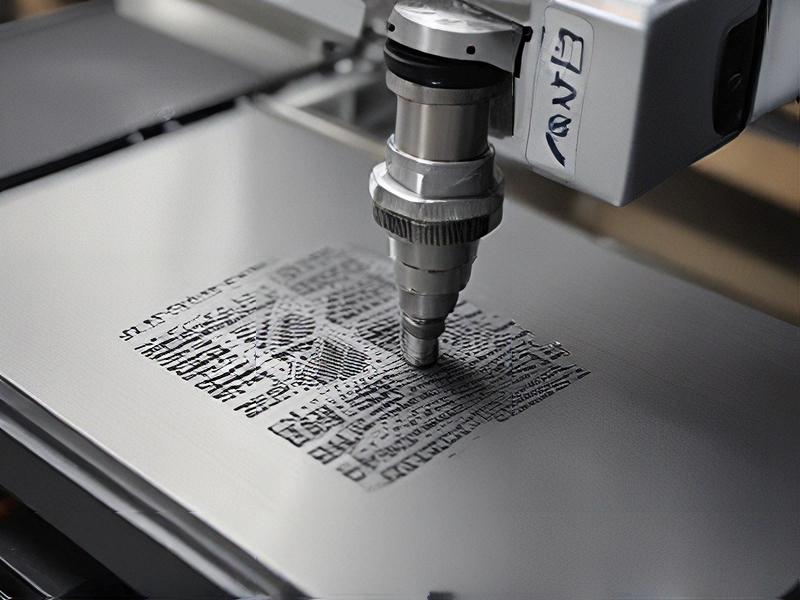

Technology and Applications of laser engraving on metal machine

Laser engraving on metal utilizes highly focused laser beams to etch designs, text, or patterns onto various metal surfaces with precision. This technology offers several advantages, including high accuracy, intricate detailing, and the ability to work with various metals such as stainless steel, aluminum, brass, and titanium.

The process involves directing a laser beam onto the metal surface, which heats and vaporizes the material in a controlled manner. This creates permanent markings without physical contact, eliminating the need for masks or chemicals typically used in traditional engraving methods. Laser engraving can achieve fine details and complex geometries, making it ideal for personalized items, industrial parts marking, and signage.

Applications of laser engraving on metal are diverse. In industrial settings, it is used for part identification, serialization, and branding due to its durability and resistance to wear. In consumer goods, it’s employed for custom jewelry, electronics casings, and personalized gifts. The technology also finds use in medical devices, aerospace components, and automotive parts where permanent marking and traceability are crucial.

Advancements in laser technology have led to enhanced speed, efficiency, and versatility, allowing for large-scale production as well as intricate artistic designs. Fiber lasers, in particular, are favored for their ability to engrave metals swiftly and precisely. Moreover, software advancements enable easy conversion of digital designs into engraved patterns, facilitating rapid prototyping and customization.

Overall, laser engraving on metal machines continues to evolve, offering manufacturers and designers powerful capabilities to meet diverse industrial and creative demands efficiently and with high precision.

Quality Testing Methods for laser engraving on metal machine and how to control quality

Quality testing methods for laser engraving on metal typically involve visual inspection, dimensional accuracy checks, and surface quality assessments. Visual inspection ensures the engraving meets design specifications without defects such as incomplete marks or irregularities. Dimensional accuracy is crucial, often verified using precision measuring tools like calipers or micrometers to ensure engraved features match intended sizes. Surface quality assessments involve examining factors like smoothness, texture, and clarity of the engraved marks, ensuring they meet desired aesthetic and functional requirements.

Controlling quality in laser engraving involves several key practices:

1. Calibration: Regularly calibrating the laser machine ensures consistent engraving depth and accuracy.

2. Material Inspection: Using high-quality metals suitable for laser engraving minimizes defects and inconsistencies.

3. Process Parameters: Optimizing laser settings (power, speed, frequency) for different metals ensures optimal engraving results.

4. Testing Protocols: Implementing systematic testing procedures to detect defects early in production.

5. Operator Training: Training operators to understand the nuances of laser engraving and quality standards improves consistency and reliability.

By integrating these methods and controls, manufacturers can ensure high-quality laser engraving on metal, meeting both technical specifications and customer expectations.

Tips for Procurement and Considerations when Purchasing from laser engraving on metal machine

When procuring a laser engraving machine for metal, consider these tips:

1. Identify Needs: Understand your specific requirements, such as the type of metals to be engraved, the precision needed, and the production volume. This helps in selecting the right machine specifications.

2. Budget: Determine your budget range, keeping in mind not just the initial purchase cost but also ongoing expenses like maintenance, power consumption, and potential upgrades.

3. Machine Specifications:

– Laser Power: Higher wattage lasers can engrave harder metals more quickly and deeply.

– Speed and Precision: Ensure the machine offers the speed and accuracy needed for your tasks.

– Cooling System: Proper cooling extends the machine’s life and maintains performance.

4. Software Compatibility: Check that the machine is compatible with the design software you use. User-friendly software can significantly improve efficiency.

5. Size and Footprint: Ensure the machine fits within your workspace and can accommodate the size of materials you plan to engrave.

6. Durability and Reliability: Look for machines with robust construction and good reviews on reliability. A well-built machine reduces downtime and maintenance costs.

7. Supplier Reputation: Purchase from reputable suppliers known for quality products and good customer support. Check reviews, ratings, and ask for references.

8. Warranty and Support: Ensure the machine comes with a comprehensive warranty and access to customer support for troubleshooting and repairs.

9. Safety Features: Prioritize machines with essential safety features like enclosed laser systems, emergency stop buttons, and proper ventilation.

10. Training and Documentation: Choose suppliers that offer training for operating the machine and provide detailed manuals and documentation.

By considering these factors, you can make an informed decision that aligns with your production needs and budget, ensuring long-term satisfaction and efficiency in your operations.

FAQs on Sourcing and Manufacturing from laser engraving on metal machine in China

Certainly! Here are some frequently asked questions (FAQs) regarding sourcing and manufacturing from laser engraving on metal machines in China:

1. What materials can be laser engraved on?

Laser engraving machines in China typically work with metals such as stainless steel, aluminum, brass, and titanium. They can also engrave on plastics, wood, glass, and some ceramics.

2. What are the advantages of using Chinese suppliers for laser engraving?

Chinese manufacturers often offer competitive pricing due to lower labor costs and efficient production capabilities. They also have experience in handling large volumes and can provide customization options.

3. How do I ensure quality control when sourcing from China?

It’s crucial to conduct thorough supplier evaluations, including factory visits if possible, and request samples to assess engraving quality. Implementing clear quality standards and regular inspections can also help maintain consistency.

4. What are typical lead times for laser engraving orders?

Lead times can vary depending on order complexity and quantity, but Chinese suppliers generally offer faster turnaround times compared to many Western manufacturers. It’s advisable to clarify lead times with suppliers before placing orders.

5. What certifications should I look for in Chinese manufacturers?

Look for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Compliance with international standards ensures adherence to quality and ethical manufacturing practices.

6. How can I handle intellectual property concerns?

Ensure suppliers sign non-disclosure agreements (NDAs) and have measures in place to protect your designs and proprietary information. Consider registering trademarks and patents in China to further safeguard your intellectual property.

7. What are the shipping and logistics considerations?

Factor shipping costs, transit times, and import/export regulations into your budget and timeline planning. Work closely with freight forwarders who specialize in shipping from China to optimize logistics.

By addressing these FAQs, you can navigate sourcing and manufacturing from laser engraving on metal machines in China more effectively while minimizing potential challenges.