Technology and Applications of laser machine for engraving

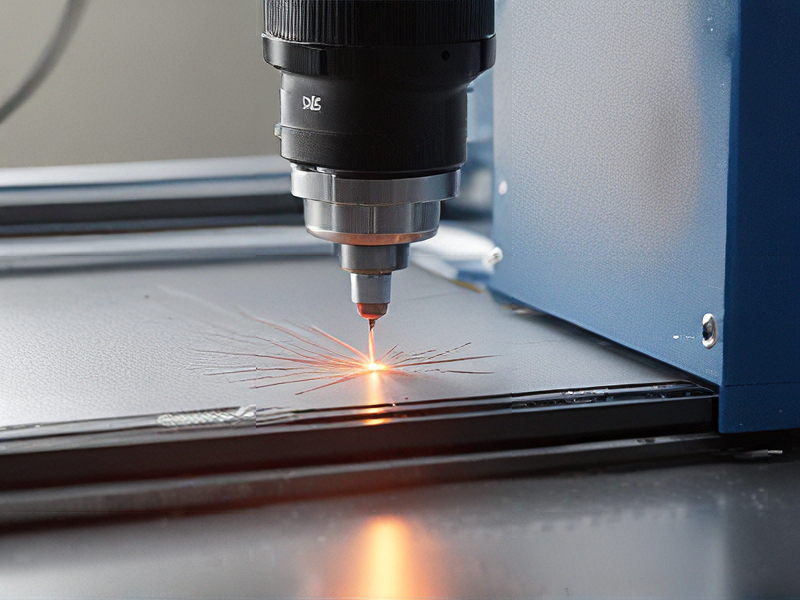

Laser engraving technology utilizes focused laser beams to etch or cut materials with precision and efficiency. This advanced technique is widely applied across various industries, including manufacturing, art, and personalization.

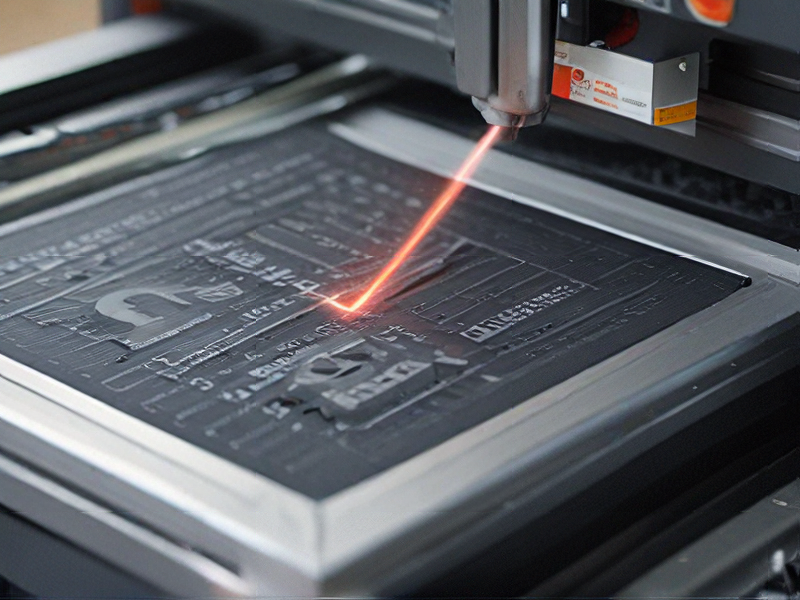

The engraving process begins with designing a digital file, which is then fed into the laser engraving machine. The machine uses a high-powered laser to remove material from the surface of the object, creating intricate designs, text, or images. Common materials suitable for laser engraving include wood, metal, glass, acrylic, leather, and even fabric.

One of the primary advantages of laser engraving is its precision. The concentrated laser beam can achieve detailed and complex patterns that traditional carving methods may struggle to replicate. Furthermore, laser engravers can accommodate both large-scale production runs and custom, one-off pieces, making them versatile for businesses and hobbyists alike.

Applications of laser engraving are diverse. In the manufacturing sector, companies use lasers for creating product identifiers, logos, and safety labels. In the art world, artists leverage laser engraving to create unique pieces and personalize gifts. The technology also finds use in the jewelry industry, allowing for intricate designs on rings or pendants.

Overall, laser engraving offers a clean, efficient, and customizable solution for marking and designing various materials. As technology advances, its applications are expected to grow, enhancing creativity and precision across industries.

Quality Testing Methods for laser machine for engraving and how to control quality

Quality testing methods for laser engraving machines are essential for ensuring precision, consistency, and overall product quality. Here are several effective approaches:

1. Dimensional Accuracy Test: Measure the dimensions of engraved patterns using calipers or micrometers. Compare these measurements to the digital design specifications to ensure precision.

2. Surface Quality Assessment: Inspect engraving surfaces under different lighting conditions to assess smoothness and clarity. Check for abnormalities such as burns or excessive charring, which can indicate incorrect settings or material issues.

3. Focus Calibration: Regularly check and adjust the laser focus. A straightforward method is to engrave a test pattern (like a grid) and observe the results. Clear, well-defined engravings confirm that the focus is set correctly.

4. Material Testing: Conduct tests with various materials to understand how each reacts to laser settings. Document the ideal settings for each material type to ensure consistent quality across different projects.

5. Engraving Speed & Power Validation: Experiment with different speeds and power settings, and identify optimal parameters for each material. Create samples and evaluate both speed and quality, ensuring that adjustments lead to desirable results.

6. Consistency Checks: Run multiple samples of the same design. Examine them closely for consistency in engraving quality. This helps identify any variance due to machine calibration or operator errors.

7. Routine Maintenance: Establish a regular maintenance schedule for the laser machine, which includes cleaning lenses and checking alignment. Ensuring the equipment is in optimal condition directly impacts engraving quality.

By implementing these testing methods and control measures, you can maintain high-quality standards in laser engraving, leading to satisfied customers and reduced waste.

Tips for Procurement and Considerations when Purchasing from laser machine for engraving

When purchasing a laser engraving machine, consider the following tips to ensure an informed and successful procurement:

1. Define Your Needs: Identify the materials you will engrave (wood, metal, acrylic, etc.) and the types of projects (small crafts, large signage). This will help you choose the right machine specifications.

2. Laser Type: Decide between CO2 and fiber lasers. CO2 lasers are versatile and great for non-metals; fiber lasers excel in engraving metals and are more efficient for high-speed work.

3. Power Rating: Higher wattage generally means faster engraving and cutting capabilities. Choose a power level that aligns with your intended projects, typically ranging from 30W for lighter materials to 100W or more for thicker materials.

4. Workspace and Size: Ensure you have adequate space for the machine, including ventilation and safety measures. Consider the machine’s footprint and working area, especially if you plan larger projects.

5. Software Compatibility: Check that the machine is compatible with design software you plan to use. User-friendly software can greatly enhance productivity and ease of use.

6. Maintenance and Support: Investigate the manufacturer’s reputation for customer service and support. Regular maintenance is crucial for optimal performance.

7. Budget: Set a budget that includes not just the machine but also additional costs like maintenance, materials, and software.

8. Reviews and Recommendations: Research reviews and seek feedback from other users to gauge reliability and performance.

9. Training and Resources: Look for vendors that offer training or resources to help you maximize your machine’s potential.

By considering these factors, you can make a more informed purchasing decision and ensure the laser engraving machine meets your specific needs.

FAQs on Sourcing and Manufacturing from laser machine for engraving in China

FAQs on Sourcing and Manufacturing Laser Engraving Machines in China

Q1: What types of laser engraving machines are available in China?

A1: China offers a variety of laser engraving machines, including CO2, fiber, and diode lasers, suitable for materials like wood, metal, acrylic, and glass.

Q2: How do I find reliable suppliers?

A2: Utilize platforms like Alibaba, Made-in-China, and Globalsources. Additionally, verify suppliers through trade certifications, customer reviews, and company audits.

Q3: What is the typical lead time for manufacturing?

A3: Lead times usually range from 30 to 90 days, depending on the machine’s complexity, order size, and supplier’s production capacity.

Q4: Are there minimum order quantities (MOQs) for laser machines?

A4: MOQs vary by supplier. Some may accept single units, while others may require larger orders to ensure profitability.

Q5: What should I consider regarding quality control?

A5: Ensure suppliers adhere to international quality standards, conduct factory audits, and request samples before bulk orders. Consider third-party inspection services for added assurance.

Q6: How do I handle shipping and import duties?

A6: Discuss shipping options with your supplier. Use freight forwarders for clarity on shipping costs and customs duties, which depend on your country’s regulations.

Q7: What kind of after-sales support should I expect?

A7: Most reputable suppliers offer technical support, warranty services, and spare parts availability. Confirm these terms before purchase.

Q8: How can I ensure compliance with safety standards?

A8: Verify that the machines comply with your country’s safety standards and certifications. Request documentation from the supplier to confirm compliance.

By understanding these key aspects, you can make informed decisions when sourcing laser engraving machines from China.