Technology and Applications of laser engravers for metal

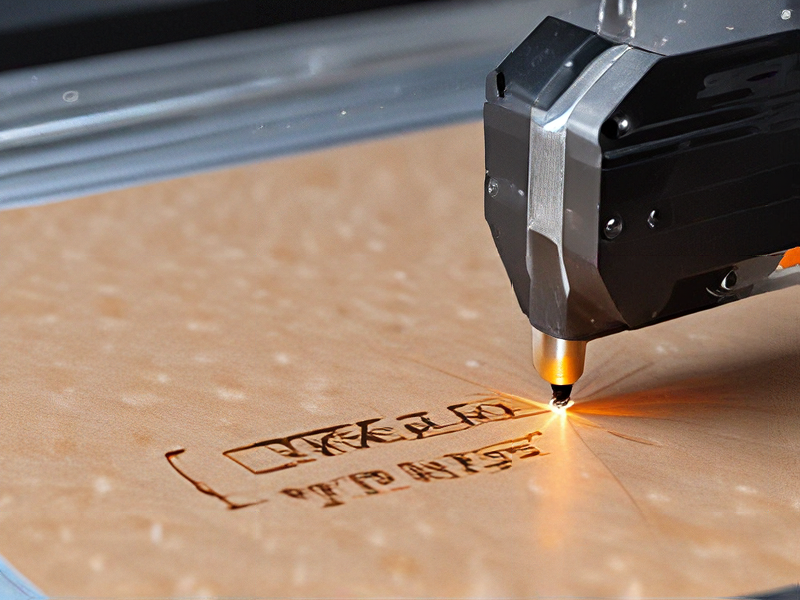

Laser engravers for metal utilize highly focused beams of light to engrave, etch, or mark various metals with precision and efficiency. This technology leverages different types of lasers, such as fiber lasers, CO2 lasers, and Nd:YAG lasers, each suitable for specific applications. Fiber lasers are particularly favored for metal engraving due to their high power, fine beam quality, and long operational life.

The process works by directing the laser beam onto the metal surface, where the intense heat either removes a layer of material or causes a color change through oxidation or annealing. This allows for creating detailed designs, serial numbers, barcodes, logos, and even intricate artwork.

Applications

1. Industrial Manufacturing: Laser engravers are widely used in industries for marking parts and components with serial numbers, batch numbers, and barcodes for traceability and quality control. This is crucial in sectors like aerospace, automotive, and electronics.

2. Jewelry and Personalization: High-precision laser engravers are ideal for customizing jewelry and other personal items. They can engrave detailed designs, names, and dates on metals like gold, silver, and stainless steel without damaging the material.

3. Medical Devices: The medical industry utilizes laser engraving to mark surgical instruments and medical devices. The marks are durable, non-corrosive, and comply with regulatory requirements for traceability.

4. Tool and Die Making: Laser engravers are used to create detailed engravings on tools and dies, which are essential for producing consistent and high-quality parts in manufacturing processes.

5. Signage and Art: Laser engraving is also popular in creating metal signage, plaques, and artworks, offering a high degree of customization and durability.

The advantages of using laser engravers for metal include high precision, speed, non-contact processing, and the ability to create complex and permanent markings. This technology continues to evolve, offering enhanced capabilities and applications across various industries.

Quality Testing Methods for laser engravers for metal and how to control quality

Quality testing methods for laser engravers for metal ensure precision, consistency, and durability. Here are key methods and quality control strategies:

Quality Testing Methods:

1. Dimensional Accuracy Testing:

– Laser Micrometry: Measures engraving depth and width to ensure they meet specifications.

– Coordinate Measuring Machine (CMM): Verifies the dimensions of engraved patterns against design blueprints.

2. Surface Roughness Testing:

– Profilometers: Measure the roughness of the engraved surfaces, ensuring smooth finishes where required.

3. Engraving Depth Measurement:

– Optical Microscopy: Examines cross-sections of engraved areas to assess depth and consistency.

– 3D Laser Scanning: Provides a detailed topographical map of the engraving.

4. Material Integrity Testing:

– Hardness Testing: Checks for changes in material hardness due to the engraving process.

– Microstructural Analysis: Ensures no undesirable changes in the material structure.

5. Durability and Adhesion Tests:

– Scratch Testing: Determines the adhesion strength of the engraving.

– Wear Testing: Evaluates the durability of the engraving under simulated usage conditions.

Quality Control Strategies:

1. Standard Operating Procedures (SOPs):

– Implement and strictly follow SOPs for the engraving process, ensuring consistency.

2. Regular Calibration:

– Periodically calibrate laser engravers and measurement instruments to maintain accuracy.

3. In-process Monitoring:

– Use real-time monitoring systems to detect deviations during the engraving process.

4. Statistical Process Control (SPC):

– Apply SPC techniques to track process performance and detect variations early.

5. Sample Testing:

– Perform regular testing on sample pieces to validate process consistency and quality.

6. Employee Training:

– Train operators and technicians on best practices and quality standards to maintain high-quality output.

By implementing these testing methods and quality control strategies, manufacturers can ensure high-quality laser engraving on metal surfaces.

Tips for Procurement and Considerations when Purchasing from laser engravers for metal

Tips for Procuring Laser Engravers for Metal

1. Define Your Needs:

– Material Types: Ensure the engraver is compatible with the metals you will be working with, such as stainless steel, aluminum, brass, or titanium.

– Engraving Depth and Detail: Specify the level of detail and depth required for your projects. High precision might need more advanced laser systems.

2. Evaluate Technology Types:

– Fiber Lasers: Ideal for metal engraving due to their high efficiency and precision.

– CO2 Lasers: Generally not suitable for metals unless coated or treated.

3. Power and Speed:

– Higher power lasers (e.g., 20W-100W) allow for deeper engravings and faster processing times.

– Match the laser power to your production needs to avoid unnecessary costs.

4. Software Compatibility:

– Ensure the engraver comes with or supports software that can handle the design files you use (e.g., DXF, SVG).

5. Budget Considerations:

– Balance between upfront cost and long-term benefits. Higher-end machines may offer better durability and efficiency, potentially lowering long-term costs.

– Consider maintenance costs, including spare parts and servicing.

6. Vendor Reliability:

– Research vendors thoroughly. Check reviews, request references, and verify the quality of customer support.

– Prefer vendors who offer training, installation, and after-sales support.

7. Warranty and Service Contracts:

– Look for comprehensive warranties that cover parts and labor.

– Service contracts can provide peace of mind and ensure minimal downtime.

8. Safety Features:

– Ensure the machine has adequate safety features, including proper shielding, emergency shutoff buttons, and ventilation systems for fumes.

9. Sample Testing:

– Request samples or a demonstration to see the laser engraver in action. This can help verify the machine’s capability to meet your specific requirements.

10. Future Scalability:

– Consider future needs and whether the machine can scale with your business. This includes the potential for software upgrades and additional features.

By considering these factors, you can make a more informed decision when purchasing a laser engraver for metal, ensuring it meets both your current and future needs.

FAQs on Sourcing and Manufacturing from laser engravers for metal in China

FAQs on Sourcing and Manufacturing Laser Engravers for Metal in China

1. Why source laser engravers from China?

China is a leading manufacturer of laser engravers, offering a wide range of models at competitive prices. The country has advanced manufacturing capabilities, high production capacity, and a robust supply chain network.

2. How do I identify reliable suppliers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Check supplier reviews, certifications, and verify their production capabilities. Visiting factories or hiring third-party inspection services can also ensure reliability.

3. What certifications should I look for?

Look for CE, FDA, and ISO certifications to ensure the products meet international standards for quality and safety.

4. How can I ensure the quality of the engravers?

Request product samples, and conduct pre-shipment inspections. Utilizing third-party quality control services can also help verify the quality of the products before they are shipped.

5. What are the common payment terms?

Common payment terms include a 30% deposit before production and 70% balance before shipment. Letter of Credit (LC) is also an option for larger orders.

6. What is the typical lead time for manufacturing?

Lead times can vary but typically range from 20 to 45 days depending on the order size and customization requirements.

7. How do I handle shipping and logistics?

Suppliers often handle logistics but you can also hire a freight forwarder. Ensure your shipping terms (like FOB, CIF) are clearly defined. Factor in customs clearance time and costs in your destination country.

8. Are there risks involved?

Risks include quality issues, delays, and potential intellectual property concerns. Mitigate these by doing thorough due diligence, using contracts, and maintaining clear communication with suppliers.

9. What after-sales support can I expect?

Check if the supplier offers warranty, technical support, and availability of spare parts. Reliable suppliers typically provide at least a one-year warranty and responsive customer service.

10. How can I protect my intellectual property?

Use non-disclosure agreements (NDAs) and work with suppliers who respect IP laws. Register your patents and trademarks in China to strengthen your IP protection.

By following these guidelines, you can effectively source and manufacture high-quality laser engravers for metal from China.