Technology and Applications of laser engraving machine for metal

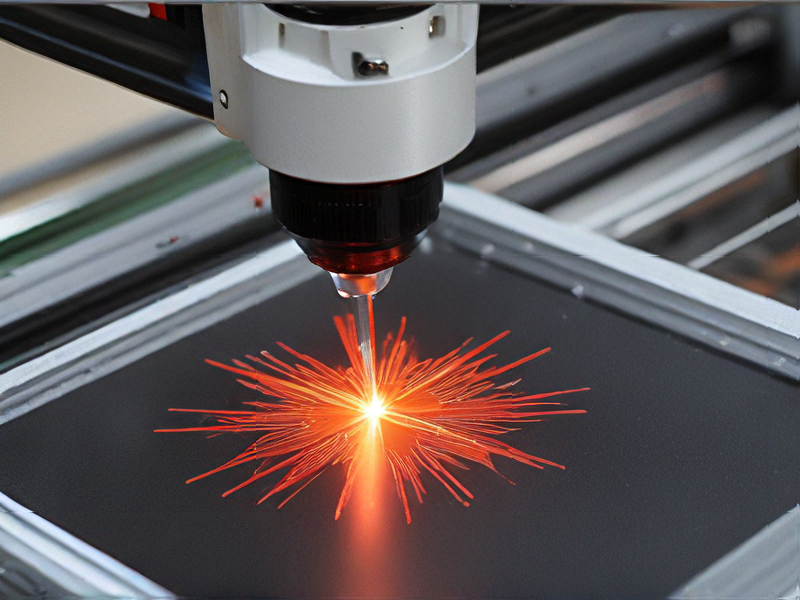

Technology and Applications of Laser Engraving Machines for Metal

Technology:

Laser engraving machines for metal utilize concentrated laser beams to etch designs, text, or patterns onto metal surfaces. The technology primarily involves two types: Fiber lasers and CO2 lasers. Fiber lasers are more commonly used for metal engraving due to their higher precision and efficiency. They operate by generating a high-intensity light beam, which is directed through optical fibers and focused onto the metal surface. This focused energy causes localized heating, melting, or vaporization of the metal, creating precise and permanent marks.

Applications:

1. Industrial Manufacturing:

– Part Identification: Engraving serial numbers, barcodes, and QR codes for tracking and inventory management.

– Tool Marking: Customizing tools with logos, part numbers, and calibration details to ensure easy identification and compliance with regulations.

2. Jewelry and Personalization:

– Custom Jewelry: Engraving intricate designs, names, or dates on rings, bracelets, and other jewelry items to create personalized gifts.

– Luxury Goods: Adding fine details to high-end watches, pens, and other luxury items to enhance their aesthetic value and uniqueness.

3. Automotive and Aerospace:

– Component Marking: Ensuring traceability of parts with permanent engravings that withstand harsh environmental conditions.

– Decorative Elements: Enhancing the aesthetic appeal of vehicle interiors and exteriors with custom engravings.

4. Medical Devices:

– Equipment Identification: Marking surgical instruments and medical devices with identification codes to meet stringent regulatory requirements.

– Customization: Personalizing medical tools for specific procedures or practitioners.

5. Electronics:

– Circuit Boards: Marking PCBs with component identifiers and traceability codes.

– Device Branding: Engraving logos and product information on electronic devices and housings.

In summary, laser engraving machines for metal are crucial in various industries due to their precision, durability, and versatility, enhancing both functional and aesthetic aspects of metal products.

Quality Testing Methods for laser engraving machine for metal and how to control quality

Quality testing methods for laser engraving machines for metal typically involve several key procedures to ensure high standards:

1. Visual Inspection: This involves examining engraved samples for clarity, depth, and consistency of markings. Operators visually assess if the engraving meets design specifications.

2. Dimensional Accuracy: Using precision measuring tools, operators verify that engraved dimensions match the intended specifications, ensuring parts fit and function correctly.

3. Surface Roughness Measurement: Instruments like profilometers assess the smoothness of the engraved surface, crucial for applications requiring a specific finish or texture.

4. Durability Testing: Samples undergo simulated real-world conditions (like exposure to heat, chemicals, or abrasion) to gauge the durability of the engraving.

5. Material Composition Analysis: Techniques such as X-ray fluorescence (XRF) analyze metal composition post-engraving, ensuring no unintended alterations affecting material integrity.

To control quality effectively:

– Establish Clear Specifications: Define engraving parameters (depth, width, resolution) and quality criteria upfront.

– Regular Calibration: Ensure laser settings and machine alignment are regularly calibrated to maintain consistent quality.

– Operator Training: Train operators on testing methods and quality standards to perform accurate inspections.

– Document and Analyze Results: Maintain records of inspection results to identify trends, troubleshoot issues, and continuously improve processes.

– Feedback Loop: Implement a feedback loop where findings from quality testing inform adjustments to engraving settings or procedures.

By integrating these methods and controls, manufacturers can maintain high-quality standards in laser engraving for metal components, meeting customer expectations and regulatory requirements effectively.

Tips for Procurement and Considerations when Purchasing from laser engraving machine for metal

When purchasing a laser engraving machine for metal, consider the following tips and factors to ensure you make an informed decision:

1. Laser Type and Power: Choose between CO2 and fiber lasers based on your material needs. Fiber lasers are better for metals due to their higher absorption rates.

2. Engraving Area and Size: Determine the maximum size of materials you plan to engrave. Ensure the machine’s bed size accommodates your typical workpieces.

3. Power and Speed: Higher wattage lasers provide faster engraving speeds and can handle thicker materials. Balance your requirements with machine capabilities.

4. Software and Compatibility: Check if the machine supports common design file formats (like .ai, .dxf) and integrates with your current design software for seamless workflow.

5. Ease of Use: User-friendly interfaces and intuitive controls reduce learning curves and operational errors, enhancing productivity.

6. Maintenance and Support: Consider the availability of technical support, spare parts, and maintenance requirements. Reliable support ensures minimal downtime.

7. Safety Features: Laser machines pose safety risks. Ensure the machine has adequate safety features like enclosures, emergency stop buttons, and interlocks.

8. Budget and ROI: Evaluate upfront costs, ongoing operational expenses (like electricity and maintenance), and potential return on investment from increased capabilities or productivity.

9. Reviews and Reputation: Research user reviews and testimonials to gauge machine performance, reliability, and customer satisfaction.

10. Training and Installation: Check if the supplier offers training for operators and assistance with installation to optimize machine usage from the start.

By considering these factors, you can select a laser engraving machine that meets your specific metal engraving needs efficiently and effectively.

FAQs on Sourcing and Manufacturing from laser engraving machine for metal in China

When sourcing a laser engraving machine for metal from China, several common questions arise:

1. Quality Assurance: How can I ensure the quality of the machine?

– Response: Research reputable manufacturers with certifications like ISO and CE. Request samples or visit their facilities if possible.

2. Costs and Pricing: What are the typical costs involved?

– Response: Prices vary based on specifications and features. Factor in shipping, import duties, and potential taxes.

3. Technical Support: What kind of technical support is provided?

– Response: Inquire about after-sales service, warranty terms, and availability of spare parts. Look for manufacturers with a reliable support system.

4. Customization: Can the machine be customized to my needs?

– Response: Many manufacturers offer customization options. Clearly communicate your requirements upfront.

5. Lead Times: How long does it take from order to delivery?

– Response: Lead times can vary widely. Get clear timelines and factor in shipping duration.

6. Language and Communication: Is language a barrier when dealing with Chinese manufacturers?

– Response: Many manufacturers have English-speaking staff. Clear communication is crucial; consider using a translator if needed.

7. Payment Terms: What are the payment terms typically used?

– Response: Common methods include T/T (Telegraphic Transfer) and sometimes, for larger orders, letters of credit (L/C).

Navigating these aspects ensures a smoother sourcing process for a laser engraving machine from China, balancing cost-effectiveness with quality and support.