Technology and Applications of laser engravable metal

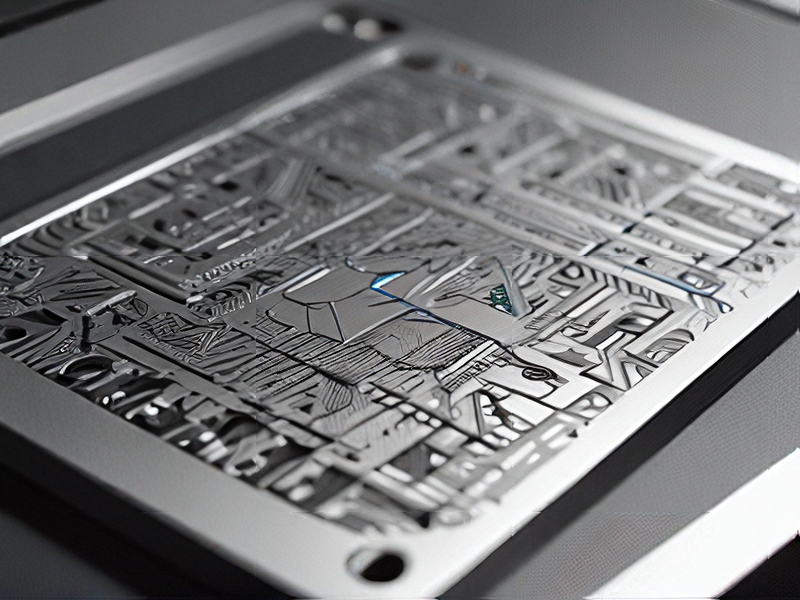

Laser engravable metals refer to various metal alloys that can be precisely marked or engraved using laser technology. This process leverages the intense, focused energy of lasers to alter the metal’s surface, creating high-resolution designs, text, or patterns.

Technology

1. Laser Types:

– Fiber Lasers: Ideal for metals due to their high power and precision.

– CO2 Lasers: Less common for metals but can be used with certain coatings.

– Nd:YAG Lasers: Suitable for both metals and non-metals.

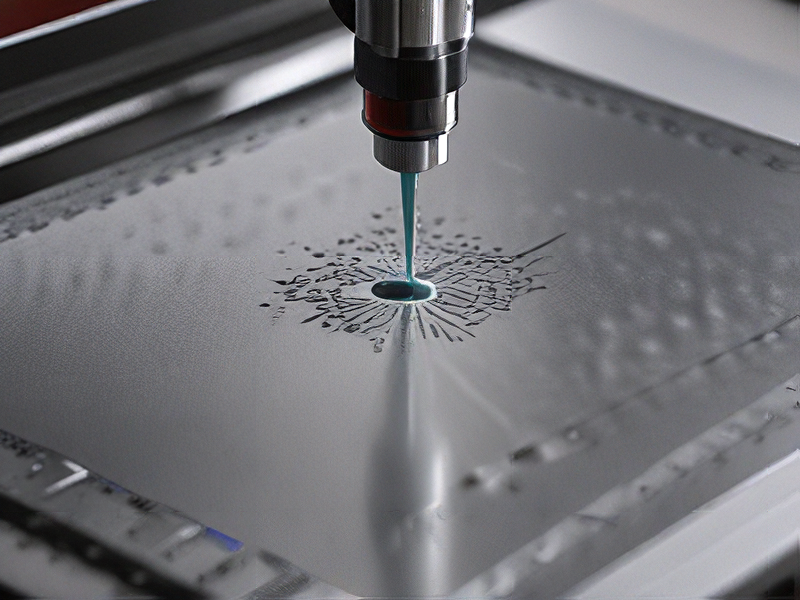

2. Engraving Process:

– Annealing: Heats the metal to change its color without removing material, suitable for stainless steel.

– Ablation: Removes material to create deep engravings.

– Foaming: Melts the metal surface to create bubbles that reflect light, resulting in a raised marking.

3. Materials:

– Commonly engraved metals include stainless steel, aluminum, brass, titanium, and copper.

Applications

1. Industrial:

– Part Identification: Serial numbers, barcodes, and QR codes for traceability.

– Tool Marking: Ensures durability and legibility in harsh environments.

2. Medical:

– Surgical Instruments: Permanent markings for sterilization cycles.

– Medical Devices: Traceability and compliance with regulatory standards.

3. Jewelry and Fashion:

– Personalization: Custom engravings on rings, bracelets, and watches.

– Branding: Logos and designs on fashion accessories.

4. Electronics:

– Component Marking: Ensures proper identification and compliance.

– PCBs: Markings on printed circuit boards for manufacturing and assembly.

5. Automotive:

– VIN Marking: Vehicle identification numbers for security and traceability.

– Parts and Tools: Markings for inventory management and quality control.

Laser engraving on metals is valued for its precision, durability, and ability to create intricate designs, making it indispensable across various industries.

Quality Testing Methods for laser engravable metal and how to control quality

Quality testing for laser engravable metal involves several methods to ensure consistency and high standards. Here’s a concise overview of the primary testing methods and quality control techniques:

Quality Testing Methods

1. Material Composition Analysis:

– X-Ray Fluorescence (XRF): Non-destructive technique to determine the elemental composition of the metal.

– Spectrometry: Used to identify and quantify the metals present, ensuring the alloy composition meets specifications.

2. Surface Integrity:

– Microscopy: Optical or electron microscopy to inspect surface finish and detect any micro-cracks or imperfections.

– Roughness Measurement: Profilometers measure the surface roughness to ensure it is within acceptable limits for engraving.

3. Hardness Testing:

– Rockwell or Vickers Hardness Test: Measures the hardness of the metal, ensuring it meets the required standards for durability and engravability.

4. Coating Thickness:

– Ultrasonic Testing: Non-destructive measurement of coating thickness to ensure uniformity.

– Eddy Current Testing: Another non-destructive method to check for coating thickness and uniformity.

5. Laser Engraving Tests:

– Test Engravings: Perform test engravings on sample pieces to assess the quality and precision of the engraving.

– Inspection of Engravings: Use microscopes or high-resolution cameras to examine the engraving for clarity and precision.

Quality Control Techniques

1. Standard Operating Procedures (SOPs): Establish SOPs for each step of the testing process to ensure consistency and reliability.

2. Training and Certification: Regularly train and certify technicians in quality testing methods and proper use of equipment.

3. Documentation and Traceability: Maintain detailed records of material batches, test results, and any deviations from standards.

4. Regular Calibration: Ensure all testing equipment is regularly calibrated and maintained to provide accurate results.

5. Statistical Process Control (SPC): Use SPC tools to monitor and control the quality of the manufacturing process, identifying any trends or variations that could affect product quality.

Implementing these methods and controls helps in maintaining the high quality of laser engravable metals, ensuring they meet the desired standards and specifications.

Tips for Procurement and Considerations when Purchasing from laser engravable metal

When procuring laser engravable metal, it’s crucial to consider a range of factors to ensure you get the best quality and value for your needs. Here are some key tips:

1. Material Quality: Check for high-quality metals that respond well to laser engraving. Common choices include stainless steel, aluminum, brass, and anodized aluminum. Verify that the material is free from defects like scratches or discoloration.

2. Supplier Reputation: Choose suppliers with a strong reputation for reliability and quality. Look for reviews, ask for references, and consider their experience in providing laser engravable metals.

3. Compatibility with Equipment: Ensure the metal is compatible with your laser engraving equipment. Different metals require specific settings for optimal results, so verify the specifications with your supplier.

4. Surface Finish: Consider the surface finish of the metal. Polished, brushed, or anodized finishes can affect the appearance and quality of the engraving. Choose the finish that best suits your project needs.

5. Thickness and Size: Select the appropriate thickness and size of metal sheets or blanks. Thicker metals may require more powerful lasers, while thinner metals might be easier to handle and engrave.

6. Cost and Budget: Balance quality with cost. While it might be tempting to go for cheaper options, investing in higher-quality metals can result in better engraving results and longer-lasting products.

7. Lead Times and Availability: Check the lead times and availability of the metal. Ensure the supplier can meet your deadlines and has sufficient stock to avoid project delays.

8. Sample Testing: Request samples for testing before placing a bulk order. This allows you to assess the engravability and finish quality firsthand.

9. Environmental Considerations: Be mindful of the environmental impact. Opt for suppliers who follow sustainable practices and provide metals with minimal environmental footprint.

10. Technical Support: Choose suppliers who offer good technical support and customer service. They can provide valuable assistance in troubleshooting and optimizing your engraving process.

By considering these factors, you can make informed decisions and ensure successful procurement of laser engravable metals.

FAQs on Sourcing and Manufacturing from laser engravable metal in China

FAQs on Sourcing and Manufacturing Laser Engravable Metal from China

1. Why source laser engravable metal from China?

China is a global leader in metal manufacturing due to its advanced technology, large production capacity, and cost-effective labor. This combination ensures high-quality products at competitive prices.

2. What types of laser engravable metals are available?

Common types include stainless steel, aluminum, brass, and coated metals. These materials are widely used for nameplates, plaques, and customized products.

3. How do I find reliable manufacturers?

Utilize platforms like Alibaba, Made-in-China, and Global Sources. Verify manufacturers through reviews, certifications, and conducting factory audits if possible.

4. What are the typical minimum order quantities (MOQs)?

MOQs vary by manufacturer but typically range from 100 to 1,000 units. Negotiations can sometimes reduce these requirements, especially for long-term contracts.

5. How long does production take?

Standard lead times range from 2 to 8 weeks, depending on order size and complexity. Custom designs may extend this timeline.

6. What are the payment terms?

Common terms include a 30% deposit upfront and the balance paid before shipment. Letters of credit and escrow services are also options for secure transactions.

7. How do I ensure product quality?

Request samples before full production, use third-party inspection services, and specify quality standards in the contract. Regular communication with the manufacturer is crucial.

8. Are there import duties and taxes?

Yes, duties and taxes depend on your country’s regulations. Consult with a customs broker to understand applicable fees.

9. What about shipping and logistics?

Manufacturers usually offer FOB (Free on Board) terms. You’ll need to arrange shipping from the port to your destination, using either sea or air freight depending on urgency and cost considerations.

10. How can I handle language barriers?

Most manufacturers have English-speaking representatives. Use clear, concise communication and consider employing a local agent if necessary.

By addressing these FAQs, you can effectively navigate the process of sourcing and manufacturing laser engravable metal from China.