Technology and Applications of laser engraved metal

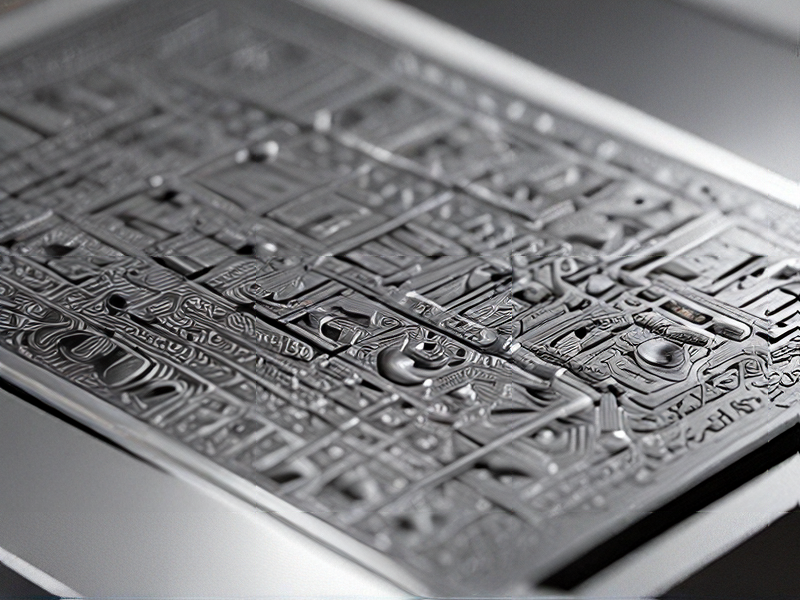

Laser engraving on metal is a precise and versatile technology that uses focused laser beams to mark, etch, or engrave surfaces. The technology relies on high-energy light to remove material or alter the surface properties of the metal, creating permanent markings that are highly resistant to wear and environmental factors.

Technology

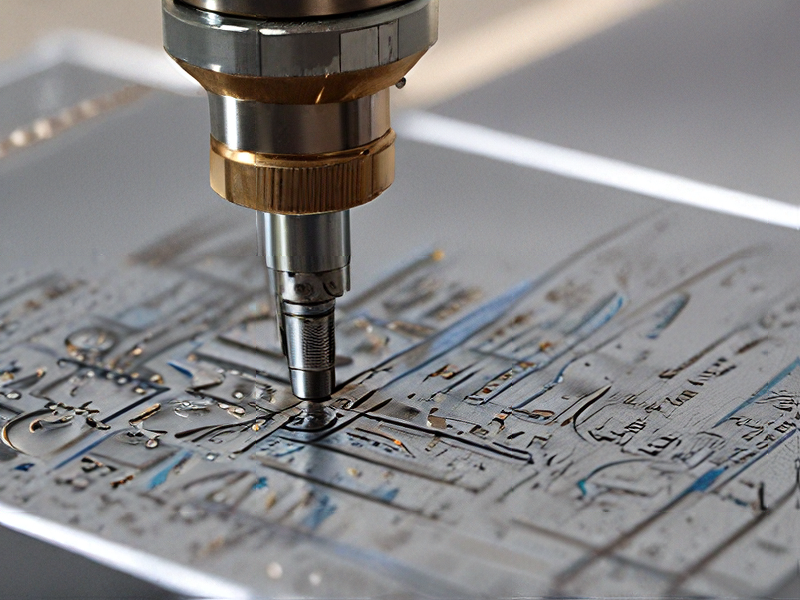

1. Laser Types: Common lasers used include fiber lasers, CO2 lasers, and diode lasers. Fiber lasers are particularly popular for metal engraving due to their efficiency, high power, and precision.

2. Process: The laser beam is directed at the metal surface, where it heats and vaporizes material or causes oxidation. The process can be finely controlled to produce detailed designs and patterns.

3. Control Systems: Computer Numerical Control (CNC) systems and specialized software enable precise control of the laser, allowing for intricate and consistent designs.

Applications

1. Industrial Marking: Used for marking parts with serial numbers, barcodes, logos, and other identifying information. This is essential for traceability, quality control, and inventory management.

2. Jewelry and Personalization: Enables detailed and artistic engraving on rings, watches, and other jewelry items, allowing for personalization and customization.

3. Medical Devices: Engraving on surgical instruments and medical implants ensures sterility and identification, complying with regulatory standards.

4. Automotive Industry: Used for marking parts and components, enhancing traceability, and ensuring authenticity.

5. Aerospace: Engraving on critical components helps in maintenance tracking and part identification, which is crucial for safety and compliance.

6. Electronics: Marking of circuit boards and electronic components for identification and assembly processes.

Laser engraving on metal is favored for its speed, accuracy, and permanence. It supports a wide range of industries by providing reliable and precise marking solutions, enhancing both functional and aesthetic aspects of metal products.

Quality Testing Methods for laser engraved metal and how to control quality

Quality testing methods for laser engraved metal focus on factors like accuracy, depth, surface finish, and marking permanence.

Accuracy:

* Visual inspection: Compare the engraved design to the original template for positional and dimensional accuracy.

* Micrometry: Use a microscope with a measuring scale to assess the precision of lines and details.

Depth:

* Depth gauge: Measure the engraved depth using a calibrated gauge to ensure consistency.

Surface Finish:

* Surface profilometry: Analyze the surface topography using a profilometer to evaluate roughness and imperfections.

* Visual inspection: Check for burrs, heat-affected zones, or discoloration that might affect the finish.

Permanence:

* Adhesion testing: Evaluate the adhesion of the engraved mark by applying stress or abrasion.

* Corrosion resistance testing: Subject the engraved metal to environmental conditions to assess its durability.

Quality Control:

* Operator training: Ensure operators are skilled in using the laser engraving system and following established procedures.

* Machine calibration: Regularly calibrate the laser engraver to maintain precise settings.

* Material testing: Test different metal types to determine optimal laser parameters for each material.

* In-process monitoring: Continuously monitor the engraving process through visual inspection and depth measurements.

* Statistical process control: Use statistical techniques to track and control quality variations.

Tips for Procurement and Considerations when Purchasing from laser engraved metal

When procuring laser-engraved metal products, consider the following tips and considerations:

Tips:

1. Research Suppliers: Identify reputable suppliers with positive reviews and a proven track record in laser engraving. Request samples to assess quality.

2. Material Quality: Ensure the metal used is high-quality and suitable for laser engraving. Common metals include stainless steel, aluminum, and brass.

3. Customization Options: Verify the range of customization options available, such as text, logos, and intricate designs. Discuss design feasibility with the supplier.

4. Precision and Detail: Evaluate the precision and detail of the engraving. High-resolution laser engravers can produce finer details and cleaner lines.

5. Durability: Confirm the durability of the engraving. Quality engravings should be resistant to wear and fading.

6. Technology and Equipment: Inquire about the technology and equipment used. Advanced laser engraving machines yield better results.

7. Volume and Lead Time: Discuss order volume and lead times. Ensure the supplier can meet your quantity requirements within your desired timeframe.

8. Cost: Obtain detailed quotes, including any setup fees or additional charges. Compare costs across suppliers to ensure competitive pricing.

9. Customer Support: Ensure the supplier provides excellent customer support and can assist with any issues or custom requests.

Considerations:

1. Purpose and Use: Define the purpose and intended use of the engraved metal items. This impacts the choice of metal and design intricacy.

2. Environmental Factors: Consider the environmental conditions the metal will be exposed to, such as moisture, temperature, and UV exposure, which may affect the longevity of the engraving.

3. Compliance and Standards: Ensure the products comply with relevant industry standards and regulations, especially for safety-critical applications.

4. Maintenance: Consider the ease of maintenance and cleaning of the engraved metal. Some metals require special care to preserve the engraving.

5. Aesthetics and Branding: Align the engraving style with your brand’s aesthetics. The visual appeal of the engraving can significantly impact brand perception.

By keeping these tips and considerations in mind, you can ensure a successful procurement process and achieve high-quality, durable laser-engraved metal products.

FAQs on Sourcing and Manufacturing from laser engraved metal in China

FAQs on Sourcing and Manufacturing Laser Engraved Metal in China

#### 1. Why source laser engraved metal from China?

China offers competitive pricing, advanced technology, and skilled labor. The combination of these factors results in high-quality products at lower costs compared to other regions.

#### 2. How do I find reliable manufacturers?

Use online platforms like Alibaba, Made-in-China, and Global Sources. Additionally, attending trade shows and seeking recommendations can help identify reputable manufacturers.

#### 3. What should I consider when choosing a manufacturer?

Evaluate the manufacturer’s experience, technology, production capacity, quality control processes, and certifications. Request samples and review past customer feedback.

#### 4. How can I ensure the quality of the products?

Request detailed product specifications and samples. Implement quality control measures such as third-party inspections and factory audits. Maintain clear communication with the manufacturer throughout the process.

#### 5. What are the common materials used for laser engraving?

Common materials include stainless steel, aluminum, brass, and titanium. Each material has its unique properties and suitability for different applications.

#### 6. What is the typical lead time for production?

Lead times can vary based on order size and complexity, but typically range from 2 to 6 weeks. It’s essential to discuss timelines with the manufacturer upfront.

#### 7. How can I protect my intellectual property?

Use non-disclosure agreements (NDAs) and register your designs and trademarks in China. Work with manufacturers who have a reputation for respecting IP rights.

#### 8. What are the payment terms?

Common payment terms include a 30% deposit before production and the remaining 70% upon completion. Payments are usually made via bank transfer, but other methods like PayPal or escrow services can also be used.

#### 9. What are the shipping options and costs?

Shipping options include air freight, sea freight, and express courier services. Costs depend on the shipment size, weight, and urgency. Discuss logistics and costs with your manufacturer and freight forwarder.

#### 10. Are there any import regulations I should be aware of?

Yes, understand the import duties, taxes, and compliance standards of your country. Work with customs brokers to ensure smooth import processes.

This concise guide provides essential insights into sourcing and manufacturing laser engraved metal products from China, ensuring informed decision-making and successful partnerships.