Technology and Applications of laser etching for metal

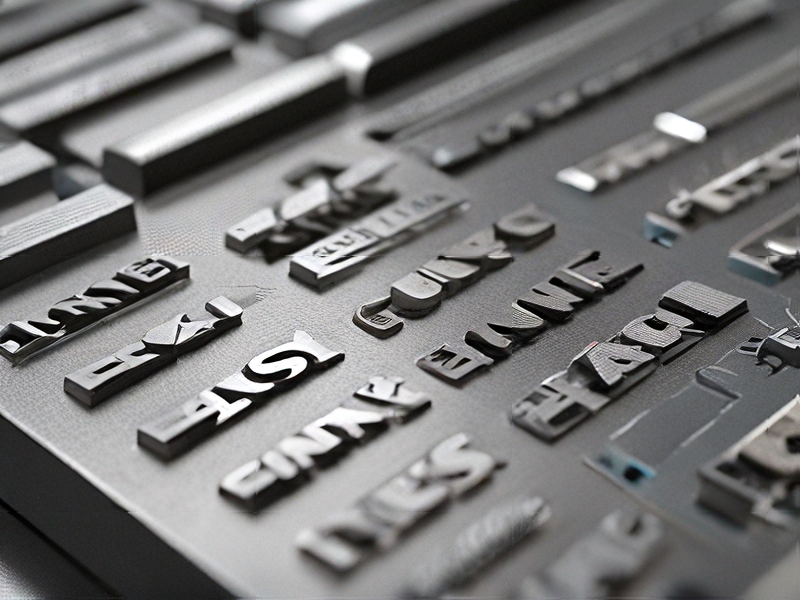

Laser etching for metal involves using a focused laser beam to create precise and permanent marks on the surface of metallic materials. This technology is widely used in various industries due to its high precision, efficiency, and versatility.

Technology

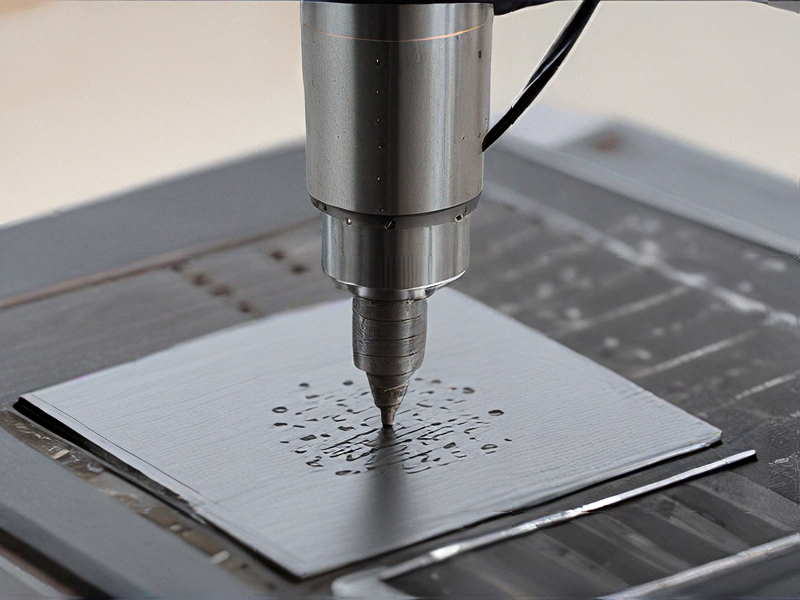

Laser etching utilizes a high-powered laser to heat the surface of the metal, causing it to oxidize and change color or texture. This process can create detailed designs, text, barcodes, and other identifiers. The main types of lasers used for metal etching include fiber lasers, CO2 lasers, and Nd:YAG lasers. Fiber lasers are particularly popular for their ability to produce high-quality marks on metals with high speed and low maintenance.

The process involves:

1. Laser Source: Generates the laser beam.

2. Beam Delivery System: Directs the beam to the desired location.

3. Controller: Manages the movement and intensity of the laser based on the design input.

Applications

1. Manufacturing: Laser etching is used for marking parts with serial numbers, logos, and other identification marks. This is crucial for traceability and quality control.

2. Aerospace: Components are marked with precise details that withstand harsh environments.

3. Automotive: Parts are etched for identification, ensuring compliance with industry standards.

4. Medical Devices: Instruments and implants are marked for traceability and sterilization purposes without affecting their integrity.

5. Jewelry: Intricate designs and personalization are achieved with high precision.

6. Electronics: Components are marked with identification codes and symbols, essential for assembly and troubleshooting.

Laser etching for metal offers durability, resistance to wear and tear, and the ability to create detailed and intricate designs. It is a vital technology for industries that require permanent and precise markings on metal surfaces.

Quality Testing Methods for laser etching for metal and how to control quality

Quality testing for laser etching on metal involves several key methods to ensure precision, durability, and consistency. Here are the main methods and how to control quality:

1. Visual Inspection: This involves checking the etched areas for clarity, sharpness, and uniformity. Ensure that all markings are legible and free from defects such as blurriness or uneven depth.

2. Microscopic Examination: Using microscopes to inspect the fine details of the etching can reveal micro-cracks, rough edges, or any other imperfections that are not visible to the naked eye.

3. Dimensional Measurement: Tools like calipers, micrometers, and coordinate measuring machines (CMM) measure the depth and dimensions of the etching to ensure they meet specified tolerances.

4. Surface Roughness Testing: Surface roughness testers (profilometers) measure the texture of the etched areas to ensure they have the desired smoothness or roughness, which can impact readability and adhesion of subsequent coatings.

5. Adhesion and Durability Testing: Testing for adhesion and durability involves subjecting the etched metal to various conditions like abrasion, corrosion, and thermal cycling to ensure the markings remain intact and legible over time.

6. Contrast Testing: This method measures the contrast between the etched and non-etched areas, ensuring high readability under different lighting conditions.

Quality Control Practices

– Calibration of Equipment: Regularly calibrate laser etching machines and measuring instruments to maintain accuracy.

– Process Standardization: Develop and follow standardized procedures for laser settings, including power, speed, and focus distance.

– Material Consistency: Use metal sheets from the same batch to ensure consistency in material properties.

– Regular Audits: Conduct regular audits of the process and equipment to identify and rectify any deviations from the set standards.

– Employee Training: Train operators and inspectors thoroughly in both the operation of the laser etching equipment and the quality testing procedures.

Implementing these methods and practices ensures high-quality, consistent results in laser etching on metal.

Tips for Procurement and Considerations when Purchasing from laser etching for metal

Tips for Procurement and Considerations for Metal Laser Etching

1. Define Requirements:

– Clearly specify the type of metal and the desired etching depth and precision.

– Determine the scale of the project and whether it requires high-volume production or bespoke items.

2. Research Suppliers:

– Look for suppliers with a strong reputation and experience in metal laser etching.

– Check reviews, certifications, and industry standards to ensure quality and reliability.

3. Quality Control:

– Ensure the supplier has robust quality control measures, including sample testing and inspection processes.

– Request samples to assess the quality of etching and consistency.

4. Technology and Equipment:

– Verify that the supplier uses advanced laser etching technology, suitable for your specific metal type.

– Ensure their equipment can handle the required precision and detail for your project.

5. Cost Analysis:

– Compare quotes from multiple suppliers, considering both the unit cost and any additional fees for setup, design, and shipping.

– Evaluate the cost-benefit ratio, focusing on long-term value rather than just upfront costs.

6. Lead Time and Flexibility:

– Discuss lead times and ensure the supplier can meet your deadlines.

– Consider their ability to handle changes in order volume or design modifications.

7. Post-Purchase Support:

– Ensure the supplier offers after-sales support, including warranties, maintenance, and troubleshooting.

– Establish clear communication channels for ongoing support and future needs.

8. Sustainability:

– Assess the environmental impact of the supplier’s processes and their commitment to sustainable practices.

– Consider suppliers that prioritize eco-friendly methods and materials.

9. Compliance and Certifications:

– Verify that the supplier adheres to relevant industry standards and certifications.

– Ensure they comply with regulatory requirements for safety and environmental impact.

By carefully considering these factors, you can ensure a successful procurement process and achieve high-quality metal laser etching results.

FAQs on Sourcing and Manufacturing from laser etching for metal in China

FAQs on Sourcing and Manufacturing Laser Etching for Metal in China

#### 1. Why source laser etching services from China?

China offers competitive pricing, advanced technology, and a broad range of suppliers with experience in high-precision laser etching for metals.

#### 2. How do I find reliable suppliers?

Utilize platforms like Alibaba, Global Sources, and Made-in-China. Verify suppliers through reviews, ratings, and by requesting samples or factory visits.

#### 3. What are the common metals used in laser etching?

Common metals include stainless steel, aluminum, brass, copper, and titanium. Each metal requires specific settings for optimal etching quality.

#### 4. What should I look for in a supplier?

Check for certifications (ISO, CE), years of experience, technological capabilities, and quality control measures. Also, consider the supplier’s communication skills and responsiveness.

#### 5. What is the typical lead time?

Lead times vary but generally range from 2 to 6 weeks, depending on the complexity and volume of the order.

#### 6. What about quality control?

Ensure the supplier has stringent quality control processes. It’s advisable to request a sample before mass production and consider third-party inspections.

#### 7. How are intellectual property and design protection handled?

Sign non-disclosure agreements (NDAs) and clarify IP rights in contracts to protect your designs. Use suppliers with a good track record of respecting IP.

#### 8. What is the cost structure?

Costs typically include setup fees, material costs, processing fees, and shipping. Bulk orders often receive discounts.

#### 9. How do I handle shipping and customs?

Suppliers often assist with logistics. Use reliable shipping companies and understand the customs requirements in your country to avoid delays and additional costs.

#### 10. What are the payment terms?

Common terms include a deposit (30-50%) upfront with the balance paid upon completion or before shipping. Use secure payment methods like escrow services to mitigate risks.

By following these guidelines, you can efficiently source high-quality laser etching services for metals from China.