bring complex design visions to life. Additionally, the speed and automation capabilities of CNC laser cutting streamline the manufacturing process, significantly reducing lead times and labor costs, thus expediting project completion and maximizing resource efficiency.

Energy Application:

In the energy sector, particularly in renewable energy technologies such as solar and wind power, laser cutting CNC systems play a crucial role in the manufacture of high-precision components. For instance, the precision cutting of metal sheets used in the construction of solar panels and wind turbine components ensures maximal structural integrity and optimal performance. The ability to produce precise and intricate cuts is essential for the development of lightweight and aerodynamic parts for turbines, which can directly affect energy efficiency and generation capacity. Moreover, laser cutting CNC technology is instrumental in the fabrication of battery cell components and intricate cooling systems in energy storage devices, where precision and consistency are paramount. This advanced manufacturing capability supports the broader energy industry’s push towards more efficient, reliable, and sustainable energy solutions, making laser cutting CNC an invaluable tool in the transition to a greener, more energy-efficient future.

The industrial equipment industry greatly benefits from the integration of laser cutting CNC (Computer Numerical Control) technology, revolutionizing manufacturing processes across various sectors. Laser cutting CNC allows for the precise and efficient cutting of materials including metals, plastics, and composites. This technology operates by directing a high-powered laser through optics, controlled by a computer to follow exact patterns and dimensions. The result is clean, accurate cuts with minimal waste, which is crucial in industries such as automotive, aerospace, and metal fabrication. This precision reduces the need for secondary processes like finishing, thereby accelerating production timelines and enabling manufacturers to meet tight deadlines while maintaining stringent quality standards.

Additionally, the use of laser cutting CNC in industrial equipment applications supports the customization and flexibility necessary in modern manufacturing. The digital control system permits rapid changes and adjustments to design specifications, which is particularly advantageous for prototyping and small-batch production runs. Custom components can be produced quickly and to exact specifications without extensive retooling. This adaptability not only boosts efficiency but also expands the range of possible designs, empowering innovation. Moreover, the non-contact nature of laser cutting minimizes wear and tear on machinery, leading to reduced maintenance costs and prolonged equipment lifespan. Consequently, the incorporation of laser cutting CNC technology stands as a cornerstone for the competitive advancement of the industrial equipment industry, driving both productivity and innovation.

Laser cutting CNC (Computer Numerical Control) technology has significantly transformed the medical device industry by enabling the precision manufacturing of intricate components. This technology utilizes high-powered lasers to cut and shape materials with microscopic accuracy, ensuring that even the most delicate and complex parts meet rigorous industry standards. Medical devices such as stents, catheters, and implantable devices often require intricate designs with tight tolerances that traditional manufacturing methods struggle to achieve. Through CNC laser cutting, manufacturers can produce these components with exceptional repeatability and minimal material wastage, ensuring each part is consistently within specification. This level of precision supports the creation of devices that function reliably within the human body, reducing the risk of complications and improving patient outcomes.

Additionally, the versatility of laser cutting CNC systems allows for the use of a wide range of biocompatible materials essential in the medical field. Metals like titanium and stainless steel, as well as polymers and ceramics, can be meticulously cut and engraved to meet specific medical requirements. The non-contact nature of laser cutting minimizes the thermal and mechanical stresses on materials, preserving their physical properties and integrity. Moreover, the flexibility of CNC programming enables quick adjustments in design and prototyping processes, accelerating the development of innovative medical solutions. This adaptability is crucial in the fast-paced medical industry, where advancements in technology and treatments constantly drive the need for new and improved medical devices. Therefore, laser cutting CNC not only enhances the performance and reliability of medical devices but also fosters innovation, leading to better healthcare solutions.

Laser cutting CNC (Computer Numerical Control) technology has significantly revolutionized the fields of machining and manufacturing due to its high precision, speed, and versatility. Unlike traditional cutting methods that may involve physical contact and wear-prone tools, laser cutting employs a focused laser beam to slice through materials. This process is capable of creating intricate and complex shapes with minimal material waste. As it is computer-controlled, the precision of the laser cutting CNC is unmatched, producing smoother edges and finer details without the need for additional finishing. This technology is especially beneficial in industries where high tolerances are crucial, such as aerospace, automotive, and medical devices, where even minor deviations can lead to significant issues.

In the realm of manufacturing, laser cutting CNC machines have also streamlined production processes, enhancing efficiency and reducing costs. The flexibility of these machines allows for quick alterations in design, which is particularly useful for customized or small-batch production runs. Additionally, laser cutting CNC systems are compatible with a wide range of materials, including metals, plastics, wood, and composites, thus broadening their application scope. Advanced features like automation and integration with other CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) systems also enable seamless workflow management from design to production. As a result, manufacturers can produce high-quality components faster, with greater consistency and less manual intervention, driving innovation and competitiveness in the industry.

Sure, here’s a list of FAQs with answers for manufacturing laser cutting CNC quality work from SourcifyChina factory.

1. What types of materials can be laser cut at SourcifyChina?

Our laser cutting CNC machines are capable of cutting a variety of materials including metals (such as steel, aluminum, and copper), plastics, wood, and acrylics. We can accommodate specific material requirements based on your project needs.

2. What is the maximum thickness of materials that can be laser cut?

The maximum thickness we can accurately and cleanly cut depends on the material. Typically, we can cut metals up to 25mm thick, plastics up to 50mm, and wood up to 30mm. Please consult with our team for specific requirements.

3. Can you provide custom laser cutting services?

Yes, we specialize in custom laser cutting services tailored to your design specifications. We work closely with our clients to ensure the final product meets their exact requirements.

4. What file formats do you accept for laser cutting projects?

We accept a variety of file formats for laser cutting projects, including DXF, DWG, AI, SVG, and PDF. If you have a different file format, please contact us to discuss compatibility.

5. How long does it take to complete a laser cutting project?

The lead time for laser cutting projects varies based on the complexity and size of the order. Typically, most projects are completed within 7-10 business days. For urgent requests, expedited services are available upon request.

6. What quality control measures are in place at SourcifyChina?

We adhere to stringent quality control measures to ensure precision and accuracy. Each piece undergoes detailed inspection for dimensional accuracy, edge quality, and overall finish before being dispatched to our clients.

7. Do you offer additional finishing services post-laser cutting?

Yes, we offer a range of finishing services including deburring, polishing, powder coating, and anodizing to enhance the final appearance and durability of the cut parts.

8. How do I request a quote for laser cutting services?

To request a quote, please contact us via email or phone with your project details, including material type, thickness, design files, and quantity. Our team will provide a detailed quote within 24 hours.

9. Is there a minimum order quantity (MOQ) for laser cutting projects?

Choosing a reliable laser cutting CNC manufacturing partner like SourcifyChina factory can greatly enhance your manufacturing efficiency and product quality. Here are some key tips:

1. Evaluate Experience and Capabilities: Assess the factory’s expertise in laser cutting technology. SourcifyChina excels in precision cutting for various materials including metals, plastics, and composites. Ensure they have a robust CNC system for complex designs.

2. Check Equipment Quality: High-quality laser cutting machines yield better results. Verify that SourcifyChina uses advanced, well-maintained machines with state-of-the-art software for precise and repeatable cuts.

3. Material Handling: Confirm they handle the specific materials your project requires. SourcifyChina should offer a range of material options and have expertise in working with them, ensuring minimal waste and optimal cutting results.

4. Customization and Prototyping: SourcifyChina should provide customizable options and rapid prototyping services. This allows you to visualize, test, and refine your designs before full-scale production, saving time and costs.

5. Quality Assurance: Investigate their quality control processes. SourcifyChina should have rigorous checks at each production stage to ensure high standards and defect-free outcomes.

6. Lead Time and Scalability: Evaluate their production lead time and capacity to scale based on your needs. SourcifyChina should demonstrate flexibility to meet tight deadlines and adapt to volume increases.

7. Supply Chain and Logistics: SourcifyChina offers comprehensive logistics solutions, ensuring timely delivery and reducing the risk of delays. Align with their supply chain procedures for smooth operations.

8. Cost Efficiency: Balance cost with quality. SourcifyChina is known for competitive pricing without compromising on quality, making it a cost-effective choice for laser cutting CNC manufacturing.

By focusing on these key factors, you can maximize the benefits of partnering with a reputable manufacturer like SourcifyChina, ensuring your production process is efficient, reliable, and high-quality.

Q: What is SourcifyChina Factory?

A: SourcifyChina Factory is a reputable supplier in China that offers a wide range of manufacturing services, including laser cutting CNC services. They are known for their quality products, competitive pricing, and efficient production timelines.

Q: What materials can SourcifyChina’s laser cutting CNC handle?

A: SourcifyChina’s laser cutting CNC can handle a variety of materials such as stainless steel, aluminum, carbon steel, acrylic, wood, and plastic. They are equipped to meet diverse cutting requirements.

Q: What is the maximum thickness that can be cut?

A: The maximum thickness varies depending on the material. For instance, stainless steel can be cut up to 20mm, while acrylic can be cut up to 30mm. It’s best to consult with SourcifyChina for specific material capabilities.

Q: What file formats are accepted for design submissions?

A: SourcifyChina accepts various file formats for design submissions, including DXF, DWG, PDF, and AI. It is important to provide a vector file for precise cutting.

Q: How long does it take to complete an order?

A: Lead times can vary based on the complexity and volume of the order. Typically, it ranges from 2 to 4 weeks. For urgent requirements, expedited services may be available.

Q: What is the minimum order quantity (MOQ)?

A: The MOQ can vary depending on the specific project requirements. However, SourcifyChina is flexible and can often accommodate smaller orders for prototypes or initial runs.

Q: Can I request a sample before placing a bulk order?

A: Yes, SourcifyChina allows for sample orders before committing to larger quantities. This helps ensure that the final product meets your specifications.

Q: What quality control measures are in place?

A: SourcifyChina follows strict quality control protocols, including inspection of raw materials, in-process checks, and final product inspections to ensure the highest standards are met.

Q: Are there any warranties or guarantees?

A: SourcifyChina provides warranties and guarantees depending on the specific product and materials used. They stand behind the quality of their work and offer after-sales support.

Sourcing laser cutting CNC machines from SourcifyChina requires a strategic approach to ensure quality, cost-effectiveness, and timely delivery. Here are some tips to guide you through the process:

1. Define Your Requirements:

– Specify the type of laser cutting CNC machine you need (e.g., CO2, fiber, or Nd:YAG).

– Determine the necessary specifications like power, cutting area, and precision.

2. Research the Supplier:

– Verify SourcifyChina’s credibility through reviews, ratings, and certifications (ISO, CE).

– Request references from other customers to gauge their satisfaction.

3. Request Detailed Quotations:

– Get comprehensive quotes that include unit price, shipping costs, customs duties, and any additional fees.

– Compare quotes from multiple suppliers to ensure competitive pricing.

4. Assess Quality Control:

– Inquire about quality control processes and request quality inspection reports.

– Consider requesting sample products before making a bulk purchase.

5. Check Payment Terms:

– Negotiate favorable payment terms, such as partial payment upfront and the balance upon delivery.

– Utilize secure payment methods to protect your transaction.

6. Evaluate Lead Time and Logistics:

– Confirm the production and delivery timelines.

– Ensure the supplier can meet your deadlines to avoid delays in your operations.

7. Negotiate Terms & Contracts:

– Clearly define terms related to warranty, after-sales service, and return policies.

– Ensure the contract covers all agreed-upon aspects to avoid misunderstandings.

8. Consider Site Visits:

– If feasible, arrange visits to SourcifyChina’s factory to assess their facilities and capabilities firsthand.

9. Utilize Communication Tools:

– Use platforms like Alibaba, Made-in-China, or direct email communication to maintain clear and consistent dialogue.

10. Stay Updated:

– Follow up regularly on the production progress and stay informed about any potential changes or issues.

By following these steps, you can ensure a smooth sourcing process for laser cutting CNC machines from SourcifyChina, leading to successful procurement and operational efficiency.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.