Technology and Applications of laser engrave metal

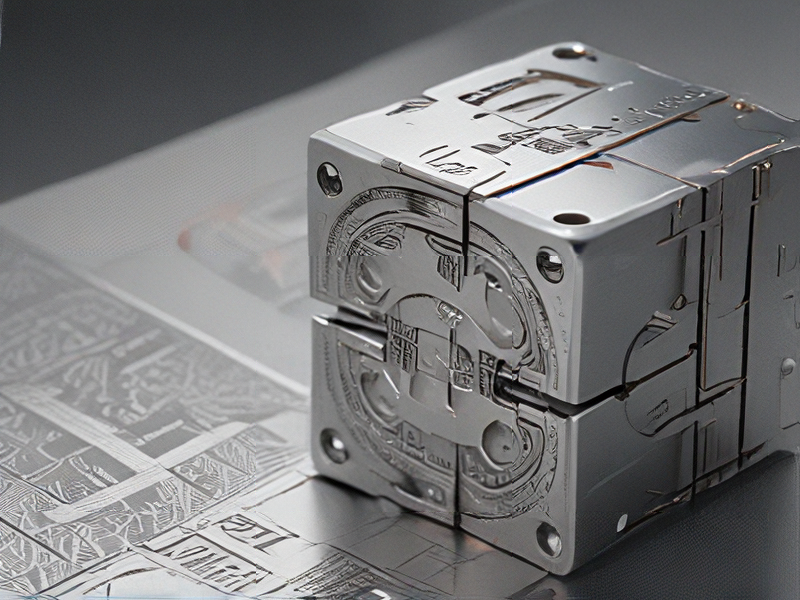

Laser engraving on metal involves using a high-powered laser beam to precisely remove or alter the surface of metal materials. This technique offers remarkable control and detail, enabling a wide range of applications.

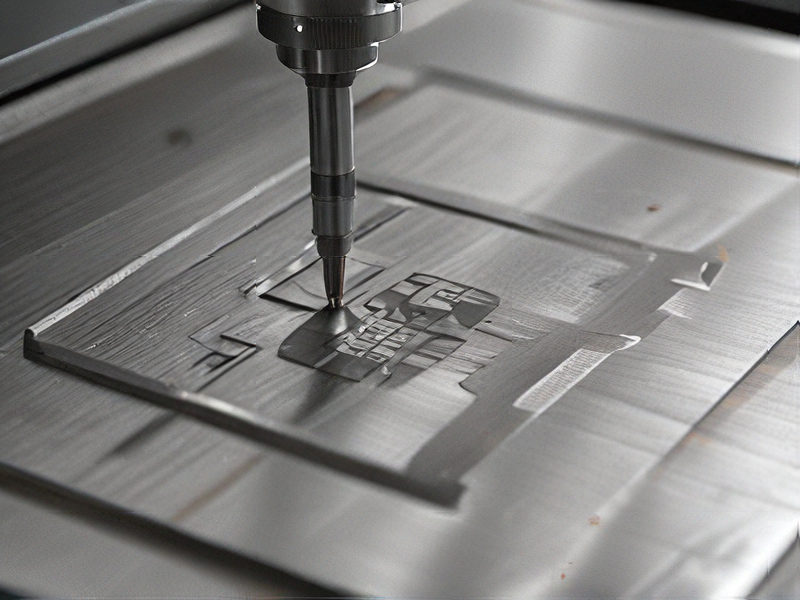

How it Works:

A focused laser beam is directed onto the metal surface. Depending on the material and application, the laser either vaporizes or melts away material, creating the desired engraving pattern.

Applications:

* Customization: Personalizing items like jewelry, trophies, and plaques with names, logos, or designs.

* Industrial Marking: Indelible marking of parts, components, and tools for identification and traceability.

* Electronic Components: Engraving circuit boards, stencils, and other components with precise markings.

* Decorative Arts: Creating intricate designs and patterns on metal surfaces for artistic and decorative purposes.

* Architectural Elements: Engraving architectural details, signage, and monuments with lasting impressions.

Advantages:

* High Precision: Laser engraving produces incredibly fine and intricate details.

* Durability: Engravings are permanent and resistant to fading, scratching, or corrosion.

* Versatility: Suitable for various metal types, including stainless steel, aluminum, brass, and copper.

* Speed and Efficiency: Laser engraving processes are generally fast and efficient, especially for high-volume production.

Quality Testing Methods for laser engrave metal and how to control quality

Quality testing for laser-engraved metal involves several methods to ensure precision, durability, and consistency. Here are the primary methods and quality control measures:

Quality Testing Methods:

1. Visual Inspection:

– Purpose: To detect visible defects like misalignment, uneven engraving, or surface irregularities.

– Tools: Magnifying glasses or microscopes for detailed inspection.

2. Dimensional Measurement:

– Purpose: To ensure the engraving matches the specified dimensions.

– Tools: Calipers, micrometers, and coordinate measuring machines (CMM).

3. Surface Roughness Testing:

– Purpose: To measure the smoothness of the engraved surface.

– Tools: Surface profilometers.

4. Material Integrity Testing:

– Purpose: To ensure the metal’s structural integrity is not compromised.

– Methods: Non-destructive testing (NDT) techniques like ultrasonic testing, X-ray, or dye penetrant inspection.

5. Durability and Wear Testing:

– Purpose: To test the engraving’s resistance to wear and environmental conditions.

– Methods: Abrasion tests, corrosion resistance tests, and thermal cycling.

Quality Control Measures:

1. Standard Operating Procedures (SOPs):

– Develop and adhere to detailed SOPs for the laser engraving process to ensure consistency.

2. Calibration and Maintenance:

– Regularly calibrate laser equipment and perform maintenance to ensure optimal performance and accuracy.

3. Training:

– Ensure operators are well-trained in both machine operation and quality inspection techniques.

4. Sample Testing:

– Regularly test samples from production batches to identify and rectify issues promptly.

5. Data Analysis:

– Collect and analyze data from quality tests to identify trends and areas for improvement.

6. Feedback Loop:

– Implement a feedback system for continuous improvement based on quality testing outcomes and customer feedback.

By combining these testing methods and control measures, manufacturers can ensure high-quality laser engraving on metal surfaces, meeting both aesthetic and functional requirements.

Tips for Procurement and Considerations when Purchasing from laser engrave metal

When procuring laser engravers for metal, consider the following tips and factors:

1. Material Compatibility: Ensure the engraver is suitable for the specific metals you plan to work with, such as stainless steel, aluminum, or brass.

2. Power and Speed: Look for an engraver with adequate power (measured in watts) for your needs. Higher power allows for faster engraving and deeper cuts but can be more expensive.

3. Precision and Resolution: Check the precision (measured in microns) and resolution (measured in DPI). Higher precision and resolution are essential for detailed and fine engravings.

4. Software Compatibility: Ensure the engraver comes with compatible software that supports your design formats. User-friendly software can enhance productivity.

5. Cooling System: A robust cooling system prevents overheating and extends the machine’s lifespan. Check if the engraver has air or water cooling systems in place.

6. Safety Features: Look for features such as automatic shutoff, enclosed work area, and laser shields to ensure operator safety.

7. Maintenance and Support: Consider the availability of spare parts, ease of maintenance, and the manufacturer’s customer support. Reliable technical support can reduce downtime.

8. Cost and Warranty: Compare prices while considering the warranty and after-sales service. A slightly higher upfront cost can be worthwhile for a machine with a longer warranty and better support.

9. Reviews and References: Research customer reviews and ask for references from the supplier. Real-world performance and reliability feedback can guide your decision.

10. Training and Setup: Some suppliers offer training and setup assistance. Proper training can maximize the efficiency and safety of your operations.

By considering these factors, you can make an informed decision that balances cost, performance, and reliability for your laser engraving needs.

FAQs on Sourcing and Manufacturing from laser engrave metal in China

FAQs on Sourcing and Manufacturing Laser Engraved Metal in China

1. Why source laser engraved metal from China?

China offers competitive pricing, advanced technology, and a vast network of suppliers skilled in laser engraving. The country’s established manufacturing infrastructure ensures high-quality products with fast turnaround times.

2. How do I find a reliable supplier?

Use platforms like Alibaba, Global Sources, and Made-in-China. Look for suppliers with positive reviews, verified credentials, and a robust history of exporting. Conduct video calls to verify their facilities and capabilities.

3. What types of metals can be laser engraved?

Common metals include stainless steel, aluminum, brass, and titanium. Each metal may require specific laser settings, so ensure your supplier has experience with your chosen material.

4. What is the typical lead time?

Lead times vary based on order size and complexity. Generally, it ranges from 2 to 6 weeks. Confirm timelines with your supplier, and consider potential delays due to holidays or supply chain disruptions.

5. How can I ensure quality control?

Request samples before full production. Implement quality control measures such as third-party inspections and detailed agreements specifying standards and tolerances.

6. What are the shipping options?

Shipping methods include air freight, sea freight, and express courier services. Sea freight is cost-effective for large orders, while air freight and express services are faster but more expensive.

7. Are there any import regulations to consider?

Yes, understand the import duties, taxes, and customs regulations of your country. Work with a freight forwarder or customs broker to navigate these requirements.

8. What should be included in a contract with the supplier?

Clearly outline product specifications, payment terms, lead times, quality standards, and penalties for non-compliance. Ensure the contract is legally binding and consider involving a legal professional.

By following these guidelines, you can effectively source and manufacture high-quality laser engraved metal products from China.