Technology and Applications of laser engraver on metal

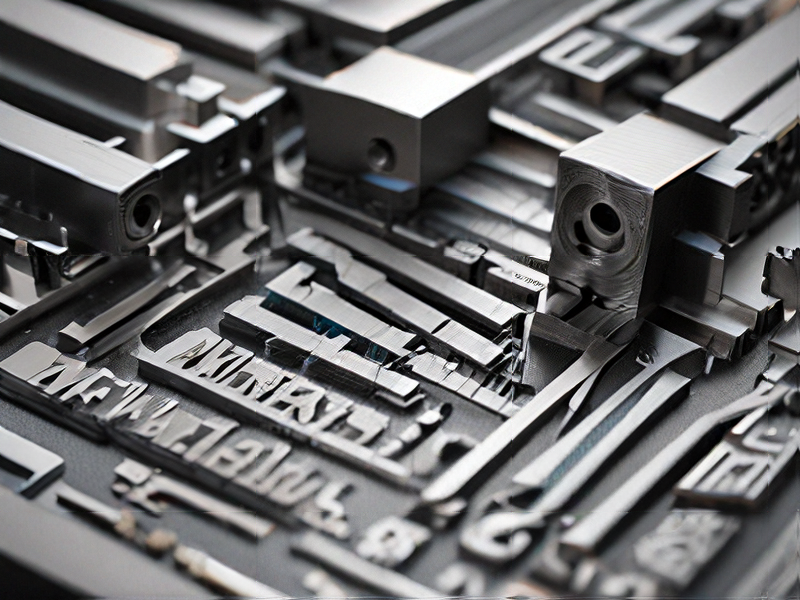

Laser engravers on metal utilize concentrated laser beams to precisely etch, mark, or cut designs into metal surfaces. This technology, known for its accuracy and speed, leverages high-intensity lasers such as fiber lasers, CO2 lasers, and diode lasers, each suited for different types of metals and applications.

Technology:

1. Fiber Lasers: Commonly used for metal engraving due to their high power and efficiency. They produce a small focal diameter, making them ideal for detailed engravings on metals like stainless steel, aluminum, and titanium.

2. CO2 Lasers: Although more commonly used for non-metal materials, they can also engrave metals when paired with a metal marking solution.

3. Diode Lasers: These are less powerful compared to fiber and CO2 lasers and are used for engraving softer metals.

Applications:

1. Industrial Manufacturing: Laser engravers mark parts and tools with serial numbers, barcodes, and logos for traceability and branding. This ensures durability and legibility even in harsh conditions.

2. Jewelry: Precision engraving allows for detailed designs, personalization, and intricate patterns on metals like gold, silver, and platinum.

3. Automotive: Components and parts are engraved for identification and traceability, enhancing safety and quality control.

4. Electronics: Circuit boards and components are marked with identification codes, ensuring proper assembly and maintenance.

5. Art and Customization: Artists and hobbyists use laser engravers to create detailed artwork, customized gifts, and decorative items.

Advantages:

– Precision: Laser engravers offer high accuracy, enabling detailed and complex designs.

– Speed: Rapid processing speeds increase productivity.

– Non-contact Process: Reduces wear and tear on tools, as there is no physical contact with the metal.

– Versatility: Capable of engraving various metals and adaptable for different applications.

Laser engravers have revolutionized metalworking by providing a versatile, efficient, and precise method for engraving and marking, catering to a wide range of industrial and artistic needs.

Quality Testing Methods for laser engraver on metal and how to control quality

To ensure high-quality results when using a laser engraver on metal, several testing methods and quality control measures can be employed:

Quality Testing Methods:

1. Visual Inspection:

– Purpose: Detect visible defects such as burns, inconsistencies, and incomplete engravings.

– Method: Use magnifying tools or microscopes to closely inspect the engraving.

2. Dimensional Accuracy:

– Purpose: Ensure engravings are within specified tolerances.

– Method: Use calipers and micrometers to measure the engraved areas.

3. Surface Roughness Measurement:

– Purpose: Assess the texture and smoothness of the engraved surface.

– Method: Employ a profilometer to measure the surface roughness.

4. Adhesion Testing:

– Purpose: Test the durability of the engraving on the metal surface.

– Method: Apply adhesive tape to the engraved area and remove it to see if any engraving material lifts off.

5. Microscopy:

– Purpose: Examine the microstructure of the engraved area for defects.

– Method: Use optical or electron microscopy.

6. Wear and Corrosion Testing:

– Purpose: Evaluate the longevity and resistance of the engraving.

– Method: Simulate environmental conditions such as exposure to moisture, chemicals, and abrasion.

Quality Control Measures:

1. Calibration and Maintenance:

– Regularly calibrate the laser engraver and perform maintenance to ensure consistent performance.

2. Material Consistency:

– Use metal materials with uniform properties to avoid variations in engraving quality.

3. Parameter Optimization:

– Adjust laser parameters such as power, speed, and focus based on material type and desired engraving depth.

4. Software and Design Files:

– Ensure that design files are correctly prepared and compatible with the laser engraver to prevent errors.

5. Operator Training:

– Train operators thoroughly on the equipment and processes to minimize human error.

6. Environmental Control:

– Maintain a stable environment (temperature, humidity) to prevent external factors from affecting engraving quality.

Implementing these methods and controls will help maintain high standards in laser engraving on metal, ensuring durability, accuracy, and visual appeal.

Tips for Procurement and Considerations when Purchasing from laser engraver on metal

When procuring a laser engraver for metal, consider the following tips and factors to ensure a successful purchase:

1. Type of Laser: Decide between fiber lasers, which are excellent for metal engraving due to their precision and efficiency, and CO2 lasers, which are typically less effective on metals but might be suitable for specific needs.

2. Power and Speed: Higher power lasers (20W to 50W) are better for engraving metals, providing deeper and faster engraving capabilities. Evaluate the trade-off between speed and precision based on your requirements.

3. Materials Compatibility: Ensure the engraver can handle the specific types of metals you plan to work with, such as stainless steel, aluminum, or titanium.

4. Software Compatibility: Check that the laser engraver comes with or is compatible with intuitive software that supports various design formats and provides control over engraving parameters.

5. Cooling System: Look for models with efficient cooling systems to prevent overheating during prolonged use, which can enhance the machine’s lifespan and performance.

6. Safety Features: Prioritize engravers with robust safety features, including proper ventilation, protective casings, and emergency shutoff mechanisms to protect users from laser exposure and fumes.

7. Size and Workspace: Consider the machine’s footprint and ensure it fits within your workspace while providing adequate engraving area for your projects.

8. Budget and Cost of Ownership: Besides the initial cost, factor in the maintenance, spare parts, and potential upgrades. Investing in a reliable machine may have higher upfront costs but lower long-term expenses.

9. Training and Support: Opt for suppliers that offer comprehensive training, customer support, and readily available technical assistance to minimize downtime and learning curves.

10. Reputation and Reviews: Research manufacturers and models through reviews and ratings to gauge the reliability and performance of the laser engraver.

By focusing on these aspects, you can make a well-informed decision, ensuring the chosen laser engraver meets your metal engraving needs efficiently and safely.

FAQs on Sourcing and Manufacturing from laser engraver on metal in China

FAQs on Sourcing and Manufacturing Laser Engravers on Metal in China

1. Why source laser engravers from China?

China is a leading global manufacturer of laser engravers, offering competitive prices, advanced technology, and a wide variety of products. The large manufacturing base ensures high availability and faster production times.

2. How to find reliable manufacturers?

Use platforms like Alibaba, Global Sources, and Made-in-China. Look for manufacturers with high ratings, positive reviews, and verified supplier status. Visiting trade shows such as the Canton Fair can also be beneficial.

3. What are the key considerations when selecting a manufacturer?

– Quality: Ensure the manufacturer meets international quality standards (ISO, CE, FDA).

– Experience: Prefer manufacturers with a long history in the industry.

– Customization: Check if they offer customization to meet specific needs.

– Support: Assess their customer service and after-sales support.

4. How to verify the quality of the products?

Request samples before placing a bulk order. Consider hiring a third-party inspection service to audit the factory and inspect products.

5. What are the typical lead times?

Lead times can vary based on order size and customization. Typically, it ranges from 30 to 60 days.

6. What are the payment terms?

Common payment terms include a 30% deposit upfront and the remaining 70% before shipment. Payment methods often include T/T (bank transfer), L/C (Letter of Credit), and sometimes PayPal for smaller transactions.

7. How to handle shipping and logistics?

Manufacturers usually assist with logistics. Shipping can be arranged via sea or air, depending on urgency and cost considerations. Ensure you understand Incoterms (FOB, CIF) to clarify responsibilities.

8. Are there any import regulations to consider?

Check your country’s import regulations for laser engravers. Ensure compliance with safety standards and certifications required for entry.

9. How to manage risks associated with international sourcing?

Use contracts that outline product specifications, delivery schedules, and penalties for non-compliance. Regular communication and relationship building with the supplier can also mitigate risks.

10. What about warranty and after-sales service?

Clarify warranty terms and the process for addressing defects or malfunctions. A reliable manufacturer should offer comprehensive after-sales support.

By following these guidelines, you can effectively source high-quality laser engravers from China while minimizing risks and ensuring a smooth procurement process.